Recent from talks

Contribute something

Nothing was collected or created yet.

Still

View on WikipediaThis article needs additional citations for verification. (August 2021) |

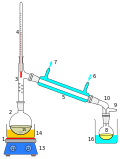

A still is an apparatus used to distill liquid mixtures by heating to selectively boil and then cooling to condense the vapor.[1] A still uses the same concepts as a basic distillation apparatus, but on a much larger scale. Stills have been used to produce perfume and medicine, water for injection (WFI) for pharmaceutical use, generally to separate and purify different chemicals, and to produce distilled beverages containing ethanol.

Application

[edit]Since ethanol boils at a much lower temperature than water, simple distillation can separate ethanol from water by applying heat to the mixture. Historically, a copper vessel was used for this purpose, since copper removes undesirable sulfur-based compounds from the alcohol. However, many modern stills are made of stainless steel pipes with copper linings to prevent erosion of the entire vessel and lower copper levels in the waste product (which in large distilleries is processed to become animal feed).[2] Copper is the preferred material for stills because it yields an overall better-tasting spirit. The taste is improved by the chemical reaction between the copper in the still and the sulfur compounds created by the yeast during fermentation. These unwanted and flavor-changing sulfur compounds are chemically removed from the final product resulting in a smoother, better-tasting drink. All copper stills will require repairs about every eight years due to the precipitation of copper-sulfur compounds. The beverage industry was the first to implement a modern distillation apparatus and led the way in developing equipment standards which are now widely accepted in the chemical industry.

There is also an increasing usage of the distillation of gin under glass and PTFE, and even at reduced pressures, to facilitate a fresher product. This is irrelevant to alcohol quality because the process starts with triple distilled grain alcohol, and the distillation is used solely to harvest botanical flavors such as limonene and other terpene like compounds. The ethyl alcohol is relatively unchanged.

The simplest standard distillation apparatus is commonly known as a pot still, consisting of a single heated chamber and a vessel to collect purified alcohol. A pot still incorporates only one condensation, whereas other types of distillation equipment have multiple stages which result in higher purification of the more volatile component (alcohol). Pot still distillation gives an incomplete separation, but this can be desirable for the flavor of some distilled beverages.

If a purer distillate is desired, a reflux still is the most common solution. Reflux stills incorporate a fractionating column, commonly created by filling copper vessels with glass beads to maximize available surface area.[3] As alcohol boils, condenses, and reboils through the column, the effective number of distillations greatly increases. Vodka and gin and other neutral grain spirits are distilled by this method, then diluted to concentrations appropriate for human consumption.

Alcoholic products from home distilleries are common throughout the world but are sometimes in violation of local statutes. The product of illegal stills in the United States is commonly referred to as moonshine and in Ireland, poitín. However, poitín, although made illegal in 1661, has been legal for export in Ireland since 1997. Note that the term moonshine itself is often misused as many believe it to be a specific kind of high-proof alcohol that was distilled from corn, but the term can refer to any illicitly distilled alcohol.[4]

See also

[edit]References

[edit]- ^ "DISTILLATION APPARATUS". Plymouth State University. Retrieved 22 March 2014.

- ^ "Distillation by-Products as Animal Feeds". Nutrition Reviews. 2 (12). Oxford University Press: 356–358. 1944. doi:10.1111/j.1753-4887.1944.tb08165.x. Retrieved 10 May 2021.

- ^ Kister, Henry Z. (1992). Distillation Design (1st ed.). McGraw-Hill. ISBN 0-07-034909-6.

- ^ "About Moonshine Stills and Alcohol Stills". Retrieved 14 November 2014.

External links

[edit]- Moonshine Still Moonshine Still Ghost from the past - Video

- Chisholm, Hugh, ed. (1911). . Encyclopædia Britannica (11th ed.). Cambridge University Press.

![]() The dictionary definition of still at Wiktionary

The dictionary definition of still at Wiktionary

Still

View on GrokipediaA still is an apparatus used for distillation, a process that separates components of a liquid mixture by heating to vaporize more volatile substances and then condensing the vapors to collect the purified distillate, exploiting differences in boiling points.[1] Primarily employed in the production of distilled spirits, a still concentrates ethanol from fermented washes such as beer or wine, yielding higher-proof alcohols like whiskey, rum, brandy, and vodka. The device's fundamental design leverages principles of thermodynamics and phase changes, enabling selective separation without chemical alteration of the core compounds.[2] Distillation via stills traces origins to ancient civilizations, with evidence of rudimentary apparatus in Mesopotamia, Egypt, or China around 2000 BC, initially for perfumes, medicines, and later alcohols.[3] The alembic, an early pot still variant, was refined by Arab alchemists like Jabir ibn Hayyan in the 8th century, spreading to Europe for spirit production by the Middle Ages.[4] Modern iterations include the batch-operated pot still, favored for retaining congeners that impart flavor complexity in aged spirits like Scotch whisky or cognac, and the continuous column still, patented by Aeneas Coffey in 1830, which achieves higher efficiency and purity for neutral spirits such as vodka or grain alcohol.[5][6] Beyond beverages, stills facilitate essential oil extraction, water desalination, and pharmaceutical purification, though their most notable role remains in the global spirits industry, where material choices like copper catalyze reactions to refine taste by removing sulfur compounds.[7] Pot stills typically produce distillate at 60-80% ABV after multiple runs, preserving character, while column stills can exceed 95% ABV in a single pass, prioritizing volume and neutrality.[8] Innovations like hybrid stills combine elements for versatility, underscoring the still's evolution from artisanal tool to industrial cornerstone.[9]

Definition and Principles

Core Definition and Etymology

A still is a distillation apparatus used to separate components of a liquid mixture by exploiting differences in their boiling points. The device typically consists of a heated vessel, such as a pot or boiler, where the mixture is vaporized, a condenser to cool and liquefy the vapors, and a collection receiver. This process selectively boils more volatile substances first, allowing their vapors to be condensed separately from less volatile residues. Stills are employed in producing alcoholic beverages, essential oils, pharmaceuticals, and purified water.[2][10] The term "still" derives from Middle English "stillen," a variant of "distillen," which traces back to Latin "destillare," meaning "to drip down" or "trickle." This nomenclature emphasizes the condensation phase, where purified liquid forms drops that trickle from the condenser. The apparatus has been referred to as a still since at least the late medieval period, evolving from earlier descriptive terms for distillation equipment that highlighted the dripping action central to the process.[11][3][2]

Thermodynamic and Chemical Principles

Distillation in a still separates components of a liquid mixture based on differences in their vapor pressures and boiling points, exploiting selective evaporation and condensation.[12] The process begins with heating the mixture, causing the more volatile (lower boiling point) components to vaporize preferentially, producing a vapor phase enriched in those components relative to the liquid.[12] This vapor is then condensed to yield a distillate with altered composition, while less volatile residues remain in the still.[13] The thermodynamic foundation lies in vapor-liquid equilibrium (VLE), where the liquid and vapor phases coexist at a given temperature and pressure, governed by the equality of fugacities for each component.[14] For ideal binary mixtures, Raoult's law applies, stating that the partial vapor pressure of a component , where is the liquid mole fraction and is the pure component vapor pressure at the system temperature.[15] The total pressure follows Dalton's law as the sum of partial pressures, determining the bubble point (onset of boiling) and dew point (onset of condensation).[16] Deviations from ideality, common in real mixtures like ethanol-water, introduce activity coefficients, leading to non-ideal VLE curves that can form azeotropes limiting complete separation.[17] Chemically, distillation is a physical separation without altering molecular structure, relying on intermolecular forces influencing vapor pressures rather than reactions.[18] The enthalpy of vaporization () quantifies the energy required per mole to transition from liquid to vapor, typically 20-40 kJ/mol for organic solvents at standard conditions, driving the phase change.[19] Entropy increases during mixing reversal, aligning with the second law, as separation reduces Gibbs free energy through phase partitioning.[20] Heat transfer in the still—conduction through vessel walls, convection in the boiling liquid, and latent heat absorption—ensures efficient vapor generation, with reflux (vapor re-condensation) enhancing purity in advanced designs by promoting repeated VLE stages.[19]First-Principles of Separation Efficiency

