Recent from talks

Nothing was collected or created yet.

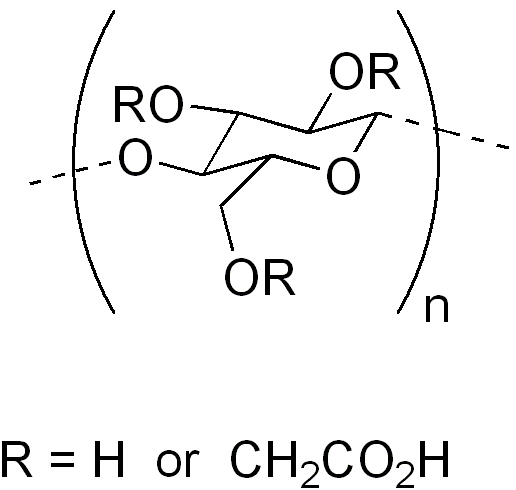

Carboxymethyl cellulose

View on WikipediaThis section has multiple issues. Please help improve it or discuss these issues on the talk page. (Learn how and when to remove these messages)

|

| |

| |

| Names | |

|---|---|

| Other names

Carboxymethylcellulose; carmellose; E466

| |

| Identifiers | |

| ChEBI | |

| ChEMBL | |

| ChemSpider |

|

| ECHA InfoCard | 100.120.377 |

| E number | E466 (thickeners, ...) |

| UNII | |

CompTox Dashboard (EPA)

|

|

| Properties | |

| variable | |

| Molar mass | variable |

Except where otherwise noted, data are given for materials in their standard state (at 25 °C [77 °F], 100 kPa).

| |

Carboxymethyl cellulose (CMC) or cellulose gum[1] is a cellulose derivative with carboxymethyl groups (-CH2-COOH) bound to some of the hydroxyl groups of the glucopyranose monomers that make up the cellulose backbone. It is often used in its sodium salt form, sodium carboxymethyl cellulose. The addition of carboxylic acid groups to the cellulose backbone allows carboxymethyl cellulose to be dissolved in water unlike natural cellulose. This allows its use in numerous food and pharmaceutical applications that require water-soluble polymers.

Preparation

[edit]Carboxymethyl cellulose is synthesized by the alkali-catalyzed reaction of cellulose with chloroacetic acid.[2][3] The polar (organic acid) carboxyl groups render the cellulose soluble and chemically reactive.[4] Fabrics made of cellulose – e.g., cotton or viscose (rayon) – may also be converted into CMC.[5]

Following the initial reaction, the resultant mixture produces approximately 60% CMC and 40% salts (sodium chloride and sodium glycolate). This product, called technical CMC, is used in detergents, where it is used as a thickening agent.[6][7] An additional purification process is used to remove salts to produce pure CMC, which is used for food and pharmaceutical applications.[8] An intermediate 'semi-purified' grade is also produced, which is typically used in paper applications such as the restoration of archival documents.[9]

Structure and properties

[edit]This section has multiple issues. Please help improve it or discuss these issues on the talk page. (Learn how and when to remove these messages)

|

Structure

[edit]CMC is a derivative of the regenerated cellulose [C6H10O5]n with hydroxy-acetic acid (hydroxyethanoic acid) CH2(OH)COOH or sodium monochloroacetate (Na[ClCH2COO]). The CMC backbone consists of D-glucose residues linked by -1,4-linkage. It has carboxymethyl groups (-CH2-COOH) bound to some of the hydroxyl groups of the glucopyranose monomers that make up the cellulose backbone. It is often used as its sodium salt, sodium carboxymethyl cellulose.[10]

Properties

[edit]CMC is a white or lightly yellow powder with no odor, flavor, or poisonous properties. It is hygroscopic and dissolves well in hot or cold water, forming a viscous solution. It is not soluble in organic solvents like methanol, ethanol, acetone, chloroform, and benzene. The functional properties of CMC depend on the degree of substitution of the cellulose structure (i.e., how many of the hydroxyl groups have been converted to carboxymethylene groups in the substitution reaction), as well as the chain length of the cellulose backbone structure and the degree of clustering of the carboxymethyl substituents. It is commonly used as a viscosity modifier or thickener and to stabilize emulsions in various products, both food and non-food-related. It is mainly used because it has a high viscosity, is nontoxic, and is generally considered to be hypoallergenic.

