Recent from talks

Nothing was collected or created yet.

Spudger

View on WikipediaThis article needs additional citations for verification. (October 2022) |

A spudger (also known as a spludger, non-marring nylon black stick tool) is a tool that has a wide flat-head screwdriver-like end that extends as a wedge, used to separate pressure-fit plastic components without causing damage during separation.

Uses

[edit]The flat end of the spudger is often used to loosen or release components inside electronics, for example during the replacement of batteries or touch screens for smartphones. The other end is often a point or a hook depending on application. When applied to separate pressure-fit panels, there is often a point to create an initial gap before the wedge end is utilized.

A spudger is also a wiring tool used for poking or adjusting small wires or components, generally in the electronics and telecommunications industries. A typical spudger is an insulating stick, made of either wood, plastic or a nylon fiberglass material. For instances where the spudger is used for prising it is commonly made of stainless steel or other metals.[1][2][3]

Materials and versions

[edit]The most common modern spudger is a black or yellow nylon stick with a metal hook at one end. Various versions have blunt, sharpened, or insulated hooks. The hook can be used for pulling bridge clips from 66 blocks, manipulating wires in a crowded wire wrap block, or setting DIP switches. The body of a plastic spudger is usually contoured to offer a better grip. Some spudgers are made of orangewood, used in electronics assembly and soldering because of its heat tolerance and dense grain. The same orangewood sticks are commonly used in filmmaking, manicure and pedicure, but these industries do not use the term "spudger".

In telecom applications like punch-down terminal blocks and cell phone repair, the spudger is made of a non-conductive material to prevent transmission of a static shock or direct short to sensitive electrical components' inputs or outputs. This is critical with high density applications where uninsulated terminals are in close proximity, like a battery or with telephone patch junctions.

See also

[edit]References

[edit]- ^ E.R. Haan, Radio Testing and Trouble Shooting, Part I, Popular Mechanics, Vol. 49, No. 5 (May 1928); pages 834–836. See page 835, column 1, for a discussion of spudgers.

- ^ Bell System Practices, Section 074-257-117, "Tools, Spudgers - Description", Issue 2, May 1978.

- ^ Types of Spudger Tool, Spudgers.com. Interfuse LLC. Retrieved 30 March 2018

External links

[edit] The dictionary definition of spudger at Wiktionary

The dictionary definition of spudger at Wiktionary

Spudger

View on GrokipediaEtymology and History

Origin of the Term

The term "spudger" derives from "spud," a Middle English word denoting a small, stout knife or digging tool used for prying, cutting roots, or similar tasks, with origins traceable to the mid-15th century.[6] Likely influenced by Old Norse spjot ("spear") or related Germanic terms for pointed implements, "spud" evolved to describe short-bladed spades for potato digging by the 17th century, emphasizing its role as a basic probing instrument.[6] This linguistic root adapted "spudger" as a diminutive or agent form, akin to "digger," to denote a specialized prying or manipulating tool in manual trades. The earliest documented use of "spudger" as a tool appears in 1840 in the Essex County Standard newspaper.[5] An 1880 U.S. Supreme Court case referenced it in isinglass manufacturing as a wide blade for preventing material burning on rollers.[5] By 1928, Popular Mechanics described wooden spudgers for radio repair.[5] In technical contexts, the term saw informal usage among electronics enthusiasts and wiring trades in the early to mid-20th century, often describing makeshift prying aids in radio repair and assembly.[7] It later entered telecommunications jargon for a hand tool handling wires without causing shorts, with Bell System Practices documentation from the 1970s and 1980s routinely listing the spudger as essential equipment for wiring and connector work.[8]Development in Telecommunications

The spudger saw formal standardization as a specialized tool in telecommunications during the 1970s through the Bell System's efforts, building on prior informal uses. In May 1978, Bell System Practices, Section 074-257-117, Issue 2, titled "Tools, Spudgers - Description," officially defined the spudger as a wiring aid, detailing models such as the KS-6320 L1 (plastic orange stick) and KS-6320 L2 (wooden) for use in panel offices.[9] This document superseded earlier practices, including Section 074-775-101, and emphasized its role as a non-conductive implement to prevent damage during wire handling.[9] Initially designed for manipulating wires in punch-down blocks, the spudger addressed the need to insert, position, or remove conductors without short-circuiting adjacent terminals, a risk inherent in the insulation-displacement connectors introduced by the Bell System in the early 1960s with the 66-series blocks.[10] Prior to dedicated tools like the spudger, early telecommunications installations from the mid-20th century relied on ad-hoc implements such as screwdrivers or hooks for wiring tasks in screw-terminal setups, which often led to inefficiencies and potential electrical faults in complex switching systems.[11] By the late 1970s, the spudger had evolved into a standard accessory, also serving as a wire positioning tool for general use in commutator spring tension testing within electromechanical panel offices.[9] A key milestone in its development was its inclusion in official toolkits by major providers like AT&T, as outlined in the 1978 practices, ensuring uniform adoption across the Bell System's vast infrastructure for reliable wiring in cross-connect frames and distribution panels.[9] This standardization marked the transition from improvised wire-poking methods in post-World War II telecom expansions to a purpose-built implement, enhancing safety and precision in an era of growing telephone network density.[12]Design and Construction

