Recent from talks

Nothing was collected or created yet.

Offset printing

View on Wikipedia

| Part of a series on the |

| History of printing |

|---|

|

Offset printing is a common printing technique in which the inked image is transferred (or "offset") from a plate to a rubber blanket and then to the printing surface. When used in combination with the lithographic process, which is based on the repulsion of oil and water, the offset technique employs a flat (planographic) image carrier. Ink rollers transfer ink to the image areas of the image carrier, while a water roller applies a water-based film to the non-image areas.

The modern "web" process feeds a large reel of paper through a large press machine in several parts, typically for several meters, which then prints continuously as the paper is fed through.

Development of the offset press came in two versions: in 1875 by Robert Barclay of England for printing on tin and in 1904 by Ira Washington Rubel of the United States for printing on paper.[1] Rubel's contemporary in Continental Europe was Kašpar Hermann, the author of the offset machine prototype (1904), holder of a patent for an offset disc machine (two rubber transfer rollers facing each other) – rolling-press. In 1907, he successfully started printing in Germany on his Triumph sheetfed offset press.[2]

History

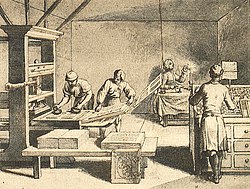

[edit]Lithography was initially created to be an inexpensive method of reproducing artwork.[3][4] This printing process was limited to use on flat, porous surfaces because the printing plates were produced from limestone.[3] In fact the word "lithograph", which comes from Greek (λιθογραφία), means "an image from stone" or "written in stone".

The first rotary offset lithographic printing press was created in England and patented in 1875 by Robert Barclay.[3] This development combined mid-19th century transfer printing technologies and Richard March Hoe's 1843 rotary printing press—a press that used a metal cylinder instead of a flat stone.[3] The offset cylinder was covered with specially treated cardboard that transferred the printed image from the stone to the surface of the metal. Later, the cardboard covering of the offset cylinder was changed to rubber,[3] which is still the most commonly used material.

As the 19th century closed and photography became popular, many lithographic firms went out of business.[3] Photoengraving, a process that used halftone technology instead of illustration, became the primary aesthetic of the era. Many printers, including Ira Washington Rubel of New Jersey, were using the low-cost lithograph process to produce copies of photographs and books.[5] Rubel discovered in 1901—by forgetting to load a sheet—that printing from the rubber roller, instead of the metal, made the printed page clearer and sharper.[5] After further refinement, the Potter Press printing Company in New York produced a press in 1903.[5] By 1907 the Rubel offset press was in use in San Francisco.[6]

The Harris Automatic Press Company also created a similar press around the same time. Charles and Albert Harris modeled their press "on a rotary letter press machine".[7]

Newspaper publisher Staley T. McBrayer invented the Vanguard web offset press for newspaper printing, which he unveiled in 1954 in Fort Worth, Texas.[8]

Modern offset printing

[edit]One of the important functions in the printing process is prepress production. This stage makes sure that all files are correctly processed in preparation for printing. This includes converting to the proper CMYK color model, finalizing the files, and creating plates for each color of the job to be run on the press.[9]

Offset lithography is one of the most common ways of creating printed materials. A few of its common applications include: newspapers, magazines, brochures, stationery, and books. Compared to other printing methods, offset printing is best suited for economically producing large volumes of high quality prints in a manner that requires little maintenance.[10] Many modern offset presses use computer-to-plate systems as opposed to the older computer-to-film work flows, which further increases their quality.

There are two types of offset printing: wet offset and waterless offset. Wet offset lithography uses a mix of wetting fluids (dampening solutions) to manage ink adhesion and to protect non-image areas. Waterless offset lithography employs a different method where a plate's non-image areas are protected via a layer of ink-repellent silicone. Waterless offset lithography is newer, invented in the 1960s by 3M. It was later sold and commercialized by Toray.[11]

Advantages of offset printing compared to other printing methods include:

- Consistent high image quality. Offset printing produces sharp and clean images and type more easily than, for example, letterpress printing; this is because the rubber blanket conforms to the texture of the printing surface;

- Quick and easy production of printing plates;

- Longer printing plate life than on direct litho presses because there is no direct contact between the plate and the printing surface. Properly developed plates used with optimized inks and fountain solution may achieve run lengths of more than a million impressions;

- Cost. Offset printing is the cheapest method for producing high quality prints in commercial printing quantities;

- Ability to adjust the amount of ink on the fountain roller with screw keys. Most commonly, a metal blade controls the amount of ink transferred from the ink duct to the fountain roller. By adjusting the screws, the operator alters the gap between the blade and the fountain roller, increasing or decreasing the amount of ink applied to the roller in certain areas. This consequently modifies the density of the color in the respective area of the image. On older machines one adjusts the screws manually, but on modern machines the screw keys are operated electronically by the printer controlling the machine, enabling a much more precise result.[12]

Disadvantages of offset printing compared to other printing methods include:

- Slightly inferior image quality compared to rotogravure or photogravure printing;

- Propensity for anodized aluminum printing plates to become sensitive (due to chemical oxidation) and print in non-image–background areas when developed plates are not cared for properly;

- Time and cost associated with producing plates and printing press setup. As a result, very small quantity printing jobs may now use digital offset machines.

