Recent from talks

Nothing was collected or created yet.

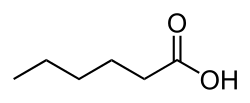

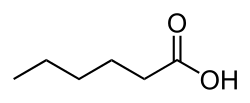

Caproic acid

View on Wikipedia | |

| |

| Names | |

|---|---|

| Preferred IUPAC name

Hexanoic acid | |

| Other names

Hexoic acid; Hexylic acid; Butylacetic acid; Pentylformic acid; 1-Pentanecarboxylic acid; C6:0 (Lipid numbers)

| |

| Identifiers | |

3D model (JSmol)

|

|

| 773837 | |

| ChEBI | |

| ChEMBL | |

| ChemSpider | |

| ECHA InfoCard | 100.005.046 |

| EC Number |

|

| 185066 | |

| KEGG | |

PubChem CID

|

|

| UNII | |

CompTox Dashboard (EPA)

|

|

| |

| |

| Properties | |

| C6H12O2 | |

| Molar mass | 116.160 g·mol−1 |

| Appearance | Oily liquid[1] |

| Odor | goat-like |

| Density | 0.929 g/cm3[2] |

| Melting point | −3.4 °C (25.9 °F; 269.8 K)[1] |

| Boiling point | 205.8 °C (402.4 °F; 478.9 K)[1] |

| 1.082 g/100 mL[1] | |

| Solubility | soluble in ethanol, ether |

| Acidity (pKa) | 4.88 |

| −78.55·10−6 cm3/mol | |

Refractive index (nD)

|

1.4170 |

| Viscosity | 3.1 mP |

| Hazards | |

| GHS labelling: | |

| |

| Danger | |

| H314 | |

| P260, P264, P280, P301+P330+P331, P302+P352, P303+P361+P353, P304+P340, P305+P351+P338, P310, P312, P321, P322, P361, P363, P405, P501 | |

| NFPA 704 (fire diamond) | |

| Flash point | 103 °C (217 °F; 376 K)[2] |

| 380 °C (716 °F; 653 K) | |

| Explosive limits | 1.3-9.3% |

| Lethal dose or concentration (LD, LC): | |

LD50 (median dose)

|

3000 mg/kg (rat, oral) |

| Related compounds | |

Related compounds

|

Pentanoic acid, Heptanoic acid |

Except where otherwise noted, data are given for materials in their standard state (at 25 °C [77 °F], 100 kPa).

| |

Caproic acid, also known as hexanoic acid, is the carboxylic acid derived from hexane with the chemical formula CH3(CH2)4COOH. It is a colorless oily liquid with a fatty, cheesy, waxy odor resembling that of goats[1] or other barnyard animals. It is a fatty acid found naturally in various animal fats and oils, and is one of the chemicals that gives the decomposing fleshy seed coat of the ginkgo its characteristic unpleasant odor.[3] It is also one of the components of vanilla and cheese. The primary use of caproic acid is in the manufacture of its esters for use as artificial flavors, and in the manufacture of hexyl derivatives, such as hexylphenols.[1] Salts and esters of caproic acid are known as caproates or hexanoates. Several progestin medications are caproate esters, such as hydroxyprogesterone caproate and gestonorone caproate.

Two other acids are named after goats: caprylic acid (C8) and capric acid (C10). Along with caproic acid, they account for 15% of the fat in goat's milk.

Caproic, caprylic, and capric acids (capric is a crystal- or wax-like substance, whereas the other two are mobile liquids) are not only used for the formation of esters, but also commonly used "neat" in: butter, milk, cream, strawberry, bread, beer, nut, and other flavors.

See also

[edit]References

[edit]- ^ a b c d e f The Merck Index: An Encyclopedia of Chemicals, Drugs, and Biologicals (11th ed.). Merck. 1989. ISBN 091191028X.

- ^ a b Record in the GESTIS Substance Database of the Institute for Occupational Safety and Health

- ^ "Ginkgo.html". Archived from the original on 2008-12-26. Retrieved 2007-03-08.