Recent from talks

Nothing was collected or created yet.

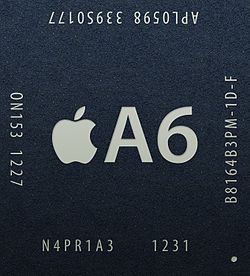

Apple A6

View on Wikipedia The A6 processor | |

| General information | |

|---|---|

| Launched | September 21, 2012 |

| Discontinued | September 9, 2015 (February 17, 2016 India)[1] |

| Designed by | Apple Inc. |

| Common manufacturer | |

| Product code | S5L8950X |

| Performance | |

| Max. CPU clock rate | 1.3 GHz[3] |

| Physical specifications | |

| Cores |

|

| GPU | PowerVR SGX543MP3 (triple-core)[5] |

| Cache | |

| L1 cache | 32 KB instruction + 32 KB data[4] |

| L2 cache | 1 MB[4] |

| Architecture and classification | |

| Application | Mobile |

| Technology node | 32 nm[6] |

| Microarchitecture | Swift[4] |

| Instruction set | ARMv7-A: ARM, Thumb-2 with "armv7s" extensions (integer division, VFPv4, Advanced SIMDv2)[7] |

| Products, models, variants | |

| Variant | |

| History | |

| Predecessors | Apple A5 (iPhone) Apple A5X (iPad) |

| Successor | Apple A7 |

The Apple A6 is a 32-bit package on package (PoP) system on a chip (SoC) designed by Apple Inc., part of the Apple silicon series. It was introduced on September 12, 2012, at the launch of the iPhone 5. Apple states that it is up to twice as fast and has up to twice the graphics power compared with its predecessor, the Apple A5.[8] Software updates for devices using this chip ceased in 2019, with the release of iOS 10.3.4 on the iPhone 5 as it was discontinued with the release of iOS 11 in 2017.

Design

[edit]The Apple A6 is said to use a 1.3 GHz[3] custom[9] Apple-designed ARMv7-A architecture based dual-core CPU, called Swift,[4] rather than a licensed CPU from ARM like in previous designs, and an integrated 266 MHz triple-core PowerVR SGX543MP3[5] graphics processing unit (GPU). The Swift core in the A6 uses a new tweaked instruction set featuring some elements of the ARM Cortex-A15 such as support for the Advanced SIMD v2, and VFPv4.[9] Analysis suggests that the Swift core has a triple-wide frontend and two FPUs, compared with a two-wide core with a single FPU in the Cortex-A9 based predecessor.[4]

The A6 processor package also incorporates 1 GB of LPDDR2-1066 RAM compared with 512MB of LPDDR2-800 RAM in the Apple A5 providing double the memory capacity while increasing the theoretical memory bandwidth from 6.4 GB/s to 8.5 GB/s.[10] The A6 includes an upgraded image signal processor (ISP), that compared with the ISP in the A5, improves the speed of image capture, low-light performance, noise reduction, and video stabilization.[11]

The A6 is manufactured by Samsung on a high-κ metal gate (HKMG) 32 nm process and the chip is 96.71 mm2 large,[6][2] which is 22% smaller than the A5.[12] The A6 also consumes less energy than its predecessor.[12]

A version of the A6 with higher frequency and four graphic cores is called Apple A6X and is found only in the fourth generation iPad.

Products that include the Apple A6

[edit]Gallery

[edit]See also

[edit]- Apple silicon, the range of ARM-based processors designed by Apple

- Apple A6X

References

[edit]- ^ Satpathy, Sambit (February 17, 2016). "Apple iPhone 4s, iPhone 5c finally discontinued in India: Report". BGR.in. Archived from the original on December 11, 2020. Retrieved December 7, 2020.

- ^ a b Apple A6 Teardown, ifixit.com, 2012-09-25, archived from the original on 2015-12-23, retrieved 2012-09-25

- ^ a b Apple's A6 CPU actually clocked at around 1.3 GHz, per new Geekbench report, Engadget, 2012-09-26, archived from the original on 2013-08-31, retrieved 2012-09-26

- ^ a b c d e f Lal Shimpi, Anand; Klug, Brian; Gowri, Vivek (2012-10-16). "The iPhone 5 Review - Decoding Swift". AnandTech. Archived from the original on 2012-12-08. Retrieved 2012-10-17.

- ^ a b Apple A6 Die Revealed: 3-core GPU, <100mm^2, Anandtech.com, 2012-09-21, archived from the original on 2012-09-22, retrieved 2012-09-22

- ^ a b "Apple iPhone 5 – the A6 Application Processor". Chipworks. September 21, 2012. Archived from the original on September 22, 2013. Retrieved September 15, 2013.

- ^ "A few things iOS developers ought to know about the ARM architecture – Wandering Coder". Archived from the original on 2020-07-04. Retrieved 2020-07-03.

- ^ "Apple Introduces iPhone 5" (Press release). Apple. 2012-09-12. Retrieved 2023-12-10.

- ^ a b Anand Lal Shimpi (2012-09-15), iPhone 5's A6 SoC: Not A15 or A9, a Custom Apple Core Instead, AnandTech, archived from the original on 2012-12-21, retrieved 2012-09-18

- ^ Shimpi, Anand Lal; Klug, Brian (September 15, 2012). "iPhone 5 Memory Size and Speed Revealed: 1 GB LPDDR2-1066". AnandTech. Archived from the original on December 17, 2012. Retrieved September 16, 2012.

- ^ Hollister, Sean (September 12, 2012). "The Apple A6: a smaller processor for the iPhone 5 with twice the performance". The Verge. Archived from the original on September 21, 2013. Retrieved September 13, 2013.

- ^ a b Apple: A6 chip in iPhone 5 has 2x CPU power, 2x graphics performance, yet consumes less energy, Engadget, 2012-09-12, archived from the original on 2013-09-14, retrieved 2012-09-18