Recent from talks

Nothing was collected or created yet.

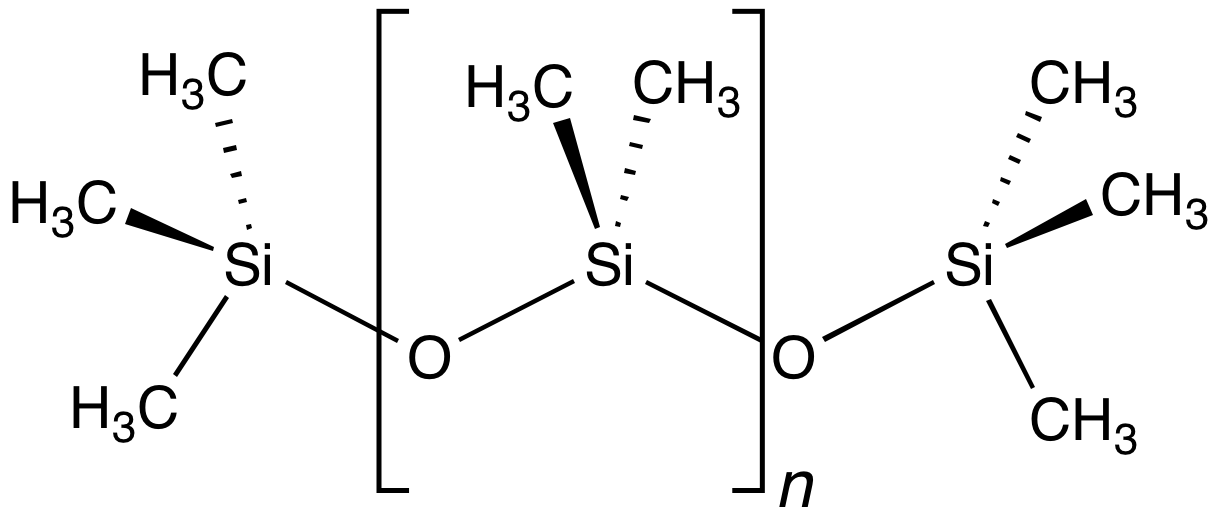

Siloxane

View on Wikipedia

In organosilicon chemistry, a siloxane is an organic compound containing a functional group of two silicon atoms bound to an oxygen atom: Si−O−Si. The parent siloxanes include the oligomeric and polymeric hydrides with the formulae H[OSiH2]nOH and [OSiH2]n.[1] Siloxanes also include branched compounds, the defining feature of which is that each pair of silicon centres is separated by one oxygen atom. The siloxane functional group forms the backbone of silicones [−R2Si−O−SiR2−]n, the premier example of which is polydimethylsiloxane (PDMS).[2] The functional group R3SiO− (where the three Rs may be different) is called siloxy. Siloxanes are manmade and have many commercial and industrial applications because of the compounds’ hydrophobicity, low thermal conductivity, and high flexibility.

Structure

[edit]Siloxanes generally adopt structures expected for linked tetrahedral ("sp3-like") centers. The Si−O bond length is 1.64 Å (vs Si–C distance of 1.92 Å) and the Si-O-Si angle is rather open at 142.5°.[3] By contrast, the C−O distance in a typical dialkyl ether is much shorter at 1.414(2) Å with a more acute C−O−C angle of 111°.[4] It can be appreciated that the siloxanes would have low barriers for rotation about the Si−O bonds as a consequence of low steric hindrance. This geometric consideration is the basis of the useful properties of some siloxane-containing materials, such as their low glass transition temperatures.

Synthesis of siloxanes

[edit]

The main route to siloxane functional group is by hydrolysis of silicon chlorides:

- 2 R3Si−Cl + H2O → R3Si−O−SiR3 + 2 HCl

The reaction proceeds via the initial formation of silanols (R3Si−OH):

- R3Si−Cl + H2O → R3Si−OH + HCl

The siloxane bond can then form via a silanol + silanol pathway or a silanol + chlorosilane pathway:

- 2 R3Si−OH → R3Si−O−SiR3 + H2O

- R3Si−OH + R3Si−Cl → R3Si−O−SiR3 + HCl

Hydrolysis of a silyldichloride can afford linear or cyclic products. Linear products are terminated with silanol groups:

- n R2Si(OH)2 → H(R2SiO)nOH + (n − 1) H2O

Cyclic products have no silanol termini:

- n R2Si(OH)2 → (R2SiO)n + n H2O

The linear products, polydimethylsiloxane (PDMS), are of great commercial value. Their production requires the production of dimethylsilicon dichloride.

Starting from trisilanols, cages are possible, such as the species with the formula (RSi)nO3n/2 with cubic (n = 8) and hexagonal prismatic (n = 12) structures. The cubic cages are cubane-type clusters, with silicon centers at the corners of a cube oxygen centres spanning each of the twelve edges.[6]

Reactions

[edit]Oxidation of organosilicon compounds, including siloxanes, gives silicon dioxide. This conversion is illustrated by the combustion of hexamethylcyclotrisiloxane:

- ((CH3)2SiO)3 + 12 O2 → 3 SiO2 + 6 CO2 + 9 H2O

Strong base degrades siloxane group, often affording siloxide salts:

- ((CH3)3Si)2O + 2 NaOH → 2 (CH3)3SiONa + H2O

This reaction proceeds by production of silanols. Similar reactions are used industrially to convert cyclic siloxanes to linear polymers.[2]

Uses

[edit]Polysiloxanes (silicones), upon combustion in an inert atmosphere, generally undergo pyrolysis to form silicon oxycarbide or silicon carbide (SiC). By exploiting this reaction, polysiloxanes have been used as preceramic polymers in various processes including additive manufacturing. Polyvinyl siloxane (vinyl polysiloxane) is used to make dental impressions and industrial impressions. The use of a poly-siloxane precursor in polymer derived ceramics allows the formation of ceramic bodies with complex shapes, although the significant shrinkage in pyrolysis needs to be taken into account.[citation needed]

Trisiloxanes may be used as diffusion pump fluid.[citation needed]

Cyclomethicones

[edit]Cyclomethicones are a group of methyl siloxanes, a class of liquid silicones (cyclic polydimethylsiloxane polymers) that possess the characteristics of low viscosity and high volatility as well as being skin emollients and in certain circumstances useful cleaning solvents.[7] Unlike dimethicones, which are linear siloxanes that do not evaporate, cyclomethicones are cyclic: both groups consist of a backbone of [(CH3)2SiO]n. They are used in many cosmetic products including deodorants and antiperspirants which need to coat the skin but not remain tacky afterward.[8] Dow is a major producer of cyclomethicones.[9]

Cyclomethicones, like all siloxanes, degrade by hydrolysis, producing silanols.[10] These silanols are produced at such low levels that they do not interfere with hydrolytic enzymes.[11] Even though some cyclomethicones structurally resemble crown ethers, they bind metal ions only weakly.[12]

Nomenclature

[edit]

The word siloxane is derived from the words silicon, oxygen, and alkane. In some cases, siloxane materials are composed of several different types of siloxane groups; these are labeled according to the number of Si−O bonds:

- M-units: (CH3)3SiO0.5,

- D-units: (CH3)2SiO,

- T-units: (CH3)SiO1.5.