Every printing technology has its own identifying marks, and offset printing is no exception. In text reproduction, the type edges are sharp and have clear outlines. The paper surrounding the ink dots is usually unprinted. The halftone dots can be hexagonal though there are different screening methods.[13]

Process variations

[edit]Several variations of the printing process exist:

- Blanket-to-blanket

- A printing method in which both sides of a sheet of paper are printed simultaneously, with two blanket cylinders per colour; a sheet of paper is passed between them, with each cylinder printing on one side of it.[15]

Blanket-to-blanket presses are also called perfecting or duplex presses because they print on both sides of the sheet at the same time.[16] There is no impression cylinder because the opposite blanket cylinders act as impression cylinders to each other during print production. This method is most used on offset presses designed for envelope printing. There are also two plate cylinders per colour on the press. Web and sheet-fed offset presses are similar in that many of them can also print on both sides of the paper in one pass, making it easier and faster to print duplex.

- Blanket-to-steel

- A printing method similar to a sheet offset press; except that the plate and cylinder pressures are quite precise. Actual squeeze between plate and blanket cylinder is optimal at 0.005″; as is the squeeze or pressure between the blanket cylinder and the substrate.[17] Blanket-to-steel presses are considered one-color presses. In order to print the reverse side, the web is turned over between printing units by means of turning bars.[17] The method can be used to print business forms, computer letters and direct mail advertising.

- Variable-size printing

- A printing process that uses removable printing units, inserts, or cassettes for one-sided and blanket-to-blanket two-sided printing.[17]

- Keyless offset

- A printing process that is based on the concept of using fresh ink for each revolution by removing residual inks on the inking drum after each revolution.[17] It is suitable for printing newspapers.

- Dry offset printing

- A printing process which uses a metal backed photopolymer relief plate, similar to a letterpress plate, but, unlike letterpress printing where the ink is transferred directly from the plate to the substrate, in dry offset printing the ink is transferred to a rubber blanket before being transferred to the substrate. This method is used for printing on injection moulded rigid plastic buckets, tubs, cups and flowerpots.

Plates

[edit]

Materials

[edit]The plates used in offset printing are thin, flexible, and usually larger than the paper size to be printed. Two main materials are used:

- Metal plates, usually aluminum, although sometimes they are made of multi-metal, paper, or plastic.[18]

- Polyester plates, which are much cheaper and can be used in place of aluminum plates for smaller formats or medium quality jobs, as their dimensional stability is lower.[18]

Computer to plate

[edit]Computer-to-plate (CTP) is a newer technology which replaced computer-to-film (CTF) technology, and that allows the imaging of metal or polyester plates without the use of film. By eliminating the stripping, compositing, and traditional plate making processes, CTP altered the printing industry, which led to reduced prepress times, lower costs of labor, and improved print quality.

Most CTP systems use thermal CTP or violet technologies. Both technologies have the same characteristics in terms of quality and plate durability (for longer runs). However, the violet CTP systems are often cheaper than thermal ones, and thermal CTP systems do not need to be operated under yellow light.

Thermal CTP involves the use of thermal lasers to expose or remove areas of coating while the plate is being imaged. This depends on whether the plate is negative, or positive working. These lasers are generally at a wavelength of 830 nm, but vary in their energy usage depending on whether they are used to expose or ablate material. Violet CTP lasers have a much shorter wavelength, 405 nm–410 nm. Violet CTP is "based on emulsion tuned to visible light exposure".[19]

Another process is the computer-to-conventional plate (CTCP) system in which conventional offset plates can be exposed, making it an economical option.

Sheet-fed offset

[edit]

Sheet-fed refers to individual sheets of paper or rolls being fed into a press via a suction bar that lifts and drops each sheet onto place. A lithographic ("litho" for short) press uses principles of lithography to apply ink to a printing plate, as explained previously. Sheet-fed litho is commonly used for printing of short-run magazines, brochures, letter headings, and general commercial (jobbing) printing. In sheet-fed offset, "the printing is carried out on single sheets of paper as they are fed to the press one at a time". Sheet-fed presses use mechanical registration to relate each sheet to one another to ensure that they are reproduced with the same imagery in the same position on every sheet running through the press.[20]

Offset duplicators

[edit]In the United States, an offset press with paper size up to 12 in × 18 in (300 mm × 460 mm), is classified as a duplicator instead of a press. Offset duplicators are used for fast, good quality reproduction of one-color and two-color copies in sizes up to 12 in × 18 in (300 mm × 460 mm).[17] Popular models were made by A. B. Dick Company, Multilith, and the Chief and Davidson lines made by A.T.F.-Davidson. Offset duplicators are made for fast and quick printing jobs; printing up to 12,000 impressions per hour. They are able to print business forms, letterheads, labels, bulletins, postcards, envelopes

Feeder system

[edit]The feeder system is responsible for making sure paper runs through the press correctly. This is where the substrate is loaded and then the system is correctly set up to the certain specifications of the substrate to the press.[21]

Printing–inking system

[edit]The Printing Unit consists of many different systems. The dampening system is used to apply dampening solution to the plates with water rollers. The inking system uses rollers to deliver ink to the plate and blanket cylinders to be transferred to the substrate. The plate cylinder is where the plates containing all of the imaging are mounted. Finally, the blanket and impression cylinders are used to transfer the image to the substrate running through the press.[22]

Delivery system

[edit]The delivery system is the final destination in the printing process while the paper runs through the press. Once the paper reaches delivery, it is stacked for the ink to cure in a proper manner. This is the step in which sheets are inspected to make sure they have proper ink density and registration.

Slur

[edit]Production or impact of double image in printing is known as slur.[23][verification needed]

Web-fed offset

[edit]Web-fed refers to the use of rolls (or "webs") of paper supplied to the printing press.[24] Offset web printing is generally used for runs in excess of five or ten thousand impressions. Typical examples of web printing include newspapers, newspaper inserts or ads, magazines, direct mail, catalogs, and books. Web-fed presses are divided into two general classes: cold-set (or non-heat-set) and heat-set offset web presses, the difference being how the inks dry. Cold web offset printing dries through absorption into the paper, while heat-set utilizes drying lamps or heaters to cure or "set" the inks. Heat-set presses can print on both coated (slick) and uncoated papers, while cold-set presses are restricted to uncoated paper stock, such as newsprint. Some cold-set web presses can be fitted with heat dryers, or ultraviolet lamps (for use with UV-curing inks), thus enabling a newspaper press to print color pages heat-set and black & white pages cold-set.

