Recent from talks

Nothing was collected or created yet.

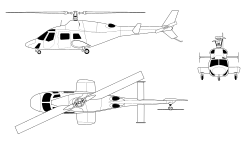

Bell 222/230

View on WikipediaThe Bell 222 is an American twin-engine light helicopter built by Bell Helicopter. The Bell 230 is an improved development with different engines and other minor changes.

Key Information

Development

[edit]Origins

[edit]In the late 1960s, Bell began designing a new twin-turbine engine light helicopter. A mockup of the new helicopter was displayed in January 1974 at a helicopter convention.[2] Following interest at the convention, the company announced the new Bell 222.[3] It was the first light commercial twin-turbine helicopter developed in the United States.[4]

The Bell 222 incorporated a number of advanced features, including dual hydraulic and electrical systems, sponsons housing the retractable landing gear, and the Noda Matic vibration reduction system developed for the Bell 214ST.[1]

Manufacturing began in 1975.[2] The Model 222 first flew on August 13, 1976. It received certification from the Federal Aviation Administration (FAA) on August 16, 1979, and was approved for visual flight rules (VFR) use on December 20, 1979. Helicopter deliveries began on January 16, 1980. The FAA approved the 222 for single-pilot instrument flight rules (IFR) operation on May 15, 1980.[5]

Improved versions

[edit]The more powerful Bell 222B was introduced in 1982 with a larger diameter main rotor. The 222B-based Bell 222UT Utility Twin, with skid landing gear, was introduced in 1983.[1]

A development of the 222 is the Bell 230, with the 222's LTS 101 engines replaced by two Allison 250 turboshaft engines, plus other refinements. A converted 222 first flew as the prototype 230 on August 12, 1991. Transport Canada awarded certification in March 1992, and the first production 230 was delivered that November. The 230 had optional skid or wheel undercarriage. Production ended in 1995 with 38 having been built, being replaced in Bell's lineup by the stretched, more powerful Bell 430.[1]

Design

[edit]

The design includes two main rotor blades of stainless-steel-fiberglass construction and rotor hub with elastomeric bearings, which are lubricant free.[4] Its cabin holds a maximum of ten persons with one-two pilots and eight to nine passengers. Seating configurations include standard seating for a pilot and seven passengers; or executive seating with one to two pilots and seating for five to six.[4] The Bell 222 and 230 are usually flown single-pilot (optional dual controls are available), and can be configured for corporate/executive, EMS or utility transport missions.[1]

The Bell 222 is powered by twin Lycoming/Honeywell LTS101-650 turboshaft engines, rated at 592 shp each.[5] Later 222 versions feature more powerful engines. Engine output is at 100% of rating at 9598 RPM. Two independent driveshafts deliver power from the engines to the transmission. The Bell 222's LTS101 engine exhaust stacks are located at the rear of the engines, while the 230's Allison engine exhaust stacks are located high on the cowling. Fuel is stored in three tanks, one in the fuselage and one in each sponson. The main rear landing gear retracts into the sponsons.[2]

The Bell 222's rotor systems include:

- Two-blade, semi-rigid high-kinetic energy main rotor with preconing and underslinging. The rotor head incorporates elastomeric bearings for hub springs, and flapping and pitch change bearings. The system is similar in design to that used by the AH-1 Cobra. Rotor speed at 100% engine speed is 348 RPM.

- All series models incorporate a pusher-type two-bladed tail rotor mounted on the left side of the tailboom, turning at 3396 RPM.

Variants

[edit]

- Bell 222

- The original Model 222, sometimes unofficially called a Bell 222A to distinguish it from the Bell 222B. It was powered by two (618 hp takeoff rated, 591 hp max continuous rated) Honeywell (formerly Lycoming) LTS101-650C-3 turboshafts.

- Bell 222B

- In 1982 the 222 was given a power upgrade (two Honeywell (formerly Lycoming) LTS101-750Cs with takeoff rating of 680 hp each), a larger main rotor, and was renamed the Bell 222B.

- Bell 222B Executive

- This model had improved systems and a luxury interior.

- Bell 222UT

- A 222B variant with skids, introduced in 1983. The lack of retractable landing gear allowed for larger auxiliary fuel tanks.

- Bell D-292

- The Advanced Composite Airframe Program (ACAP) was a 1985 all-composite LHX proof-of-concept project. The Bell D-292 used the Avco Lycoming engines, transmission, two-bladed main and tail rotors, tailboom, vertical fin, and rotor pylon of the 222. The D-292 had a new composite airframe.

- Bell 230

- In 1991, the 222B design was updated, given more uprated engines, and renamed the Bell 230. Production ended in 1995.