| Cyclic siloxanes (cyclomethicones) | CAS | Linear siloxanes | CAS |

|---|---|---|---|

| L2, MM: hexamethyldisiloxane | 107-46-0 | ||

| D3: hexamethylcyclotrisiloxane | 541-05-9 | L3, MDM: octamethyltrisiloxane | 107-51-7 |

| D4: octamethylcyclotetrasiloxane | 556-67-2 | L4, MD2M: decamethyltetrasiloxane | 141-62-8 |

| D5: decamethylcyclopentasiloxane | 541-02-6 | L5, MD3M: dodecamethylpentasiloxane | 141-63-9 |

| D6: dodecamethylcyclohexasiloxane | 540-97-6 | L6, MD4M: tetradecamethylhexasiloxane | 107-52-8 |

Safety and environmental considerations

[edit]Because silicones are heavily used in biomedical and cosmetic applications, their toxicology has been intensively examined. "The inertness of silicones toward warmblooded animals has been demonstrated in a number of tests." With an LD50 in rats of >50 g/kg, they are virtually nontoxic.[13] Questions remain however about chronic toxicity or the consequences of bioaccumulation since siloxanes can be long-lived.

Findings about bioaccumulation have been largely based on laboratory studies. Field studies of bioaccumulation have not reached consensus. "Even if the concentrations of siloxanes we have found in fish are high compared to concentrations of classical contaminants like PCBs, several other studies in the Oslo Fjord in Norway, Lake Pepin in the US, and Lake Erie in Canada have shown concentrations of siloxanes decrease at higher range in the food chain. This finding raises questions about which factors influence the bioaccumulation potential of siloxanes."[14]

Cyclomethicones are ubiquitous because they are widely used in biomedical and cosmetic applications. They can be found at high levels in American cities. They can be toxic to aquatic animals in concentrations often found in the environment.[15][16] The cyclomethicones D4 and D5 are bioaccumulative in some aquatic organisms, according to one report.[17]

In the European Union, D4, D5, D6 and octamethyltrisiloxane have been deemed hazardous as per the REACH regulation. They were characterized as substances of very high concern (SVHC) in 2024 due to their PBT (persistent, bioaccumulative and toxic) and vPvB (very persistent and very bioaccumulative) properties and were subsequently added to the REACH Candidate List in 2025.[18] Canada regulates D4 under a pollution prevention plan.[15] A scientific review in Canada in 2011 concluded that "Siloxane D5 does not pose a danger to the environment."[19]

Literature

[edit]- Christoph Rücker, Klaus Kümmerer: Environmental Chemistry of Organosiloxanes. In: Chemical Reviews. 115(1), 2015, p. 466–524, doi:10.1021/cr500319v.

References

[edit]- ^ Siloxanes, IUPAC Gold Book.

- ^ a b Röshe, L.; John, P.; Reitmeier, R. "Organic Silicon Compounds" Ullmann’s Encyclopedia of Industrial Chemistry. John Wiley and Sons: San Francisco, 2003. doi:10.1002/14356007.a24_021.

- ^ H. Steinfink, B. Post and I. Fankuchen. "The crystal structure of octamethyl cyclotetrasiloxane". Acta Crystallogr. 1955, vol. 8, 420–424. doi:10.1107/S0365110X55001333.

- ^ K. Vojinović, U. Losehand, N. W. Mitzel. "Dichlorosilane–dimethyl ether aggregation: a new motif in halosilane adduct formation". Dalton Trans., 2004, 2578–2581. doi:10.1039/B405684A.

- ^ Silicon: Organosilicon Chemistry. Encyclopedia of Inorganic Chemistry Online, 2nd ed.; Wiley: New Jersey, 2005. doi:10.1002/0470862106.ia220.

- ^ S. D. Kinrade, J. C. H. Donovan, A. S. Schach and C. T. G. Knight (2002), Two substituted cubic octameric silicate cages in aqueous solution. J. Chem. Soc., Dalton Trans., 1250–1252. doi:10.1039/b107758a.

- ^ Barbara Kanegsberg; Edward Kanegsberg (2011). Handbook for Critical Cleaning: Cleaning Agents and Systems. CRC. p. 19. ISBN 978-1-4398-2827-4.

- ^ Amarjit Sahota (25 November 2013). Sustainability: How the Cosmetics Industry is Greening Up. Wiley. p. 208. ISBN 978-1-118-67650-9.

- ^ Meyer Rosen (23 September 2005). Delivery System Handbook for Personal Care and Cosmetic Products: Technology, Applications and Formulations. William Andrew. p. 693. ISBN 978-0-8155-1682-8.

- ^ S. Varaprath, K. L. Salyers, K. P. Plotzke and S. Nanavati "Identification of Metabolites of Octamethylcyclotetrasiloxane (D4) in Rat Urine" Drug Metab Dispos 1999, 27, 1267-1273.

- ^ R. Pietschnig, S. Spirk (2016). "The Chemistry of Organo Silanetriols". Coord. Chem. Rev. 323: 87–106. doi:10.1016/j.ccr.2016.03.010.

- ^ F. Dankert, C. von Hänisch (2021). "Siloxane Coordination Revisited: Si−O Bond Character, Reactivity and Magnificent Molecular Shapes". Eur. J. Inorg. Chem. 2021 (29): 2907–2927. Bibcode:2021EJIC.2021.2907D. doi:10.1002/ejic.202100275. S2CID 239645449.

- ^ Moretto, Hans-Heinrich; Schulze, Manfred; Wagner, Gebhard (2005). "Silicones". Ullmann's Encyclopedia of Industrial Chemistry. Weinheim: Wiley-VCH. doi:10.1002/14356007.a24_057. ISBN 3527306730.

- ^ "Siloxanes: Soft, shiny -- and dangerous?" by Christine Solbakken, Science Nordic, August 28, 2015. Retrieved May 31, 2016

- ^ a b Karpus, Jennifer (20 June 2014). "Exec: Silicone industry must focus on safety, environment". Rubber & Plastic News. Retrieved 8 April 2015.

- ^ Bienkowski, Brian (30 April 2013). "Chemicals from Personal Care Products Pervasive in Chicago Air". Scientific American. Retrieved 8 April 2015.

- ^ Wang, De-Gao; Norwood, Warren; Alaee, Mehran; Byer, Jonatan D.; Brimble, Samantha (October 2013). "Review of recent advances in research on the toxicity, detection, occurrence and fate of cyclic volatile methyl siloxanes in the environment". Chemosphere. 93 (5): 711–725. Bibcode:2013Chmsp..93..711W. doi:10.1016/j.chemosphere.2012.10.041. PMID 23211328.

- ^ "Candidate List of substances of very high concern for Authorisation". ECHA. Retrieved 2019-12-18.

