Recent from talks

Nothing was collected or created yet.

Beef clod

View on WikipediaThis article needs additional or more specific categories. (February 2025) |

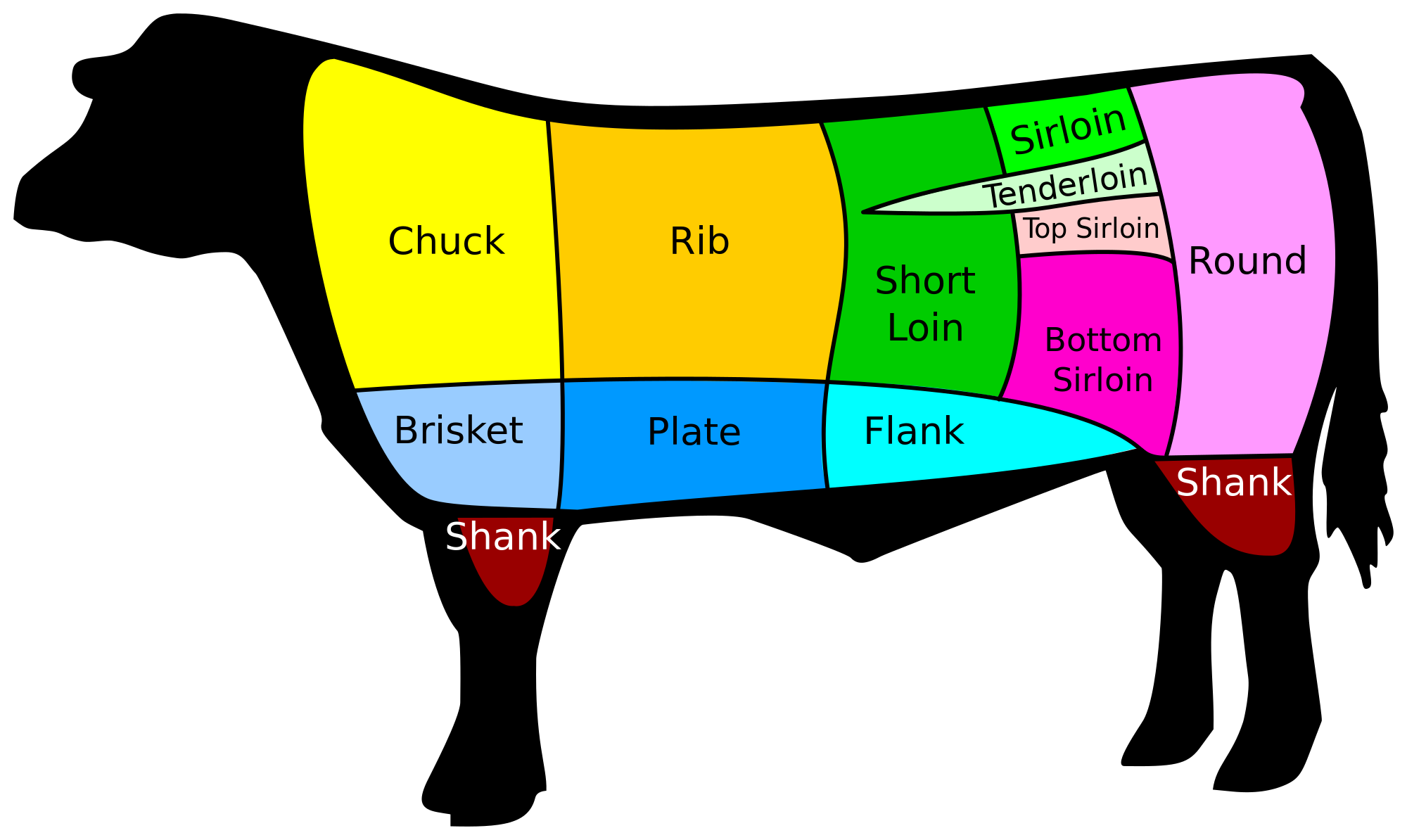

Beef cuts |

The beef clod or shoulder clod is one of the least expensive cuts of beef and is taken from the shoulder (chuck) region of the animal. Beef clod is a large muscle system, with some fat that covers the muscles.[1] The clod's composition is mainly three muscles: the shoulder tender, the top blade and the clod heart and is one of two chuck subprimal cuts. It is often divided into its three separate muscle cuts for retail sale.[2]