Web offset presses are beneficial in long run printing jobs, typically press runs that exceed 10,000 or 20,000 impressions. Speed is a determining factor when considering the completion time for press production; some web presses print at speeds of 3,000 feet (910 meters) per minute or faster. In addition to the benefits of speed and quick completion, some web presses have the inline ability to cut, perforate, and fold.

Heat-set web offset

[edit]This subset of web offset printing uses inks which dry by evaporation in a dryer typically positioned just after the printing units; it is typically done on coated papers, where the ink stays largely on the surface, and gives a glossy high contrast print image after the drying. As the paper leaves the dryer too hot for the folding and cutting that are typically downstream procedures, a set of "chill rolls" positioned after the dryer lowers the paper temperature and sets the ink. The speed at which the ink dries is a function of dryer temperature and length of time the paper is exposed to this temperature. This type of printing is typically used for magazines, catalogs, inserts, and other medium-to-high volume, medium-to-high quality production runs.

Cold-set web offset

[edit]This is also a subset of web offset printing, typically used for lower quality print output. It is typical of newspaper production. In this process, the ink dries by absorption into the underlying paper. A typical coldset configuration is often a series of vertically arranged print units and peripherals. As newspapers seek new markets, which often imply higher quality (more gloss, more contrast), they may add a heatset tower (with a dryer) or use UV (ultraviolet) based inks which "cure" on the surface by polymerization rather than by evaporation or absorption.

Sheet-fed vs. web-fed

[edit]Sheet-fed presses offer several advantages. Because individual sheets are fed through, a large number of sheet sizes and format sizes can be run through the same press. In addition, waste sheets can be used for make-ready (which is the testing process to ensure a quality print run). This allows for lower cost preparation so that good paper is not wasted while setting up the press, for plates and inks. Waste sheets do bring some disadvantages as often there are dust and offset powder particles that transfer on to the blankets and plate cylinders, creating imperfections on the printed sheet. This method produces the highest quality images.

Web-fed presses, on the other hand, are much faster than sheet-fed presses, with speeds up to 80,000 cut-offs per hour (a cut-off is the paper that has been cut off a reel or web on the press; the length of each sheet is equal to the cylinder's circumference). The speed of web-fed presses makes them ideal for large runs such as newspapers, magazines, and comic books. However, web-fed presses have a fixed cut-off, unlike rotogravure or flexographic presses, which are variable.

Inks

[edit]Offset printing uses inks that, compared to other printing methods, are highly viscous. Typical inks have a dynamic viscosity of 40–100 Pa·s.[25]

There are many types of paste inks available for utilization in offset lithographic printing and each have their own advantages and disadvantages. These include heat-set, cold-set, and energy-curable (or EC), such as ultraviolet- (or UV-) curable, and electron beam- (or EB-) curable. Heat-set inks are the most common variety and are "set" by applying heat and then rapid cooling to catalyze the curing process. They are used in magazines, catalogs, and inserts. Cold-set inks are set simply by absorption into non-coated stocks and are generally used for newspapers and books but are also found in insert printing and are the most economical option. Energy-curable inks are the highest-quality offset litho inks and are set by application of light energy. They require specialized equipment such as inter-station curing lamps, and are usually the most expensive type of offset litho ink.[citation needed]

- Letterset inks are mainly used with offset presses that do not have dampening systems and use imaging plates that have a raised image.[26]

- Waterless inks are heat-resistant and are used to keep silicone-based plates from showing toning in non-image areas. These inks are typically used on waterless Direct Imaging presses.[26]

- Single Fluid Inks are newer inks that use a process allowing lithographic plates on a lithographic press without using a dampening system during the process.[26]

In industry

[edit]Offset lithography became the most popular form of commercial printing from the 1950s ("offset printing"). Substantial investment in the larger presses required for offset lithography was needed, and had an effect on the shape of the printing industry, leading to fewer, larger, printers. The change made a greatly increased use of colour printing possible, as this had previously been much more expensive. Subsequent improvements in plates, inks, and paper have further refined the technology of its superior production speed and plate durability. In 2003 lithography was described as the primary printing technology used in the U.S.; most often as offset lithography, “responsible for over half of all printing using printing plates”.[27]

See also

[edit]References

[edit]- ^ "offset printing (printing technique)". Encyclopædia Britannica. Retrieved 2013-11-24.

- ^ Stejskalova, Helena (14 November 2016). "Ofsetová tisková technika: Přišla na svět díky zapomnětlivosti?". EpochaPlus. No. Podzim. Retrieved 30 December 2022.

- ^ a b c d e f Meggs, Philip B. (1998). A History of Graphic Design (Third ed.). John Wiley & Sons, Inc. pp. 146–150. ISBN 978-0-471-29198-5.

- ^ Carter, Rob, Ben Day, Philip Meggs. Typographic Design: Form and Communication, Third Edition. (2002) John Wiley & Sons, Inc. p 11

- ^ a b c Howard, Nicole (2005). The book: the life story of a technology. Greenwood Publishing Group. pp. 140–148. ISBN 0-313-33028-X.

- ^ "Rubel Offset Lithographic Press". HistoryWired: A few of our favorite things. Smithsonian Institution. Retrieved 30 Sep 2012.

- ^ "Short History of Offset Printing"

- ^ "Staley McBrayer, 92; Inventor of Offset Press for Newspaper Printing". Associated Press. April 18, 2002. Retrieved October 19, 2017 – via Los Angeles Times.