- ^ Report of the Board of Review for Decamethylcyclopentasiloxane (Siloxane D5)

External links

[edit]Siloxane

View on GrokipediaSiloxanes are a class of synthetic organosilicon compounds characterized by chains of alternating silicon and oxygen atoms forming Si–O–Si linkages, typically with organic groups such as methyl attached to the silicon atoms. [1][2] These structures, often linear, cyclic, or branched, constitute the backbone of silicones, which are renowned for their thermal stability, hydrophobicity, flexibility, and low toxicity under normal use conditions. [3][4] Developed primarily through hydrolysis and polymerization of chlorosilanes like dichlorodimethylsilane, siloxanes enable diverse applications in sealants, adhesives, lubricants, cosmetics, medical implants, and electronics due to their chemical inertness and biocompatibility. [4][5] While generally regarded as safe with minimal environmental impact from polymerized forms, volatile cyclic siloxanes such as decamethylcyclopentasiloxane have sparked debate over persistence in ecosystems and bioaccumulation potential, prompting regulatory scrutiny in regions like the European Union despite limited empirical evidence of widespread harm. [4][6]

Definition and Fundamental Properties

Molecular Structure and Bonding

Siloxanes constitute a class of organosilicon compounds featuring a backbone composed of alternating silicon and oxygen atoms connected by Si-O-Si linkages. The fundamental repeating unit is R₂SiO, where R typically denotes alkyl groups such as methyl, enabling the formation of linear chains, branched structures, or cyclic oligomers. In linear siloxanes, terminal units are often R₃SiO-, while cyclic variants consist of closed rings of -R₂SiO- units, exemplified by decamethylcyclopentasiloxane ((CH₃)₂SiO)₅.[7][8] The Si-O bonds in siloxanes are polar covalent, arising from σ-overlap between silicon's sp³ hybridized orbitals and oxygen's p-orbitals, with silicon exhibiting tetrahedral coordination to four ligands—two oxygens and two R groups. Bond dissociation energies for Si-O exceed those of C-O bonds, contributing to thermal stability, while the polarity stems from electronegativity differences (oxygen 3.44, silicon 1.90 on Pauling scale).[9][10] Empirical data indicate Si-O bond lengths of approximately 1.64 Å, with minimal variation across siloxane structures. The Si-O-Si interatomic angle displays significant flexibility, ranging from 105° in constrained heterocycles to 150°-170° in acyclic chains, averaging around 143° in polysiloxanes; this variability arises from d-orbital involvement or electrostatic repulsions between lone pairs on adjacent oxygens, contrasting with the more rigid ~109.5° tetrahedral angles at silicon (O-Si-O). Such angular freedom facilitates conformational adaptability in siloxane polymers.[11][9][8]Physical and Thermal Characteristics

Siloxanes, particularly polydimethylsiloxanes (PDMS), are characterized by their colorless, odorless nature and low intermolecular forces, resulting in low viscosity, surface tension, and water solubility.[12] These properties stem from the flexible Si-O-Si backbone and non-polar methyl groups, enabling high compressibility and spreadability. Densities typically range from 0.95 to 1.0 g/cm³ at 25°C, with viscosities varying widely based on molecular weight—from low-viscosity fluids (e.g., <1 cP for short chains) to gums and elastomers for higher polymers.[13] Thermal conductivity is low at approximately 0.15 W/m·K, and specific heat capacity is about 1.46 kJ/kg·K for PDMS.[14] Cyclic siloxanes, such as octamethylcyclotetrasiloxane (D4), decamethylcyclopentasiloxane (D5), and dodecamethylcyclohexasiloxane (D6), exhibit volatility suitable for applications requiring evaporation. The following table summarizes key physical properties:| Property | D4 | D5 | D6 |

|---|---|---|---|

| Melting Point (°C) | 17.7 | -38 | Not specified |

| Boiling Point (°C) | 175 | 211 | ~245 |

| Density (g/cm³ at 25°C) | 0.95 | 0.954 | 0.96 |

| Vapor Pressure (Pa at 25°C) | 132 | Lower than D4 | Lower than D5 |

Historical Development

Early Scientific Discoveries

The foundations of siloxane chemistry trace back to mid-19th-century efforts in organosilicon synthesis. In 1863, Charles Friedel and James Mason Crafts reported the first organosilicon compound, tetraethylsilane (Si(C₂H₅)₄), obtained via the reaction of silicon tetrachloride with diethylzinc.[22] This breakthrough bridged organic and inorganic realms but did not yet yield siloxane structures featuring Si-O-Si bonds.[23] The initial synthesis of a siloxane occurred in 1872, when Albert Ladenburg reacted triethoxychlorosilane with diethylzinc, isolating a compound identified as diethylsilanone ((C₂H₅)₂SiO), the first recognized siloxane.[22] [23] Ladenburg's work highlighted the tendency of organosilicon halides to hydrolyze into oxygen-linked species, though the polymeric nature of such products remained unexplored at the time.[24] Systematic investigation of siloxanes advanced in the early 20th century through Frederic Stanley Kipping's research at the University of Nottingham. Beginning in 1899, Kipping employed Grignard reagents to prepare organosilicon halides, leading to the first polysiloxane in 1901 via hydrolysis of diphenyldichlorosilane, yielding polydiphenylsiloxane (Ph₂SiO)_n.[25] [26] In 1904, he coined the term "silicone" for these materials, analogizing their hypothetical silanone intermediates to organic ketones, despite their actual polymeric siloxane composition.[27] Kipping published over 50 papers on silicon chemistry through 1944, elucidating the challenges of isolating discrete siloxanes due to their propensity for polymerization and establishing key synthetic routes like hydrolysis and condensation of silanols.[28] His findings laid the groundwork for recognizing siloxanes' unique stability and flexibility, though commercial applications emerged decades later.[22]Commercialization and Key Innovations

The commercialization of siloxanes, primarily in the form of silicone polymers, accelerated in the 1940s amid demand for heat-resistant materials during World War II. Foundational organosilicon research by Frederic Stanley Kipping from 1899 to 1944 established key synthetic routes, such as Grignard reactions for alkyl- and arylsilanes, but Kipping did not pursue industrial applications, viewing silicones as scientifically intriguing yet commercially limited. Practical exploitation began with J. F. Hyde at Corning Glass Works, who in the 1930s developed early silicone resins demonstrating exceptional thermal stability up to 300°C, enabling their use in insulating electrical components and coating glass fabrics for aerospace and military applications.[29][28] A pivotal innovation was the 1943 formation of Dow Corning Corporation as a joint venture between Dow Chemical Company and Corning Glass Works, formalized via a handshake agreement in 1942 to scale silicone production from laboratory hydrolysis of chlorosilanes like dichlorodimethylsilane. This partnership enabled the first commercial silicone output in July 1944, starting with polydimethylsiloxane (PDMS)-based fluids and resins for lubricants, sealants, and electrical insulators, which outperformed organic alternatives in extreme temperatures from -50°C to over 200°C.[30][31] Dow Corning's proprietary equilibrium polymerization process for cyclic siloxanes into high-molecular-weight PDMS chains represented a key breakthrough, allowing controlled viscosity and elasticity tailored for gaskets in aircraft engines and submarine components.[22] In Europe, commercialization lagged until 1947, when Wacker Chemie AG initiated silicone research, achieving initial silane-based production by 1949 and scaling to resins and elastomers post-war, positioning it as a major global player by leveraging similar condensation methods but adapting for chemical and automotive sectors. Subsequent innovations included cross-linked silicone rubbers via peroxide curing, patented in the late 1940s, which enhanced mechanical durability for consumer goods like baking molds and medical tubing, expanding market volume from niche military uses to billions in annual production by the 1950s. These developments prioritized empirical performance over theoretical yields, with source data from industry archives confirming reliability gains through iterative testing rather than unverified projections.[32][33]Synthesis and Industrial Production

