Recent from talks

Contribute something

Nothing was collected or created yet.

IDEF0

View on Wikipedia

IDEF0, a compound acronym ("Icam DEFinition for Function Modeling", where ICAM is an acronym for "Integrated Computer Aided Manufacturing"), is a function modeling methodology for describing manufacturing functions, which offers a functional modeling language for the analysis, development, reengineering and integration of information systems, business processes or software engineering analysis.[1]

IDEF0 is part of the IDEF family of modeling languages in the field of software engineering, and is built on the functional modeling language Structured Analysis and Design Technique (SADT).

Overview

[edit]The IDEF0 Functional Modeling method is designed to model the decisions, actions, and activities of an organization or system.[2] It was derived from the established graphic modeling language Structured Analysis and Design Technique (SADT) developed by Douglas T. Ross and SofTech, Inc. In its original form, IDEF0 includes both a definition of a graphical modeling language (syntax and semantics) and a description of a comprehensive methodology for developing models.[3] The US Air Force commissioned the SADT developers "to develop a function model method for analyzing and communicating the functional perspective of a system. IDEF0 should assist in organizing system analysis and promote effective communication between the analyst and the customer through simplified graphical devices".[2]

Where the Functional flow block diagram is used to show the functional flow of a product, IDEF0 is used to show data flow, system control, and the functional flow of lifecycle processes. IDEF0 is capable of graphically representing a wide variety of business, manufacturing and other types of enterprise operations to any level of detail. It provides rigorous and precise description, and promotes consistency of usage and interpretation. It is well-tested and proven through many years of use by government and private industry. It can be generated by a variety of computer graphics tools. Numerous commercial products specifically support development and analysis of IDEF0 diagrams and models.[1]

An associated technique, Integration Definition for Information Modeling (IDEF1x), is used to supplement IDEF0 for data-intensive systems. The IDEF0 standard, Federal Information Processing Standards Publication 183 (FIPS 183), and the IDEF1x standard (FIPS 184) are maintained by the National Institute of Standards and Technology (NIST).[1]

FIPS PUB 183 "Integration Definition for Function Modeling (IDEF0)," was withdrawn as a Federal Standard (in favor of OPEN Specifications and Standards) September 2, 2008, as cited in "The Federal Register", Volume 73, page 51276 (73FR/51276). [4]

History

[edit]During the 1970s, the U.S. Air Force Program for Integrated Computer Aided Manufacturing (ICAM) sought to increase manufacturing productivity through systematic application of computer technology. The ICAM program identified the need for better analysis and communication techniques for people involved in improving manufacturing productivity. As a result, in 1981 the ICAM program developed a series of techniques known as the IDEF (ICAM Definition) techniques which included the following:[3]

- IDEF0, used to produce a "function model". A function model is a structured representation of the functions, activities or processes within the modeled system or subject area.[5]

- IDEF1, used to produce an "information model". An information model represents the structure and semantics of information within the modeled system or subject area.[6]

- IDEF2, used to produce a "dynamics model". A dynamics model represents the time-varying behavioral characteristics of the modeled system or subject area.[7]

In 1983, the U.S. Air Force Integrated Information Support System program enhanced the IDEF1 information modeling technique to form IDEF1X (IDEF1 Extended), a semantic data modeling technique. By the 1990s, IDEF0 and IDEF1X techniques are widely used in the government, industrial and commercial sectors, supporting modeling efforts for a wide range of enterprises and application domains. In 1991 the National Institute of Standards and Technology (NIST) received support from the U.S. Department of Defense, Office of Corporate Information Management (DoD/CIM), to develop one or more Federal Information Processing Standard (FIPS) for modeling techniques. The techniques selected were IDEF0 for function modeling and IDEF1X for information modeling. These FIPS documents are based on the IDEF manuals published by the U.S. Air Force in the early 1980s.[3] Sometime later, IEEE created the IDEF0 standard, and ISO adopted and published it as IEEE/ISO/IEC 31320-1.