- ^ "What is Offset Printing? Differences Between Offset and Digital Printing". Refine Packaging. 2020-10-20. Retrieved 2022-07-09.

- ^ Kipphan, Helmut (2001). Handbook of print media: technologies and production methods (Illustrated ed.). Springer. p. 354. ISBN 3-540-67326-1.

- ^ "History of Waterless Printing". Classic Colours. Retrieved 5 January 2023.

- ^ "Printing Process Explained - Lithography". Dynodan.com. Retrieved 2012-11-15.

- ^ Johansson, Kaj; Lundberg, Peter; Ryberg, Robert (2007). A guide to graphic print production (second ed.). Wiley. p. 353. ISBN 978-0-471-76138-9.

- ^ Kipphan, Helmut (2001). Handbook of print media: technologies and production methods (Illustrated ed.). Springer. pp. 130–144. ISBN 3-540-67326-1.

- ^ Commercial Color Offset Printing – A Compendium of Commercial Printing Terminology

- ^ Michael Bruno, Frank Romano, Michael Riordan (2003). Pocket Pal - A Graphic Arts Production Handbook. INTERNATIONAL PAPER CO. p. 137.

{{cite book}}: CS1 maint: multiple names: authors list (link) - ^ a b c d e Romano & Riordan 139–141

- ^ a b Kipphan 209

- ^ Bruno, Romano and Riordan 126

- ^ "What is Offset Printing"[which?]

- ^ DeJidas & Destree, 2005, p. 55-57

- ^ DeJidas & Destree, 2005, p. 143

- ^ AMAN-2008

- ^ Spectrum Printers

- ^ Kipphan, Helmut (2001). Handbook of print media: technologies and production methods (Illustrated ed.). Springer. p. 137. ISBN 3-540-67326-1.

- ^ a b c Romano & Riordan 160

- ^ Bruno, Romano and Riordan 137

Further reading

[edit]- "Offset Printing". Encyclopædia Britannica. Retrieved March 22, 2004, from Encyclopædia Britannica Premium Service.

- Hird, Kenneth F. (2000). Offset Lithographic Technology. Tinley Park, Illinois: Goodheart - Willcox. ISBN 978-1-56637-621-1.

External links

[edit]Offset printing

View on GrokipediaHistory

Early development

The origins of offset printing trace back to 1875, when Robert Barclay in the United Kingdom patented the first rotary offset lithographic press designed primarily for printing on tin surfaces, adapting earlier transfer techniques to a rotary mechanism; however, this innovation remained limited in commercial viability, particularly for paper substrates.[5] A pivotal advancement occurred in 1904 through the accidental discovery of Ira Washington Rubel, an American lithographer and paper mill owner in Nutley, New Jersey. While running a lithographic press without inserting a sheet of paper between the inked stone plate and the impression cylinder, the dampened rubber blanket on the cylinder picked up the image; when paper was subsequently fed through, it received a clear, reversed impression from the blanket, demonstrating the potential of indirect transfer via a water-dampened rubber blanket to produce sharper results on paper than direct stone-to-paper contact.[7] Rubel refined this process into the first practical offset press for paper printing, partnering with Chicago lithographer Alex Sherwood to form the Sherbel Syndicate and manufacture commercial models starting in 1906.[8] Concurrent developments in Europe advanced the technology further. In 1906, German engineer Caspar Herrmann established the world's first dedicated offset press by modifying existing rotary lithographic machines to incorporate rubber blankets, enabling efficient sheet-fed production.[5] Initial applications emerged in specialized areas such as wallpaper printing, leveraging the process's ability to handle large, continuous sheets with consistent quality. Between 1905 and 1910, early experiments shifted from fragile lithographic stones to more durable metal plates, including zinc and aluminum, which improved press speed and plate longevity in offset setups.[9] By 1911, offset printing achieved significant commercial adoption in the United States, particularly for multicolor catalogs, as manufacturers like MAN Roland introduced reliable offset presses that supported high-volume, vibrant reproductions and spurred widespread use in the printing industry.[10]Evolution to modern techniques

In the 1920s, advancements in rotary offset presses marked a significant step toward continuous high-speed production suitable for large-scale commercial runs. Companies such as the Harris Automatic Press Company and Goss Printing Press Company played pivotal roles, with Harris developing early rotary models that integrated offset lithography into web-fed configurations, allowing for faster printing speeds of up to 5,000 sheets per hour on presses like the Klein-Roland 00 variant.[10][11] These innovations enabled offset to handle diverse substrates and reduced setup times compared to traditional letterpress, fostering greater adoption in book and periodical printing.[12] The 1940s saw economic factors drive offset's expansion into smaller-scale applications, particularly through affordable sheet-fed duplicators that lowered costs for short runs and facilitated office adoption. Devices like the Davidson offset duplicators, produced by the Davidson Printing Press Company, allowed businesses to produce up to 5,000 copies per hour from simple lithographic masters, making offset accessible beyond industrial printers for tasks such as forms and memos.[13] This democratization reduced reliance on expensive external printing services and contributed to offset's versatility in post-war economic recovery.[10] By the 1950s, advancements in automated inking systems and plate technologies further streamlined operations, minimizing manual labor and enhancing consistency. Early automatic offset machines, introduced around this decade, incorporated basic ink distribution mechanisms that improved efficiency over manual adjustments, while initial photopolymer experiments—such as Kodak's KPR plates—laid groundwork for more durable alternatives to metal plates, though full offset adoption occurred later.[14][15] These developments reduced production times and costs, positioning offset as a competitive alternative to letterpress.[16] The post-World War II era witnessed a boom in offset printing, surpassing letterpress by the 1960s due to its superior versatility in multicolor reproduction and adaptability to photographic images. Offset's ability to print sharp, clean colors without the embossing limitations of letterpress made it ideal for magazines and advertising, with production volumes exceeding letterpress by the mid-1960s.[11] A key milestone came in the 1970s with the widespread implementation of web-fed offset presses for newspapers, exemplified by the 1974 COLORMAN model—the largest in Europe at the time with 62 units for 17-page color sections—enabling high-volume daily output of up to 40,000 copies efficiently.[17][18] This shift revolutionized news printing, supporting peak readership in the US by 1973.[18] In the 1980s, the introduction of computer-to-plate (CTP) technology revolutionized prepress by allowing direct digital imaging onto plates, eliminating intermediate film steps and improving accuracy and speed. The 1990s saw further digital integration, with automated workflow systems and hybrid offset-digital presses emerging to handle variable data printing, paving the way for modern advancements.[1]Principles of Operation