Laboratory Synthesis Techniques

Laboratory synthesis of siloxanes primarily relies on the hydrolysis and condensation of chlorosilanes, a method established since the early 20th century for producing both cyclic and linear oligomers. Dihalosilanes like dichlorodimethylsilane ((CH₃)₂SiCl₂) react with water to initially form silanediols, which then undergo dehydration to establish Si-O-Si bonds, favoring cyclic structures such as hexamethylcyclotrisiloxane (D₃) or octamethylcyclotetrasiloxane (D₄) under dilute conditions to minimize intermolecular reactions.[34] This process is typically conducted by dropwise addition of the chlorosilane to a stirred mixture of water and an organic solvent like diethyl ether or toluene at controlled temperatures (0–25°C) to manage exothermic HCl evolution and prevent gelation.[35] Conductometric titration serves as a precise technique to monitor hydrolysis progress in homogeneous solutions, revealing stoichiometric endpoints for complete conversion based on conductivity changes from HCl formation and silanol reactivity.[36] Basic catalysis, using agents like sodium bicarbonate, accelerates condensation while neutralizing acid byproducts, enabling tailored molecular weights; for instance, yields of cyclic dimethylsiloxanes exceed 80% when hydrolysis occurs at low concentrations (e.g., <10% chlorosilane in solvent).[34] Alternative routes include silanol condensation in liquid ammonia, which achieves high yields (up to 95%) for phenylsiloxanes without organic solvents, leveraging ammonia's dual role as solvent and base.[37] For functionalized or hybrid siloxanes, sol-gel methods hydrolyze alkoxysilanes or mixed chlorosilanes in alcoholic media with acid/base catalysts, producing siloxane networks integrable with organic polymers; this approach, detailed in 1997 studies, allows incorporation of up to 50 mol% siloxane units while controlling gelation times from minutes to hours.[38] Specialized syntheses, such as rhodium-catalyzed silylation of aryl halides or semihydrogenation of alkynylsilanes, yield aryl- or alkenyl-substituted cyclic siloxanes with stereoselectivities >90% (E/Z ratios), suitable for small-scale preparation of monomers for advanced materials.[39][40] These techniques prioritize inert atmospheres and anhydrous handling of precursors to avoid premature hydrolysis.Large-Scale Manufacturing Processes

The predominant industrial route for siloxane production commences with the Müller-Rochow direct process, wherein powdered metallurgical silicon (purity typically 98-99%) is contacted with methyl chloride gas at temperatures of 270-350°C under pressure (2-5 atm) in a fluidized-bed reactor, catalyzed primarily by copper (often as CuCl or promoted alloys). This reaction yields a mixture of methylchlorosilanes, dominated by dimethyldichlorosilane (Me₂SiCl₂, ~70-90% selectivity), alongside byproducts like methyldichlorosilane (MeSiCl₃, ~5-10%) and trimethylchlorosilane (Me₃SiCl, ~5%).[41] The process, operational since the 1940s, achieves throughputs of thousands of tons annually per plant, with catalyst contact times of seconds to minutes; side reactions generate disilanes and silicon dust, necessitating downstream purification.[42] The crude chlorosilane mixture undergoes fractional distillation under reduced pressure to isolate high-purity Me₂SiCl₂ (boiling point 70°C), essential for subsequent steps, as impurities degrade polymer quality. Hydrolysis follows by controlled addition of Me₂SiCl₂ to excess water or ice slurries at 0-50°C, liberating HCl gas (recovered for reuse) and forming transient silanols that rapidly condense: n Me₂SiCl₂ + (n+1) H₂O → HO[Me₂SiO]_nH + 2n HCl. This yields a hydrolysate comprising cyclic oligomers (e.g., octamethylcyclotetrasiloxane, D4, ~85%) and linear/cyclic low-molecular-weight siloxanes, with water removal via stripping or azeotropic distillation to drive polycondensation.[43] Industrial setups employ continuous stirred-tank reactors for scalability, minimizing gelation via pH control and additives like solvents.[44] For high-molecular-weight linear polydimethylsiloxanes (PDMS), the cyclic-rich hydrolysate undergoes ring-opening polymerization (ROP) or equilibration in large batch or continuous reactors using strong acid (e.g., H₂SO₄) or base (e.g., KOH) catalysts at 100-150°C under vacuum, targeting viscosity grades from 100 to over 100,000 cSt. End-blockers like Me₃SiCl or hexamethyldisiloxane cap chains to control molecular weight (10³-10⁶ g/mol). Catalyst quenching and neutralization follow, with devolatilization removing cyclics (recycled) and residuals; yields exceed 95% for commercial silicones.[45] Alternative routes, such as direct cohydrolysis of mixed chlorosilanes for copolymers, scale similarly but require precise stoichiometry to avoid branching.[46] Volatile methylsiloxanes (VMS) like D4 and D5 are purified via distillation from hydrolysis streams for standalone use or as ROP monomers, with global capacities exceeding 1 million tons/year integrated into silicone plants. Process efficiency hinges on HCl recovery (up to 99%) and energy integration, though challenges include copper catalyst deactivation (lifetimes ~100-500 hours) and byproduct management.[47] Emerging continuous flow variants aim to reduce batch variability and enhance sustainability by minimizing solvent use.[45]Economic Scale and Market Dynamics

The global siloxane market was valued at US 5.91 billion by 2034 at a compound annual growth rate (CAGR) of 6.1%, driven primarily by demand in elastomers, fluids, and resins.[48] In contrast, the combined silicones and siloxanes market reached USD 24.5 billion in value and 6.23 million metric tons (MMT) in volume the same year, expected to expand to 10.95 MMT by 2034 at a 5.8% CAGR, reflecting siloxanes' role as key intermediates in silicone polymer production.[49] Annual production volumes for select high-volume siloxanes, such as cyclic variants, range from 45,000 to 227,000 metric tons worldwide, underscoring their industrial scale despite comprising a subset of broader organosilicon output.[2] Market concentration is high among a few dominant producers, including Dow Inc., Wacker Chemie AG, Shin-Etsu Chemical Co. Ltd., and Momentive Performance Materials Inc., which collectively control significant shares through integrated supply chains from chlorosilane precursors to end-use silicones.[50] [51] Asia-Pacific commands the largest regional share, accounting for 35-45% of global demand, with China alone boasting production capacity exceeding 200,000 tons annually due to expansive manufacturing infrastructure and export-oriented policies.[52] This regional dominance is supported by cost advantages in raw materials like silicon metal and methanol, though it exposes the market to supply chain vulnerabilities from energy price fluctuations and trade restrictions. Key dynamics include steady demand growth from applications in construction sealants, electronics encapsulation, and personal care emulsions, offset by pricing pressures; siloxanes prices declined in the first half of 2025 across Asia, Europe, and North America amid oversupply and subdued downstream demand, with modest recovery anticipated later in the year.[53] Environmental regulations targeting persistent cyclic siloxanes like octamethylcyclotetrasiloxane (D4) and decamethylcyclopentasiloxane (D5) for bioaccumulation risks have prompted reformulations and capacity shifts toward linear alternatives, potentially constraining short-term expansion in cosmetics and biogas sectors while fostering innovation in biodegradable variants.[2] Overall, the market's oligopolistic structure ensures stable supply but heightens sensitivity to raw material costs and geopolitical factors, with forecasts emphasizing sustainable production as a differentiator for long-term competitiveness.[54]Chemical Reactivity and Modifications