Uses

[edit]Carboxymethyl cellulose (CMC) is used in applications ranging from food production to medical treatments.[11][10] It is commonly used as a viscosity modifier or thickener and to stabilize emulsions in both food and non-food products. It is used primarily because it has high viscosity, is nontoxic, and is generally considered to be hypoallergenic, as the major source fiber is either softwood pulp or cotton linter. It is also used in non-food products which include products such as toothpaste, laxatives, diet pills, water-based paints, detergents, textile sizing, reusable heat packs, various paper products, filtration materials, synthetic membranes, wound healing applications, and also in leather crafting to help burnish edges.[12][13][14][verification needed]

Food

[edit]CMC is registered as E466 or E469 (when it is enzymatically hydrolyzed). It is used for a viscosity modifier or thickener and to stabilize emulsions in various products, including ice cream, mayonnaise, and beverages. It is also used extensively in gluten-free and reduced-fat food products.[15] CMC injections have also been used in food fraud, to fraudulently increase the weight and visual appeal of shrimp and prawns so as to short-weight customers.[16]

CMC's variable viscosity (high while cold, and low while hot) makes it useful in the preparation of cold foods and textures in beverages and edible gels. With a degree of substitution (DS) around 1.0, it can prevent dehydration and shrinkage of gelatin while also contributing to a more airy structure. In some foods, it can be used to control oil and moisture content.[17]

CMC is used to achieve tartrate or cold stability in wine, which can prevent excess energy usage while chilling wine in warm climates. It is more stable than metatartaric acid and inhibits tartrate crystal nucleation and growth.[18][19][20]

CMC powder is widely used in the ice cream industry to make ice creams without the need for churning or extremely low temperatures.[21] CMC is used in baking breads and cakes. The use of CMC gives the loaf an improved quality (e.g., texture) at a reduced cost by reducing the need for fat. CMC is also used as an emulsifier in sweet biscuits. Dispersing fat uniformly in the dough improves the release of the dough from the molds and cutters, achieving well-shaped biscuits without any distorted edges. It can also help to reduce the amount of egg yolk or fat used in making the biscuits. The use of CMC in candy preparation ensures smooth dispersion in flavor oils and improves texture and quality. CMC is used in chewing gums, margarine, and peanut butter as an emulsifier.[22]

Detergent uses

[edit]CMC is a common ingredient in cleaning products because of its thickening and stabilizing properties and nontoxic composition. In detergent and cleaning products, it can be used to enhance texture and assist in the suspension of dirt and grime in the cleaning product. Its adjustable viscosity can be used to standardize the textures of the products, especially when used along with other chemicals.[7][6]

CMC helps with the removal of grease and aids in the creation of small bubbles in the soap. This, along with its ability to suspend dirt in mixtures, can make soaps and other cleaning products more efficient.[23]

Textile uses

[edit]CMC is used in textiles as a thickening agent in textile printing, constituting about 2-3% of printing pastes. It is also used in fabric finishing to affect the fabric's texture. Additionally, CMC serves as a binding agent in non-woven fabrics, contributing to the strength and stability of the material. In sizing applications, about 1-3% of CMC is used to protect yarns during weaving to reduce breakages.