Separation efficiency in distillation fundamentally derives from differences in the vapor-liquid equilibrium (VLE) behaviors of mixture components, enabling selective vaporization and condensation. The core metric quantifying this separability is relative volatility, , defined for components and as , where and denote equilibrium vapor and liquid mole fractions, respectively.[21][22] For ideal solutions obeying Raoult's law, approximates the ratio of pure-component saturation vapor pressures, , at the prevailing temperature, reflecting intrinsic differences in molecular intermolecular forces and thus boiling tendencies.[23] Values of permit enrichment of the more volatile component () in the vapor phase, with the degree of enrichment scaling directly with ; as approaches 1, separation becomes thermodynamically infeasible without excessive stages or energy input.[24] In a single-stage equilibrium contact, such as a basic pot still, the maximum separation is limited: the vapor composition for binary systems, yielding modest purity gains per vaporization-condensation cycle.[12] This inefficiency arises because the liquid phase depletes in volatiles over time, requiring repeated batch operations or continuous feed adjustments for higher recovery. Efficiency, often expressed as the ratio of actual to ideal separation (e.g., via Murphree efficiency for trays), is causally tied to mass transfer rates across the interface, governed by Fickian diffusion and Henry's law constants for non-ideals, but fundamentally capped by VLE constraints.[25] To achieve high-purity separations, multiple equilibrium stages—emulated via reflux in batch stills or packing/trays in columns—counteract entropy of mixing by leveraging the logarithmic dependence of required stages on , as derived from the Fenske equation for minimum trays under total reflux: N_\min = \frac{\log[(x_D/(1-x_D))/(x_B/(1-x_B))]}{\log \alpha}.[23] Deviations from ideality, such as azeotropes where at specific compositions, impose hard limits, necessitating alternative methods like extractive distillation. Empirical tray efficiencies typically range 50-90% due to hydrodynamic and kinetic resistances, underscoring that thermodynamic favorability () sets the baseline while engineering amplifies it.[25][21]Historical Development

Ancient and Pre-Industrial Origins

The earliest archaeological evidence of distillation apparatus dates to approximately 3500 BCE in Mesopotamia (modern-day Iraq), where fragments of clay or terracotta devices, likely used for separating aromatic compounds through vaporization and condensation, were discovered at sites such as Tepe Gawra.[26][27] These primitive stills, consisting of heated vessels connected to receivers via simple tubing or direct condensation surfaces, facilitated the production of perfumes and essential oils from plant materials rather than alcoholic beverages, reflecting an empirical understanding of phase changes without advanced theoretical frameworks.[28] Similar terracotta setups appear in the Indus Valley Civilization around 2500–2000 BCE, suggesting parallel independent developments in South Asia for extracting volatile substances from fermented or botanical sources.[29] In ancient Egypt, distillation techniques evolved for perfumery and medicinal preparations by the 2nd millennium BCE, with textual and iconographic evidence from temple reliefs at Memphis depicting apparatus akin to basic pot stills employing water baths for gentle heating.[4] Greek philosophers, including Aristotle (384–322 BCE), provided early textual descriptions of distillation as a natural process involving the evaporation and recondensation of vapors, though practical apparatus remained rudimentary until Hellenistic Alexandria around the 2nd century BCE, where multiple still variants—pot, retort, and pelican types—were employed by alchemists for purifying substances like mercury and acids.[30] These devices operated on batch principles, heating mixtures in sealed vessels to drive off vapors captured in cooled receivers, achieving modest separation efficiencies limited by material purity and lack of reflux mechanisms.[28] During the Islamic Golden Age, from the 8th to 13th centuries CE, scholars like Jabir ibn Hayyan (c. 721–815 CE, known as Geber) systematically refined distillation apparatus, introducing the alembic (from Arabic al-anbiq), a glass or metal pot still with a swan-neck condenser that improved yield and purity for both non-potable distillates and early aqua vitae.[4] This innovation, documented in treatises emphasizing empirical experimentation, enabled fractional distillation of alcohol from wine, marking a causal shift toward potable spirits for medicinal use, though yields remained low due to empirical trial-and-error rather than thermodynamic optimization.[31] Knowledge of these alembic stills spread to Europe via translations in the 12th century, where monastic distillers adopted copper pot stills for producing therapeutic elixirs, as evidenced by records from Salerno's medical school around 1100 CE; these pre-industrial setups prioritized small-scale batch operation, with capacities rarely exceeding a few liters, constrained by fuel efficiency and corrosion-resistant materials like copper for its catalytic removal of sulfides.[30][32]Advancements in Europe and Colonial Era

In the 12th century, distillation techniques reached Europe primarily through translations of Arabic texts preserved by scholars in Spain and Italy, enabling the production of aqua vitae (water of life), an alcoholic spirit initially used for medicinal purposes by monastic orders.[33] Monks refined simple pot stills, often made of clay or copper, heating fermented wine or ale to capture vapors via rudimentary condensers, marking a shift from purely alchemical pursuits to practical application in healing and preservation.[34] By the 13th century, figures like Arnold of Villanova documented improved alembic designs with descending condensers, enhancing purity and yield for spirits like brandy, as detailed in treatises emphasizing fractional distillation for therapeutic elixirs.[35] During the Renaissance (14th–17th centuries), European alchemists and distillers advanced still efficiency through better metallurgy and geometry; for instance, the adoption of coiled worm tubing in copper stills improved vapor cooling and separation, reducing impurities in rectified spirits.[36] In 1603, French physician Claude Dariot described steam distillation in his treatise, using enclosed boilers to gently heat mashes without direct fire contact, preventing scorching—a method later replicated by Johann Glauber in 1648 for volatile oils and alcohols, allowing safer scaling for commercial aquavitae production across Germany and the Low Countries.[37] These innovations prioritized reflux control, where partial vapor re-condensation increased alcohol concentration, as evidenced in 16th-century German texts on brennweyn (burnt wine), laying groundwork for beverage-focused distillation amid rising demand from trade and urbanization.[38] The colonial era (late 16th–18th centuries) saw European still designs exported to the Americas, Africa, and Asia, adapted for New World crops like sugarcane and corn, though core pot still technology remained batch-oriented with minimal mechanical changes.[39] In the Caribbean, British and French planters in Barbados established rum distillation around 1650 using molasses from sugar refineries, employing copper pot stills with lyne arms for double distillation to yield potable spirits for sailors and slaves, boosting colonial economies via triangular trade.[40] In North America, Dutch settler Cornelius van Tienhoven distilled the first recorded brandy from imported European wine in New Netherland (now New York) by 1640, while Scots-Irish immigrants in Pennsylvania adapted wooden pot stills for corn-based whiskey by the 1680s, incorporating indigenous maize cultivation techniques to sustain frontier production amid scarce barley.[41] These adaptations emphasized durability for remote operations, with earthen or wooden hybrids emerging, but lacked novel designs until 19th-century industrialization, relying instead on empirical tweaks for local feedstocks like agave in Mexico or fruit in South America.[42]Industrial-Scale Innovations (18th-19th Centuries)