Primary Reaction Mechanisms

Siloxanes demonstrate high chemical stability owing to the strong Si-O-Si bonds, which confer resistance to hydrolysis, oxidation, and thermal degradation under standard conditions.[55] However, their primary reactivity manifests through catalyzed bond cleavage and reformation processes, particularly in equilibration and polymerization reactions.[56] These mechanisms enable structural rearrangements, such as chain lengthening, shortening, or cyclization, driven by thermodynamic equilibria favoring mixtures of linear and cyclic species.[57] Ring-opening polymerization (ROP) of cyclic siloxanes represents a dominant mechanism for synthesizing linear polysiloxanes, proceeding via either anionic or cationic pathways.[55] In anionic ROP, initiators like potassium silanolates generate siloxide anions that perform nucleophilic attack on the silicon atom of the cyclic monomer, such as decamethylcyclopentasiloxane, leading to ring scission and propagation through sequential additions.[57] [56] This process often incorporates redistribution steps, where intramolecular cyclization (backbiting) competes with chain growth, resulting in a Poisson distribution of chain lengths at equilibrium.[57] Cationic ROP, facilitated by strong protic acids or Lewis acids like trifluoromethanesulfonic acid, involves protonation or coordination to the oxygen atom, enhancing electrophilicity at silicon and promoting bond heterolysis.[55] Propagation occurs via insertion of additional monomer units into the activated chain end, with potential side reactions including branching or premature termination under high acidity.[58] Both mechanisms highlight the role of siloxane bond polarity, where silicon's partial positive charge renders it susceptible to nucleophilic or electrophilic assault under catalysis.[10] Equilibration reactions in linear siloxanes, also acid- or base-catalyzed, proceed through reversible Si-O-Si bond breaking, allowing segment interchange and adjustment to minimize free energy.[56] Base-catalyzed variants favor silanolate intermediates, while acid catalysis leverages protonated oxygen for departure, with kinetics influenced by substituent effects on silicon electronegativity.[58] These processes underpin industrial polymer synthesis and modification, enabling control over molecular weight and end-group functionality.[57]Functional Group Introductions

Functional groups are introduced into siloxane structures primarily to enhance reactivity, compatibility with other materials, or specific performance characteristics such as adhesion, cross-linking ability, or bioactivity, achieved through modifications to the silicon-bound substituents or chain termini.[59] Common approaches leverage the inherent reactivity of siloxane precursors or polymers, including substitution reactions on halosiloxanes and catalytic additions to Si-H bonds.[60] Hydrosilylation represents a cornerstone method, involving the platinum- or rhodium-catalyzed addition of hydride-functional siloxanes (containing Si-H groups) to unsaturated compounds like alkenes, alkynes, or acrylates, thereby appending groups such as vinyl, allyl, or aminoalkyl moieties. This process, typically conducted at temperatures of 50–150°C, yields high regioselectivity (anti-Markovnikov addition) and is widely used for end-group or side-chain functionalization in silicone polymers, with conversion rates often exceeding 95% under optimized conditions.[60] [61] For instance, polyhydrosiloxanes react with terminal alkenes to form β-substituted alkyl chains, enabling the incorporation of ester, amide, or nitrile functionalities.[62] Nucleophilic substitution on chlorosiloxanes provides another direct route, where dichlorodimethylsilane or analogous chloro-terminated oligomers undergo reaction with organometallic reagents (e.g., Grignard or organolithium compounds) or amines/alcohols to install organic substituents like phenyl, amino, or alkoxy groups. This method, rooted in early organosilicon synthesis, proceeds via SN2-like mechanisms at silicon and is effective for preparing telechelic siloxanes with dual functional ends, though it requires anhydrous conditions to prevent hydrolysis.[63] Yields can reach 80–90%, but byproduct salts necessitate purification steps like distillation or precipitation.[64] Polymerization-based introductions incorporate functional monomers during ring-opening polymerization (ROP) of cyclic siloxanes or hydrolytic polycondensation of silanes, allowing statistical distribution of groups along the chain. Anionic ROP of hexamethylcyclotrisiloxane with functionalized initiators (e.g., lithiated alcohols) yields siloxanes with hydroxy or vinyl termini, while cationic variants enable blocked end groups via controlled quenching.[65] These techniques support molecular weights from 1,000–50,000 g/mol and polydispersities below 1.5, facilitating tailored polydimethylsiloxanes with mercapto, epoxy, or methacrylate pendants for applications in coatings and composites.[61] Emerging catalytic methods, such as iron-mediated C-H silylation, further expand options by directly grafting aryl or heteroatom-containing groups onto siloxane frameworks under mild conditions (e.g., 80°C, 24 hours).[62] Post-polymerization modifications, including dehydrogenative coupling or aryne insertions, offer versatility for pre-formed siloxanes but often require specialized catalysts and may introduce defects like branching. Overall, method selection balances yield, scalability, and group compatibility, with hydrosilylation dominating industrial processes due to its efficiency and tolerance for diverse substrates.[66][10]Nomenclature and Classification

Naming Conventions

Siloxanes, compounds featuring alternating silicon and oxygen atoms in chains or rings, are named under IUPAC recommendations for silicon parent hydrides, where the core structure is designated as a siloxane based on the number of silicon atoms. Linear unbranched siloxanes follow the pattern "disiloxane" for two silicon atoms (H₃Si–O–SiH₃), "trisiloxane" for three, and so forth, with organic substituents prefixed and hydrogens on silicon replaced accordingly, using locants to specify positions. For instance, the compound with methyl groups on both silicons in a disiloxane chain is named 1,1,1,3,3,3-hexamethyldisiloxane.[67] Cyclic siloxanes are named as "cyclotrisiloxane," "cyclotetrasiloxane," or higher homologs, reflecting the ring size (n silicon atoms), with substituents detailed similarly; a common example is decamethylcyclopentasiloxane, featuring ten methyl groups on a five-silicon ring.[67] Branched structures employ the "siloxy" prefix (–O–SiR₃) for side chains attached to the main siloxane backbone.[68] In polymer nomenclature, particularly for polydimethylsiloxanes (PDMS), industrial and source-based naming prevails alongside IUPAC, using repeating unit descriptors: "M" for monofunctional trimethylsiloxy end-groups ((CH₃)₃SiO–), "D" for difunctional dimethylsiloxy ((CH₃)₂SiO), "T" for trifunctional methylsiloxy ((CH₃)SiO₁.₅), and "Q" for tetrafunctional siloxy (SiO₂). Polymers are thus denoted as, e.g., MD₄M for a linear chain with M ends and four D units, facilitating concise representation in patents and manufacturing contexts.[69][70] Chemical Abstracts Service (CAS) indexes siloxanes via repeating unit or source-based names, especially for hydrolytic polymers from silanes, prioritizing structural fidelity over strict substitutive rules for complex mixtures.[71][69]Structural Variants and Polymers