Basic Features

A spudger is characterized by its elongated handle, typically measuring 4 to 6 inches in length, which provides sufficient reach for precise manipulation in confined spaces.[13][3] The tool features a flat, wedge-like end designed for prying or probing components without causing damage, allowing users to separate pressure-fit parts effectively.[3][1] Most spudgers adopt a dual-ended design, with one end flat or wedge-shaped for separation tasks and the other end hooked, notched, or tapered for wire manipulation and guiding.[13][14] This configuration enhances versatility, enabling the tool to handle both prying and precise adjustments in a single implement.[15] The handle is ergonomically shaped to facilitate a secure, precision grip, often incorporating a non-slip surface to minimize slippage during delicate operations.[1][13] Additionally, spudgers are constructed with non-conductive properties to prevent electrical shorts when working on live circuits, ensuring safety in electronics and telecommunications applications.[1][16] While ends may vary slightly for specific fields, these core attributes remain consistent across general designs.[15]Materials Used

Spudgers are primarily constructed from non-conductive polymers such as nylon and ABS plastic for their bodies, which provide a non-marring surface essential for safely prying delicate components without scratching or damaging sensitive electronics.[17][18] In heavy-duty variants, stainless steel or other metals are incorporated for the edges or tips to offer enhanced durability during more forceful separations.[19][20] These material choices ensure the tool's body remains electrically insulating, preventing electrostatic discharge (ESD) that could harm integrated circuits.[21][22] Key properties of these materials include high tensile strength in plastics, allowing them to withstand prying forces up to several pounds without deforming or breaking, while their soft, flexible nature avoids marring surfaces.[17][23] Glass-filled nylon variants, containing about 15% fiberglass, further enhance resistance to static buildup and provide temperature tolerance up to 150°C, making them suitable for environments near soldering irons.[21][23] Metals like stainless steel contribute corrosion resistance and rigidity for repeated use in demanding telecom applications.[20] Modern designs have shifted to polymer composites to improve ESD safety and compatibility with fragile electronics.[24] This evolution reflects broader advancements in electronics repair, prioritizing non-conductive materials to minimize risks in static-sensitive workflows.[5] Manufacturing of plastic spudgers typically involves injection molding, where molten nylon or ABS is injected under high pressure into precision molds to achieve uniform flexibility without brittleness, ensuring consistent performance across production batches.[25] This process allows for the integration of features like wedge ends that leverage the material's inherent toughness for effective, damage-free prying.[18]Types and Variations

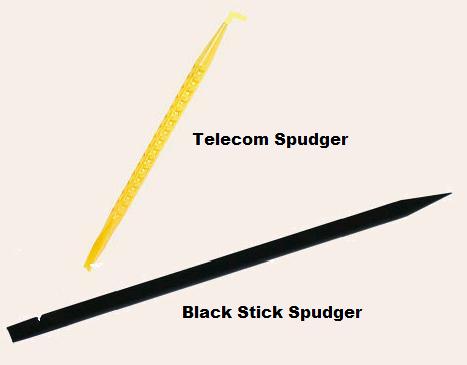

Telecom Spudgers

Telecom spudgers are specialized tools designed for manipulating wires in telecommunications wiring environments, particularly for tasks involving punch-down blocks. These tools feature a hook-ended design, typically an L-shaped hook, which allows technicians to guide, probe, separate, and extract wires from standard punch-down blocks such as 66-type and 110-type blocks without causing damage to the insulation or conductors.[26][27] The hook facilitates precise removal of individual wires from densely packed terminals, enabling efficient troubleshooting and reconfiguration in cross-connect systems.[28] A key element of the telecom spudger is its notched blade, often a flat, tapered end with a notch, which is used for cutting or positioning insulation while avoiding harm to the underlying conductors. This notched feature helps in trimming excess insulation or debris around terminals, ensuring clean connections during cable termination processes.[29] Such design precision is essential for maintaining signal integrity in high-density wiring setups.[30] Telecom spudgers are built with robust construction to withstand repeated use in demanding cable termination environments, often featuring durable materials like reinforced nylon or Lexan plastic that resist wear from frequent handling and contact with wiring components.[29] This durability supports long-term reliability in professional installations.[26] These tools are standardized components in professional telecom kits, ensuring compatibility with installations compliant with TIA/EIA-568 cabling standards for commercial buildings.[31] They are commonly included alongside punch-down tools to provide a complete set for wire management in telecommunications infrastructure.[32] Telecom spudgers are typically non-conductive to prevent electrical shorts during wire handling.[30]Electronics Spudgers