Basic mechanism

Offset printing, also known as offset lithography, operates on the fundamental lithographic principle that oil-based inks and water do not mix, allowing for the selective application of ink to designated areas of a printing plate.[19][20] This repulsion ensures that non-image areas remain ink-free by attracting a water-based dampening solution, while image areas repel water and accept ink due to their oleophilic (oil-attracting) properties.[19] The process relies on a planographic plate where both image and non-image areas lie on the same flat plane, with no raised or recessed elements.[19] The printing plate features image areas that are hydrophobic (water-repelling) and oleophilic, enabling them to wet preferentially with ink owing to their lower surface energy compared to non-image areas.[20] In contrast, non-image areas are hydrophilic (water-attracting), coated with a solution like gum arabic that repels ink and maintains cleanliness during printing.[20][19] As the plate rotates, it first contacts rollers applying the dampening solution, which adheres only to the hydrophilic non-image regions, followed by inking rollers that deposit oil-based ink solely on the hydrophobic image areas.[19] The offset mechanism involves indirect image transfer: the inked image on the plate contacts an elastic rubber blanket cylinder, transferring the ink in an inverted form to the blanket's surface.[20][19] The blanket then presses against the substrate, such as paper, re-inverting the image and applying it evenly without direct contact between the plate and the substrate.[20] This intermediary step via the deformable rubber blanket minimizes plate wear and accommodates printing on rough or uneven surfaces by conforming to irregularities, ensuring uniform ink distribution.[19][20]Image transfer process

In offset printing, the image transfer process involves a series of precise interactions among the plate cylinder, blanket cylinder, and impression cylinder to ensure accurate reproduction from the printing plate to the substrate. First, the plate cylinder, wrapped with the lithographic plate, rotates and contacts dampening rollers that apply a thin film of water or fountain solution to the non-image areas, which are hydrophilic and repel ink. Subsequently, inking rollers apply oil-based ink selectively to the hydrophobic image areas of the plate. This inked plate then contacts the blanket cylinder, transferring the image in reverse orientation onto the compressible rubber blanket wrapped around it.[21][20] The blanket cylinder plays a pivotal role by receiving the reversed inked image from the plate, avoiding direct contact between the plate and the substrate to protect the plate's surface and enhance print quality. The impression cylinder then presses the substrate—such as paper—against the blanket, transferring the ink in an upright orientation to form the final image. This indirect method minimizes distortion and allows for even pressure distribution across irregular surfaces. The blanket itself is typically a multi-layered compressible rubber sheet, 1.5 to 2.0 mm thick, designed for elasticity and resilience to maintain consistent ink transfer while withstanding mechanical stress. These properties enable the blanket to conform to the substrate, ensuring high-quality impressions, with durable blankets capable of lasting up to 16 million cycles before replacement due to wear or damage.[22][23][24][25] For multi-color printing, the process occurs across inline printing units, each dedicated to one of the CMYK (cyan, magenta, yellow, black) colors, with the substrate passing sequentially through them. Precise registration is achieved through cylinder phasing and mechanical alignment to overlay colors accurately without misalignment. The blanket's elasticity contributes to efficient ink transfer, often approaching near-complete adhesion to the substrate, which minimizes distortion and supports the high fidelity required for color reproduction. This setup, building on the inking mechanics of selective ink application, allows for vibrant, layered images in high-volume production.[21][20][26]Printing Plates

Materials and types

Offset printing plates are primarily constructed from aluminum as the base material, valued for its lightweight nature, high durability, and recyclability, which facilitates efficient handling and environmental sustainability in printing operations.[27][28] The aluminum substrate is typically anodized to create a porous surface that enhances adhesion of the photosensitive coating and provides resistance to wear during press runs.[29] These plates generally range in thickness from 0.1 to 0.3 mm, allowing them to be flexible enough to wrap around printing cylinders while maintaining structural integrity for high-volume production.[30] Coatings applied to the aluminum base, such as diazo compounds or photopolymers, enable image retention by becoming ink-receptive in exposed areas and water-receptive elsewhere, supporting the lithographic principle of oil-and-water repulsion.[27] The primary types of offset printing plates include conventional, presensitized, and wipe-on varieties, each differing in coating application and suitability for various run lengths. Conventional plates feature an anodized aluminum base with a photosensitive coating that must be applied and processed in the printing facility, offering versatility for custom preparations but requiring more manual intervention.[27] Presensitized plates, also known as PS plates, arrive pre-coated by the manufacturer with diazo or photopolymer layers, allowing direct exposure to light sources and providing consistent sensitivity for runs exceeding 50,000 impressions, with potential for up to 1 million impressions when enhanced by heat fusing techniques.[27][31] Wipe-on plates involve manual application of an aqueous diazo coating in the plateroom onto a grained aluminum base, making them cost-effective for shorter runs of up to 100,000 impressions, though they are less durable than presensitized options due to potential inconsistencies in coating uniformity.[27] Compared to earlier stone plates used before the 1900s, which were heavy and cumbersome, modern aluminum-based plates offer superior flatness for precise cylinder mounting and easier storage without degradation, revolutionizing scalability in offset printing.[27] For demanding applications like long-run packaging on abrasive substrates, bimetal plates provide exceptional wear resistance; these consist of a base layer such as aluminum or stainless steel electroplated with copper for the image area, capable of enduring over 1 million impressions while minimizing issues like scumming or blinding.[32][27]Preparation methods

