Recent from talks

Nothing was collected or created yet.

Tweel

View on Wikipedia

This article needs additional citations for verification. (May 2008) |

This article contains promotional content. (June 2025) |

The Tweel (a portmanteau of tire and wheel) is an airless tire design developed by the French tire company Michelin. Its significant advantage over pneumatic tires is that the Tweel does not use a bladder full of compressed air, and therefore cannot burst, leak pressure, or become flat. Instead, the Tweel's hub is connected to the rim via flexible polyurethane spokes which fulfil the shock-absorbing role provided by the compressed air in a traditional tire.

Design

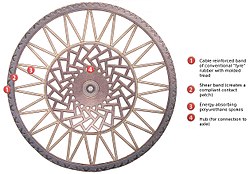

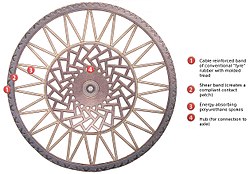

[edit]The Tweel consists of a band of conventional tire rubber with molded tread, a shear beam just below the tread that creates a compliant contact patch, a series of energy-absorbing polyurethane spokes, and an integral inner hub structure. Both the shear beam and the polyurethane spokes can be designed to provide a calibrated directional stiffness in order to control both how the Tweel handles and how it handles loads. The inner hub structure may be either rigid or compliant,[1] depending on the application requirements, and as such may contain a matrix of deformable plastic structures that flex under load and subsequently return to their original shape. By varying the thickness and size of the spokes the design elements can be manipulated to engineer a wide range of ride and handling qualities. The tread can be as specialized as any conventional tires and is replaceable.[2]

Benefits and drawbacks

[edit]Potential benefits of the Tweel include not only the obvious safety and convenience of never having flat tires, but also, in automotive applications, the Tweel airless tire has the potential to be able to brake better – a significant performance compromise that is inherent to pneumatic tires. Unlike a pneumatic tire, a Tweel can be designed to have high lateral stiffness while simultaneously having low vertical stiffness. This can be achieved because, in the design elements of a Tweel, the vertical and lateral stiffness are not inseparably linked and can thus be optimized independently. Because there is no air bladder under the tread, tread patterns can, if desired, even incorporate water evacuation through holes in the design thus eliminating or significantly reducing hydroplaning. Michelin expects the tread to last two to three times as long as a conventional tire.[3] Because the tread rubber around the outer circumference is replaceable when worn (as opposed to disposing of a whole worn tire), the potential environmental impact of a Tweel airless tire can be less than that of a conventional pneumatic tire.

Tweel is useful for: "vehicles that don't have suspensions like lawn mowers – those low speed specialty vehicles that don't have suspensions. The comfort is quite good and better than inflated tyres" said Terry K. Gettys, executive vice-president, research and development, and member of the group executive committee at French tire company Michelin.[4]

Military testing has indicated that the Tweel deflects mine blasts away from the vehicle better than standard tires and that the Tweel remains mobile even with several spokes damaged or missing.[citation needed]

Although it is acknowledged that the initial prototype automotive Tweel tires did demonstrate flaws with regard to noise and high-speed vibration[5] and produced 5 percent more friction compared to a radial tire,[3] these early issues were resolved in subsequent prototypes and, in 2013, automotive Tweel prototype products had been shown to be well-behaved and reliable. As a demonstration of Tweel viability and reliability, three highway-driven vehicles (a 2012 Honda CR-Z, a resto-modded 1955 Morris Minor Traveller, and an Aluma brand trailer hauling a Polaris ATV which was also equipped with Tweel tires) successfully participated in the entire 2013 Hot Rod Power Tour long-distance road trip event in June 2013.[6]

Applications

[edit]

The iBOT mobility device and Segway's Concept Centaur were both introduced with Tweel airless tires. Michelin also has additional projects for the Tweel concept on small construction equipment, such as skid-steer loaders, for which it seems well suited.

NASA has contracted Michelin to develop a wheel for the next-generation lunar rover based on the Tweel concept.[7] This has resulted in the Lunar Rover Initiative AB Scarab wheels.[8]

In October 2012, Michelin North America Inc. began commercial sales of the Michelin 12N16.5 X Tweel for skid-steer loaders used in landscaping, construction, contracting, refuse/recycling and agricultural industries.[9]

Awards

[edit]On 8 November 2005, Popular Science magazine named Michelin's Tweel as the "Best of What's New"[10] honor in the Automotive Technology category. The next day, Michelin NA was awarded a Hall of Fame Award by InnoVision[11] for continued leadership in innovation as evidenced by the development of the Tweel. TIME Magazine named the Tweel as "One of the Most Amazing Inventions of 2005"[12] a few short days later on 14 November 2005. The Intermat innovation commission in Paris (the International Exhibition of Equipment, Machinery and Techniques for the Construction and Building Materials Industry) awarded the Tweel with a 2006 Gold Medal for Innovation.[13] This prize reinforced Michelin's technological leadership and rewarded Michelin’s contribution to improvements in productivity and safety for the construction industry. The jury of Intermat 2006 was made up of recognized European experts and professionals and required to rank the innovations according to five criteria:

- Technical design and technologies: improvement in productivity, ease of maintenance;

- Economy: lower purchase price and maintenance costs;

- Quality of work carried out;

- Ease of use, ergonomics, comfort, safety and improvement in working conditions;

- Environmental friendliness.