Siloxanes exhibit diverse structural architectures, including linear chains, cyclic oligomers, branched configurations, and cross-linked networks, primarily defined by the connectivity of siloxy units (Si-O-Si). Linear siloxanes feature a backbone of repeating difunctional -SiR₂O- units (denoted as D units, where R is typically methyl), capped by monofunctional trialkylsiloxy end groups (M units), yielding structures like hexamethyldisiloxane or higher polydimethylsiloxanes.[15][72] Cyclic variants, such as octamethylcyclotetrasiloxane (D₄) or decamethylcyclopentasiloxane (D₅), form ring structures with 3 to 8 siloxy units, lacking end groups and exhibiting volatility due to their closed conformation.[2][4] Branched siloxanes incorporate trifunctional -SiRO- units (T units) or tetrafunctional -SiO- units (Q units), enabling tree-like or dendritic growth, while cross-linked variants combine these with D or M units to form elastomers or resins with three-dimensional networks.[73][72] Substituent variations on silicon atoms, such as replacing methyl with phenyl, vinyl, or fluoroalkyl groups, modify properties like flexibility, thermal stability, or reactivity without altering core topology.[74] For instance, polyphenylmethylsiloxane introduces phenyl branches to enhance compatibility with organic polymers.[75] Polysiloxanes represent the polymeric extension of these structures, with polydimethylsiloxane (PDMS) as the predominant example, comprising high-molecular-weight linear chains of [Si(CH₃)₂O]_n that confer exceptional flexibility due to wide Si-O-Si bond angles (around 140–150°) and low intermolecular forces.[76][77] PDMS variants include copolymers with alternating D units bearing different R groups, such as dimethyl-vinylmethylsiloxane for cross-linkable elastomers, or grafted structures for specialized applications. Cross-linked polysiloxanes, often via hydrosilylation or condensation, yield silicone rubbers with T/Q branching, exhibiting moduli tunable from fluids to rigid solids based on cross-link density.[73] Polymerization of cyclic monomers like D₄ via ring-opening yields stereoirregular chains, contrasting with organic vinyl polymers, due to the lack of tacticity control in siloxane equilibria.[74] These polymeric forms underpin silicones' utility, with molecular weights typically ranging from 400 to over 10⁶ g/mol, influencing viscosity from oils to gums.[76]Applications and Practical Uses

Industrial and Engineering Applications

Polysiloxanes, particularly polydimethylsiloxanes (PDMS), are integral to sealants and adhesives in construction and automotive engineering, offering elasticity, adhesion to diverse substrates, and resistance to weathering and chemicals. In building applications, they seal joints in facades, windows, and sanitary installations, maintaining integrity under thermal expansion and UV exposure. Automotive uses include gaskets, hoses, and body adhesives that endure engine heat up to 260°C and vibrational stress.[78][79] In mechanical and electrical engineering, siloxane-based fluids function as lubricants, hydraulic media, and dielectric insulators, leveraging their low volatility, wide viscosity range (-50°C to 230°C operating temperatures), and high dielectric strength (approximately 400-500 V/mil). Hydraulic formulations provide shear stability and fire resistance in aerospace and industrial machinery, while dielectric variants insulate transformers and capacitors, minimizing electrical breakdown.[80][81] Polysiloxanes serve as antifoaming agents in chemical processing, oil refining, and wastewater treatment, where their low surface tension disrupts foam stability without altering process chemistry. In coatings for marine and industrial structures, hybrid polysiloxane systems enhance corrosion resistance and durability through covalent bonding and hydrophobic surfaces. Electrical insulation applications in cables and potting compounds exploit their thermal conductivity and flexibility.[82][83][84]Consumer and Personal Care Products

Siloxanes, especially volatile methylsiloxanes (VMS) like cyclotetrasiloxane (D4), cyclopentasiloxane (D5), and cyclohexasiloxane (D6), serve as solvents, carriers, and emollients in personal care products such as shampoos, conditioners, antiperspirants, and skin creams.[85] [86] These compounds provide lubricity, spreadability, and a smooth texture, enabling even application and enhancing product sensory properties like silkiness without altering skin or hair health directly.[26] [87] In hair care formulations, non-volatile siloxanes such as dimethicone act as conditioning agents, improving manageability, reducing frizz, and imparting shine by forming a hydrophobic film on hair shafts.[26] [87] Shampoos and conditioners often exhibit the highest concentrations of cyclic VMS, with D5 being the most prevalent, contributing to detangling and moisture retention effects.[88] [89] Antiperspirants and deodorants utilize linear and cyclic siloxanes for their antistatic and film-forming qualities, facilitating quick-drying and non-greasy finishes. [90] Cosmetic foundations and lotions incorporate cyclomethicone and dimethicone crosspolymers to create breathable barriers, enhance wear resistance, and provide a lightweight, non-comedogenic feel on skin.[26] Approximately 16% of analyzed European cosmetics contain cyclic VMS, predominantly D5, underscoring their ubiquity in rinse-off and leave-on products for texture modification and emulsification.[89] These applications leverage siloxanes' chemical inertness and low surface tension for superior product performance, though their persistence prompts scrutiny in other contexts.[86]Specialized and Emerging Uses

Siloxanes exhibit biocompatibility and tunable properties that enable their use in advanced biomedical applications, such as drug delivery and theranostics. Silica nanoparticles coated with polysiloxanes have been developed for dual imaging and therapy, allowing targeted detection and treatment of diseases like cancer through enhanced permeability and retention effects.[91] In 2024, researchers incorporated siloxane composites into lipid nanoparticles for mRNA delivery, achieving precise organ targeting—such as liver or spleen—due to the materials' established safety in medical implants and ability to modulate biodistribution without altering mRNA integrity.[92] These applications leverage siloxanes' low toxicity and flexibility, as demonstrated in prostheses, artificial organs, and vitreous substitutes since the late 20th century.[93] In electronics and nanotechnology, siloxane-based polymers support emerging flexible and wearable technologies. Polysiloxane/nanosilica nanodielectrics provide high dielectric permittivity (up to 10-15 at 1 kHz) and low loss tangents (<0.05), making them suitable for stretchable capacitors and sensors in wearable devices, with mechanical strains exceeding 100% without dielectric breakdown.[94] Dynamic siloxane networks, incorporating reversible bonds, are being engineered for self-healing electronics, smart optical devices, and antifouling coatings, where molecular dynamics enable responses to stimuli like temperature or light.[95] Additionally, siloxane chemistry facilitates molecular imprinting in nanomaterials for selective sensing and separation, as seen in hybrid structures combining top-down lithography with bottom-up assembly for microelectronics and advanced plastics.[96][97] Surface functionalization represents another specialized domain, with siloxanes serving as versatile modifiers for diverse substrates. Reactive siloxanes enable the creation of hybrid metal-organic frameworks (MOFs) via hexacarboxylic acid derivatives, enhancing porosity and stability for gas storage or catalysis applications reported in 2020 studies.[98] In environmental and optical technologies, cyclosiloxane-containing polymers exhibit low surface energy and high transparency, supporting uses in separation membranes and blood oxygenators, where permeability coefficients for gases like oxygen reach 10^{-6} to 10^{-5} cm²/s STP.[74][99] These developments underscore siloxanes' role in bridging traditional silicone properties with innovative, stimulus-responsive functionalities.Safety, Toxicology, and Health Effects