IDEF0 topics

[edit]

The IDEF0 approach

[edit]IDEF0 may be used to model a wide variety of automated and non-automated systems. For new systems, it may be used first to define the requirements and specify the functions, and then to design an implementation that meets the requirements and performs the functions. For existing systems, IDEF0 can be used to analyze the functions the system performs and to record the mechanisms (means) by which these are done. The result of applying IDEF0 to a system is a model that consists of a hierarchical series of diagrams, text, and glossary cross-referenced to each other. The two primary modeling components are functions (represented on a diagram by boxes) and the data and objects that inter-relate those functions (represented by arrows).[3]

IDEF0 Building blocks

[edit]

The IDEF0 model displayed here on the left is based on a simple syntax. Each activity is described by a verb-based label placed in a box. Inputs are shown as arrows entering the left side of the activity box while output are shown as exiting arrows on the right side of the box. Controls are displayed as arrows entering the top of the box and mechanisms are displayed as arrows entering from the bottom of the box. Inputs, Controls, Outputs, and Mechanisms (ICOM) are all referred to as concepts.[2]

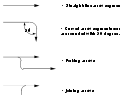

- Arrow : A directed line, composed of one or more arrow segments, that models an open channel or conduit conveying data or objects from source (no arrowhead) to use (with arrowhead). There are 4 arrow classes: Input Arrow, Output Arrow, Control Arrow, and Mechanism Arrow (includes Call Arrow). See Arrow Segment, Boundary Arrow, Internal Arrow.

- Box : A rectangle, containing a name and number, used to represent a function.

-

Box Syntax

-

Arrow Syntax

-

Arrow Positions and Roles

-

Label and Name Semantics

- Context : The immediate environment in which a function (or set of functions on a diagram) operates.

- Decomposition : The partitioning of a modeled function into its component functions.

-

Example Top-level Diagram

-

Decomposition Structure

-

Detail Reference Expression Use

-

Arrow Fork and Join Structures

- Fork : The junction at which an IDEF0 arrow segment (going from source to use) divides into two or more arrow segments. May denote unbundling of meaning.

-

Connections Between Boxes

-

Boundary and Internal Arrows

-

Typical Node Tree

-

Negative Node-Numbered Context

- Function : An activity, process, or transformation (modeled by an IDEF0 box) identified by a verb or verb phrase that describes what must be accomplished.

- Join : The junction at which an IDEF0 arrow segment (going from source to use) merges with one or more other arrow segments to form a single arrow segment. May denote bundling of arrow segment meanings

- Node : A box from which child boxes originate; a parent box. See Node Index, Node Tree, Node Number, Node Reference, Diagram Node Number.

Graphical notation

[edit]IDEF0 is a model that consists of a hierarchical series of diagrams, text, and glossary cross referenced to each other. The two primary modeling components are:

- functions (represented on a diagram by boxes), and

- data and objects that interrelate those functions (represented by arrows).

As shown by Figure 3 the position at which the arrow attaches to a box conveys the specific role of the interface. The controls enter the top of the box. The inputs, the data or objects acted upon by the operation, enter the box from the left. The outputs of the operation leave the right-hand side of the box. Mechanism arrows that provide supporting means for performing the function join (point up to) the bottom of the box.[1]

The IDEF0 process

[edit]The IDEF0 process starts with the identification of the prime function to be decomposed. This function is identified on a “Top Level Context Diagram,” that defines the scope of the particular IDEF0 analysis. An example of a Top Level Context Diagram for an information system management process is shown in Figure 3. From this diagram lower-level diagrams are generated. An example of a derived diagram, called a “child” in IDEF0 terminology, for a life cycle function is shown in Figure 4.[1]

Federal Information Processing Standards

[edit]In Dec 1993 the National Institute of Standards and Technology announcing the standard for Integration Definition for Function Modeling (IDEF0) in the category Software Standard, Modeling Techniques. This publication announces the adoption of the IDEF0 as a Federal Information Processing Standard (FIPS). This standard was based on the Air Force Wright Aeronautical Laboratories Integrated Computer-Aided Manufacturing (ICAM) Architecture from June 1981.[3]

On September 2, 2008, the associated NIST standard, FIPS 183, has been withdrawn (decision on Federal Register vol. 73 / page 51276.[4]

See also

[edit]References

[edit]Systems Engineering Fundamentals. Defense Acquisition University Press, 2001.