- Bell 230 Executive

- Executive transport version.

- Bell 230 Utility

- Utility transport version.

- Bell 230 EMS

- Air ambulance version, equipped with one or two stretchers.

- Bell 222SP

- During the 1990s, some Bell 222s were modified with the 222B's engines and 230's Allison 250-C30G engines for improved single engine (engine-out) performance, and redesignated as 222SPs.[6]

- Bell 430

- In 1995 the Bell 430, a stretched 230 (adding another seating row), was launched, with uprated engines and a four-blade main rotor.

Operators

[edit]

The Bell 222 has seen service with a large number of civil operators, but only limited military service.

- Albtransport (crashed in 2006)[7][8]

Former operators

[edit]- Government of Uttar Pradesh: Operated a Bell 230 between 1995 and 2015. Replaced by Bell 412EP.[13][14]

Specifications

[edit]

| Model | 222 | 222B | 222U | 230 |

|---|---|---|---|---|

| Announced | 1974 | 1982 | 1982 | 1990 |

| First Flight | August 13, 1976 | 1982 | 1983 | August 12, 1991 |

| Certified | December 1979 | August 1982 | April 1983 | March 1992 |

| Delivered | 1980 | 1982 | 1983 | November 1992 |

| Seats | Front: pilot + one. Main: four–six (depending on seat types) Maximum ten (pilot and nine passengers)[15] | |||

| Height | 11 ft 8 in (3.56 m) | 12 ft 2 in (3.71 m) | 11 ft 8 in (3.56 m) | |

| Fuselage length | 42 ft 2 in (12.85 m)[16] | 42 ft 11 in (12.78 m) | 42 ft 3 in (12.88 m) | |

| Rotor diameter | 39 ft 9 in (12.12 m)[17] | 42 ft (12.80 m) | ||

| Length overall | 49 ft 6 in (15.1 m) | 50 ft 3 in (15.32 m) | ||

| Engine (2x) | Lycoming LTS101-650C-3 | Lycoming LTS101-750C | Rolls-Royce 250-C30G/2 | |

| Power (2x) | 620 shp (462 kW)[17] | 684 shp (510 kW)[16] | 700 hp (520 kW) | |

| Max speed | 133 kn (153 mph; 246 km/h)[17] (cruise) |

135 kt (155 mph, 250 km/h) |

140 kt (161 mph, 260 km/h) | |

| Climb rate | 1,600 ft/min (8.1 m/s)[17] | 1,730 ft/min (8.79 m/s) | ~1,600 ft/min (8.13 m/s) | |

| Service ceiling | 20,000 ft (6,100 m)[17] | 15,800 ft (4,816 m) | 15,500 ft (4,724 m) | |

| Hover ceiling | 4,200 ft (1,300 m)[17] | 10,300 ft (3,139 m) | 12,400 ft (3,780 m) | |

| Fuel capacity | 188+48 US gal (710+182 L) | 188+122 US gal (710+460 L) | 188+ US gal (710+ L) | |

| Range | 282 nmi (325 mi; 522 km)[17] | 378 nmi (434 mi, 700 km) |

486 nmi (559 mi, 900 km) |

378 nmi (434 mi, 700 km) |

| Empty weight | 4,860 lb (2,200 kg)[17] | 4,577 lb (2,076 kg) | 4,537 lb (2,058 kg) | 5,097 lb (2,312 kg) |

| Maximum takeoff weight | 8,100 lb (3,670 kg)[17] (external load) |

8,250 lb (3,742 kg) | 8,400 lb (3,810 kg) | |

Sources: Airliners.net,[18] Helicopterdirect,[19] others[20][21]

Notable appearances in media

[edit]See also

[edit]Related development

Aircraft of comparable role, configuration, and era

References

[edit]- ^ a b c d e Frawley, Gerard, The International Directory of Civil Aircraft, 2003-2004, Aerospace Publications Pty Ltd, 2003, ISBN 1-875671-58-7

- ^ a b c Apostolo, Giorgio. "Bell Model 222". The Illustrated Encyclopedia of Helicopters. New York: Bonanza Books. 1984. ISBN 978-0-517-43935-7.

- ^ Frawley, Gerard, "Bell 222 & 230", The International Directory of Civil Aircraft, 2003-2004, p. 46, Aerospace Publications Pty Ltd, 2003, ISBN 1-875671-58-7

- ^ a b c Donald, David, ed. "Bell Model 222". The Complete Encyclopedia of World Aircraft. Barnes & Nobel Books, 1997. ISBN 0-7607-0592-5.

- ^ a b Pelletier, Alain J. Bell Aircraft Since 1935. US Naval Institute Press, 1992. ISBN 1-55750-056-8.