During the 18th century, distillation primarily relied on batch-operated pot stills, with incremental improvements focused on material durability and minor efficiency gains, such as the use of tin-coated copper arms and worms to prevent corrosion and enhance heat transfer in Scottish Lowlands distilleries.[43] These refinements allowed for slightly larger operations but did not fundamentally alter the labor-intensive, discontinuous nature of production, limiting output to small-scale volumes unsuitable for emerging industrial demands.[43] The transition to industrial-scale distillation accelerated in the early 19th century with the development of continuous column stills, which enabled uninterrupted operation and vastly increased throughput. In 1826, Robert Stein, a distiller at the Cameronbridge facility in Scotland, patented the first viable continuous still design, incorporating a rectifying column that separated vapors through multiple stages of condensation and re-vaporization, boosting annual production capacity from approximately 5,000 gallons in traditional pot stills to over 150,000 gallons.[44][45][46] This innovation addressed inefficiencies in batch processing by maintaining a steady flow of wash and distillate, reducing fuel consumption and operational downtime.[44] Building on Stein's work, Irish inventor Aeneas Coffey patented an enhanced two-column continuous still in 1830, featuring perforated plates for improved rectification and interconnected columns for sequential vapor enrichment, which further optimized purity and yield for neutral spirits production.[44][47] Coffey's design, often called the patent still, was rapidly adopted across Europe and North America, facilitating the mass production of rectified spirits like gin and grain whiskey, and laying the groundwork for modern industrial distilleries by minimizing human intervention and scaling output to meet burgeoning consumer markets.[48][44] Preceding these by two decades, French inventor Jean-Baptiste Cellier-Blumenthal constructed the first vertical fractionation column still in 1808, patented in 1813, which introduced multi-stage vapor separation but saw limited immediate commercial success compared to later Anglo-Irish iterations.[49] Additional auxiliary innovations, such as William Grimble's 1825 tube condenser, complemented column stills by improving vapor capture efficiency and enabling safer, larger-scale heat management.[44] These advancements collectively shifted distillation from artisanal craft to mechanized industry, prioritizing volume and consistency over the flavor complexity retained in traditional pot methods.[46]Types and Designs

Batch Distillation Stills

Batch distillation stills operate by processing a discrete quantity of liquid feedstock, known as the charge, loaded into the still pot prior to each run. The mixture is heated to produce vapor, which is then condensed and collected as distillate, with the process continuing until the desired separation is achieved or the pot is depleted of volatiles. This method contrasts with continuous distillation by requiring shutdowns for charging, emptying residues, and cleaning between cycles.[50] The core principle relies on the differential volatility of components in the mixture, where lower-boiling-point substances vaporize preferentially, leading to a distillate composition that evolves over time—initially richer in lighter fractions and progressively heavier as distillation proceeds. In a simple batch setup, such as a Rayleigh distillation without reflux, the vapor-liquid equilibrium shifts as the pot liquid depletes, modeled by equations like , where is residual liquid mass, its composition, and the relative volatility. Operators monitor temperature, alcohol content, and sensory qualities to make cuts separating foreshots (volatile impurities), hearts (desired product), and tails (higher-boiling residues).[51] Common designs include the pot still, featuring a spherical or cylindrical boiler with a swan-neck vapor pipe leading to a condenser, often constructed from copper to catalyze reactions removing sulfur compounds and enhancing flavor. Alembic stills, an early variant, incorporate similar batch operation with a cucurbit pot and phial head for vapor collection. These setups predominate in artisanal spirit production, where batch flexibility allows retention of congeners—flavor compounds like esters and fusel oils—that contribute to the complexity of whiskies, rums, and brandies. Historical records trace batch pot stills to medieval Europe, with refinements by the 15th century enabling higher-proof spirits from fermented mashes.[52][3] Operationally, batch stills suit small-to-medium scales, with capacities from laboratory 1-5 liters to industrial 10,000+ liters, heated via direct fire, steam jackets, or electric elements. Advantages encompass adaptability for varying feedstocks, precise cut-making for quality control, and lower capital costs for startups, as evidenced by craft distilleries favoring pots for single-malt scotch yielding 60-70% alcohol per run after multiple distillations. However, drawbacks include intermittent production limiting throughput—typically 1-2 batches daily versus continuous systems' steady output—and higher energy use per unit volume due to repeated heat-up and cool-down phases. Efficiency hovers at 70-80% recovery of ethanol, versus 95%+ in continuous columns, making batch methods less economical for high-volume neutral spirits like vodka.[53][54] In alcohol production, batch stills excel for premium categories requiring character preservation, such as Irish whiskey distilled thrice in pots to achieve 80% ABV hearts. Modern optimizations, like automated temperature controls and reflux augmentation via thumpers or doublers, mitigate inefficiencies while preserving batch hallmarks. Empirical data from distilleries indicate pot still congeners (e.g., 200-500 mg/L higher esters than column spirits) drive sensory profiles validated in GC-MS analyses.[52]Continuous Distillation Stills

Continuous distillation stills, also known as column stills, enable ongoing separation of volatile components from a liquid feed without interruption, contrasting with batch processes that require sequential filling, heating, and emptying.[46] These apparatus typically consist of a vertical column divided into sections with trays, bubble caps, or structured packing that facilitate repeated vapor-liquid contacts, achieving multiple theoretical distillation stages in a single pass.[55] The design relies on countercurrent flow: preheated feed enters mid-column, vapors rise from the base driven by reboiler heat, and condensed reflux descends from the top, enriching the vapor in lower-boiling components like ethanol.[56] The foundational patent for a practical continuous still was granted to Irish inventor Aeneas Coffey in 1830, building on earlier designs such as Robert Stein's 1826 apparatus and Jean-Baptiste Cellier-Blumenthal's 1813 patent.[46][48] Coffey's two-column system—an analyzer for initial vaporization and a rectifier for further purification—allowed for efficient, large-scale production of high-proof spirit at lower cost, revolutionizing industrial distillation.[44] By the mid-19th century, adoption spread in Scotland and Ireland for neutral grain spirits, though traditional pot still advocates criticized the output for lacking congeners that impart flavor complexity.[57] In operation, a continuous stream of fermented wash (typically 6-10% ABV) is fed into the column base or mid-section, where indirect steam heating vaporizes volatiles, which ascend through trays promoting intimate contact with descending cooler liquid.[58] Reflux ratios, controlled by overhead condenser withdrawal rates, determine output purity; ratios above 5:1 yield near-azeotropic ethanol (95.6% ABV) suitable for vodka rectification.[56] Modern variants incorporate packed columns for enhanced mass transfer efficiency, reducing pressure drop and enabling operation at atmospheric or vacuum conditions to preserve heat-sensitive compounds.[59] Compared to batch pot stills, continuous systems offer superior throughput—operating indefinitely with minimal downtime—and energy savings of 20-30% per unit alcohol due to optimized heat integration via reboilers and preheaters.[60] Scalability favors industrial volumes exceeding 1,000 liters per hour, ideal for neutral spirits in vodka or blended whiskies, though the process strips fusel oils and flavor esters, necessitating post-distillation additions for character in some products.[61][62] Safety features include automated controls for temperature, pressure, and flow to mitigate risks like foaming or flooding, with stainless steel construction predominating for corrosion resistance in acidic feeds.[63]Specialized Variants (e.g., Hybrid and Reflux)