CMC aids in thickening printing pastes, which makes the prints themselves more precise. It is also used to thicken dyes. Additionally, it is an alternative to synthetic thickeners.[24]

Cosmetics uses

[edit]CMC is an ingredient used in over 50% of cosmetic products. As a thickening agent, it is used in formulations where viscosity needs to be precisely controlled. In hair care, about 25% of shampoos and conditioners utilize CMC for its conditioning and detangling effects. It is also used in the makeup and toothpaste industries to control the products' texture. Due to its ability to retain moisture, it is also used in skincare products. CMC serves as a film-forming agent in approximately 10% of sunscreens.

CMC aids in pigment suspension and dispersion, binding other ingredients for even distribution. CMC, when combined with Fatty Acid Ethanolamine or 2,2'-Iminodiethanol in a hair product, can form a thin film around the hair.[25]

Oil Drilling

[edit]As a thickening agent, CMC can increase the viscosity of drilling fluids and form a network structure in the mud, thereby enhancing their suspension capacity. CMC can effectively protect the wellbore and manage the penetration and loss of moisture in the drilling fluid. Ultra-high viscosity Sodium Carboxymethyl Cellulose can be used in fracturing fluids, primarily to carry fillers into oil wells.[26]

Medical applications

[edit]CMC is also used in numerous medical applications.[11][14][27][28]

Some examples include:

- Device for epistaxis (nose bleeding). A poly-vinyl chloride (PVC) balloon is covered by CMC knitted fabric reinforced by nylon. The device is soaked in water to form a gel, which is inserted into the nose of the patient and inflated. The combination of the inflated balloon and the therapeutic effect of the CMC stops the bleeding.[29]

- Hydrofiber fabric used as a medical dressing following ear, nose, and throat surgical procedures.[30]

- Water is added to form a gel, and this gel is inserted into the sinus cavity following surgery.[31]

- In ophthalmology, CMC is used as a lubricating agent in artificial tears solutions for the treatment of dry eyes.[32]

- In veterinary medicine, CMC is used in abdominal surgeries in large animals, particularly horses, to prevent the formation of bowel adhesions.[33]

Research applications

[edit]Insoluble CMC (water-insoluble) can be used in the purification of proteins, particularly in the form of charged filtration membranes or as granules in cation-exchange resins for ion-exchange chromatography.[34] Its low solubility is a result of a lower DS value (the number of carboxymethyl groups per anhydroglucose unit in the cellulose chain) compared to soluble CMC.[35] Insoluble CMC offers physical properties similar to insoluble cellulose, while the negatively charged carboxylate groups allow it to bind to positively charged proteins.[36] Insoluble CMC can also be chemically cross-linked to enhance the mechanical strength of the material.[37]

Moreover, CMC has been used extensively to characterize enzyme activity from endoglucanases (part of the cellulase complex); it is a highly specific substrate for endo-acting cellulases, as its structure has been engineered to decrystallize cellulose and create amorphous sites that are ideal for endoglucanase action.[citation needed] CMC is desirable because the catalysis product (glucose) is easily measured using a reducing sugar assay, such as 3,5-dinitrosalicylic acid.[citation needed] Using CMC in enzyme assays is especially important in screening for cellulase enzymes that are needed for more efficient cellulosic ethanol conversion.[citation needed] CMC was misused in early work with cellulase enzymes, as many had associated whole cellulase activity with CMC hydrolysis.[according to whom?] As the mechanism of cellulose depolymerization became better understood, it became clear that exo-cellulases are dominant in the degradation of crystalline (e.g. Avicel) and not soluble (e.g. CMC) cellulose.[citation needed]

Other uses

[edit]This section needs additional citations for verification. (November 2022) |

In laundry detergents, it is used as a soil suspension polymer designed to deposit onto cotton and other cellulosic fabrics, creating a negatively charged barrier to soils in the wash solution.[citation needed] CMC is also used as a thickening agent, for example, in the oil-drilling industry as an ingredient of drilling mud, where it acts as a viscosity modifier and water retention agent.[citation needed]