- ^ "Bell 222". Jane's Helicopter Markets and Systems. Jane's Information Group, 2009. (subscription article)[permanent dead link].

- ^ "Albanian Govt. Bell 222UT AL-HOV". helis.com. Retrieved 15 January 2013.

- ^ "Albania - Government / Bell 222UT". Demand media. Retrieved 15 January 2013.

- ^ https://www.helis.com/database/cn/12045/ [bare URL]

- ^ "World Air Forces 2011/12" (PDF). flightglobal.com. Retrieved 4 August 2018.

- ^ "Bell 222UT | Jamaican Defence Force". 17 April 2016.

- ^ "Mercy Air". helis.com. Retrieved 14 August 2018.

- ^ Verma, Lalmani (2015-08-13). "Uttar Pradesh: For Rs 124 cr, govt gets two new aircraft to bolster fleet". The Indian Express. Archived from the original on 2025-08-10. Retrieved 2025-08-10.

- ^ "New aircraft to fly UP ministers, babus". The Times of India. 2015-09-08. ISSN 0971-8257. Retrieved 2025-08-08.

- ^ FAA Type Certificate Data Sheet[permanent dead link]

- ^ a b Taylor 1988, pp. 346–347

- ^ a b c d e f g h i Taylor 1982, p. 312

- ^ Bell 222 & 230 page on airliner.net

- ^ Bell helicopter technical data, helicopterdirect.com

- ^ Bell 222 technical data on airwolf.tv-series.com Archived 2007-12-27 at the Wayback Machine

- ^ "Helicopters - Manufacturers and Models of Helicopters A - BEL". aircraftone.com. Archived from the original on 20 June 2016. Retrieved 22 June 2016.

Bibliography

[edit]- Elliott, Bryn (May–June 1999). "On the Beat: The First 60 Years of Britain's Air Police, Part Two". Air Enthusiast (81): 64–69. ISSN 0143-5450.

- Bell 222/230 Field Maintenance Training Manual

- Bell 222U Rotorcraft Flight Manual

- Taylor, John W. R., ed. (1982). Jane's All the World's Aircraft 1982–83. London: Jane's Yearbooks. ISBN 0-7106-0748-2.

- Taylor, John W. R., ed. (1988). Jane's All the World's Aircraft 1988–89. London: Jane's Defence Data. ISBN 0-7106-0867-5.

External links

[edit]Bell 222/230

View on GrokipediaDevelopment

Origins

In the late 1960s, Bell Helicopter conducted market research that identified a growing demand for a light twin-engine commercial helicopter in the United States, aimed at competing with emerging European models such as the Aérospatiale Dauphin. This research highlighted the need for a reliable, redundant powerplant configuration to enhance safety and appeal to business, executive, and utility operators in an expanding civil aviation sector. Studies initiated during this period evolved into the Design D-306 concept by 1973, a twin-turboshaft proposal that laid the groundwork for what would become the Bell 222.[8][1] Bell Helicopter formally announced the Model 222 project on April 20, 1974, positioning it as the first light commercial twin-turbine helicopter developed in the United States. A full-scale mockup of the design was displayed at the Helicopter Association of America convention in January 1974, generating significant interest that confirmed the market viability. Key design goals included accommodating 8 to 10 passengers, incorporating twin turboshaft engines for operational redundancy, retractable tricycle landing gear for improved aerodynamics and ground clearance, and provisions for instrument flight rules (IFR) capability to support all-weather operations. These features were intended to provide a versatile platform for corporate transport and offshore utility missions.[8][1][2] Prototype construction began in 1975, with the first of five prototypes (serial number 47001, registration N9988K) completing assembly at Bell's facility in Fort Worth, Texas. The maiden flight occurred on August 13, 1976, at Arlington Municipal Airport near Fort Worth, piloted by Bell test pilot Donald Bloom. Over the subsequent years, the prototypes underwent extensive testing to refine handling characteristics and mitigate vibration issues inherent to the twin-rotor configuration.[8][1][9] The FAA certification process culminated in the issuance of Type Certificate H9SW on August 16, 1979, following resolutions to the identified vibration and handling challenges through modifications to the rotor system and flight controls. Initial production commenced shortly thereafter, with the first customer delivery—a Bell 222A—to Petroleum Helicopters International on January 16, 1980. This marked the entry of the Bell 222 into service, paving the way for subsequent enhancements like the 222B and the related 230 series.[8][1][10]Further development