In conventional offset plate preparation, a photosensitive coating on the plate is exposed to ultraviolet (UV) light through a film negative using a vacuum frame to ensure close contact between the film and plate. The light passes through the clear areas of the negative, hardening the coating in the image areas while leaving non-image areas soluble.[33] Exposure typically lasts approximately 1 minute with UV sources like metal-halide lamps operating at 350-450 nm wavelengths, achieving optimal results when the solid step 6 appears on a 21-step sensitivity guide.[27] Following exposure, the plate undergoes chemical development where unexposed areas are removed using alkaline or solvent-based developers, revealing the hydrophilic non-image regions. The plate is then rinsed with water and treated with a gum arabic solution to protect the non-image areas from oxidation and ink acceptance.[33] This traditional workflow, reliant on film intermediates, has been the standard for producing durable plates capable of high-volume runs.[27] Computer-to-plate (CTP) technology represents a shift to digital preparation by directly imaging plates from computer files using lasers, bypassing film and improving accuracy and speed. Thermal CTP employs infrared lasers for ablation, removing non-image coating through heat in daylight-safe conditions, suitable for plates achieving resolutions over 300 LPI and run lengths up to 400,000 impressions.[34] Violet laser CTP, using 405 nm wavelengths, exposes photopolymer plates for faster throughput and lower costs, though it requires safelights and typically yields run lengths around 100,000 impressions.[35] Post-imaging processing enhances plate longevity through baking and gumming steps. The exposed plate is coated with a baking gum and heated in an oven at 240-255°C for 1.5 to 3 minutes, promoting polymerization in image areas for greater abrasion resistance and run lengths exceeding 1 million impressions when post-baked.[36] After baking, the gum is removed, and a finishing gum is applied to safeguard non-image areas, ensuring stable hydrophilicity during storage and press mounting.[36] Advancements in the 2010s introduced processless plates, which eliminate chemical development entirely by relying on UV or thermal exposure to create press-ready images directly. These plates, such as Kodak's SONORA series, polymerize upon imaging and require only a simple clean-out or no further treatment, reducing workflow steps and environmental impact from chemical waste. Processless plates have achieved widespread adoption by the 2020s, comprising a growing share of the market as of 2024.[37][38] By the mid-2010s, processless technology had become viable for commercial offset, offering high contrast and stability even under ambient light exposure, and as of 2024, the digital offset printing plate market, including processless variants, is valued at over USD 2 billion globally, supporting sustainability goals.[35][39]Inks and Inking

Ink compositions

Offset printing inks are complex formulations designed to meet the lithographic process's demands, where ink must transfer efficiently from rollers to plates and substrates while resisting unwanted mixing with the aqueous fountain solution. The primary components include pigments, which provide color and opacity, typically comprising 20-40% of the ink by weight to ensure vibrant hues and coverage; vehicles, such as oils and resins that act as carriers for the pigments and control flow; solvents that facilitate drying; and additives like driers to accelerate oxidation and anti-skinning agents to prevent surface drying during storage.[40][41] Inks for offset printing are categorized by their drying mechanisms and application suitability. Heat-set inks, used predominantly in web-fed presses, incorporate volatile solvents that evaporate rapidly under high heat, enabling quick drying on high-speed production lines. Sheet-fed inks rely on oxidation and penetration for drying, oxidizing through air exposure to form a durable film suitable for slower, individual sheet processing. UV-curable inks, an energy-curable variant, contain monomers and oligomers that polymerize instantly under ultraviolet light, offering immediate set-off resistance ideal for high-quality, non-porous substrates. Low-migration inks, essential for food packaging applications, are specially formulated with low-diffusivity components and rigorously tested to limit the migration of substances into contact materials, complying with regulations such as EU Regulation (EC) No 10/2011 and FDA guidelines; these are often UV-curable or conventional offset inks ensuring overall migration below 10 mg/dm² as of 2025.[42][43][44] Key properties of offset inks are optimized for roller transfer and plate interaction, with viscosity ranging from 10,000 to 50,000 centipoise (cps) to maintain stability on inking systems while allowing controlled flow without excessive spreading. Formulations are designed to minimize emulsification with the acidic fountain solution (pH 4-5), preventing ink-water instability that could lead to poor transfer or scumming.[45][46] Since the 1980s, vegetable oil-based inks, primarily using soy or linseed oils in the vehicle component, have gained widespread adoption in offset printing to reduce volatile organic compound (VOC) emissions, driven by U.S. Environmental Protection Agency regulations aimed at improving air quality and worker safety in pressrooms. These bio-based vehicles replace petroleum distillates, lowering VOC content by up to 90% while maintaining print quality, and now constitute a significant portion of sheet-fed and web inks in environmentally regulated markets.[47][40]Inking system mechanics

