Recent from talks

Nothing was collected or created yet.

Diphenyl ether

View on Wikipedia | |

| |

| |

| Names | |

|---|---|

| Preferred IUPAC name

1,1′-Oxydibenzene[1] | |

| Systematic IUPAC name

Phenoxybenzene | |

| Other names | |

| Identifiers | |

3D model (JSmol)

|

|

| 1364620 | |

| ChEBI | |

| ChEMBL | |

| ChemSpider | |

| ECHA InfoCard | 100.002.711 |

| EC Number |

|

| 165477 | |

PubChem CID

|

|

| RTECS number |

|

| UNII | |

| UN number | 3077 |

CompTox Dashboard (EPA)

|

|

| |

| |

| Properties | |

| C12H10O | |

| Molar mass | 170.211 g·mol−1 |

| Appearance | Colorless solid or liquid |

| Odor | geranium-like |

| Density | 1.08 g/cm3 (20 °C)[2] |

| Melting point | 25 to 26 °C (77 to 79 °F; 298 to 299 K) |

| Boiling point | 258.55 °C (497.39 °F; 531.70 K)[3] at 100 kPa (1 bar), 121 °C at 1.34 kPa (10.05 mm Hg) |

| Insoluble | |

| Vapor pressure | 0.02 mmHg (25 °C)[2] |

| −108.1·10−6 cm3/mol | |

| Hazards | |

| GHS labelling: | |

| |

| Danger | |

| H317, H319, H360Fd, H400, H411 | |

| P264, P273, P280, P305+P351+P338, P337+P313, P391, P501 | |

| NFPA 704 (fire diamond) | |

| Flash point | 115 °C (239 °F; 388 K) |

| Explosive limits | 0.7%–6.0%[2] |

| Lethal dose or concentration (LD, LC): | |

LD50 (median dose)

|

3370 mg/kg (rat, oral) 4000 mg/kg (rat, oral) 4000 mg/kg (guinea pig, oral)[4] |

| NIOSH (US health exposure limits): | |

PEL (Permissible)

|

TWA 1 ppm (7 mg/m3)[2] |

REL (Recommended)

|

TWA 1 ppm (7 mg/m3)[2] |

IDLH (Immediate danger)

|

100 ppm[2] |

| Safety data sheet (SDS) | Aldrich MSDS |

Except where otherwise noted, data are given for materials in their standard state (at 25 °C [77 °F], 100 kPa).

| |

Diphenyl ether is the organic compound with the formula (C6H5)2O. It is a colorless, low-melting solid. This compound, the simplest diaryl ether, has a variety of niche applications.[5]

Synthesis and reactions

[edit]Diphenyl ether was discovered by Heinrich Limpricht and Karl List in 1855, when they reproduced Carl Ettling's destructive distillation of copper benzoate and separated it from the low-melting oily distillate components ignored by previous researchers. They named the compound phenyl oxide (German: Phenyloxyd) and studied some of its derivatives.[6]

Now it is synthesized by a modification of the Williamson ether synthesis, here the reaction of phenol and bromobenzene in the presence of base and a catalytic amount of copper:

- PhOH + PhBr → PhOPh + HBr

Involving similar reactions, diphenyl ether is a significant side product in the high-pressure hydrolysis of chlorobenzene in the production of phenol.[7]

Related compounds are prepared by Ullmann reactions.[8]

The compound undergoes reactions typical of other phenyl rings, including hydroxylation, nitration, halogenation, sulfonation, and Friedel–Crafts alkylation or acylation.[5]

Uses

[edit]The main application of diphenyl ether is as a eutectic mixture with biphenyl, used as a heat transfer fluid. Such a mixture is well-suited for heat transfer applications because of the relatively large temperature range of its liquid state. A eutectic mixture (commercially, Dowtherm A) is 73.5% diphenyl ether and 26.5% biphenyl.[9][10]

Diphenyl ether is a starting material in the production of phenoxathiin via the Ferrario reaction.[11] Phenoxathiin is used in polyamide and polyimide production.[12]

Because of its odor reminiscent of scented geranium, as well as its stability and low price, diphenyl ether is used widely in soap perfumes. Diphenyl ether is also used as a processing aid in the production of polyesters.[5]

Related compounds

[edit]It is a component of important hormone T3 or triiodothyronine.