Reflux stills are column-based distillation apparatuses that achieve high ethanol purity through the controlled return of condensed vapors—termed reflux—to the column, facilitating multiple theoretical separation stages in a single operation.[64] This process relies on vapor-liquid equilibrium, where ascending ethanol-rich vapors contact descending reflux liquid on packing materials or trays, selectively volatilizing ethanol while heavier congeners drain downward.[65] Reflux ratios, typically ranging from 1:1 to 5:1 (returned condensate to product distillate), dictate purity; higher ratios yield near-azeotropic concentrations above 95% ABV, essential for neutral spirits like vodka. Design variants include packed columns using random or structured media for efficient mass transfer and tray columns with sieve, valve, or bubble-cap trays to promote intimate contact.[65] Valved reflux stills incorporate adjustable column valves to modulate internal reflux independently of boiler heat, allowing distillers to balance purity with retention of desirable flavors during operation.[66] In continuous reflux systems, such as those derived from Aeneas Coffey's 1830 patent, steady-state operation maintains constant reflux via external condensers and pumps, enabling industrial-scale production with energy efficiencies surpassing batch methods.[58] Hybrid stills integrate a pot still boiler with an attached rectification column, providing configurable modes between low-reflux pot-like distillation for flavor preservation and high-reflux column operation for impurity removal.[67] This versatility stems from diverter valves and bypass piping, enabling single-pass production of spirits ranging from whiskey (operated without full column engagement) to high-proof vodka or gin (with column rectification up to 96.5% ABV).[68] Adopted widely in craft distilleries post-2010, hybrids reduce equipment needs and operational costs for multi-product facilities while leveraging copper-stainless construction for corrosion resistance and flavor catalysis.[69][70]Construction and Operation

Materials and Fabrication Techniques

Copper remains the predominant material for traditional pot stills in spirits distillation due to its chemical reactivity with sulfur compounds, such as hydrogen sulfide, generated during fermentation; these compounds bind to copper surfaces under distillation conditions, forming insoluble precipitates that are removed, thereby reducing off-flavors and odors in the output.[71][72] Copper's high thermal conductivity, approximately 400 W/m·K, facilitates efficient heat transfer, minimizing energy loss and enabling precise temperature control during operation.[73][74] Stainless steel, particularly grades like 304 or 316, is favored for continuous column stills and modern hybrid designs owing to its superior corrosion resistance against acidic washes, mechanical durability under high pressure, and hygienic properties that simplify cleaning and prevent microbial contamination.[75][76] Unlike copper, stainless steel does not impart reactive benefits, prompting some distillers to incorporate copper packing, mesh, or plates within steel columns to mimic sulfide removal.[72] Fabrication of copper stills traditionally involves coppersmithing techniques, where sheets of high-purity copper (often 99.9% pure) are cut, hammered, or spun into components like pots, domes, and lyne arms, then joined using silver soldering or riveting to create vapor-tight seals without lead-based materials that could contaminate the distillate.[77] Modern copper fabrication may employ computer numerical control (CNC) machining for precision shaping and tungsten inert gas (TIG) welding for seams, ensuring consistency in large-scale production.[78] Stainless steel stills are typically constructed via precision welding methods, such as TIG or plasma arc welding, on pre-formed sheets or tubes, followed by electropolishing to enhance surface smoothness and corrosion resistance.[75] Historical distillation apparatuses, dating to 3500 BC in Mesopotamia, utilized terracotta or early bronze for basic separation, evolving to glass retorts in medieval Europe for laboratory-scale work where transparency allowed visual monitoring.[26] In contemporary non-spirits applications, such as pharmaceutical purification, borosilicate glass or quartz is preferred for its chemical inertness and resistance to thermal shock.[79]

Operational Mechanics and Control Parameters

The operational mechanics of a distillation still rely on the principles of vapor-liquid equilibrium, where differences in component volatilities drive separation through selective vaporization and condensation. A liquid mixture, or charge, is heated in a reboiler or pot, causing the more volatile components to vaporize preferentially and rise as vapor, while less volatile residues remain liquid. This vapor contacts cooler surfaces or descending liquid (in reflux-equipped designs), leading to partial re-condensation and enrichment of the vapor phase in lighter fractions, with the process governed by Raoult's law and relative volatility metrics.[80][81] In batch stills, such as traditional pot designs, the process operates discontinuously: a fixed volume of charge is heated to boiling, vapors ascend through a simple lyne arm or short column to a condenser, where they liquefy into distillate collected in sequential cuts—foreshots (low-boiling impurities), hearts (desired product), and tails (higher-boiling fractions)—based on monitored vapor temperature or alcohol content to avoid contamination.[58] This yields variable composition over time, with energy demands around 11,000–12,000 BTU per gallon for 90% ethanol production, roughly three times higher than continuous systems due to repeated equilibrations.[58] Continuous stills, often column-based like Coffey or packed designs, enable steady-state operation with ongoing feed introduction at mid-column, bottom heating to generate rising vapors, and countercurrent contact with reflux liquid descending from the top condenser, achieving multiple theoretical stages (trays or packing equivalents) for progressive purification.[80] Vapors exit the top for condensation, with a portion refluxed to enhance separation efficiency, while bottoms are withdrawn continuously; this setup handles large volumes efficiently but requires stable feed composition.[54] Key control parameters optimize separation, purity, and throughput across both modes. Reflux ratio—the proportion of condensed overhead returned to the column versus withdrawn as product—directly trades off purity against energy use, with higher ratios (e.g., >5:1) yielding purer distillate via increased vapor-liquid contacts but raising reboiler duty.[80][54] Boil-up rate, or vapor generation from the reboiler, influences mass transfer rates and separation sharpness, typically adjusted via heat input to maintain column flooding limits without excessive energy.[80] In batch operation, still pot temperature serves as a primary indicator for cut transitions, reflecting composition shifts as volatiles deplete, while continuous systems emphasize pressure control (atmospheric or vacuum to lower boiling points for heat-sensitive feeds) and feed/distillate flow rates for steady profiles.[58][80][54]| Parameter | Role in Batch Stills | Role in Continuous Stills | Impact on Operation |

|---|---|---|---|

| Reflux Ratio | Adjusted dynamically for purity during cuts | Set for steady-state purity vs. throughput | Higher values enhance separation but increase energy costs[54][80] |

| Still Pot Temperature | Monitors composition for cut decisions | Less variable; used for bottoms quality | Guides impurity rejection; deviations signal process instability[58][54] |

| Pressure | Often atmospheric; vacuum for sensitive materials | Controlled to adjust boiling points | Reduces thermal degradation risk in vacuum mode[80] |

Scaling from Laboratory to Industrial

Laboratory-scale distillation stills typically employ batch processes with capacities of 1 liter or less, utilizing glassware for direct observation and precise manual control of heating and condensation.[82] Industrial stills, by contrast, process volumes exceeding 1,000 liters per batch in pot designs—such as 1,700-liter (450-gallon) units yielding approximately 72 proof gallons of spirit per run—or enable continuous operation for higher throughput, prioritizing efficiency and product consistency over visual accessibility.[83][84] Scaling introduces engineering challenges rooted in fluid dynamics and thermodynamics, including non-linear increases in heat transfer demands relative to volume, which necessitate larger surface areas for boiling and condensation to avoid hotspots and ensure uniform vapor-liquid equilibrium.[85] Pot stills, favored for retaining congeners that contribute to spirit flavor, face efficiency limitations at larger sizes due to prolonged batch cycles and reduced reflux control, often requiring multiple parallel units or hybrid designs rather than simple enlargement.[86] Continuous column stills mitigate these by facilitating ongoing fractionation, as exemplified by Aeneas Coffey's 1830 patented design, which boosted whiskey production scalability; by 1876, 17 such stills operated in Scotland, enabling lighter, higher-volume grain whisky output that transformed industrial distilling.[87][48] Material selection shifts from inert glass in labs to metals suited for thermal conductivity and chemical interaction: copper predominates in spirits stills for its catalytic removal of sulfur compounds, yielding cleaner, more aromatic distillates, though stainless steel offers superior durability, corrosion resistance, and ease of sanitation at the cost of inferior heat distribution and no sulfide scavenging.[75][76] Hybrid constructions, with copper vapor contact surfaces over stainless bodies, balance these properties for large-scale reliability.[88] Operational controls advance from manual thermometers to automated systems with sensors for temperature, pressure, and reflux ratios, essential for maintaining separation fidelity across vast scales where minor deviations amplify yield losses or quality inconsistencies.[89] Pilot-scale testing, often at 10-100 times lab volume, validates these parameters empirically, accounting for phenomena like flooding or weeping in trays and packing that deviate from small-scale predictions.[90] Safety scales analogously, with reinforced pressure vessels and explosion-proof instrumentation addressing heightened risks from larger vapor volumes and energy inputs.[91]Applications

