Recent from talks

Nothing was collected or created yet.

Extractive distillation

View on WikipediaThis article needs additional citations for verification. (October 2021) |

Extractive distillation is defined as distillation in the presence of a miscible, high-boiling, relatively non-volatile component, the solvent, that forms no azeotrope with the other components in the mixture. The method is used for mixtures having a low value of relative volatility, nearing unity. Such mixtures cannot be separated by simple distillation, because the volatility of the two components in the mixture is nearly the same, causing them to evaporate at nearly the same temperature at a similar rate, making normal distillation impractical.[1]

The method of extractive distillation uses a separation solvent, which is generally non-volatile, has a high boiling point and is miscible with the mixture, but doesn't form an azeotropic mixture. The solvent interacts differently with the components of the mixture thereby causing their relative volatilities to change. This enables the new three-part mixture to be separated by normal distillation. The original component with the greatest volatility separates out as the top product. The bottom product consists of a mixture of the solvent and the other component, which can again be separated easily because the solvent does not form an azeotrope with it. The bottom product can be separated by any of the methods available.

It is important to select a suitable separation solvent for this type of distillation. The solvent must alter the relative volatility by a wide enough margin for a successful result. The quantity, cost and availability of the solvent should be considered. The solvent should be easily separable from the bottom product, and should not react chemically with the components or the mixture, or cause corrosion in the equipment. A classic example to be cited here is the separation of an azeotropic mixture of benzene and cyclohexane, where aniline is one suitable solvent.[2]

See also

[edit]References

[edit]- ^ Robert E., Treybal (1981). MASS-TRANSFER OPERATIONS (3 ed.). McGraw-Hill. pp. 457–460. ISBN 0-07-066615-6.

- ^ Gerbaud, Vincent (2019). "Review of extractive distillation. Process design, operation, optimization and control" (PDF). Chemical Engineering Research and Design. 141: 229. doi:10.1016/j.cherd.2018.09.020. S2CID 105285092.

External links

[edit]Extractive distillation

View on GrokipediaPrinciples

Definition and Purpose

Extractive distillation is a specialized separation technique in chemical engineering that involves the addition of a selective solvent, often referred to as an entrainer, to a liquid mixture undergoing distillation. This solvent is typically a high-boiling, relatively non-volatile liquid that is completely miscible with the feed mixture and does not form azeotropes with the components. By interacting preferentially with one or more components in the liquid phase, the solvent alters the relative volatility between the target substances, facilitating their separation in the vapor phase while the solvent itself remains largely in the liquid phase and is recovered separately.[4][5] The primary purpose of extractive distillation is to overcome limitations of conventional simple distillation, particularly for mixtures exhibiting close boiling points or forming azeotropes, where standard vapor-liquid equilibrium prevents effective fractionation. In such cases, the entrainer enhances the differences in volatility without vaporizing significantly, allowing for higher purity separations at potentially lower energy costs compared to alternative methods like azeotropic distillation. This process is especially valuable in industries requiring precise component isolation, assuming a basic understanding of vapor-liquid equilibrium principles.[4][5] Extractive distillation emerged in the early 20th century as part of advancements in distillation techniques for complex mixtures, with conceptual foundations laid in the 1920s amid growing needs in petroleum refining to separate hydrocarbons with similar properties. Its industrial viability was solidified through key patents and theoretical developments in the late 1930s and 1940s, including applications for extracting high-purity olefins like butadiene during wartime synthetic rubber production.[5]Thermodynamic Basis

Extractive distillation relies on the introduction of a solvent to modify the relative volatility between components in a mixture, enabling the separation of close-boiling or azeotropic systems that are otherwise difficult to distill. Relative volatility, denoted as , is defined as , where and are the vapor and liquid mole fractions of component , respectively, and similarly for component . The solvent selectively interacts with the components, typically reducing the volatility of the more volatile component or enhancing that of the less volatile one, thereby shifting to facilitate separation. This modification is crucial for pairs where the native relative volatility is near unity, as the solvent's presence alters the vapor-liquid equilibrium (VLE) curve, allowing distillation to proceed without pinch points.[6][5] The thermodynamic foundation for predicting these solvent effects lies in non-ideal solution models that account for activity coefficients, which quantify deviations from ideal behavior in the liquid phase. Activity coefficients are functions of temperature , pressure , and composition, often modeled using equations such as those in the Non-Random Two-Liquid (NRTL) or Universal Quasi-Chemical (UNIQUAC) frameworks to describe VLE data accurately. In the NRTL model, for instance, , where and are interaction parameters; UNIQUAC similarly uses combinatorial and residual contributions to . These models enable the prediction of how the solvent influences activity coefficient ratios , which directly impact relative volatility via the relation (where is saturation vapor pressure), ensuring reliable simulation and design of extractive processes.[6][7] For azeotropic mixtures, the solvent disrupts the azeotrope by altering intermolecular interactions, which changes the azeotropic composition and eliminates the vapor-liquid pinch where . This is achieved through differential solvation effects that shift the equilibrium, preventing the composition where vapor and liquid phases have identical mole fractions. Heavy entrainers, with boiling points significantly higher than those of the target components, are preferred to maintain the solvent predominantly in the liquid phase, minimizing its vaporization and ensuring it acts effectively as a selectivity enhancer without complicating downstream recovery. This phase behavior supports the solvent's role in concentrating at the liquid-vapor interface, promoting efficient mass transfer during distillation.[6][5][7]Process Description

