Recent from talks

All channels

Be the first to start a discussion here.

Be the first to start a discussion here.

Be the first to start a discussion here.

Be the first to start a discussion here.

Welcome to the community hub built to collect knowledge and have discussions related to Spectralon.

Nothing was collected or created yet.

Spectralon

View on Wikipediafrom Wikipedia

Not found

Spectralon

View on Grokipediafrom Grokipedia

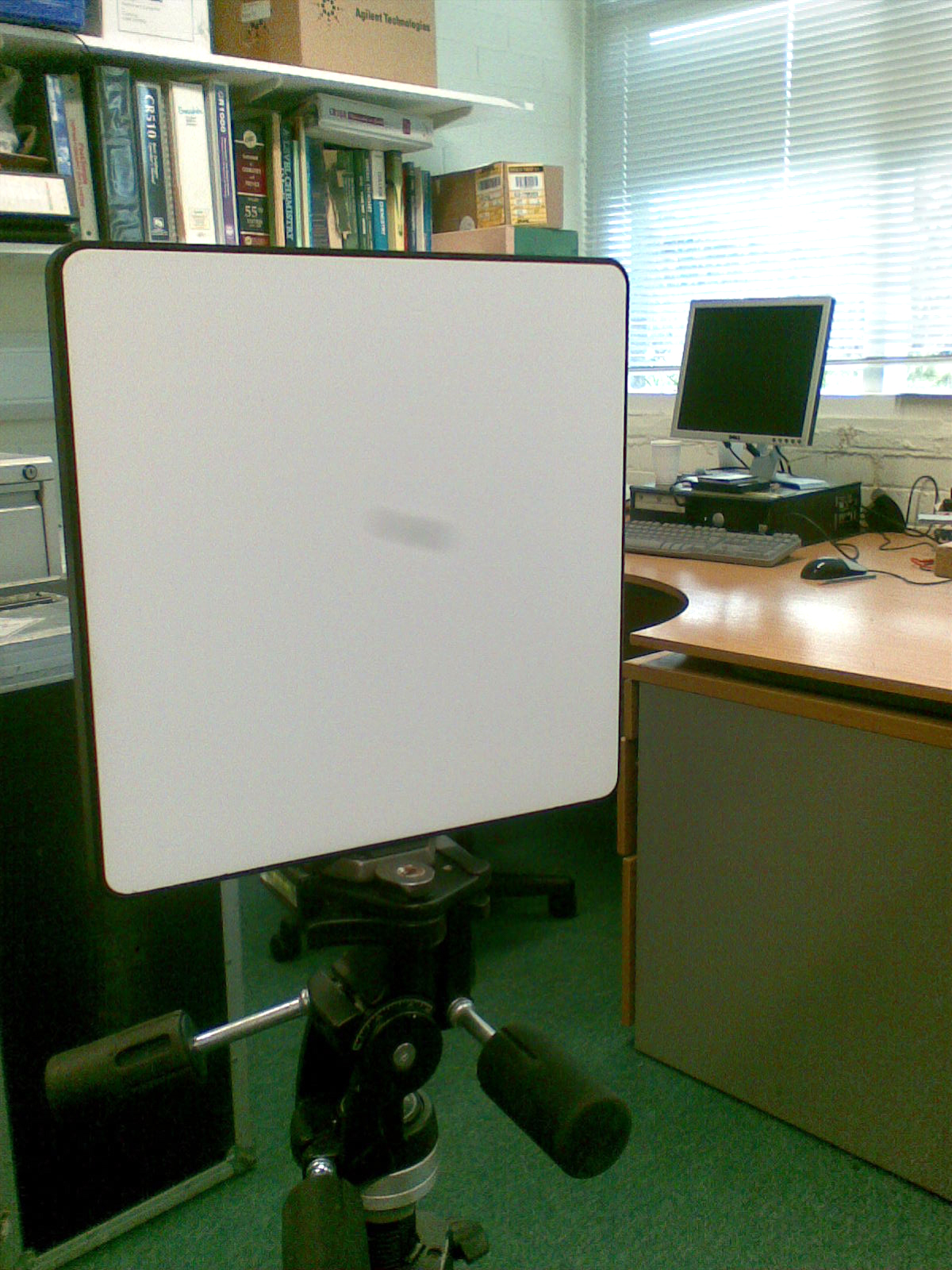

Spectralon is a sintered polytetrafluoroethylene (PTFE) fluoropolymer material renowned for its exceptionally high diffuse reflectance, exceeding 99% from 400 nm to 1500 nm and greater than 95% from 250 nm to 2500 nm across the ultraviolet (UV), visible, and near-infrared (NIR) spectrum.[1] Developed and commercialized by Labsphere, Inc. in 1986, it exhibits near-perfect Lambertian diffusion, meaning it scatters light uniformly in all directions without specular reflection, making it an ideal reference standard for optical measurements. With a hardness comparable to high-density polyethylene and thermal stability up to over 400°C, Spectralon is chemically inert, hydrophobic, and environmentally durable, allowing it to withstand harsh conditions without degrading its reflectance properties.[1]

This material's superior performance surpasses traditional coatings like barium sulfate paints, offering a flat spectral response and NIST-traceable calibration for precise applications.[1][2] Key uses include integrating spheres, spectrophotometers, and densitometers for laboratory calibration, as well as on-orbit standards for Earth-observing satellites in remote sensing, where it serves as a vicarious calibration target with uncertainties as low as 2%.[2] Space-grade variants undergo specialized cleaning and inspection to ensure reliability in extraterrestrial environments, supporting missions in aerospace and planetary science.[3] Its machinability enables custom shapes for optical components, from targets to diffusers, while variants like color pastels provide controlled reflectance levels for specialized testing.[1]