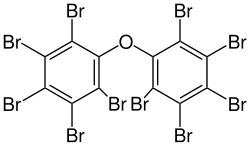

Several polybrominated diphenyl ethers (PBDEs) are useful flame retardants. Of penta-, octa-, and decaBDE, the three most common PBDEs, only decaBDE is still in widespread use since its ban in the European Union in 2003.[13] DecaBDE, also known as decabromodiphenyl oxide,[14] is a high-volume industrial chemical with over 450,000 kilograms produced annually in the United States. Decabromodiphenyl oxide is sold under the trade name Saytex 102 as a flame retardant in the manufacture of paints and reinforced plastics.

References

[edit]- ^ a b c "CHAPTER P-6. Applications to Specific Classes of Compounds". Nomenclature of Organic Chemistry : IUPAC Recommendations and Preferred Names 2013 (Blue Book). Cambridge: The Royal Society of Chemistry. 2014. p. 705. doi:10.1039/9781849733069-00648. ISBN 978-0-85404-182-4.

- ^ a b c d e f NIOSH Pocket Guide to Chemical Hazards. "#0496". National Institute for Occupational Safety and Health (NIOSH).

- ^ Byers, Charles H.; Williams, David F. (July 1987). "Viscosities of pure polyaromatic hydrocarbons". Journal of Chemical & Engineering Data. 32 (3): 344–348. doi:10.1021/je00049a018. ISSN 0021-9568.

- ^ "Phenyl ether". Immediately Dangerous to Life or Health Concentrations (IDLH). National Institute for Occupational Safety and Health (NIOSH).

- ^ a b c Fiege, H.; Voges, H.-M.; Hamamoto, T; Umemura, S.; Iwata, T.; Miki, H.; Fujita, Y.; Buysch, H.-J.; Garbe, D.; Paulus, W. (2000). "Phenol Derivatives". Ullmann's Encyclopedia of Industrial Chemistry. Weinheim: Wiley-VCH. doi:10.1002/14356007.a19_313. ISBN 978-3-527-30673-2.

- ^ K. List; H. Limpricht (1854). "Ueber das sogenannte Benzoëoxyd und einige andere gepaarte Verbindungen". Annalen der Chemie und Pharmacie. 90 (2): 190–210. doi:10.1002/JLAC.18540900212. ISSN 0075-4617. Wikidata Q56658706.

- ^ Fahlbusch, K.-G.; Hammerschmidt, F.-J.; Panten, J.; Pickenhagen, W.; Schatkowski, D.; Bauer, K.; Garbe, D.; Surburg, H. (2003). "Flavor and Fragrances". Ullmann's Encyclopedia of Industrial Chemistry. Weinheim: Wiley-VCH. doi:10.1002/14356007.a11_141. ISBN 978-3-527-30673-2.

- ^ Ungnade, H. E.; Orwoll, E. F. (1946). "2-Methoxy Diphenyl Ether". Org. Synth. 26: 50. doi:10.15227/orgsyn.026.0050.

- ^ Patent Appeal No. 7555 United States Court of Customs and Patent Appeals 7 April 1966 http://openjurist.org/358/f2d/750/application-of-edward-s-blake-and-william-c-hammann

- ^ "Dowtherm® A 44570".

- ^ Suter, C. M.; Maxwell, C. E. (1943). "Phenoxthin". Organic Syntheses; Collected Volumes, vol. 2, p. 485.

- ^ Mitsuru Ueoda; Tatsuo Aizawa; Yoshio Imai (1977). "Preparation and properties of polyamides and polyimides containing phenoxathiin units". Journal of Polymer Science: Polymer Chemistry Edition. 15 (11): 2739–2747. Bibcode:1977JPoSA..15.2739U. doi:10.1002/pol.1977.170151119.