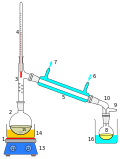

Operational Steps

The extractive distillation process commences with the introduction of the feed mixture—a typically azeotropic or close-boiling liquid stream—into an intermediate stage of the extractive column, where it is preheated to near its bubble point to facilitate efficient vaporization. Concurrently, the solvent is introduced at an upper stage, above the feed entry point, to establish an extractive section that promotes intimate contact between the descending liquid and rising vapors without excessive mixing of the feed and solvent streams. This staged addition ensures the solvent selectively alters the relative volatilities of the mixture components throughout the column.[8] In the subsequent countercurrent operation, heat is supplied at the reboiler to generate rising vapors enriched in the more volatile component, as the solvent's thermodynamic interaction—such as hydrogen bonding or polarity differences—depresses the volatility of the targeted less volatile species. The solvent-laden liquid descends through the column, absorbing and carrying the less volatile component downward, while the vapors progressively purify the more volatile component in the upper sections; this multi-section dynamics (rectifying, extractive, and stripping) maintains steady-state separation under controlled reflux and reboil ratios.[8] The purified more volatile product is then withdrawn as the overhead distillate from the top of the extractive column, often condensed and partially refluxed to enhance purity. The bottoms stream, comprising the less volatile component intimately mixed with the spent solvent, is collected and directed to the subsequent recovery stage.[8] Solvent recovery follows in a dedicated stripper column, where the bottoms from the extractive column are introduced, and steam or direct heating is applied to volatilize and separate the less volatile product overhead, leaving the high-boiling solvent in the bottoms for recycling back to the extractive column; this closed-loop minimizes solvent losses through makeup streams. Mass balance considerations are critical, with the solvent-to-feed ratio typically ranging from 1:1 to 10:1 by weight, selected to achieve desired product purities (e.g., >99%) while optimizing energy efficiency and column throughput.[8][9]Equipment and Configuration

The main extractive column in an extractive distillation process is typically a multi-stage tray or packed column designed to facilitate the separation of close-boiling or azeotropic mixtures through the addition of a selective solvent. These columns generally require 20-100 theoretical plates to achieve the desired purity, depending on the mixture's relative volatility and separation difficulty. The solvent is introduced via a dedicated feed tray positioned above the main feed tray, typically in the upper third of the column, to ensure it descends countercurrently through the mixture without premature volatilization and to maximize its extractive effect in the stripping section below.[10][1][11] A secondary stripper column is employed for solvent regeneration, receiving the bottoms stream from the main extractive column and operating at reduced pressure or with reboiling to separate the solvent from the heavy key component. This unit typically achieves greater than 99% solvent recovery, enabling its recycle to the main column while minimizing losses and operational costs. The stripper is often a simpler tray or packed column with fewer stages than the main unit, focused on high-purity solvent reclamation.[12][11] Heat integration is essential for efficiency, incorporating condensers to cool overhead vapors, reboilers to generate rising vapors, and pumps for liquid transfer between columns. Due to the dual-column setup and higher solvent circulation, the total energy input is higher than that of simple distillation for separable mixtures, primarily from increased reboiler duties, though optimizations like heat exchanger networks can mitigate this.[13][14] Control systems monitor temperature profiles across key trays to maintain solvent selectivity and prevent deviations in composition, often using PID controllers or advanced neural networks for real-time adjustments to reflux ratios and feed flows. Safety features, such as pressure relief valves and corrosion-resistant materials, address the handling of high-boiling solvents that may cause fouling or thermal degradation. Industrial-scale columns measure 1-5 meters in diameter, capable of processing 100-1000 tons per day, supporting large-volume operations like aromatic hydrocarbon recovery.[15][16][1]Solvent Selection