CMC is sometimes used as an electrode binder in advanced battery applications (i.e. lithium ion batteries), especially with graphite anodes.[38] CMC's water solubility allows for less toxic and costly processing than with non-water-soluble binders, like the traditional polyvinylidene fluoride (PVDF), which requires toxic n-methylpyrrolidone (NMP) for processing.[citation needed] CMC is often used in conjunction with styrene-butadiene rubber (SBR) for electrodes requiring extra flexibility, e.g. for use with silicon-containing anodes.[39]

CMC is also used in ice packs to form a eutectic mixture resulting in a lower freezing point, and therefore more cooling capacity than ice.[40]

Aqueous solutions of CMC have also been used to disperse carbon nanotubes, where the long CMC molecules are thought to wrap around the nanotubes, allowing them to be dispersed in water.[citation needed]

In conservation-restoration, it is used as an adhesive or fixative (commercial name Walocel, Klucel).[citation needed]

Adverse reactions

[edit]Effects on inflammation, microbiota-related metabolic syndrome, and colitis are a subject of research.[41] Carboxymethyl cellulose, along with other emulsifiers, is suggested as a possible cause of inflammation of the gut,[42] through alteration of the human gastrointestinal microbiota, and has been suggested as a triggering factor in inflammatory bowel diseases such as ulcerative colitis and Crohn's disease.[43][44] A small randomized human study found that consumption of high amounts of CMC altered gut microbiota composition and was associated with increased gastrointestinal discomfort. [45]

While thought to be uncommon, case reports of severe reactions to CMC exist.[46] Skin testing is believed to be a useful diagnostic tool for this purpose.[47]

See also

[edit]References

[edit]- ^ Codex Alimentarius Commission (2016). "Sodium carboxymethyl cellulose (Cellulose gum)". GFSA Online. FAO. Archived from the original on 2017-09-12. Retrieved 2017-05-08.

- ^ US3574188A, Takehara, Kikuo; Senda, Hisakazu & Hirano, Kazuhiro, "Process for preparing carboxymethyl cellulose or its alkali salt of high viscosity", issued 1971-04-06

- ^ Hollabaugh, C. B.; Burt, Leland H.; Walsh, Anna Peterson (October 1945). "Carboxymethylcellulose. Uses and Applications". Industrial & Engineering Chemistry. 37 (10): 943–947. doi:10.1021/ie50430a015.

- ^ "CMC Sodium Carboxymethylcellulose" (PDF). colonygums.com. Archived (PDF) from the original on 12 April 2023. Retrieved 19 May 2023.

- ^ Wu, Jiamin; Feng, Zhaoxue; Dong, Chaohong; Zhu, Ping; Qiu, Jianhui; Zhu, Longxiang (29 March 2022). "Synthesis of Sodium Carboxymethyl Cellulose/Poly(acrylic acid) Microgels via Visible-Light-Triggered Polymerization as a Self-Sedimentary Cationic Basic Dye Adsorbent". Langmuir. 38 (12): 3711–3719. doi:10.1021/acs.Langmuir.1c03196. PMID 35290066.

- ^ a b "Carboxymethyl cellulose (cmc, cellulose gum), sodium carboxymethyl cellulose (cmc)". Center for Science in the Public Interest. May 2025. Retrieved 2025-05-16.

- ^ a b "CARBOXYMETHYL CELLULOSE". Ataman Kimya (in Turkish). Retrieved 2025-05-16.

- ^ Ergun, R.; Guo, J.; Huebner-Keese, B. (2016). "Cellulose". Encyclopedia of Food and Health. pp. 694–702. doi:10.1016/B978-0-12-384947-2.00127-6. ISBN 978-0-12-384953-3.

Due to its high solubility and clarity of its solutions, CMC is commonly used in beverages and beverage dry mixes to provide rich mouthfeel. It is also used in acidified protein drinks to stabilize protein and prevent it from precipitating. CMC is also added to syrup and sauce formulations to increase viscosity.

- ^ "Sodium Carboxymethylcellulose CMC Uses In Papermaking Industry". Jining Fortune Biotech.