Production of Distilled Spirits

Distilled spirits are produced by heating fermented washes or mashes in stills to vaporize and condense ethanol, concentrating alcohol content from typically 6-12% ABV to 40% or higher while separating impurities.[92] [93] This distillation exploits ethanol's lower boiling point of 78.4°C compared to water's 100°C, allowing selective vaporization under controlled heat.[94] In practice, the process yields three fractions: foreshots (volatile heads discarded for safety due to methanol), hearts (desirable ethanol-rich middle cut), and tails (fusel oils often recycled or discarded).[92] Pot stills dominate batch production of flavorful spirits like Scotch whisky and rum, operating by charging the still with wash, heating to boil, and collecting distillate in runs that retain congeners for complexity.[95] Single malt Scotch whisky, for instance, undergoes double or triple pot still distillation, with the second run often reaching 60-70% ABV before dilution and barrel aging as mandated by UK regulations.[31] Rum production similarly favors pot stills for "heavy" styles, where batch processing preserves ester-rich profiles from molasses washes, contrasting lighter column-distilled variants used in blends.[96] Column stills enable continuous distillation for neutral spirits such as vodka and gin bases, achieving higher efficiency and purity through multiple vapor-liquid equilibria in stacked plates or packing.[6] Vodka requires rectification to minimize congeners, often via tall columns distilling to 95% ABV, followed by filtration and dilution to 40% ABV per EU standards defining it as neutral alcohol flavored minimally if at all.[97] In the US, bourbon whiskey employs column stills for initial stripping runs to no more than 160 proof (80% ABV), with doubler pot stills for rectification, per TTB standards ensuring flavor retention within legal proof limits.[98] Hybrid systems combine pot and column elements for versatility, as in many American whiskeys, balancing efficiency with character.[95] Post-distillation, hearts are proofed down, with aging in oak for whiskies (minimum 3 years for Scotch) or immediate bottling for unaged spirits like vodka, all under strict ABV and composition rules to prevent adulteration.[99] Copper in still construction reacts with sulfides to purify output, a practice rooted in empirical tradition for cleaner spirits.[92]Non-Alcoholic Industrial and Pharmaceutical Uses

Distillation stills find extensive application in pharmaceutical manufacturing for producing Water for Injection (WFI), a critical component requiring bacterial endotoxin levels below 0.25 EU/mL and conductivity under 1.3 μS/cm at 25°C to comply with standards such as USP <643> and <645>. Multiple-effect stills, which cascade vapor from one evaporation chamber to heat subsequent ones, achieve this through successive distillation stages, yielding pyrogen-free water with energy efficiencies up to 90% compared to single-effect systems.[100] [101] In API synthesis, batch and fractional distillation stills separate heat-sensitive intermediates and final compounds by exploiting differences in vapor pressures, often under vacuum to minimize thermal decomposition; for instance, this process isolates pharmaceuticals like antibiotics or analgesics from reaction mixtures containing impurities with boiling points differing by as little as 10–20°C.[102] Such purification ensures compliance with ICH Q3A guidelines on residual solvents and impurities, with recovery rates exceeding 95% in optimized setups.[103] Beyond pharmaceuticals, industrial stills produce high-purity distilled water for applications in electronics (e.g., semiconductor rinsing requiring resistivity >18 MΩ·cm) and power generation (boiler feed to prevent scaling), via simple or multi-stage pot stills that remove minerals and organics through repeated vaporization-condensation cycles.[104] In chemical processing, they distill non-volatile impurities from solvents like toluene or acetone, enabling reuse in paints, adhesives, and polymer production, with throughput capacities scaling to 10,000 L/h in continuous variants adapted from traditional still designs.[105] These uses prioritize stainless steel or glass-lined construction to avoid contamination, contrasting with copper stills in alcoholic contexts.[104]Emerging Uses in Biofuels and Essential Oils

In biofuel production, distillation stills play a critical role in purifying bioethanol from fermented biomass, separating ethanol from water and fusel oils through fractional distillation. Industrial processes typically employ multi-column continuous stills, such as beer columns followed by rectification columns, achieving ethanol concentrations of 92-95% by mass before dehydration.[106] Batch distillation variants, including extractive methods using entrainers like glycerol, have been explored to enhance separation efficiency in smaller-scale or variable feedstock operations.[107] Emerging applications focus on energy optimization; for instance, revamped distillation systems in ethanol plants reduce steam consumption by up to 20-30% through redesigned vapor-liquid flows and heat integration, lowering operational costs and carbon footprints as of 2025 implementations.[108] These advancements support advanced biofuels from lignocellulosic feedstocks, where hybrid still designs handle higher impurity loads from non-food biomass.[109] For essential oils, steam distillation stills vaporize volatile compounds from plant materials by passing steam through perforated baskets or packed columns, with oils separating upon condensation due to density differences. Traditional copper or stainless steel alembic-style stills predominate in commercial extraction, yielding 0.5-5% oil by plant weight depending on species like lavender or eucalyptus.[110] Recent innovations integrate ultrasound-assisted hydrodistillation into still setups, accelerating extraction times by 50-70% and improving yields by disrupting cell walls without thermal degradation, as demonstrated in pilot-scale systems for rosemary and thyme.[111] Microwave-assisted variants enhance steam generation within the still, reducing energy use by 40% compared to conventional heating while preserving bioactive terpenes, per 2023-2024 process evaluations.[112] Patent analyses indicate a shift toward automated, sensor-equipped stills for real-time parameter control, addressing inefficiencies in yield consistency amid rising demand for sustainable botanicals.[113] These developments enable scalable production from underutilized agro-waste, minimizing solvent residues inherent in alternatives like supercritical extraction.[114]Safety and Risk Management

Inherent Hazards and Causal Factors

The primary inherent hazards associated with distillation stills stem from the flammability of vapors generated during the heating and vaporization of organic compounds, particularly alcohols like ethanol and methanol, which have low flash points of approximately 13–17°C for ethanol and 11–12°C for methanol.[115][116] These vapors, released from leaks, incomplete condensation, or inadequate venting, can form explosive mixtures with air when concentrations fall within the flammable range, typically 3.3–19% by volume for ethanol.[117] Causal factors include the exothermic nature of boiling processes, which concentrates volatile components and elevates local temperatures, combined with ignition sources such as hot boiler surfaces exceeding the autoignition temperature of ethanol at 363°C or sparks from mechanical agitation.[115][118] Explosion risks arise from confined vapor accumulation within the still or connected piping, where pressure build-up from rapid vapor expansion—driven by uncontrolled heat input or blockages—can exceed vessel design limits, leading to rupture.[119] In batch operations common to spirits production, uneven heating or foam-over from impurities can cause sudden vapor surges, exacerbating overpressurization; empirical analyses of industrial incidents attribute such events to thermal runaway in reactive distillates or air ingress oxidizing flammable atmospheres.[120] Still designs without adequate relief valves or burst disks amplify these factors, as the phase change from liquid to vapor inherently increases volume by factors of 100–500 times at atmospheric pressure.[121] Secondary hazards include thermal burns from contact with superheated liquids or steam at 100–150°C during operation, caused by material failures like weld cracks under cyclic thermal stress or corrosion from acidic congeners in mashes.[122] Toxic exposures, such as methanol vapors with neurotoxic effects, result from incomplete separation in pot stills, where higher-boiling impurities carry over due to azeotropic limitations or insufficient reflux.[117] While fires and explosions in properly maintained equipment remain rare relative to operational volume, causal chains often trace to inherent process thermodynamics—vapor pressure curves dictating release rates—interacting with design tolerances, underscoring the need for empirical validation of safety margins through pressure-temperature testing.[123]Mitigation Strategies and Empirical Data on Incidents