A Silver Award in the Transportation category was awarded to the Tweel SSL on 26 April 2013 by the 2013 Edison Awards.[14] Of the 7,156 applications received, 131 finalists were selected by the Edison Awards Committee. The Tweel SSL was one of 42 winners, who represented 12 categories and symbolize the persistence and excellence personified by Thomas Alva Edison. The Tweel SSL was selected as one of the 2013 Contractors’ Top 50 New Products[15] by readers of Equipment Today as one of the industry’s most innovative products for the year. In January 2014, Equipment World named one of the “five game-changing” construction products of 2013 for their 2014 Innovations Awards. The Tweel SSL was named as one of those five product winners.[16] The inventors of the Tweel, Timothy B. Rhyne and Steven M. Cron jointly received the Charles Goodyear Medal in recognition of the singular impact of the Tweel.[17]

Uptis

[edit]Michelin partnered with GM in 2020 to offer the Unique Puncture-proof Tire System (Uptis) that may be available for the 2024 model vehicles. [18] The tire made its first public appearance at the Internationale Automobil-Ausstellung (IAA) mobility show in Germany on an electric Mini Cooper.[19]

GM began testing the tires on a fleet of 2019 Chevrolet Bolt electric cars with the possibility for the Uptis to be an option on some GM vehicles in 2024.[20]

The Uptis uses an aluminum wheel assembly and rubber reinforced with glass composite and vinyl ester resin, an improvement over designs such as the Tweel.[21]

See also

[edit]References

[edit]- ^ "How the 12N16.5 MICHELIN® X® Tweel® SSL Works". Michelin. Retrieved 9 February 2014.

- ^ Grabianowski, Ed (10 May 2007). "How the Tweel Airless Tire Works". HowStuffWorks. Retrieved 9 February 2014.

- ^ a b Mayersohn, Norman (3 January 2005). "Reinventing the Wheel (and the Tire, Too)". The New York Times. Retrieved 15 January 2012.

- ^ "In future, tyres will be connected to vehicle information system: Terry Gettys". Businesstoday.in. 2 November 2015. Retrieved 9 November 2015.

- ^ Jaime Holguin (27 January 2005). "Airless Tires? Consider The Tweel". CBS News. Retrieved 16 September 2021.

- ^ "Foothills British Car Club of South Carolina Newsletter" (PDF). Fbccsc.org. July 2014. Archived from the original (PDF) on 18 May 2016. Retrieved 18 January 2017.

- ^ Mircea, Serafim (16 February 2009). "Nasa's Rover Vehicle equipped with Michelin tires". Inautonews. Retrieved 10 February 2014.

- ^ Wettergreen, David. "Scarab's Wheels". Lunar Rover Initiative. Carnegie Mellon University. Retrieved 10 February 2014.

- ^ "Michelin 'Tweel' for skid-steers launched". Tire Business. 29 October 2012. Retrieved 10 February 2014.

- ^ "Michelin Tweel − The tire that never needs air". Popular Science. 8 November 2005. Archived from the original on 9 March 2013.

- ^ "2005 Innovision Technology Award Winners Named" (PDF). ISS Corp. 9 November 2005. Archived from the original (PDF) on 14 May 2006.

- ^ "Tweel wins awards: But Michelin's non-pneumatic tire/wheel a couple years from market availability". Tire Business. 6 May 2006. Retrieved 18 January 2017.

- ^ Warner, John (29 April 2006). "Michelin TWEEL - Gold Medal for Innovation, Intermat 2006". Swamp Fox. Archived from the original on 24 December 2013.

- ^ "2013 Edison Awards Winners". Edisonawards.com. 2 December 2016. Retrieved 18 January 2017.

- ^ "Construction-Trade-Magazine". ForConstructionPros.com. Archived from the original on 18 January 2017. Retrieved 18 January 2017.

- ^ "2014 Innovations Winner: Michelin Tweel airless tire | Equipment World | Construction Equipment, News and Information | Heavy Construction Equipment". Equipment World. 6 January 2014. Retrieved 18 January 2017.

- ^ "Tweel inventors named co-recipients of Charles Goodyear Medal". Tire Business. Crain. 6 October 2021. Retrieved 5 July 2022.

- ^ Turpen, Aaron (5 June 2019). "Michelin and GM unveil airless tires for a puncture-free ride". New Atlas. Retrieved 22 May 2022.

- ^ McEacnern, Joel (11 October 2021). "Michelin Uptis Airless Tire Successfully Demoed At IAA Mobility In Munich: Video". GM Authority. Retrieved 22 May 2022.

- ^ Stocksdale, Sam (19 June 2019). "Michelin and GM test airless tires on Chevy Bolt EV". autoblog. US. Retrieved 22 May 2022.

- ^ McEacnern, Sam (4 June 2019). "GM Partners With Michelin To Introduce Airless Tires By 2024". GM Authority. Retrieved 22 May 2022.

External links

[edit]- Michelin Tweel press releases

- Radical new wheel technology

- Rubber Spokes Give Bounce to Airless Safety Tires (May, 1938) Archived 8 November 2011 at the Wayback Machine

- Amerityre Zero Pressure Spare Tyre