In 1982, Bell introduced the 222B variant to address performance limitations of the initial 222A model, featuring a main rotor extended by two feet to a 42-foot diameter for improved lift capability and upgraded Lycoming LTS101-750C turboshaft engines rated at 684 shaft horsepower (shp) each.[2][1][8] This upgrade also included a stretched tail boom to accommodate the larger rotor system.[1] Production of the Bell 222 and 222B proceeded at Bell's manufacturing facility in Mirabel, Quebec, Canada, with a total of 199 units completed between 1980 and 1991.[1][8] These helicopters served primarily in executive transport and emergency medical roles, establishing the 222 series as a reliable light twin-turbine platform during the 1980s.[2] By 1989, Bell initiated development of the Bell 230 to mitigate ongoing reliability and maintenance challenges with the LTS101 engines, which had affected operational availability in the 222 series.[2] The prototype, a modified 222 airframe, achieved its first flight on August 12, 1991, leading to Canadian certification in March 1992.[11] Key enhancements in the Bell 230 included replacement of the LTS101 engines with more robust Allison 250-C30G/2 turboshafts, each delivering 700 shp for takeoff, along with an increased standard fuel capacity of 188 US gallons (wheeled gear) or 247 US gallons (skid gear), with optional auxiliary tanks, to extend range and mission endurance.[12][6] Additionally, the integration of full authority digital engine control (FADEC) improved engine management efficiency and reduced pilot workload. Bell produced 38 Bell 230 helicopters from 1992 to 1995 at the Mirabel facility before ceasing output in August 1995, as market preferences shifted toward larger, more versatile models capable of accommodating greater passenger loads and advanced avionics.[13][14] The 222 and 230 series collectively informed the design of the subsequent Bell 430, which debuted in 1996 as a stretched derivative with enhanced power and cabin space, building directly on the established twin-engine light helicopter architecture.[1][13]Design

Airframe and rotor system

The Bell 222/230 utilizes a conventional semi-monocoque fuselage constructed primarily from aluminum alloy, measuring 42 ft 2 in (12.85 m) in length and with an overall height of 11 ft 6 in (3.51 m).[15][1] This design provides a robust, lightweight structure optimized for twin-engine light utility operations, incorporating sponsons that house the retractable landing gear for improved aerodynamics.[16] The landing gear consists of a hydraulically retractable tricycle configuration with single-wheel main units and a steerable nose wheel, enhancing ground handling and operational versatility in various environments.[17] The main rotor system features two blades in a teetering hub arrangement, with a diameter of 39 ft 9 in (12.12 m) on the Bell 222 and 42 ft (12.80 m) on the 222B and 230 variants.[15] It employs Nodamatic elastomeric bearings, which are lubrication-free and function as hub springs for flapping, lagging, and pitch change motions, significantly reducing vibration transmission to the airframe.[18][17] The tail rotor is a two-blade pusher-type assembly with a diameter of 6 ft 6 in (1.98 m), mounted on the left side of the tail boom to counter torque effectively.[8][15] The cabin offers a spacious passenger compartment with a volume of approximately 136 cu ft (3.8 m³) designed for flexibility, seating up to 10 occupants (one pilot plus nine passengers) in utility configurations, with large sliding doors on each side facilitating easy access and optional emergency medical service (EMS) layouts for specialized roles.[8][19][18] Redundancy is emphasized through dual independent hydraulic systems operating at 103.5 bars with a maximum flow rate of 15.1 liters per minute, complemented by dual electrical systems, an integrated autopilot, and an instrument flight rules (IFR)-certified avionics suite.[8][16]Powerplant and performance features

The Bell 222 is powered by two Lycoming LTS101-650C-3 turboshaft engines, each rated at 592 shaft horsepower (shp) at takeoff, providing reliable twin-engine redundancy for safe operations in diverse conditions.[2] Later variants, such as the 222B, feature upgraded LTS101-750C-1 engines delivering 684 shp each, enhancing overall power output and performance in high-altitude or hot environments.[20] The Bell 230 replaces these with two Allison 250-C30G/2 turboshaft engines, each producing 700 shp at takeoff, which represents approximately a 20% increase in power compared to the original 222 configuration and improves hot-and-high capabilities.[7] The fuel system in the Bell 222 consists of crash-resistant tanks with a standard capacity of 188 US gallons (710 L) in the main fuselage tank, supplemented by 48 US gallons (182 L) in the sponsons for a total of around 236 US gallons, supporting typical mission ranges.[18] In the Bell 230, this system is expanded to an internal capacity of approximately 246 US gallons (930 L), with optional auxiliary tanks allowing up to 359 US gallons (1,359 L), enabling extended range for longer flights without refueling.[6] Performance features of the 222/230 series are bolstered by the Nodamatic vibration reduction system, which uses a focal pylon and nodal beam to isolate rotor-induced vibrations, significantly lowering cabin noise and enhancing passenger comfort during flight.[21] The twin-engine setup also improves autorotation capabilities, allowing safe descent and landing in the event of an engine failure due to the remaining engine's power margin. Key flight envelope characteristics include a maximum cruise speed of 133 knots (246 km/h) for the 222 and 141 knots (261 km/h) for the 230, service ceilings of around 12,800 feet (3,900 m) for the 222 and 15,500 feet (4,724 m) for the 230, and a hover in-ground-effect (IGE) ceiling of approximately 9,700 feet (2,960 m).[22][5]Operational history