Electronics spudgers are specialized prying tools designed for delicate disassembly in consumer electronics, featuring a flat, broad wedge tip that enables the separation of pressure-fit plastic housings without causing damage to components. This tip is particularly effective for opening slim devices such as smartphones and laptops, where snap-fit enclosures require precise leverage to avoid cracking or deforming the casing.[18][33][34] The thin profile of these spudgers allows insertion into narrow seams and gaps, facilitating access to internal parts while minimizing the risk of surface scratches on sensitive materials like anodized aluminum or polished plastics. This slender design ensures controlled prying action, making it suitable for tasks involving ribbon cables or adhesive-backed panels in compact electronics.[35][36] Variants of electronics spudgers often include color-coded options, such as black nylon models engineered for anti-static properties, which are essential in cleanroom or electrostatic discharge (ESD)-sensitive environments to prevent static buildup that could harm microchips. These ESD-safe materials, typically composed of glass-filled nylon, provide durability alongside conductivity control, ensuring safe handling of integrated circuits during repair.[21][37] Electronics spudgers are commonly integrated into professional repair kits offered by companies like iFixit, where they form a core component for DIY and technician workflows. By 2019, iFixit had sold over two million spudger units worldwide, highlighting their widespread adoption in the electronics repair ecosystem.[5]Applications

In Telecommunications

In telecommunications, spudgers are essential for maintaining clean and reliable connections in punch-down block wiring, where their hook ends allow technicians to precisely hook and remove stray wire clippings and insulation debris that could otherwise cause intermittent faults or signal degradation.[26] This process ensures secure terminations in insulation-displacement connectors (IDCs) commonly used in 110 or 66-style blocks, preventing debris accumulation that might lead to poor contact integrity.[38] The tool's notched flat end further aids in separating bundled wires without nicking insulation, promoting long-term network stability in structured cabling systems.[39] During cable splicing and termination tasks, spudgers facilitate safe adjustments on live lines by probing and separating individual conductors, reducing the risk of accidental short circuits through their non-conductive construction.[26] In these applications, the L-shaped hook extension enables technicians to guide wires into splice enclosures or termination points without bridging adjacent contacts, a critical precaution in high-density environments where metallic tools might induce faults.[39] This precision is particularly valuable for modular connectors and fusion splice preparations, where minimizing conductor crossover ensures optimal signal transmission.[26] Spudgers play a key role in the upkeep of network infrastructure, including private branch exchange (PBX) systems, where they probe electrical contacts and remove debris from backplane wiring to maintain voice and data pathway reliability.[26] In fiber optic terminations, they support general maintenance by separating buffer tubes and clearing residue from connector housings, aiding in the alignment of multimode or single-mode fibers without contamination.[40] These tasks help sustain the performance of hybrid copper-fiber networks in enterprise and carrier environments.[39] The use of spudgers yields efficiency gains in wire manipulation, enabling faster probing and separation compared to improvised tools like screwdrivers, which often risk scratching insulation or causing shorts due to conductivity.[41] Integrated designs in professional kits further streamline workflows, reducing termination times in field installations by allowing one-handed debris clearance and wire feeding.[38] This specialized functionality minimizes downtime in telecom maintenance operations.[26]In Electronics Repair

In electronics repair, spudgers serve as essential non-conductive tools for safely accessing and manipulating internal components of consumer devices such as smartphones, laptops, and wearables.[1] These tools feature a flat, rigid blade or probe that allows technicians to pry apart snap-fit enclosures and clips without scratching delicate surfaces or causing structural damage, facilitating entry to areas like battery compartments or display assemblies. For instance, during smartphone disassembly, a spudger can be inserted along the edges of the rear case to release interlocking tabs, enabling removal of the back panel to reach the battery or other internals. A key application involves disconnecting ribbon cables, which connect components like displays, cameras, and sensors to the motherboard. Spudgers are used to gently lift locking tabs or pry connectors straight up from their sockets, preventing bent pins or torn traces that could render the device inoperable. This precision is critical in laptops, where narrow flex cables route through hinges; the tool's thin profile allows insertion without applying excessive force, preserving alignment during reconnection.[18] Flat wedge tip variations enhance this functionality by providing broader leverage for stubborn connectors in wearables like smartwatches.[42] Spudgers are also commonly used to release the clips or latches securing RAM modules (DIMMs) in laptops, desktops, and servers, particularly in tight PC builds where space is limited. A plastic spudger enables precise, gentle pushing of the slot latches outward, allowing the RAM module to pop up at an angle for safe removal or installation without risking damage to the module, motherboard, or nearby components. This non-conductive and non-marring tool is widely recommended in electronics repair and PC building communities for confined spaces where fingers may lack sufficient access or precision, preventing scratches or short circuits.[43][4] Spudgers are prominently featured in DIY repair resources, such as iFixit tutorials for iPhone screen replacements or laptop teardowns, where step-by-step instructions recommend them for initial prying and cable handling to guide users through safe disassembly.[5] These guides emphasize starting repairs with a spudger to avoid using metal tools that risk shorting circuits.[44] The primary benefits include minimizing cosmetic damage to plastic housings and reducing electrostatic discharge (ESD) risks, as most spudgers are made from antistatic materials like nylon or carbon fiber that dissipate static buildup during handling of sensitive semiconductors.[45] This ESD safety is particularly vital when replacing components near exposed boards, where even minor static could damage chips, and the tool's non-marring edges ensure clean reassembly without visible scratches.Other Uses