![]() This article incorporates public domain material from the National Institute of Standards and Technology

This article incorporates public domain material from the National Institute of Standards and Technology

- ^ a b c d e Systems Engineering Fundamentals. Defense Acquisition University Press, 2001.

- ^ a b c Varun Grover, William J. Kettinger (2000). Process Think: Winning Perspectives for Business Change in the Information Age. p.168.

- ^ a b c d e FIPS Publication 183 Archived 2009-02-27 at the Wayback Machine released of IDEFØ December 1993 by the Computer Systems Laboratory of the National Institute of Standards and Technology (NIST).

- ^ a b Withdrawn FIPS Listed by Number, Updated 12/15/16)

- ^ ICAM Architecture Part II-Volume IV - Function Modeling Manual (IDEF0), AFWAL-TR-81-4023, Materials Laboratory, Air Force Wright Aeronautical Laboratories, Air Force Systems Command, Wright-Patterson Air Force Base, Ohio 45433, June 1981.

- ^ ICAM Architecture Part II, Volume V - Information Modeling Manual (IDEF1), AFWAL-TR-81-4023, Materials Laboratory, Air Force Wright Aeronautical Laboratories, Air Force Systems Command, Wright-Patterson Air Force Base, Ohio 45433, June 1981.

- ^ ICAM Architecture Part II, Volume VI - Dynamics Modeling Manual (IDEF2), AFWAL-TR-81-4023, Materials Laboratory, Air Force Wright Aeronautical Laboratories, Air Force Systems Command, Wright-Patterson Air Force Base, Ohio 45433, June 1981.

External links

[edit]- FIPS Publication 183 released of IDEFØ December 1993 by the Computer Systems Laboratory of the National Institute of Standards and Technology (NIST). (Withdrawn by NIST 08 Sep 02 see Withdrawn FIPS by Numerical Order Index)

- Federal Register vol. 73 / page 51276 withdrawal decision

- Overview of IDEF0 at www.idef.com

IDEF0

View on GrokipediaIntroduction

Definition and Purpose

IDEF0, or Integration Definition for Function Modeling, is a graphical modeling language designed to represent the functions of a system or enterprise in a structured manner. It provides a method for describing decisions, actions, and activities within an organization or system through hierarchical diagrams that emphasize functional relationships and interfaces.[1] The primary purpose of IDEF0 is to facilitate the analysis, integration, and communication of functional aspects in complex environments, such as business processes or engineering systems. By modeling "what" a system does rather than "how" it operates, IDEF0 supports requirements definition, system design, and operational planning, ensuring a consistent and comprehensive view of functional dependencies. This black-box approach focuses on inputs, outputs, controls, and mechanisms without delving into internal implementation details.[1] A key concept in IDEF0 is hierarchical decomposition, where high-level functions are progressively broken down into more detailed sub-functions, typically limited to 3-6 per diagram level, to manage complexity and reveal interdependencies. This methodology promotes a conceptual understanding of system behavior.[1] IDEF0 distinguishes itself from other methods in the IDEF family by concentrating exclusively on function modeling; for instance, unlike IDEF1X, which addresses data modeling and relational structures, IDEF0 prioritizes the transformation of inputs into outputs through functional processes.[1]Applications and Benefits