Acute and Chronic Toxicity Data

Acute toxicity of siloxanes is characterized by high LD50 and LC50 values, indicating low hazard potential for short-term exposures. For linear polydimethylsiloxanes (PDMS), oral LD50 values exceed 20,000 mg/kg body weight in rats, with no observed adverse effects at tested doses up to 24% in diet. Dermal LD50 for PDMS and similar siloxanes typically surpasses 2,000 mg/kg in rabbits, showing minimal skin absorption and irritation. Inhalation LC50 for volatile methylsiloxanes like decamethylcyclopentasiloxane (D5) is greater than 1 mg/L (4-hour exposure) in rats, though data for aerosols may vary. Cyclic siloxanes such as octamethylcyclotetrasiloxane (D4) exhibit comparable low acute toxicity, with oral LD50 >2,500 mg/kg in rats and no deaths at dermal doses up to 2,000 mg/kg.[100][101][102][103]| Compound Type | Endpoint | Value | Species | Reference |

|---|---|---|---|---|

| PDMS (linear) | Oral LD50 | >20,000 mg/kg | Rat | [100] |

| Various siloxanes | Dermal LD50 | >2,000 mg/kg | Rabbit | [101] [102] |

| D5 (cyclic) | Inhalation LC50 (4h) | >1.08 mg/L | Rat | [103] |

Exposure Routes and Risk Assessments

Humans are primarily exposed to cyclic siloxanes such as D4, D5, and D6 through dermal contact and inhalation during the use of consumer products like cosmetics, shampoos, conditioners, and antiperspirants, where these compounds serve as solvents or emollients.[109] Dermal absorption is limited, with in vitro and in vivo studies showing approximately 0.05–0.5% systemic uptake for D4 and D5 applied to human or pig skin, as the majority volatilizes rapidly from the skin surface.[109] Inhalation exposure predominates for volatile methyl siloxanes (VMS), particularly indoors, with peak concentrations of 0.9–6.0 mg/m³ measured during hair care product application and emissions ranging from 110–1500 mg per person depending on product type, hair length, and styling tool temperature.[110] Occupational exposure in manufacturing settings involves higher levels via inhalation and dermal routes, while environmental contributions through air, dust, or diet are minor for the general population.[4] Oral exposure is negligible from cosmetics but possible via incidental ingestion or contaminated food, though data indicate low bioavailability.[109] Risk assessments by regulatory bodies, including the European Commission's Scientific Committee on Consumer Safety (SCCS), conclude that D4 and D5 are safe for use in cosmetics at average concentrations of 8.3% (range 0.06–89%), yielding systemic exposure doses of 0.1–0.2 mg/kg body weight/day, with margins of safety for D4 ranging from 89–178 based on no-observed-adverse-effect levels (NOAELs) of 150–300 ppm from inhalation and reproductive studies in rats.[109] D4 exhibits reproductive toxicity in category 3 under EU classification, with effects like increased endometrial adenomas observed in female rats at 700 ppm inhalation, though human relevance is questioned due to species-specific metabolism and low dermal/inhalation absorption rates of 5–6% in rodents and <1% dermally in humans.[109] [4] For D5, no significant toxicity occurs up to 1600 mg/kg body weight dermally or 160 ppm inhalation in rats, with potential uterine tumors at higher doses deemed of unclear relevance to humans; annual inhalation exposure from consumer products is estimated at 1–20 mg/day for D5, warranting further long-term studies but not indicating acute risks at current levels.[109] [110] The U.S. EPA's ongoing risk evaluation for D4 under TSCA considers all pathways (inhalation, dermal, oral) for general population and occupational scenarios, incorporating measured data on partitioning and transport, but preliminary findings emphasize low human health hazards relative to environmental persistence concerns.[108] Overall, empirical toxicity data support low human health risks from typical exposures, with effects confined to high-dose animal models, though low-molecular-weight siloxanes may pose organ accumulation risks if impurities are present in products.[4]Environmental Fate and Impact

Persistence, Degradation, and Mobility

Volatile methylsiloxanes (VMS), particularly cyclic variants such as octamethylcyclotetrasiloxane (D4), decamethylcyclopentasiloxane (D5), and dodecamethylcyclohexasiloxane (D6), exhibit high environmental persistence due to their chemical stability, with atmospheric half-lives ranging from approximately 7 to 9 days for D4 and D5 via reaction with hydroxyl radicals, and longer for D6.[111] [112] In aquatic and soil compartments, persistence is greater, as biodegradation rates are negligible under aerobic conditions, with probabilities approaching zero for D5 in water or soil, and hydrolysis half-lives exceeding months to years at neutral pH.[113] [114] Empirical data indicate D4's overall environmental persistence aligns with PBT (persistent, bioaccumulative, toxic) criteria under REACH, driven by slow degradation in sediments where it partitions preferentially.[115] Degradation primarily occurs atmospherically through oxidation by OH radicals, yielding silanols and ultimately silica, with no significant direct photolysis or thermal breakdown observed under ambient conditions; rate constants increase with ring size (D4 ≈ D5 < D6).[111] Hydrolysis, catalyzed by acids or bases, proceeds via nucleophilic attack on Si-O bonds but is minimal in neutral environmental waters, with measured half-lives for D4 exceeding 100 days.[112] Biodegradation is limited, with studies showing <1% mineralization for cyclic VMS in standard OECD tests, though engineered enzymes have demonstrated potential Si-C bond cleavage in lab settings, not yet observed in natural systems.[116] [117] Mobility is dominated by volatilization, as >90% of VMS emissions partition to air due to high Henry's law constants (e.g., air-water partition for D5 ≈ 0.3-0.5 dimensionless), facilitating long-range atmospheric transport before deposition.[118] In soils, sorption to organic matter is strong (log Koc >5 for cyclic VMS), reducing leaching potential, though cyclic forms like D3-D6 exhibit plant uptake and translocation in crops such as peas.[119] [120] Low water solubility (<0.03 mg/L for D5) further limits aqueous mobility, with preferential accumulation in sediments over time.[121]Bioaccumulation and Ecological Studies