Beef clod, along with beef brisket, is historically the foundation of Central Texas-style barbecue, as epitomized by Kreuz Market in Lockhart, Texas, where the clod has been prepared since 1900 by long, slow smoking.[3] Beef clod may also be prepared with moist heat or braising.[4][5]

Shoulder tender

[edit]A shoulder tender[6][7] also called beef shoulder petite tender,[8] beef shoulder tender petite roast,[9] bistro filet, rat or teres major steak[6][7] is a US cut of beef of the teres major muscle from the blade of the shoulder (chuck). It is one of the tenderest beef muscles and is said to be "white-tablecloth quality",[6][10] being a similar quality to filet mignon, but cheaper.[11] It is rarely used, as it requires skill to extract.[6][failed verification] It is known as petite tender medallion, petite tender[9] or tender medallions if sliced into medallions (after being roasted or grilled whole).[8][10] It is shaped like a pork tenderloin,[10] and weighs 8 to 10 ounces (230 to 280 g).[8]

The flat iron steak lies above it, and is distinct from this steak, as it is formed from different muscles: teres minor and infraspinatus.

See also

[edit]References

[edit]- ^ Culinary Institute of America & Thomas Schneller (2009). Kitchen Pro Series: Guide to Meat Identification, Fabrication and Utilization. Cengage Learning. pp. 66–68. ISBN 9781428319943. Retrieved 16 May 2018.

- ^ Adam Danforth (2014). Butchering Beef: The Comprehensive Photographic Guide to Humane Slaughtering and Butchering. Storey Publishing. pp. 165–183. ISBN 9781612121833. Retrieved 16 May 2018.

- ^ Steven Raichlen (2003). BBQ USA: 425 Fiery Recipes from All Across America. Workman Publishing. pp. 164 - 166. ISBN 9780761120155. Retrieved 16 May 2018.

beef clod.

- ^ John Perkins (1796). Every Woman Her Own House-keeper; Or, The Ladies' Library: Containing the Cheapest and Most Extensive System of Cookery Ever Offered to the Public. James Ridgway. pp. 66 - 67. Retrieved 16 May 2018.

beef clod.

- ^ Bruce Aidells & Denis Kelly (2001). The Complete Meat Cookbook: A Juicy and Authoritative Guide to Selecting, Seasoning, and Cooking Today's Beef, Pork, Lamb, and Veal. Houghton Mifflin Harcourt. pp. 190–192. ISBN 9780547347608. Retrieved 16 May 2018.

- ^ a b c d "U.S. Wellness Meats — Our Animals Eat Right So You Can Too". US Wellness Meats. Archived from the original on 2010-07-20. Retrieved 2010-06-05.

- ^ a b "Deli Brands of America - Product View". Deli Brands of America. 2007. Archived from the original on 2011-07-09. Retrieved 2010-06-05.

- ^ a b c "BCC - Beef Shoulder Petite Tender". Beef Culinary Center. Cattlemen's Beef Board and National Cattlemen's Beef Association. Retrieved 2010-06-05.

- ^ a b "BIG - Petite Tender". Beef Innovations Group. Cattlemen's Beef Board and National Cattlemen's Beef Association. Archived from the original on 2008-06-05. Retrieved 2010-06-05.

- ^ a b c Beriau, Mickey (2001-09-01). "What's Your Beef?". Food Product Design. Virgo Publishing LLC. Retrieved 2010-06-05.

- ^ Friedland, Ann (2004-01-01). "Beef Stakes". Food Management. Penton Media Inc. Archived from the original on 2010-02-21. Retrieved 2010-06-05.

External links

[edit]- [1] Contains information, recipes, cooking instructions and nutritional information