IDEF0 has been widely applied in systems engineering to model and analyze complex systems, including functional decomposition for requirements definition and integration across hardware, software, and human elements.[1] In business process reengineering, it supports the identification and redesign of organizational workflows by providing a structured view of activities and interactions.[1] Manufacturing analysis benefits from IDEF0 through its use in mapping production processes, such as in the design and optimization of assembly lines.[4] For software requirements gathering, IDEF0 facilitates the specification of functional needs by representing system behaviors and data flows early in development.[1] In defense systems integration, it aids in modeling life-cycle processes for weapon systems and logistics, ensuring traceability from concept to deployment.[4] Key benefits of IDEF0 include facilitating clear communication among diverse stakeholders by offering a visual, hierarchical representation of functions and interfaces that is accessible to both technical and non-technical audiences.[1] It supports requirements traceability by linking high-level objectives to detailed activities, enabling verification of system compliance throughout the design process.[4] The methodology aids in identifying inefficiencies, such as bottlenecks or redundant processes, through systematic decomposition that highlights resource dependencies and constraints.[5] Additionally, IDEF0 promotes system integration by explicitly revealing interfaces between components, which reduces errors in multi-disciplinary projects.[1] Practical examples demonstrate IDEF0's versatility; in U.S. Air Force programs, it was employed for aircraft manufacturing to model assembly and quality control functions, improving operational efficiency.[1] Modern extensions appear in enterprise architecture frameworks, where it underpins process improvement initiatives for supply chain management and service-oriented systems.[6] As of 2024, IDEF0 continues to be utilized in frameworks such as the DoD Architecture Framework (DoDAF) for modeling operational activities.[7] While IDEF0 excels in static functional analysis, it may oversimplify highly dynamic systems due to its hierarchical structure, which limits flexibility in modeling real-time interactions or process reuse without additional adaptations.[8] Its strengths lie in providing rigorous, precise models for well-defined environments, making it particularly valuable for initial planning and validation phases.[4]Historical Development

Origins in the ICAM Program

IDEF0 emerged in the late 1970s as a key output of the Integrated Computer-Aided Manufacturing (ICAM) program, a U.S. Air Force initiative aimed at revolutionizing aerospace manufacturing through advanced computational methods.[9] The program originated from conceptual master planning in 1973, driven by the need to address escalating costs and inefficiencies in military aircraft production at facilities like Wright-Patterson Air Force Base.[10] By systematically applying computer technology, ICAM sought to create a unified architecture for manufacturing subsystems, fostering interoperability across the defense industry.[1] Central to IDEF0's creation were contributions from Douglas T. Ross, a pioneer in structured analysis, and his firm SoftTech, Inc., which held the primary development contract (F33615-78-C-5158) from the Air Force.[9] Ross and his team adapted the Structured Analysis and Design Technique (SADT), originally developed in the early 1970s, to suit ICAM's focus on functional modeling for complex systems.[1] This adaptation emphasized graphical representations to support decision-making in manufacturing environments, building on SADT's box-and-arrow notation while incorporating ICAM-specific constraints for precision and scalability.[9] The core objectives of IDEF0 within ICAM were to streamline manufacturing processes, lower operational costs by optimizing resource allocation, and enable seamless integration of computer-aided design and manufacturing tools in aerospace applications.[9] These goals addressed the fragmented nature of existing systems, promoting a common language for engineers and managers to analyze and improve production workflows.[1] ICAM's foundational studies, spanning 1973 to 1978, laid the groundwork through architecture definition and pilot implementations, culminating in the IDEF0 prototype release in 1979 as a practical tool for function modeling.[9] This prototype marked the transition from theoretical frameworks to deployable methodologies, setting the stage for broader adoption in defense manufacturing.[1]Standardization and Evolution