Cyclic volatile methylsiloxanes (cVMS), including octamethylcyclotetrasiloxane (D4), decamethylcyclopentasiloxane (D5), and dodecamethylcyclohexasiloxane (D6), demonstrate bioaccumulation potential in aquatic organisms primarily due to high octanol-water partition coefficients (log Kow 6.7–8.1). Laboratory bioconcentration factor (BCF) measurements for D4 in fish species such as rainbow trout (Oncorhynchus mykiss) and fathead minnow (Pimephales promelas) range from 5,695 to 13,400 L/kg wet weight, exceeding the threshold of 5,000 L/kg indicative of bioaccumulative substances under regulatory criteria like those from the U.S. Environmental Protection Agency (EPA). For D5, non-radiolabeled BCF values in fish fall between 1,040 and 4,920 L/kg wet weight, while radiolabeled studies report higher values up to 13,700 L/kg. These metrics suggest uptake from water, though high volatility limits aqueous exposure durations.[122][123] Dietary bioaccumulation studies highlight mitigating factors against net accumulation and trophic transfer. In juvenile rainbow trout exposed via feed, assimilation efficiencies for D4 and D5 were low at 15.5% and 21.0%, respectively, accompanied by substantial intestinal biotransformation rates of 2.1 day−1 for D4 and 0.88 day−1 for D5, yielding lipid-normalized biomagnification factors (BMFL) of 0.44 and 0.78 kg-lipid/kg-lipid. Somatic biotransformation further reduces body burdens, with rates of 0.0158 day−1 for D4. Field-derived bioaccumulation factors (BAF) in fish muscle tissue vary, e.g., 4,141–5,900 L/kg for D4 in crucian carp, but biota-sediment accumulation factors (BSAF) for sediment-associated organisms like midges and shrimp range from 0.7 to 2.6, reflecting sedimentary sources for linear siloxanes in bivalves.[124][122] Ecological investigations across food webs, such as Lake Chaohu and Oslofjord, reveal detection of cVMS in multiple trophic levels, yet trophic magnification factors (TMF) are predominantly below 1 (mean TMF 0.79 for D4), indicating dilution rather than amplification up the chain. Exceptions include select systems like Lake Mjøsa where TMF >1 for D5, but overall, no consistent biomagnification occurs due to rapid depuration and metabolism. Risk evaluations integrating these data assess low ecological hazard, as environmental concentrations (e.g., D4 surface water 0.051 µg/L) and bioaccumulated levels yield margins of exposure above chronic no-observed-effect concentrations (NOEC) for aquatic species. Sedimentary persistence, however, sustains benthic exposure potentials.[125][123][122]

Regulatory Status and Controversies

Global Regulations and Bans

Cyclic siloxanes, particularly octamethylcyclotetrasiloxane (D4), decamethylcyclopentasiloxane (D5), and dodecamethylcyclohexasiloxane (D6), have faced regulatory scrutiny globally due to their environmental persistence, bioaccumulation potential, and toxicity profiles, with D4 classified as persistent, bioaccumulative, and toxic (PBT), and D5 and D6 as very persistent and very bioaccumulative (vPvB).[126] These properties prompted actions under frameworks like the EU's REACH regulation, though no universal international bans exist as of October 2025.[127] In the European Union, D4 was designated a substance of very high concern (SVHC) in 2018 for PBT characteristics, leading to a restriction in wash-off cosmetic products effective January 31, 2020, limiting concentrations to below 0.1% by weight to mitigate aquatic releases.[126] Commission Regulation (EU) 2024/1328, adopted May 16, 2024, and published in the Official Journal on May 17, 2024, amends REACH Annex XVII to broadly restrict D4, D5, and D6, prohibiting their placement on the market in mixtures or articles at concentrations of 0.1% or more for consumer and professional uses starting June 6, 2026. This includes bans in leave-on cosmetics from June 6, 2027, and medical devices from June 6, 2031, with derogations for specific industrial applications such as silicone polymer production and non-metal surface treatments, aiming to reduce environmental emissions by up to 90%.[128] Outside the EU, regulations are less stringent, with no equivalent comprehensive bans. In the United States, the Environmental Protection Agency (EPA) completed scoping for a Toxic Substances Control Act (TSCA) risk evaluation of D4 in March 2022 and released a draft evaluation in September 2025 assessing hazards and exposures across uses, but no federal restrictions or bans have been imposed as of October 2025.[108] Canada lists D4 as toxic under the Canadian Environmental Protection Act and implements risk management measures, including a 2012 Pollution Prevention Planning Notice to minimize releases and restrictions in certain pest control products, but has not enacted cosmetic bans akin to the EU's, favoring a risk-based approach without broad prohibitions on D5 or D6.[129][130] Other regions, such as Asia-Pacific countries, largely align with or defer to EU standards for exports but lack independent sweeping regulations.[127]Scientific Debates on Risks vs. Benefits

Scientific debates surrounding siloxanes center on balancing their utility in industrial and consumer applications against potential environmental and health hazards, particularly for volatile methylsiloxanes (VMS) such as octamethylcyclotetrasiloxane (D4), decamethylcyclopentasiloxane (D5), and dodecamethylcyclohexasiloxane (D6). Proponents, including industry groups like the Global Silicones Council, emphasize empirical evidence of low acute and chronic toxicity in mammalian studies, with no-observed-adverse-effect levels (NOAELs) exceeding 100 mg/kg/day for dermal and oral exposures in rats, attributing benefits to their chemical inertness, thermal stability, and low reactivity that enable uses in lubricants, cosmetics, and sealants without significant human health risks under typical exposure scenarios.[4][131] These properties derive from the Si-O-Si backbone's resistance to hydrolysis and oxidation, providing durable performance in products where alternatives like hydrocarbons may degrade faster or pose higher flammability risks.[132] Critics, often from regulatory bodies like the European Chemicals Agency (ECHA), highlight persistent, bioaccumulative, and toxic (PBT) classifications for D4 based on half-lives exceeding 60 days in freshwater sediments (measured at >1 year in lab tests) and bioconcentration factors (BCFs) up to 12,400 in fish, arguing that continuous emissions from wastewater lead to long-term ecological accumulation despite rapid volatilization in air (half-life ~1-2 days).[89][133] For D5 and D6, debates hinge on impurity thresholds; ECHA deems them PBT if containing >0.1% D4, prompting EU restrictions limiting concentrations to 0.1% in wash-off products from 2026 to curb emissions by up to 90%, though industry counters that modeled environmental concentrations remain below effect thresholds (e.g., predicted no-effect concentration of 5.6 μg/L for D5 in aquatic systems).[134][128] A core contention lies in risk assessment methodologies: hazard-based approaches prioritize intrinsic properties like persistence, leading to precautionary bans, while exposure-based models, as adopted in Canada's 2019 assessments, integrate release volumes (e.g., <1% of D5 production enters ecosystems via consumer products) and degradation pathways, concluding negligible population-level risks with margins of safety >1,000-fold.[135] Peer-reviewed weight-of-evidence analyses challenge overestimation of bioaccumulation, noting that field BCFs for D5 in wild fish average 200-500 versus lab maxima, attributed to metabolic clearance rates of 0.01-0.05 day⁻¹ in organisms, and argue that benefits in reducing energy use (e.g., via efficient silicone antifoams in wastewater treatment) outweigh modeled hazards absent direct causal links to toxicity in ecosystems.[136][137] Conversely, some toxicology reviews cite in vitro evidence of endocrine disruption at micromolar concentrations for D4, though human relevance remains unproven due to poor dermal penetration (<1% absorption in ex vivo skin studies) and lack of reproductive effects in multigenerational rodent trials at doses up to 160 mg/kg/day.[138][139]| Aspect | Evidence Supporting Benefits | Evidence Supporting Risks | Key Debate Points |

|---|---|---|---|

| Human Toxicity | NOAEL >100 mg/kg/day; inert in acute dermal/oral studies[4] | Potential endocrine effects in vitro; skin absorption of cyclics[132] | Exposure levels too low for effects vs. precautionary hazard focus |

| Environmental Fate | Rapid air volatilization; low field bioaccumulation (BCF ~200-500)[137] | Sediment persistence (D4 half-life >1 year); PBT classification[133] | Hazard vs. risk: modeled PEC/PNEC ratios <1 vs. intrinsic properties |

| Product Utility | Enables low-volatility, stable formulations in cosmetics/sealants[131] | Emissions from wash-off products contribute to aquatic loads[89] | Alternatives inferior in performance vs. emission reduction feasibility |