- ^ DIRECTIVE 2003/11/EC of the European Parliament and of the Council

- ^ Sutker, B. J. (2005). "Flame Retardants". Ullmann's Encyclopedia of Industrial Chemistry. Weinheim: Wiley-VCH. doi:10.1002/14356007.a11_123. ISBN 978-3-527-30673-2.

Diphenyl ether

View on GrokipediaHistory

Discovery and early synthesis

Diphenyl ether was first obtained in 1843 by C. Ettling and Stonehouse via the destructive distillation of copper(II) benzoate, though initial characterization was incomplete and focused primarily on the major product, phenyl benzoate.[4] In reproducing this reaction, Heinrich Limpricht reported in 1854 the isolation of a secondary distillate product, which he identified as diphenyl ether (C12H10O) after purification and analysis, confirming its structure through elemental composition and boiling point determination at approximately 259 °C.[5] This work by Limpricht, detailed in Annalen der Chemie (volume 90, p. 190), marked the compound's formal discovery, as prior efforts had not distinguished it clearly from related benzoates or impurities.[5] Early synthetic routes emphasized thermal decompositions, with diphenyl ether emerging as a byproduct in phenol processing attempts, such as incomplete etherifications or distillations involving benzoic acid derivatives.[5] For instance, heating sodium phenoxide with halobenzenes under forcing conditions occasionally yielded traces, but yields were low due to competing side reactions like hydrolysis or coupling without oxygen linkage.[6] A more reliable laboratory method for diphenyl ether synthesis was established in 1904–1905 through Fritz Ullmann's copper-catalyzed coupling of chlorobenzene and sodium phenoxide, heated to 200–250 °C in the presence of copper powder or salts, achieving moderate yields (20–40%) via nucleophilic aromatic substitution facilitated by the metal.[7] This Ullmann diaryl ether synthesis provided the first controlled route, contrasting haphazard distillations, and relied on the phenoxide's attack on the activated aryl halide, with copper promoting halide displacement without requiring electron-withdrawing groups on the ring.[7]Commercial and industrial development

Diphenyl ether first gained commercial significance in the early 20th century as a key component in specialized heat transfer fluids. In 1929, Dow Chemical Company introduced Dowtherm A, a eutectic mixture containing approximately 73.5% diphenyl ether and 26.5% biphenyl, engineered for high-temperature operations up to 400°C where traditional media like steam or hot water proved inadequate.[8] This formulation exploited the compound's low melting point of 12–27°C and thermal stability, enabling its adoption in industrial processes requiring efficient, non-corrosive heating systems.[9] Industrial production initially arose as a byproduct during the high-pressure alkaline hydrolysis of chlorobenzene to phenol, a process commercialized by Dow around 1916 to meet growing demand for phenolic resins and explosives precursors. The Ullmann condensation—reacting phenol with chlorobenzene under copper catalysis—provided an alternative route, scaling with phenol availability amid wartime expansions in organic synthesis during the 1910s and 1940s.[10] Following World War II, the petrochemical revolution, including widespread adoption of the cumene process for phenol production from 1944 onward, lowered feedstock costs and facilitated direct dehydration of phenol to diphenyl ether on a larger scale.[11] This shift supported expanded output, transitioning diphenyl ether from niche byproduct to a more readily available commodity for emerging thermal and chemical applications.[12]Properties

Physical and thermodynamic properties

Diphenyl ether (C12H10O) is a colorless crystalline solid or low-melting liquid with a characteristic mild odor, existing as crystals below its melting point and as a clear, pale yellowish liquid upon melting.[13][14] Its molar mass is 170.21 g/mol.[15] Key physical constants include a melting point of 26–27 °C, a boiling point of 259 °C at 1 atm, a liquid density of 1.073 g/mL at 25 °C, and low water solubility of approximately 0.02 g/L at 25 °C.[16][14] The compound exhibits a dipole moment of 1.17 D, arising from the asymmetric ether oxygen bridging two phenyl groups.[17]| Property | Value | Conditions |

|---|---|---|

| Vapor pressure | 2.7 Pa | 25 °C |

| Relative vapor density | 5.9 | vs. air |

| Heat of fusion | 17,216 J/mol | At melting point |