Military service

In the early 1980s, the Bell 222 garnered interest from U.S. military branches for potential utility and VIP transport applications. The U.S. Coast Guard included the Bell 222 in its search and rescue (SAR) helicopter evaluation program, conducting qualitative flight tests of approximately five hours to assess its suitability for short-range recovery missions.[23] However, the service did not adopt the type, opting instead for the Eurocopter HH-65 Dauphin to meet its operational needs.[23] The Albanian Air Force introduced the Bell 222 as its first Western-built helicopter in 1991, primarily for VIP transport duties.[24] A single Bell 222UT served in this role until a fatal crash near Tirana on July 16, 2006, which resulted in six fatalities and the write-off of the aircraft.[25] The Chilean Navy leased a Bell 230 (converted from a Bell 222 airframe) in 1993 specifically for SAR operations in maritime environments.[26] The helicopter, registered N230CH, underwent modifications to enhance its suitability for naval tasks but was returned without purchase after the lease period.[27] Despite these instances, the Bell 222/230 achieved only limited military adoption worldwide, overshadowed by purpose-built platforms such as the Sikorsky UH-60 Black Hawk, which offered superior tactical versatility and ruggedness for defense applications.[2]Civilian applications

The Bell 222 entered civilian service in 1980 as an executive transport helicopter for offshore oil companies in the Gulf of Mexico, with Petroleum Helicopters International (PHI) as its inaugural customer.[2] This twin-engine design provided superior speed and range compared to prevailing single-engine models, enabling efficient personnel transport to remote oil platforms.[8] Widespread adoption followed in air ambulance services, exemplified by U.S. operator Mercy Air, which began deploying Bell 222s for emergency medical services in 1985.[28] In Canada, similar EMS roles were undertaken by operators such as Vancouver Island Helicopters, utilizing the 222UT variant for coastal medical evacuations.[29] Corporate and charter operations expanded the model's footprint, with PHI incorporating multiple Bell 222 units into its early fleet for commercial passenger services.[30] The enhanced range of the Bell 230 variant proved particularly advantageous for offshore oil rig support, facilitating extended missions in demanding environments like the North Sea and Alaska.[31] In the 1990s, Bell 222/230 helicopters were adapted for training and diverse utility roles, including news gathering by television stations such as KWTV in Oklahoma.[32] Bell 230 production concluded in 1995, contributing to a decline in new sales after more than 190 units across the series had been manufactured since 1980.[33] Despite this, approximately 59 aircraft remained in active civilian service as of 2024, valued for their reliability in remote operational areas.[2]Variants

Bell 222 series

The Bell 222 series represents the original production lineup of twin-engine light helicopters developed by Bell Helicopter, featuring the Lycoming LTS 101 turboshaft engines and a four-bladed main rotor system shared across variants for enhanced lift and stability.[1] These models were designed primarily for executive transport, emergency medical services, and utility roles, with production spanning from 1980 to 1991.[8] The baseline Bell 222A, introduced in 1980, served as the initial production model equipped with two LTS 101-650C-3 turboshaft engines each rated at 592 shaft horsepower, supporting an 8-passenger configuration in a spacious cabin. Approximately 80 units of the 222A were built.[2] A total of 199 units were built across the series.[1] In 1982, Bell introduced the Bell 222B to address performance limitations at higher altitudes and temperatures, incorporating an extended main rotor diameter of 42 feet and uprated LTS 101-750C engines delivering 684 shaft horsepower each, which improved hover performance by approximately 10% compared to the 222A.[2][1] This variant maintained the retractable tricycle landing gear and executive interior options, with 26 aircraft produced to meet demands for more versatile operations in varied environmental conditions.[8] The Bell 222U, also known as the 222UT or Utility Twin, emerged in 1983 as a specialized adaptation of the 222B for rugged fieldwork, replacing the wheeled landing gear with fixed skids to better suit rough terrain in applications such as logging and construction.[8] These modifications reduced weight and costs while increasing internal fuel capacity, enabling 72 units to be built for utility-focused missions requiring durability over luxury.[2] For demanding high-altitude environments, the Bell 222SP special performance variant featured uprated engines optimized for superior power output, allowing operations in regions with thin air, though production was limited to 10 units due to niche requirements.[2] Experimental derivatives of the 222 series included the Bell D-292, an experimental helicopter demonstrator that utilized the 222's airframe as a platform to test advanced composite materials and rotor technologies under the U.S. Army's Advanced Composite Airframe Program, with first flight in 1985.[34] This effort influenced subsequent developments, such as the stretched fuselage design of the Bell 430, by validating lightweight structures for improved efficiency.[1] Overall, the Bell 222 series achieved a total production of 199 helicopters, with an estimated fleet remaining in service as of the early 2020s, supported by ongoing maintenance and upgrades.[35][2]Bell 230 series