Mitigation strategies for hazards in distillation stills emphasize engineering controls, administrative procedures, and personal protective equipment (PPE) to address primary risks such as flammable vapor ignition, pressure buildup, and thermal runaway. Engineering controls include installing explosion-proof electrical equipment, flame arrestors on vents, and pressure relief valves to prevent over-pressurization during heating or blockages.[124] Ventilation systems must maintain ethanol vapor concentrations below 25% of the lower flammable limit (LFL), typically achieved through explosion-rated fans and monitoring sensors, while stills should be grounded to mitigate static electricity sparks.[122] Automatic shutoff systems tied to temperature and pressure sensors, along with regular integrity inspections of boilers and columns under OSHA Process Safety Management (PSM) standards, reduce operational failures.[125] Administrative measures involve operator training on hazard recognition, standardized operating procedures limiting charge volumes to prevent foaming overflows, and prohibiting open flames or hot work near active stills.[126] Distilleries often segregate still operations from storage areas by at least 100 feet, with fire-rated barriers, and mandate fire suppression systems like sprinklers designed for high-hazard occupancies per NFPA 13.[122] PPE such as flame-resistant clothing, chemical-resistant gloves, and respirators is required for handling hot liquids or vapors, complemented by emergency response plans including spill containment and evacuation drills.[127] Empirical data on still-related incidents reveal they are infrequent relative to operational volume but often severe, primarily involving fires or explosions from ignition of ethanol vapors or structural failures. Historical records document 48 fatalities across 10 major distillery disasters from 1919 to 2013, with causes including lightning strikes, overheating beyond boiling points, and tank ruptures leading to spills that ignited.[128] For instance, the 1960 Cheapside Street whisky bond fire in Glasgow resulted from whisky exceeding its boiling point, causing an explosion that killed 19 firefighters and destroyed 1 million gallons.[128] Similarly, the 1996 Heaven Hill Distillery fire in Kentucky consumed 90,000 barrels due to probable lightning ignition of vapors, representing about 2% of global whiskey stock at the time.[122]| Incident | Date | Cause | Consequences |

|---|---|---|---|

| Great Molasses Flood (Boston) | 1919 | Tank burst from thermal expansion | 2.3 million gallons spilled; 21 deaths, 150 injuries[128] |

| Cheapside Street Fire (Glasgow) | 1960 | Overheating explosion | 1 million gallons lost; 19 firefighter deaths[128] |

| Heaven Hill Fire (Kentucky) | 1996 | Lightning/vapor ignition | 90,000 barrels destroyed; no deaths[122] |

| Wild Turkey Fire (Kentucky) | 2000 | Warehouse fire | 17,000 barrels lost; 228,000 fish killed from runoff[128] |

| Lincolnshire Illicit Explosion (UK) | 2011 | Equipment failure in unlicensed operation | 5 deaths[128] |

Health Implications of Distilled Products

Distilled alcoholic beverages, produced via concentration of ethanol through distillation, carry health risks primarily attributable to ethanol itself, a known toxic metabolite that disrupts cellular function and DNA integrity. The World Health Organization states that no level of alcohol consumption is safe, with risks escalating dose-dependently from even low intake.[131] [132] Globally, alcohol accounts for 2.6 million deaths annually as of 2019, representing 4.7% of all mortality, including 401,000 from cardiovascular diseases, 398,000 from cancers, and 284,000 from injuries such as traffic accidents and violence.[132] [133] Acute effects include central nervous system depression leading to impaired coordination, judgment, and reaction times, elevating risks of falls, drownings, and motor vehicle crashes; binge consumption of high-proof spirits exacerbates rapid intoxication due to their concentrated ethanol content (typically 40% ABV or higher).[134] Chronic exposure causes liver pathology, with ethanol-induced inflammation progressing to alcoholic hepatitis and cirrhosis; distilled spirits, often consumed in larger ethanol volumes per sitting compared to beer or wine, correlate with higher incidence of acute pancreatitis and fatty liver disease.[135] [136] Ethanol is metabolized to acetaldehyde, a genotoxic intermediate that damages DNA and impairs repair mechanisms, contributing to carcinogenesis.[137] The International Agency for Research on Cancer classifies alcoholic beverages as Group 1 carcinogens, with sufficient evidence linking consumption to increased risks of oral cavity, pharyngeal, laryngeal, esophageal, liver, colorectal, and breast cancers; risk rises linearly with intake, independent of beverage type when adjusted for ethanol equivalents.[138] [139] Meta-analyses indicate no differential cancer risk between spirits, beer, and wine beyond ethanol dose, though congeners (e.g., methanol, fusel oils) in darker distilled products like whiskey may amplify oxidative stress and inflammation.[140] Cardiovascular claims of moderate benefits (e.g., J-shaped curve for heart disease) have been refuted by recent genetic and longitudinal studies, revealing confounders like former drinkers misclassified as abstainers; low-to-moderate intake instead associates with atrial fibrillation, hypertension, and stroke.[142] [143] Neurological and psychiatric harms encompass alcohol use disorder, affecting 5.1% of adults globally, with distilled spirits' potency facilitating dependence via reinforced reward pathways; withdrawal risks include seizures and delirium tremens.[132] Prenatal exposure causes fetal alcohol spectrum disorders, with no threshold for neurodevelopmental deficits.[134] Empirical data from cohort studies show spirits consumption patterns—often episodic and higher-volume—heighten overall morbidity compared to dilute forms, though ethanol remains the causal agent.[144] Cessation reduces risks substantially, with former drinkers exhibiting normalized cancer and liver outcomes within years.[138]Legal and Regulatory Aspects

Historical Prohibitions and Economic Controls

In 1791, the United States Congress enacted the first federal excise tax on distilled spirits, proposed by Treasury Secretary Alexander Hamilton to generate revenue for Revolutionary War debts, imposing rates of up to 9 cents per gallon on smaller producers based on proof strength and still capacity.[145] This tax, the nation's initial internal levy, disproportionately burdened frontier farmers who distilled surplus grain into whiskey for portable currency and barter, as cash payments were required despite scarce specie.[146] Resistance escalated into the Whiskey Rebellion of 1794 in western Pennsylvania, where armed insurgents tarred tax collectors and threatened federal authority, prompting President George Washington to mobilize 13,000 militia to suppress the uprising, affirming federal taxing power but highlighting distillation's economic centrality to rural livelihoods.[145] The tax persisted until its repeal in 1802 amid ongoing opposition, only to be reinstated during the War of 1812 for fiscal needs.[147] Temperance movements in the early 19th century framed distilled spirits as a moral hazard, leading to piecemeal state-level prohibitions; Tennessee enacted the U.S.'s first such law in 1838, criminalizing liquor sales in public venues while allowing private production, though enforcement faltered due to cultural entrenchment of spirits consumption.[148] By the 1850s, 13 states had banned hard liquor outright, driven by Protestant reformers citing empirical links between spirits and pauperism, crime, and family dissolution, yet these measures often collapsed under evasion via hidden stills and interstate smuggling.[149] The national culmination arrived with the 18th Amendment in 1919, effective January 17, 1920, prohibiting the manufacture, sale, transportation, and importation of intoxicating liquors including distilled spirits, enforced via the Volstead Act despite President Wilson's veto.[149] This era shuttered legal distilleries, spurring illicit operations with rudimentary stills that caused over 1,000 alcohol-related poisoning deaths annually from contaminated moonshine, while permitting limited medicinal production at six facilities like Brown-Forman.[150] Economic controls extended beyond taxes to monopolistic structures for revenue maximization and supply regulation; in late 19th-century America, the Whiskey Trust consolidated 80% of rye production by 1887 through predatory pricing and output restrictions, inflating prices until antitrust scrutiny under the 1890 Sherman Act fragmented it.[151] European precedents included French Indochina's alcohol monopoly from the 1900s, leveraging industrial distillation advances to centralize production and excise collection, yielding substantial colonial revenues but stifling local artisanal stills.[152] Post-Prohibition, Nordic countries like Norway established state monopolies such as Vinmonopolet in 1922 to ration spirits distribution, blending control motives with temperance goals and generating fiscal surpluses from high markups on imported and domestic distillates.[153] These mechanisms underscored distillation's dual role as a taxable commodity and perceived societal risk, often prioritizing state coffers over unfettered production despite black market proliferation.Current Global Licensing Frameworks