Criteria for Solvents

In extractive distillation, the primary criterion for solvent selection is selectivity, which refers to the solvent's ability to preferentially interact with one component of the mixture over the other, thereby altering the relative volatility to facilitate separation. This preferential interaction often occurs through mechanisms such as hydrogen bonding or differences in polarity, which disrupt the interactions in the original azeotrope or close-boiling mixture. Selectivity is quantitatively measured by the parameter , where denotes the activity coefficient of components 1 and 2; values significantly greater than 1 indicate effective enhancement of relative volatility.[17] Selectivity is quantitatively measured by the infinite dilution selectivity , where A is the more volatile component and B the less volatile; typical feasible values exceed 1.05–1.4, though lower values (e.g., ~0.8) can enable separation with higher solvent flows and process optimization.[18][1] Solvency requirements emphasize the solvent's capacity to dissolve the target components while minimizing mutual solubility with the separated products to simplify downstream recovery. High solvency is characterized by a large capacity factor, such as , reflecting strong solute-solvent interactions at infinite dilution.[1] Additionally, the solvent's boiling point should be 50-100°C higher than that of the mixture's highest-boiling component to ensure it remains predominantly in the liquid phase during distillation, reducing entrainment losses.[1] Solvents must exhibit thermal and chemical stability under operating conditions, typically up to 200-250°C, to prevent decomposition that could contaminate the products or require frequent replacement.[17] They should also be non-corrosive to equipment materials, non-toxic for handling and environmental compliance, and recyclable without significant degradation to maintain process efficiency over multiple cycles.[19] Economic viability is crucial, with the solvent cost ideally comprising less than 5% of the product value to avoid undermining the overall process profitability. Low vapor pressure is essential to minimize solvent losses in the overhead vapor, often quantified by a Henry's law constant exceeding 10 atm to limit volatilization.[20] Solvent candidates are evaluated through laboratory vapor-liquid equilibrium (VLE) measurements to determine activity coefficients and phase behavior experimentally, followed by process simulations using software like Aspen Plus to predict performance, optimize flows, and estimate total annual costs.[19]Common Solvents and Properties

Sulfolane (tetramethylene sulfone) is one of the most widely used solvents in extractive distillation due to its high boiling point of 285°C and density of 1.26 g/cm³ at 25°C, which facilitate its recovery by distillation without excessive energy input.[21] With a molecular weight of 120.17 g/mol and low toxicity, sulfolane exhibits excellent selectivity for separating aromatics from aliphatics, such as in benzene-toluene-xylene (BTX) extraction, where it preferentially solvates aromatic hydrocarbons while showing low solubility for non-aromatics.[22] Its thermal stability up to 250°C and non-corrosive nature make it suitable for industrial-scale operations.[23] N-Methylpyrrolidone (NMP), a polar aprotic solvent with a boiling point of 202°C and viscosity of 1.7 cP at 25°C, is effective for separations involving polar mixtures, including alcohol-water systems.[24] Its molecular weight is 99.13 g/mol, and it provides good solvency for organics while being recoverable via distillation. However, NMP is subject to environmental regulations due to potential reproductive toxicity and persistence in the environment. It demonstrates selectivity in reversing relative volatilities for azeotropic mixtures like isopropanol-water. Ethylene glycol (EG), with a boiling point of 197°C and molecular weight of 62.07 g/mol, serves as a cost-effective solvent for dehydration processes, offering high solvency for water and hydrocarbons in alcohol-water separations. Its density is 1.113 g/cm³ at 25°C, but it can pose corrosion risks to equipment, necessitating stainless steel or alloy construction.[25] EG enhances the relative volatility of ethanol over water, with an infinite dilution selectivity () of approximately 1.62 for the ethanol-water pair.[1] Glycerol, a natural and biodegradable solvent, has a high boiling point of 290°C and molecular weight of 92.09 g/mol, making it suitable for biofuel-related separations where sustainability is prioritized. Despite its high viscosity of 1.5 Pa·s at 25°C, which can impact mass transfer, glycerol effectively breaks azeotropes in ethanol-water mixtures (), though its lower selectivity requires higher entrainer flows or mixed systems for optimal performance.[1] Its renewability and low cost derive from biodiesel production byproducts. Emerging solvents such as ionic liquids (ILs) and deep eutectic solvents (DES) are gaining prominence for their tunability, negligible vapor pressure, and high selectivity (often >1.5 for aromatic/aliphatic or alcohol/water systems). For example, ILs like [bmim][BF4] offer thermal stability up to 300°C and reduced energy use by 20-30% in simulations, while DES (e.g., choline chloride-urea) provide biodegradable alternatives with selectivities around 1.2-2.0 for ethanol-water, lowering costs to ~$0.73 \times 10^6 annually for certain processes as of 2023. These are evaluated similarly via VLE data but prioritized for eco-compliance.[2][26]| Solvent | Boiling Point (°C) | Molecular Weight (g/mol) | Selectivity Index Example |

|---|---|---|---|

| Sulfolane | 285 | 120.17 | High for aromatics/aliphatics (e.g., benzene/heptane ~12 at infinite dilution)[23] |

| N-Methylpyrrolidone | 202 | 99.13 | Suitable for alcohol/water (reverses volatility in isopropanol/water) |

| Ethylene Glycol | 197 | 62.07 | (ethanol/water)[1] |

| Glycerol | 290 | 92.09 | (ethanol/water)[1] |