The Bell 230 series comprises refined configurations derived from the Bell 222 twin-engine light helicopter, emphasizing improved power, capacity, and mission adaptability through the adoption of Allison 250-C30G turboshaft engines rated at 700 shp each.[6] The core Bell 230 model featured an increased maximum gross weight of 8,400 lb (3,810 kg) and was offered in an executive configuration seating up to 8 passengers in a spacious cabin.[11] This variant prioritized corporate transport with enhanced fuel capacity for extended operations.[36] Specialized sub-variants expanded the series' utility. The Bell 230 Utility employed skid landing gear for operations involving external loads up to 2,800 lb, supporting tasks such as aerial logging and construction in rugged terrain.[6] The Bell 230 EMS configuration was tailored for medical evacuation, incorporating provisions for one or two stretchers and dedicated bays for medical equipment, enabling rapid response in emergency scenarios.[6] Compared to its Bell 222 predecessor, the 230 series delivered a range extension to approximately 390 nautical miles with standard fuel, facilitated by greater fuel capacity and more efficient powerplants, alongside cockpit refinements that simplified pilot workload.[5] A total of 38 Bell 230 helicopters were produced across these configurations.[36] The model also paved the way for the Bell 430, serving as its developmental prototype with adaptations leading to the successor's four-bladed rotor system; production of the 230 concluded with the final delivery in 1995.[37]Operators

Current operators

As of 2024, approximately 59 Bell 222-series helicopters remain airworthy worldwide, with production having ceased in 1995 and ongoing activity in the secondary market supporting their use in remote and utility operations; the Bell 230 variant had 38 units produced, with an unknown number currently airworthy.[2] Note that a Bell 222 (N222EX) was substantially damaged in a crash on October 11, 2025, in Huntington Beach, California.[38] The majority of active aircraft are in civil service, concentrated in Africa and North America. In South Africa, Henley Air operates the largest fleet with six Bell 222UT helicopters configured for emergency medical services (EMS) through its ROCKET (Rapid On Call Emergency Transport) program, serving mining, construction, and remote areas with air ambulance and rescue capabilities; the company also maintains a Bell 222 simulator for training.[39][40][41] North America accounts for a significant portion of the remaining civil fleet, including about 19 aircraft in the United States used primarily for private utility, charter, and occasional EMS roles.[2] In Canada, a small number of Bell 230s support charter and utility missions in remote regions. European operations are limited to private owners employing the helicopters for personal and light utility transport. Military use is minimal, with no large active fleets reported; historical operators have largely retired their Bell 222/230 aircraft in favor of newer models.[2] Continued airworthiness is maintained through Bell Textron's ongoing support programs, including parts availability and optional upgrades such as modern avionics for enhanced safety and IFR capability in select fleets.[39]Former operators

The Uruguayan Navy acquired one Bell 222 in 1980 for search and rescue and maritime surveillance missions.[42] The aircraft served in coastal patrol roles until its retirement in 1991. The Royal Oman Police Air Wing operated a fleet of two Bell 222 helicopters from 1980 to 1987, primarily for VIP transport and utility duties.[43] These were the initial examples delivered to the organization and were decommissioned in 1987, with both airframes subsequently exported for civilian use.[44] In the United States, Petroleum Helicopters International (PHI) became the launch customer for the Bell 222, receiving the first production example in January 1980 for offshore oil support operations.[8] PHI's fleet of Bell 222s was gradually retired during the 2000s as the company transitioned to newer single- and twin-engine models better suited to evolving industry demands.[2] Life Link III, a Minnesota-based emergency medical services provider, utilized Bell 222 helicopters for patient transport until April 14, 2000, when one of their Bell 222U models (N225LL) crashed during approach to St. Paul Downtown Airport, resulting in substantial damage to the aircraft.[45] The Government of Uttar Pradesh, India, operated one Bell 230 for government transport from 1995 to 2015.[7] The Chilean Navy operated at least one Bell 230 for utility roles. Globally, the Bell 222/230 series underwent widespread phase-out by the mid-2010s, with 129 of the 188 Bell 222-series airframes retired by 2024 due to aging airframes, rising maintenance costs, and the availability of successors like the Bell 407, Bell 427, and Airbus Helicopters H135 (formerly Eurocopter EC135).[2]Accidents and incidents