The inking system in offset printing presses employs a roller train consisting of typically 10 to 20 rollers, including combinations of metal, rubber, and composite materials, to transport ink from the fountain to the plate cylinder while ensuring uniform distribution. These rollers vary in function: form rollers directly contact the plate, distributor rollers spread the ink evenly, and oscillator rollers move laterally to shear and thin the ink film, preventing pattern repetition from the plate cylinder gap. The train's design breaks down the viscous ink into a thin, consistent layer suitable for image transfer, with oscillation speeds adjusted to match ink viscosity for optimal flow.[48][49] The ink fountain serves as the reservoir, where adjustable keys—thin blades positioned along the fountain roller—control the ink film thickness applied to the roller, typically ranging from 0.1 to 1 micron depending on job requirements. Ductor rollers bridge the gap between the fountain and the main roller train, oscillating or rotating intermittently to pick up ink from the fountain roller and transfer it to the first distributor roller, maintaining a steady supply without flooding the system. This metering mechanism allows precise zonal control, with keys motorized in modern presses for rapid adjustments during production.[48][50] Automation in inking systems leverages CIP3 and CIP4 standards, which use digital prepress files to generate ink preset values for each zone, enabling automatic key adjustments before printing begins. These protocols calculate ink coverage from image data and transfer curves, significantly reducing makeready time to under 5 minutes on compatible presses by minimizing trial sheets and manual tuning. Integration with press consoles allows real-time feedback for further refinements, enhancing efficiency across sheet-fed and web-fed operations.[51][52] Uneven ink distribution can lead to ghosting, where faint duplicate images appear due to ink starvation or mechanical repetition in solid areas. This issue arises from insufficient oscillation or imbalanced roller pressures, causing localized variations in ink film thickness. Mitigation involves zoned inking systems, which divide the fountain into 20 to 40 independent zones per printing unit, allowing targeted ink delivery to match image density and prevent lateral ink flow between areas. Proper zone calibration, combined with oscillator adjustments, ensures consistent density and minimizes waste.[53][54]Sheet-Fed Offset

Feeder and sheet handling

In sheet-fed offset printing, the feeder system is responsible for loading individual sheets from a pile, separating them accurately, and transferring them to the printing units via a feedboard. Two primary types of feeders are employed: continuous stream feeders and intermittent feeders. Continuous stream feeders, which utilize suction cups and vacuum tapes combined with air blasts for sheet separation, enable high-speed operation exceeding 15,000 sheets per hour by feeding sheets in an overlapping shingle pattern for enhanced control and stability, particularly with sensitive substrates.[55][56] In contrast, intermittent feeders deliver single sheets with gaps between them, suitable for lower speeds and simpler setups but less efficient for prolonged high-volume runs.[57] Sheet registration ensures precise alignment before transfer to the printing cylinders, minimizing misprints and color shifts. This is achieved through side lays, which adjust lateral positioning, and front guides or lays that control forward alignment, typically achieving an accuracy of ±0.1 mm to meet industry standards for multi-color overprinting.[58][59] Once aligned, pull-side grippers on the feedboard grasp the leading edge of the sheet and transfer it smoothly to the impression cylinder of the first printing unit.[60] Pile feeders accommodate a wide substrate range, handling papers from 40 to 400 gsm and boards up to 0.8 mm thick, allowing versatility for commercial, packaging, and label applications.[61][62] These systems typically hold piles of 2,000 to 10,000 sheets, corresponding to heights of 900 to 1,300 mm depending on substrate thickness, with automatic pile loaders facilitating efficient replenishment.[63][64] Modern advancements include non-stop feeders equipped with pallet changers, which allow seamless replacement of empty substrate piles without halting production, using automated swords or lifts to insert new pallets while the press continues running at full speed.[65][66] This feature, common in presses from manufacturers like Heidelberg and Koenig & Bauer, significantly boosts uptime for long runs by integrating with servo-driven adjustments for format and air settings.[67][62]Printing units and delivery

In sheet-fed offset printing, the printing units are organized as modular color towers, with each tower responsible for applying one color of ink to the sheet. These presses commonly feature 1 to 10 towers, enabling configurations from single-color to full-color (typically four-color CMYK plus additional spot colors) printing in a straight or perfecting setup. Each tower houses three primary cylinders: the plate cylinder, which carries the imaged printing plate; the blanket cylinder, which receives the inked image from the plate and transfers it to the substrate; and the impression cylinder, which presses the sheet against the blanket for image transfer. The cylinders rotate at synchronized surface speeds to ensure precise, non-slipping contact, with the blanket providing a compressible, resilient surface that accommodates minor substrate variations.[29][68][60] For duplex (two-sided) printing, a perfecting unit is integrated into the press configuration, typically positioned after the initial set of straight printing towers (e.g., between the fourth and fifth units in an eight-tower setup). This unit inverts the sheet using transfer mechanisms, allowing subsequent towers to print on the reverse side in a single pass through the press, which enhances efficiency for applications requiring printing on both sides without manual handling. Sheet transfer between units occurs via grippers on the impression cylinders or intermediate transfer cylinders, maintaining registration to prevent misalignment across colors.[68][29] Following the final printing tower, sheets enter the delivery system, where they are released from grippers and collected into a stack. Chain delivery systems, utilizing endless chains equipped with gripper bars, transport the sheets from the last impression cylinder to the delivery pile board, ensuring controlled deceleration to avoid damage. Some presses incorporate belt systems for slowdown sections to gently guide sheets before piling. To prevent set-off—where wet ink from one sheet transfers to the back of another—anti-set-off sprays apply fine powder or liquid agents over the printed surface in the delivery area. Jogging devices, including side and rear vibrators operating at 1,000 to 3,000 cycles per minute, then align the sheets squarely in the pile for stable stacking and easy removal.[69][70] Quality control in the printing units and delivery is critical, as issues like slur and hickeys can compromise output. Slur occurs due to mechanical "throw" or velocity differences between cylinders, causing image distortion such as elongated halftone dots in the direction of sheet travel or perpendicular to it. Hickeys are unintended spots or voids resulting from dust, paper fibers, or debris adhering to the plate or blanket surfaces during printing. Mitigation strategies include periodic blanket washes to remove ink residues, debris, and glaze from the blanket cylinder, restoring its surface integrity, and air blasts—directed streams of compressed air in the units and delivery—to dislodge and evacuate particles before they affect the print. These practices, combined with routine press maintenance, help maintain consistent quality.[71][72][69] High-speed operation is a hallmark of modern sheet-fed offset presses, with B2 format (50 × 70 cm) models achieving maximum production rates of up to 18,000 sheets per hour in straight printing configurations, depending on substrate, ink, and automation features. This speed supports high-volume commercial and packaging runs while integrating inline monitoring for real-time adjustments.[73]Web-Fed Offset