The IDEF0 methodology was formally released as a standard in June 1981 by the United States Air Force through the Integrated Computer-Aided Manufacturing (ICAM) program's Function Modeling Manual, providing a structured graphical language for representing system functions and interfaces.[9] This initial publication established IDEF0 as a key tool for manufacturing and systems analysis within the Air Force, building on earlier structured analysis techniques. In 1993, the National Institute of Standards and Technology (NIST) adopted IDEF0 as Federal Information Processing Standard (FIPS) 183, effective June 30, 1994, making it a mandatory reference for federal agencies in modeling functions, decisions, actions, and activities of organizations or systems.[1] During the 1990s, IDEF0 evolved through integration with complementary methods in the IDEF family, such as IDEF1 for information modeling, which allowed for more comprehensive enterprise representations by linking functional models to data structures.[1] Minor revisions during this period, culminating in the FIPS 183 specification, extended its applicability beyond manufacturing to broader systems engineering and business process analysis, incorporating enhancements like refined syntax for hierarchical decomposition.[1] These updates were supported by the Department of Defense and NIST to align IDEF0 with emerging information technology standards, ensuring interoperability with tools like IDEF1X for relational data modeling.[1] FIPS 183 was rescinded on September 2, 2008, by the Secretary of Commerce, as the standard had become obsolete due to its references to outdated technologies and lack of updates to incorporate current voluntary industry standards or NIST guidelines.[3] Despite the withdrawal, IDEF0 continues to be used in legacy systems and niche applications within government and industry, particularly for functional decomposition in defense and engineering contexts where established models remain relevant. As of 2025, it is still applied in academic research and specific domains like asset management frameworks.[1][11] Post-withdrawal, NIST maintains the IDEF0 documentation as a non-mandatory legacy publication for reference.Core Components

Functions and Activities

In IDEF0, functions serve as the primary modeling elements, represented as labeled boxes that depict the core activities, processes, or transformations within a system. Each function encapsulates a specific task that contributes to the overall purpose of the modeled system, focusing on what must be accomplished rather than how it is performed. For instance, a function might be labeled "Produce Report" to indicate the transformation of input data into an output document. This representation allows modelers to abstract the system's operations into discrete, purposeful units, enabling a structured analysis of functional requirements.[1] Functions in IDEF0 are categorized into three main types based on their level of detail and decomposition within the model hierarchy. Basic functions refer to the general activities shown as boxes on any diagram, illustrating the fundamental transformations that occur. Elementary functions represent the lowest level of detail, consisting of undecomposable activities that cannot be broken down further; these are typically arranged in groups of three to six on a single child diagram to maintain clarity and completeness. Parent functions, in contrast, are higher-level activities that are decomposed into multiple sub-functions on subsequent child diagrams, forming the backbone of the hierarchical structure. This typology ensures that the model progresses from high-level overviews to granular specifics without redundancy.[1] Semantically, each IDEF0 function is defined by a concise label in the form of an active verb or verb phrase paired with a noun, such as "Assemble Components" or "Verify Data," which precisely conveys the action and its object. This naming convention emphasizes the function's purpose— the intended outcome or reason for its existence within the system—while also considering activation conditions, where the function may behave differently based on varying combinations of inputs and constraints, leading to distinct outputs. By prioritizing purpose, these semantics guide the model's development, ensuring that functions align with the system's objectives and support decision-making in areas like systems engineering and process improvement.[1] The role of functions in IDEF0 modeling is to capture the "what" of the system—its essential operations and transformations—facilitating a comprehensive blueprint for analysis, design, and communication among stakeholders. Through hierarchical decomposition, functions enable the progressive refinement of complex systems into manageable components, revealing interdependencies and supporting requirements validation without delving into implementation details. Arrows may connect to these functions to indicate flows, but the emphasis remains on the functions themselves as the drivers of system behavior. This approach has been foundational in functional modeling since its formalization, promoting clarity in enterprise and software system representations.[1]Interfaces and Arrows

In IDEF0, interfaces represent the interactions between functions, depicted as arrows that connect the borders of function boxes to illustrate the flow of data, objects, and resources. These arrows serve as the primary means to model how functions transform inputs under specific constraints to produce outputs, ensuring a clear depiction of system dynamics without implying temporal sequence.[1] Arrows are classified into four types based on their attachment to the function box and their semantic role, collectively known as the ICOM (Input-Control-Output-Mechanism) standard. The following table summarizes these classifications:| Type | Attachment Side | Description |

|---|---|---|

| Input | Left | Data or objects entering the function to be transformed or processed.[1] |

| Control | Top | Constraints, conditions, or guidance that govern the function's behavior, such as rules or parameters, without being altered by the function.[1] |

| Output | Right | Results or data produced by the function, which may serve as inputs, controls, or mechanisms for other functions.[1] |

| Mechanism | Bottom | Resources or enablers, such as personnel, tools, or equipment, that facilitate the function's execution.[1] |