Notable crashes

One of the most notable accidents involving the Bell 222 occurred on April 14, 2000, when a Bell 222U (N225LL), operated by Air Methods Corporation doing business as Life Link III, crashed near St. Paul Downtown Airport (Holman Field) in St. Paul, Minnesota. The helicopter was on a positioning flight under 14 CFR Part 91 when the pilot encountered icing conditions during maneuvering at low altitude, leading to a loss of control and aerodynamic stall. The pilot and one medical crew member were fatally injured, while the other medical crew member sustained serious injuries; the helicopter was substantially damaged upon impact with a building rooftop. The National Transportation Safety Board (NTSB) determined the probable cause to be the pilot's failure to maintain adequate airspeed in known icing conditions, compounded by the absence of a stall warning system, marking this as a preventable case in emergency medical services operations.[45] A more recent incident took place on October 11, 2025, during the arrival of a Bell 222 (N222EX) to the Cars 'N Copters airshow event in Huntington Beach, California. The privately owned 1980-model helicopter, performing a low-altitude hover, experienced a suspected mechanical failure in the tail rotor system, causing it to lose control, separate from the tail, and crash onto a roadway, impacting a pedestrian bridge. The pilot and passenger sustained serious injuries, while three people on the ground received minor injuries; there were no fatalities, and the aircraft was substantially damaged. The NTSB is investigating the event, with preliminary reports indicating a possible pitch link or drive system failure during the Part 91 personal flight.[38] Since entering service in 1980, the Bell 222/230 family has recorded over 30 hull-loss accidents worldwide, according to the Aviation Safety Network database, with early Bell 222 models particularly affected by reliability issues in the Lycoming LTS101 turboshaft engines, including power losses and malfunctions that contributed to several crashes in the 1980s.[46] These engine problems prompted operational pauses and upgrades, such as conversions to Allison 250-C30 engines in later variants like the Bell 230, improving overall safety.[47]Safety analysis

The Bell 222/230 series has demonstrated a generally favorable safety profile as a twin-engine light helicopter, with accident rates lower than comparable single-engine models due to its redundant power systems and robust design. According to analyses of U.S. civil rotorcraft accidents, twin-turbine helicopters like the 222/230 exhibit an accident rate of 0.76 per 100,000 flight hours for operations at stationary elevated structures (1984-1988 data), compared to 0.21 for single-turbine helicopters.[48] This performance has improved over time through targeted modifications, though specific operational contexts such as emergency medical services (EMS) have highlighted areas for enhancement. Early production models of the Bell 222 were affected by issues with the Lycoming LTS101 turboshaft engines, including component failures that prompted multiple FAA Airworthiness Directives (ADs) in the 1980s and beyond. These concerns, including reports of impeller and power turbine rotor issues, were mitigated in the 222B variant through reinforced engine components and higher-rated LTS101-650C-1 engines, enhancing reliability without altering the core powerplant.[49] Subsequent ADs, such as 92-15-07 and later revisions, further mandated removals and inspections for affected LTS101 series engines installed on Bell 222 helicopters.[50] Tail rotor vulnerabilities have been a recurring concern, with several incidents attributed to drive shaft fatigue and related component failures. At least four documented cases, including a 1987 crash of a Bell 222 (G-META) where the tail rotor drive shaft was severed, and the October 11, 2025, crash of N222EX in Huntington Beach, California, marked another such event, where preliminary findings indicated a tail rotor gearbox separation due to a control part disconnection, leading to loss of anti-torque control.[51][52] In response, Bell issued Alert Service Bulletin 222-95-76 in 1995, mandating periodic inspections of tail rotor blades for cracks and fatigue, with removal required if damage is detected; this was incorporated into FAA-mandated compliance schedules.[53] In EMS operations, the Bell 222/230 has faced elevated risks, with factors including night operations and wire strikes, as seen in multiple Bell 222 EMS crashes, such as the 2008 N992AA wirestrike that resulted in four fatalities.[54] Post-2000 mitigations, including FAA-mandated IFR certification upgrades for EMS-configured models and enhanced pilot training requirements under 14 CFR Part 135, have reduced these risks by improving situational awareness and operational standards.[55] The introduction of the Bell 230 series brought incremental safety enhancements, such as upgraded Allison 250-C30G engines with improved torque characteristics, though not full FADEC implementation until later derivatives like the 430.[1] Overall, accident rates for twin-engine light helicopters have trended downward in recent years, reflecting these evolutions, with U.S. rotorcraft fatal accident rates at 0.58 per 100,000 flight hours as of fiscal year 2024 (October 2023–July 2024).[56] Regulatory oversight has been proactive, with FAA ADs addressing key components; for example, AD 88-02-03 required inspections of the main rotor yoke (P/N 222-011-102-101) to prevent fatigue cracks, building on early certification in 1983.[57] For export models, the European Union Aviation Safety Agency (EASA) validated the type certificate under IM.R.114, ensuring equivalent airworthiness standards for international operations.[58]Specifications