Licensing frameworks for distillation stills, particularly those used in alcohol production, are predominantly established at the national level, with no overarching global treaty imposing uniform standards; instead, regulations emphasize excise tax enforcement, public safety, and prevention of illicit production, reflecting causal links between unregulated distillation and revenue loss or health hazards from adulterated spirits.[154] In most jurisdictions, operating a still for beverage alcohol requires specific permits, while possession of equipment for non-alcoholic purposes (e.g., essential oils or fuels) often faces fewer barriers, though intent to produce spirits can trigger scrutiny.[155] International trade in distilled products involves compliance with importing countries' certification requirements, such as age and origin proofs, but does not directly regulate still ownership or operation.[156] In the United States, the Alcohol and Tobacco Tax and Trade Bureau (TTB) mandates a basic permit under 27 CFR Part 19 for any entity engaging in distilled spirits production, alongside an operations permit for distillery activities, with applications requiring detailed facility plans, equipment specifications, and bonding for tax liability; state-level liquor manufacturer licenses are additionally required, and federal law prohibits home distillation of beverage alcohol, classifying it as a felony punishable by fines up to $10,000 and imprisonment up to five years, though still ownership for non-alcohol uses is permissible without permit.[157] Over 2,500 craft distilleries operated under these frameworks as of 2023, illustrating regulatory adaptation to industry growth while maintaining strict oversight to curb tax evasion, which historically accounted for significant federal revenue—distilled spirits taxes generated approximately $10 billion annually in recent years.[154] European regulations vary by member state under the EU's harmonized spirits framework (Regulation (EU) 2019/787), which defines production standards but delegates licensing to national authorities; for instance, in the United Kingdom, HM Revenue & Customs requires distillers to obtain approval for premises and equipment, with distilled spirits relief allowing duty suspension during production, while home distillation remains illegal without license across most EU countries to prevent unmonitored alcohol output linked to higher poisoning risks from methanol contamination.[158] In contrast, New Zealand uniquely permits unlicensed home distillation for personal use up to 7 liters of pure alcohol annually under the Summary Offences Act 1981, provided it is not sold, reflecting empirical data showing low illicit production rates compared to stricter regimes.[159] Other nations impose analogous barriers: Australia mandates an excise license from the Australian Taxation Office for any distillation activity, with unlicensed operation carrying penalties up to AUD 222,000 in fines; Japan requires a minimum annual production of 3,000 kiloliters for spirits licenses, effectively barring small-scale craft operations until recent 2022 reforms eased entry for distilleries producing under 3,000 liters; and in South Africa, the National Liquor Act necessitates a manufacturing license with facility inspections, underscoring a global pattern where frameworks prioritize scalable, taxable production over personal liberty to mitigate societal costs from unregulated spirits, estimated at billions in lost excise revenue worldwide.[160] These disparate systems highlight tensions between economic controls—rooted in post-Prohibition revenue models—and emerging craft trends, with no evidence of convergence toward looser international norms as of 2025.[161]Debates on Home Distillation and Personal Liberty

The debate over home distillation centers on the tension between individual autonomy in producing spirits for personal consumption and government interests in revenue collection and public safety. In the United States, federal law prohibits distilling alcohol for beverage purposes without a permit, classifying it as a felony punishable by fines up to $10,000 and imprisonment for up to five years under 26 U.S.C. § 5601(a)(6) and § 5601(a)(8).[162] This ban, rooted in 19th-century revenue laws, contrasts with the legality of homebrewing beer and wine, permitted since the Homemade Wine and Beer Consumer Tax Simplification Act of 1978, allowing up to 200 gallons annually per household.[163] Advocates for reform argue that the prohibition infringes on personal liberty without commensurate justification, drawing parallels to historical practices where small-scale distillation was commonplace before excise taxes were imposed in 1791 to fund federal operations.[164] Proponents of legalization emphasize constitutional limits on federal power and consistency in private production rights. They contend that the ban exceeds Congress's taxing authority under Article I, Section 8, as it outright prohibits production rather than merely imposing taxes, a distinction sharpened after the 16th Amendment in 1913 shifted taxation from direct to income sources.[165] Organizations like the Buckeye Institute and Liberty Justice Center assert that upholding such a ban could justify intrusive regulation of any home activity under the guise of tax enforcement, eroding privacy and self-reliance akin to pre-Prohibition traditions.[166][167] Recent legal challenges, such as Hobby Distillers Association v. Alcohol and Tobacco Tax and Trade Bureau, culminated in a July 2024 federal district court ruling in Texas declaring the ban unconstitutional, granting an injunction against enforcement while noting that tax evasion concerns do not warrant a total prohibition.[168] This decision, currently under appeal, highlights arguments that home distillation fosters innovation, potentially seeding commercial ventures, as seen in state-level pushes like Maine's 2025 legislative efforts to permit small-scale personal stills.[169] Opponents, including federal regulators, prioritize empirical risks and fiscal imperatives over liberty claims. Distillation involves heating flammable vapors, raising fire and explosion hazards, with historical data linking improper home practices to methanol contamination and fatalities, as methanol—a byproduct of fermentation—concentrates in early distillate fractions if not discarded.[170][171] Government revenue from spirits excise taxes, at $13.50 per proof gallon, totals billions annually, and home production circumvents this, echoing evasion issues from the Whiskey Rebellion era when untaxed stills undermined federal authority.[172] Safety data, while showing home distilling fires comprise less than 0.14% of U.S. residential incidents, underscore that concentrated alcohol production amplifies dangers beyond brewing, justifying blanket restrictions to prevent widespread non-compliance.[130] Critics of liberalization, including some craft industry voices, warn that normalizing home distillation could exacerbate black-market dynamics without yielding net societal benefits, given regulated commercial alternatives ensure purity standards.[165] Internationally, the debate varies: New Zealand and the United Kingdom permit home distillation for personal use with quantity limits (e.g., 25 liters annually in the UK), reflecting a balance favoring liberty where tax losses are minimal, while Canada and Australia maintain U.S.-style prohibitions citing analogous safety and revenue rationales.[173] These divergences fuel U.S. discourse, with reform advocates citing lower abuse rates in permissive jurisdictions as evidence that education and limits suffice over outright bans, challenging claims of inherent causal risks.[164] Ultimately, the contention pits first-hand empirical incident rates against precautionary regulation, with ongoing litigation likely to clarify federal overreach boundaries.Economic and Cultural Impact