- ^ a b Ergun, R.; Guo, J.; Huebner-Keese, B. (2016). "Cellulose". Encyclopedia of Food and Health. pp. 694–702. doi:10.1016/B978-0-12-384947-2.00127-6. ISBN 978-0-12-384953-3.

- ^ a b Rahman, Md Saifur; Hasan, Md Saif; Nitai, Ashis Sutradhar; Nam, Sunghyun; Karmakar, Aneek Krishna; Ahsan, Md Shameem; Shiddiky, Muhammad J. A.; Ahmed, Mohammad Boshir (2021). "Recent Developments of Carboxymethyl Cellulose". Polymers. 13 (8): 1345. doi:10.3390/polym13081345. PMC 8074295. PMID 33924089.

- ^ "CP Kelco Cellulose Gum / Carboxymethyl Cellulose". Archived from the original on 2013-08-24. Retrieved 2013-07-17.

- ^ "Sodium Carboxymethylcellulose – The Ideal Hydrocolloid for Bakery & Dough Products" (PDF). Archived from the original (PDF) on 2015-06-26.

- ^ a b Tudoroiu, Elena-Emilia; Dinu-Pîrvu, Cristina-Elena; Albu Kaya, Mădălina Georgiana; Popa, Lăcrămioara; Anuța, Valentina; Prisada, Răzvan Mihai; Ghica, Mihaela Violeta (2021). "An Overview of Cellulose Derivatives-Based Dressings for Wound-Healing Management". Pharmaceuticals. 14 (12): 1215. doi:10.3390/ph14121215. PMC 8706040. PMID 34959615.

- ^ Stanford, John (January 2012). "Food Processing Technologies for Reduction of Fat in Products" (PDF). Food & Health Innovation Service. Scotland Food & Drink. Archived from the original (PDF) on 2014-10-23.

- ^ "Fraudulent and deceptive practices on seafood products" (PDF). marketac.eu. European Commission. Retrieved 23 June 2024.

- ^ "FOOD GRADE CARBOXYMETHYL CELLULOSE APPLICATIONS". 3 November 2023.

- ^ Gerbaud, Vincent (18 October 1996). Determination de l'etat de supersaturation et effet des polysaccharides sur la crystallization du bitartrate de potassium dans les vins [Determination of the state of supersaturation and effect of polysaccharides on the crystallization of potassium bitartrate in wines] (PDF) (Ph.D.) (in French). Institut National Polytechnique de Talouse. Docket 961NP1030G. Archived (PDF) from the original on 2016-10-13. Retrieved 2017-05-07.

- ^ Gerbaud, Vincent; Gabas, Nadine; Blouin, Jacques; Crachereau, Jean-Christophe (31 December 2010). "Study of wine tartaric acid salt stabilization by addition of carboxymethylcellulose (CMC): comparison with the « protective colloids » effect". OENO One. 44 (4): 231. doi:10.20870/oeno-one.2010.44.4.1474.

- ^ Bajul, Audrey; Gerbaud, Vincent; Teychene, Sébastien; Devatine, Audrey; Bajul, Gilles (August 2017). "Effect of carboxymethylcellulose on potassium bitartrate crystallization on model solution and white wine" (PDF). Journal of Crystal Growth. 472: 54–63. Bibcode:2017JCrGr.472...54B. doi:10.1016/j.jcrysgro.2017.03.024.

- ^ Bahramparvar, Maryam; Mazaheri Tehrani, Mostafa (October 2011). "Application and Functions of Stabilizers in Ice Cream". Food Reviews International. 27 (4): 389–407. doi:10.1080/87559129.2011.563399.

- ^ "C.m.c. Glossary – Recipes with C.m.c. - Tarladalal.com". Archived from the original on 15 December 2016. Retrieved 9 November 2016.

- ^ "DETERGENT GRADE CARBOXYMETHYL CELLULOSE APPLICATIONS". 13 November 2023.