Web handling and tension control

In web-fed offset printing, roll stands serve as the foundational component for managing continuous paper supply, typically designed as dual or turret systems to enable splice-free operation during high-volume runs. These stands accommodate multiple paper rolls—often two or three per unit—allowing automatic splicing at full press speed to minimize downtime. Common configurations support web widths ranging from 20 to 60 inches, with operational speeds reaching up to 2,000 feet per minute, facilitating efficient production for applications like newspapers and magazines.[74][75][76] Tension control is critical to maintaining web stability throughout the printing process, preventing issues such as breaks, wrinkles, or misalignment that could compromise print quality. Systems employ load cells to measure tensile force directly and dancer rollers to provide dynamic feedback, automatically adjusting motor speeds or brake pressures to sustain optimal tension levels of 0.5 to 2 pounds per linear inch. This closed-loop regulation ensures uniform web transport across printing units, adapting to variations in substrate properties or speed changes.[77][78][79] Web guiding mechanisms further enhance precision by using edge sensors and steering actuators to align the continuous web, compensating for any lateral drift caused by roll imperfections or tension fluctuations. These sensors, often optical or ultrasonic, detect deviations in real-time and adjust guide rollers to keep the web centered, which is essential for accurate registration in multi-color printing. Downstream, folder systems process the printed web into signatures, typically producing 16- to 32-page sections through jaw or pin folding techniques, enabling efficient post-press handling.[80][81][74] Suitable substrates for web-fed offset include newsprint at around 40 grams per square meter (gsm) for economical, high-speed runs and coated papers up to 100 gsm for enhanced image quality on magazines or catalogs. Roll diameters commonly reach up to 60 inches, allowing extended production cycles without frequent changes while accommodating the press's high throughput.[82][61][83]Drying and finishing processes

In web-fed offset printing, drying processes are essential to solidify the ink on the continuous paper web, enabling high-speed production without smearing or set-off. Heat-set drying, commonly used for coated papers in commercial applications, employs gas or electric dryers to evaporate volatile solvents from the ink. The printed web passes through these dryers, where temperatures reach 130–150°C in the initial sections, allowing solvent evaporation during a brief dwell time of 0.7–1 second.[84] Following evaporation, chill rolls cool the web rapidly, typically reducing its temperature to solidify the ink film and prevent re-liquefaction, ensuring the web can be handled immediately downstream.[85] In contrast, cold-set drying relies on natural absorption of the ink into uncoated or absorbent substrates like newsprint, combined with oxidation and evaporation at ambient conditions, eliminating the need for dedicated dryers. This method suits high-volume, low-cost applications such as newspapers, where the ink's vegetable oil components penetrate the paper fibers over time without external heat. Cold-set processes consume significantly less energy than heat-set due to the absence of heating equipment.[86][87] Post-drying finishing operations convert the printed web into final products, often inline for efficiency. Sheeters cut the web into individual sheets for further binding, while folders create signatures or booklets by folding the web into sections. Rewinders collect the web back into rolls for later processing, common in label or packaging production. For specialized items like labels, inline die-cutting trims shapes directly from the web, integrating precision cuts with the printing line.[88][89] Heat-set drying is energy-intensive, primarily due to the thermal requirements of evaporating solvents, but optimizations such as infrared (IR)/ultraviolet (UV) hybrid systems—adopted widely since the 2010s—reduce consumption by combining targeted IR pre-drying with UV curing for faster, more efficient ink setting. These hybrids lower overall energy use compared to traditional hot-air systems alone.[90]Process Comparisons

Sheet-fed versus web-fed

Sheet-fed offset printing is ideal for short to medium run lengths, generally under 5,000 copies, due to its relatively quick setup and changeover times, which enable efficient production for customized or low-volume jobs. In comparison, web-fed offset printing is optimized for high-volume runs exceeding 10,000 copies, where the continuous roll feed minimizes waste per unit and achieves greater overall efficiency by amortizing setup costs over large quantities.[91] Regarding quality, sheet-fed systems provide superior handling of thick or specialty substrates, allowing for precise application of spot colors and finishes that enhance premium print products like brochures and packaging. Web-fed systems, however, deliver exceptional consistency in color registration and speed, making them preferable for applications such as newspapers and magazines where uniform output across vast quantities is essential.[92][93] Cost considerations favor sheet-fed for smaller projects with lower upfront setup expenses, while web-fed incurs higher initial investments due to the complexity and scale of the equipment, yet yields lower unit costs for extended runs through economies of scale. For instance, web-fed operations can reduce per-sheet expenses significantly in high-volume scenarios, often recovering the added capital outlay through sustained production.[91][93] Key performance metrics highlight these differences:| Metric | Sheet-fed Offset | Web-fed Offset |

|---|---|---|

| Typical Speed | 10,000–18,000 sheets per hour | 600–915 meters per minute |

| Optimal Run Length | <5,000 copies | >10,000 copies |

| Unit Cost (long runs) | Higher than web-fed | Lower due to economies of scale |