Spudgers find application in model building and hobby crafts, where their non-marring nylon construction allows for precise manipulation of delicate plastic components without causing surface damage. In scale modeling, particularly with large kits, the tool is used for prodding parts into tight gaps, wedging assemblies together, and scraping away excess material during construction.[46] Its soft tip also facilitates peeling off stickers or applying rub-on decals, avoiding scratches on painted surfaces that could otherwise occur with metal alternatives.[46] In automotive maintenance, spudgers are employed for disassembling dashboard components and interior trim panels, leveraging their pry action to separate clips and retainers while preventing scratches on plastic or painted finishes. For instance, during instrument cluster repairs, a spudger gently lifts trim bezels to access underlying electronics without marring the vehicle's interior.[47] Similarly, in door panel or stereo unit removal, the tool releases locking tabs on dashboard-mounted devices, ensuring clean separation of pressure-fit parts common in modern vehicle designs.[48] This utility stems from the spudger's versatile, blunt-edged design, which adapts to low-precision prying tasks across non-specialized fields.Safety and Maintenance

Proper Usage Techniques

When using a spudger for separating components in electronics repair, begin by inserting the flat end at the edges of the assembly, then gently rock the tool back and forth to create separation while applying minimal force to prevent damage to delicate parts or adhesives. This technique is particularly effective for disconnecting ribbon cables or prying open enclosures, where the non-conductive material of the spudger aids in safe handling without risking short circuits. In telecommunications wiring tasks, employ the hook end of the spudger to lift wires perpendicularly from terminal blocks or punchdown panels, ensuring the motion is straight upward to avoid tearing insulation or disturbing adjacent connections.[49] This method allows for precise manipulation of fine wire terminals in telephones and network cables without causing debris or misalignment. To maintain the spudger's effectiveness, clean it after each use by wiping with isopropyl alcohol to remove any adhesive residue, oils, or debris that could compromise future precision.[50] Store the tool in a protective case or organized kit to prevent bending or contamination, extending its lifespan for repeated applications. Inspect regularly for wear, as spudgers are consumable and may require replacement to ensure safe and precise use.[1] For optimal workflow integration, especially in electronics work, pair the spudger with anti-static mats and wrist straps to ground the user and protect sensitive components from electrostatic discharge during prying or probing tasks.[51] This practice ensures a complete, safe disassembly process in both repair and installation environments.Potential Hazards and Precautions

Using a spudger, particularly during prying operations in electronics repair, carries the risk of component snapping, which can result in flying debris capable of causing eye or skin injuries. This hazard arises when adhesive bonds or plastic clips break unexpectedly under pressure, propelling small fragments. Additionally, employing conductive versions of spudgers, such as metal ones, on live circuits or ESD-sensitive components may lead to electrical shorts, potentially damaging devices or causing shocks to the user.[52] To mitigate these risks, users should wear safety glasses or other appropriate eye protection whenever performing prying tasks to shield against potential flying debris.[52] Before working on live circuits or ESD-vulnerable electronics, it is essential to verify the tool's non-conductivity, opting for anti-static materials like glass-filled nylon that prevent static buildup and comply with ESD safety protocols.[21] Common errors in spudger use include applying excessive force, which can cause surface scratches on delicate components or break fragile connectors.[52] Improper storage, such as exposing the tool to abrasive surfaces or high humidity, may dull the tip over time, reducing its effectiveness and increasing the likelihood of slippage during use.[50] In electronics environments, spudger use must align with regulatory standards for ESD control, such as ANSI/ESD S20.20, which mandates grounding and material selection to protect sensitive parts from electrostatic discharge.[51] Compliance involves integrating ESD-safe spudgers into a broader program that includes personnel grounding and ionized workstations to minimize hazards like latent component failures.[21]References

- https://en.wiktionary.org/wiki/spudger