- ^ "TEXTILE GRADE CARBOXYMETHYL CELLULOSE APPLICATIONS". 13 November 2023.

- ^ "COSMETICS GRADE CARBOXYMETHYL CELLULOSE APPLICATIONS". 13 November 2023.

- ^ "Sodium Carboxymethyl Cellulose (CMC)". 31 December 2024.

- ^ Zennifer, Allen; Senthilvelan, Praseetha; Sethuraman, Swaminathan; Sundaramurthi, Dhakshinamoorthy (March 2021). "Key advances of carboxymethyl cellulose in tissue engineering & 3D bioprinting applications". Carbohydrate Polymers. 256 117561. doi:10.1016/j.carbpol.2020.117561. PMID 33483063.

- ^ Ciolacu, Diana Elena; Nicu, Raluca; Ciolacu, Florin (2020). "Cellulose-Based Hydrogels as Sustained Drug-Delivery Systems". Materials. 13 (22): 5270. Bibcode:2020Mate...13.5270C. doi:10.3390/ma13225270. PMC 7700533. PMID 33233413.

- ^ "Behandlung der anterioren Epistaxis mit Nasentamponade - Behandlung der anterioren Epistaxis mit Nasentamponade". MSD Manual Profi-Ausgabe (in German). Retrieved 2024-06-21.

- ^ Antonelli, Patrick J.; Sampson, Edith M.; Lang, Dustin M. (March 2010). "Safety and efficacy of carbomethylcellulose foam in guinea pig middle ear surgery". Otolaryngology–Head and Neck Surgery. 142 (3): 405–408. doi:10.1016/j.otohns.2009.11.009. PMID 20172389.

- ^ Leunig, Andreas; Betz, Christian S.; Siedek, Vanessa; Kastl, Konrad G. (2009). "CMC packing in functional endoscopic sinus surgery: does it affect patient comfort?". Rhinology. 47 (1): 36–40. PMID 19382492.

- ^ "Carboxymethylcellulose: Indications, Side Effects, Warnings". Drugs.com. Archived from the original on 2023-08-10. Retrieved 2023-08-08.

- ^ Murphy, David J.; Peck, Lynn S.; Detrisac, Carol J.; Widenhouse, Christopher W.; Goldberg, Eugene P. (2002-10-01). "Use of a high-molecular-weight carboxymethylcellulose in a tissue protective solution for prevention of postoperative abdominal adhesions in ponies". American Journal of Veterinary Research. 63 (10): 1448–1454. doi:10.2460/ajvr.2002.63.1448. PMID 12371775.

- ^ "Whatman Filters & Sample Collection". Archived from the original on 2 May 2013. Retrieved 9 November 2016.

- ^ Wang, Mengying; Jia, Xiangxiang; Liu, Wanshuang; Lin, Xiaobo (March 2021). "Water insoluble and flexible transparent film based on carboxymethyl cellulose". Carbohydrate Polymers. 255 117353. doi:10.1016/j.carbpol.2020.117353. PMID 33436193.

- ^ Lopez, Carlos G.; Colby, Ralph H.; Cabral, João T. (2018-04-24). "Electrostatic and Hydrophobic Interactions in NaCMC Aqueous Solutions: Effect of Degree of Substitution". Macromolecules. 51 (8): 3165–3175. Bibcode:2018MaMol..51.3165L. doi:10.1021/acs.macromol.8b00178. hdl:10044/1/58673.

- ^ Nakayama, Ryo-ichi; Yano, Tomoya; Namiki, Norikazu; Imai, Masanao (November 2019). "Highly Size-Selective Water-Insoluble Cross-Linked Carboxymethyl Cellulose Membranes". Journal of Polymers and the Environment. 27 (11): 2439–2444. Bibcode:2019JPEnv..27.2439N. doi:10.1007/s10924-019-01532-w.