Bell 222

The Bell 222 is the original production model of the twin-engine light utility helicopter series, introduced in 1980 as the first fully FAA-certified light twin-turbine commercial helicopter in the United States. Powered by Lycoming turboshaft engines, it was designed for executive transport, utility roles, and emergency medical services, accommodating a crew of one or two pilots along with up to 8 passengers in its spacious cabin. Sub-variants such as the 222A and 222B incorporated improvements in avionics, performance, rotor diameter, and engine power while retaining the core Lycoming powerplant configuration.[2] Key technical specifications for the baseline Bell 222 model are summarized below. These figures represent standard configurations with retractable landing gear, emphasizing the model's balance of payload, range, and speed for light commercial operations.| Category | Specification |

|---|---|

| Crew and Capacity | Crew: 1–2 Capacity: up to 8 passengers |

| Weights | Empty weight: 4,828 lb (2,190 kg) Max takeoff weight: 7,850 lb (3,560 kg) |

| Dimensions | Rotor diameter: 39 ft 9 in (12.12 m) Length: 42 ft 2 in (12.85 m) Height: 11 ft 6 in (3.51 m) |

| Powerplant | 2 × Lycoming LTS101-650C-2 turboshafts, 590 shp (440 kW) each |

| Performance | Max speed: 130 kn (150 mph, 240 km/h) Range: 283 nmi (325 mi, 525 km) Service ceiling: 12,800 ft (3,900 m) |

| Fuel and Climb | Fuel capacity: 236 US gal (893 L) Rate of climb: 1,580 ft/min (8.0 m/s) |

Bell 230

The Bell 230 represents an evolution of the Bell 222, incorporating upgraded Allison 250-C30G turboshaft engines that provide 700 shp each, compared to the 222's 590 shp Lycoming LTS101-650C units, resulting in enhanced power margins, a modest increase in maximum takeoff weight, and improved overall performance such as higher cruise speeds and extended range capabilities.[5] This upgrade maintained the twin-engine light utility configuration while emphasizing reliability and passenger comfort in executive or utility roles. Key specifications for the Bell 230 are summarized below, reflecting its design for versatility in civil operations with wheeled landing gear.| Parameter | Value (Imperial) | Value (Metric) |

|---|---|---|

| Crew | 1–2 | 1–2 |

| Passenger Capacity | up to 8 | up to 8 |

| Empty Weight | 5,097 lb | 2,312 kg |

| Maximum Takeoff Weight | 8,400 lb | 3,810 kg |

| Rotor Diameter | 42 ft 0 in | 12.80 m |

| Overall Length | 50 ft 0 in | 15.24 m |

| Height | 12 ft 2 in | 3.71 m |

| Powerplant | 2 × Allison 250-C30G/2 turboshafts, 700 shp each | 2 × Allison 250-C30G/2 turboshafts, 522 kW each |

| Maximum Speed | 141 kn (162 mph) | 261 km/h |

| Range | 385 nmi (443 mi) | 713 km (with auxiliary fuel) |

| Service Ceiling | 15,500 ft | 4,724 m |

| Fuel Capacity | 350 US gal (with auxiliary tanks) | 1,325 L (with auxiliary tanks) |

| Rate of Climb | 1,510 ft/min | 7.67 m/s |

Television

- Airwolf (1984–1987): A modified Bell 222A (registration N3176S, serial number 47085) served as the iconic "Airwolf" helicopter, central to the action-adventure series about a covert military project. The aircraft featured cosmetic modifications including retractable chin guns and extended skids for the show's supersonic capabilities.[61][62]

- Walker, Texas Ranger (1990s episodes): A Bell 222UT was used in various episodes.[63]

Film

- Other People's Money (1991): A Bell 222 appears in scenes involving corporate travel.[64]

- X-Men (2000): A Bell 222 (false registration N1972J) is used as Senator Kelly's personal helicopter during key action sequences.[65][66]