- ^ Park, Jeong Hoon; Kim, Sun Hyung; Ahn, Kyung Hyun (May 2023). "Role of carboxymethyl cellulose binder and its effect on the preparation process of anode slurries for Li-ion batteries". Colloids and Surfaces A: Physicochemical and Engineering Aspects. 664 131130. doi:10.1016/j.colsurfa.2023.131130.

- ^ [1] Archived 2017-12-04 at the Wayback Machine Applications of sodium carboxymethyl cellulose As a Binder In Batteries

- ^ "Use in ice packs". Archived from the original on July 8, 2011.

- ^ Healy, Melissa (2015-02-25). "Is common food additive to blame for rising rates of bowel disease?". Los Angeles Times. Archived from the original on 2017-07-12. Retrieved 2017-07-12.

- ^ Costa, Eduardo M.; Silva, Sara; Pereira, Carla F.; Ribeiro, Alessandra B.; Casanova, Francisca; Freixo, Ricardo; Pintado, Manuela; Ramos, Óscar L. (22 May 2023). "Carboxymethyl Cellulose as a Food Emulsifier: Are Its Days Numbered?". Polymers. 15 (10): 2408. doi:10.3390/polym15102408. PMC 10221013. PMID 37242982.

- ^ Martino, John Vincent; Van Limbergen, Johan; Cahill, Leah E. (1 May 2017). "The Role of Carrageenan and Carboxymethylcellulose in the Development of Intestinal Inflammation". Frontiers in Pediatrics. 5 96. doi:10.3389/fped.2017.00096. PMC 5410598. PMID 28507982.

- ^ Swidsinski, Alexander; Ung, Victoria; Sydora, Beate C.; Loening-Baucke, Vera; Doerffel, Yvonne; Verstraelen, Hans; Fedorak, Richard N. (March 2009). "Bacterial Overgrowth and Inflammation of Small Intestine After Carboxymethylcellulose Ingestion in Genetically Susceptible Mice". Inflammatory Bowel Diseases. 15 (3): 359–364. doi:10.1002/ibd.20763. PMID 18844217.

- ^ Chassaing, Benoit; Compher, Charlene; Bonhomme, Brittaney; Liu, Qing; Tian, Yuan; Walters, William; Nessel, Lisa; Delaroque, Clara; Hao, Fuhua; Gershuni, Victoria; Chau, Lillian; Ni, Josephine; Bewtra, Meenakshi; Albenberg, Lindsey; Bretin, Alexis (2022-03-01). "Randomized Controlled-Feeding Study of Dietary Emulsifier Carboxymethylcellulose Reveals Detrimental Impacts on the Gut Microbiota and Metabolome". Gastroenterology. 162 (3): 743–756. doi:10.1053/j.gastro.2021.11.006. ISSN 0016-5085. PMC 9639366.

- ^ Chassaing, Benoit; Compher, Charlene; Bonhomme, Brittaney; Liu, Qing; Tian, Yuan; Walters, William; Nessel, Lisa; Delaroque, Clara; Hao, Fuhua; Gershuni, Victoria; Chau, Lillian; Ni, Josephine; Bewtra, Meenakshi; Albenberg, Lindsey; Bretin, Alexis; McKeever, Liam; Ley, Ruth E.; Patterson, Andrew D.; Wu, Gary D.; Gewirtz, Andrew T.; Lewis, James D. (11 November 2021). "Randomized Controlled-Feeding Study of Dietary Emulsifier Carboxymethylcellulose Reveals Detrimental Impacts on the Gut Microbiota and Metabolome". Gastroenterology. 162 (3): 743–756. doi:10.1053/j.gastro.2021.11.006. PMC 9639366. PMID 34774538.

- ^ Lieberman, Phil. "Anaphylaxis to carboxymethylcellulose". American Academy of Allergy, Asthma, and Immunology. Archived from the original on 2017-07-12. Retrieved 2017-07-12.