Contributions to Trade and Innovation

Distillation via stills facilitated the production of spirits with alcohol contents eight to nine times higher than wine, enabling efficient long-distance trade by minimizing volume, weight, and spoilage risks compared to beer or wine.[174] This portability supported colonial exchanges, such as the rum trade in the Atlantic triangle involving molasses from the Caribbean, distillation in New England, and export to Europe and Africa for slaves, underpinning mercantile economies from the 17th century onward.[175] Spirits constituted approximately 50% of global alcohol consumption by volume in historical assessments, driving export values that rivaled other commodities in profitability.[175] In contemporary terms, the distilled spirits sector generated $730 billion in gross value added (GVA) contributions to global GDP in 2022, equivalent to 1 in every $140 of worldwide economic output, with trade volumes sustaining multinational supply chains from raw materials to finished products.[176] U.S. spirits exports alone reached a record $2.4 billion in 2024, reflecting sustained demand despite tariffs and disruptions, while the global market was valued at approximately $146 billion in 2024, projected to grow at a 4.8% compound annual rate through 2029.[177][178] These figures underscore stills' role in scalable production that bolsters balance-of-payments for exporting nations like Scotland, Ireland, and the U.S., where whiskey and bourbon dominate trade surpluses.[179] Technological innovations in still design have amplified these trade contributions by enhancing efficiency and product diversity. The 1830 patent for the column still by Irish inventor Aeneas Coffey introduced continuous distillation, replacing batch pot stills with a multi-plate system that recycled vapors for higher purity and output rates up to ten times greater, fundamentally scaling industrial production.[35][180] This apparatus enabled lighter, neutral spirits suitable for blending and aging into premium whiskies, propelling Scotland's industry dominance by the mid-19th century as distillers adopted it for cost-effective volume.[48] Earlier advancements, such as copper pot stills refined in the 16th century, improved flavor extraction and impurity removal through copper's catalytic properties, fostering regional specialties like cognac and brandy that became trade staples.[181] Post-1830 refinements, including steam distillation patented in 1785, further optimized heat distribution and yield, laying groundwork for modern hybrid stills that support diversified outputs from vodka to biofuels precursors.[49] These developments not only reduced production costs—enabling competitive global pricing—but also spurred patent-driven R&D, with column stills' adoption correlating to exponential growth in spirits exports during the 19th and 20th centuries.[6]Illicit Production and Black Market Dynamics

Illicit production of distilled spirits typically involves unlicensed, often rudimentary stills operated in hidden locations to evade regulatory oversight, taxation, or outright bans on distillation. This practice, commonly known as moonshining in the United States or analogous activities globally, circumvents excise duties that can exceed 100% of production costs in many jurisdictions, enabling producers to offer products at significantly lower prices than legal alternatives. According to estimates from the Transnational Alliance to Combat Illicit Trade (TRACIT), illicit alcohol constitutes approximately 26% of global consumption on average, with shares reaching 15% in Latin America and higher in parts of Africa, resulting in substantial fiscal losses estimated at billions annually.[182] These operations rely on makeshift pot stills or converted equipment, which lack the precision of industrial setups, frequently leading to incomplete separation of distillate fractions and retention of hazardous congeners. Black market dynamics are driven by high profit margins from tax evasion and demand for affordable intoxicants, particularly in regions with stringent alcohol controls or poverty. In the U.S., post-Prohibition persistence of moonshine production stems from federal excise taxes on spirits, which can generate weekly revenues of around $6,000 per small operation without government payments, as noted in economic analyses of Appalachian distilling.[183] Globally, the illicit trade attracts organized crime groups due to low barriers to entry and high returns, with the OECD reporting that the sector's scale—tied to 6.2 liters of pure alcohol per capita worldwide in 2018—fuels smuggling networks and counterfeit operations blending industrial ethanol with flavors.[184] Historical precedents, such as U.S. Prohibition (1920–1933), demonstrate how bans amplify violence, as competing black market factions vied for control, elevating homicide rates through armed enforcement of territories.[185] Health risks from illicit distillation arise primarily from methanol contamination, a byproduct concentrated in the "heads" fraction if not discarded during improper cuts—a step often skipped to maximize yield. Peer-reviewed studies document outbreaks, including 59 methanol poisoning cases in Norway from 2002–2004 linked to home-distilled and smuggled spirits, and a 2024 U.S. incident where an illegal distiller's product, containing 35–40% methanol, caused three deaths, leading to a four-year prison sentence.[186][187] These hazards underscore causal links between regulatory evasion and adulteration, as producers prioritize volume over safety, contrasting with licensed facilities' quality controls; WHO data attributes thousands of annual deaths to such unrecorded alcohol, predominantly in low-income settings where enforcement is lax.[188] Economically, black markets distort legal industries by undercutting prices—illicit spirits can retail at 20–50% below taxed equivalents—while imposing externalities like lost revenue and enforcement costs. In developing economies, informal networks dominate, with production scaled via portable stills transported covertly, evading traceability. Mitigation efforts, such as enhanced border controls and chemical markers in legal products, have reduced volumes in some areas, but persistent demand sustains the trade, perpetuating cycles of innovation in evasion tactics among producers.[189]Criticisms and Societal Costs vs. Benefits

Distilled spirits, produced via stills, contribute to alcohol consumption patterns associated with significant global health burdens, including 2.6 million attributable deaths annually as of 2019, representing 4.7% of all deaths worldwide.[190] These include 1.6 million from noncommunicable diseases like liver cirrhosis and cardiovascular conditions, 720,000 from injuries such as traffic accidents and violence, and 284,000 from communicable diseases.[132] In the United States, excessive alcohol use led to 178,307 deaths per year during 2020–2021, a 29.3% increase from 2016–2017, shortening lives by an average of 24 years per decedent.[191] Economic costs encompass healthcare expenditures, lost productivity, and criminal justice involvement, totaling approximately 2.6% of global GDP or $1,306 international dollars per adult.[192] Social costs extend to family disruption, domestic violence, and impaired child development, with alcohol misuse exacerbating inequality through disproportionate impacts on lower-income groups.[193] Empirical analyses indicate that while moderate consumption may offer limited cardiovascular benefits in some cohorts, overall harms predominate, particularly from binge drinking facilitated by high-alcohol-content distilled products.[194] Critics argue the distillation industry externalizes these costs via marketing that normalizes heavy use, with peer-reviewed reviews concluding that public health negatives, including 116 million disability-adjusted life-years lost globally in 2019, far outweigh purported positives.[195] [193] In contrast, the legal distilled spirits sector generates substantial economic activity, contributing $730 billion in gross value added to global GDP in 2022, supporting 36 million jobs across production, distribution, and hospitality, and yielding $390 billion in government tax revenues.[176] In regions like Kentucky, distilling alone produced $357.5 million in state taxes in recent years, bolstering agriculture, tourism, and manufacturing.[196] Proponents highlight innovation in distillation techniques driving export trade, with the U.S. spirits industry adding $250 billion annually and 1.7 million jobs as of 2025.[197] Culturally, distilled beverages underpin traditions and social rituals in many societies, potentially fostering moderate enjoyment.[198] Weighing these, systematic reviews affirm that alcohol-related societal costs exceed industry benefits, with net global losses estimated at 1.5–2.6% of GDP after accounting for revenues, as harms like premature mortality and productivity declines eclipse fiscal gains.[199] [200] Distillation's concentration of ethanol amplifies risks of acute intoxication compared to lower-proof fermented beverages, underscoring calls for targeted regulation over unfettered production.[193] While taxes partially offset burdens, they capture only a fraction of externalities, with evidence from pricing studies showing that higher levies on spirits reduce consumption and harms without proportionally eroding economic viability.[201]Recent Developments and Future Directions

Technological Innovations Post-2000

Since 2000, innovations in distillation stills have primarily focused on integrating automation, hybrid designs, and energy-efficient systems to enhance precision, reduce operational costs, and address sustainability concerns in alcohol production. These advancements build on traditional pot and column still principles but incorporate digital controls and materials that allow for real-time process optimization, enabling smaller craft distilleries to achieve industrial-scale efficiency without sacrificing flavor complexity.[202][203] A pivotal development is the iStill hybrid still, first commercially delivered in April 2013 by Dutch inventor Dr. Edwin van Eijk. This system combines elements of pot and reflux column stills with computerized automation for automated temperature, pressure, and reflux ratio adjustments during distillation runs. It achieves up to 90% lower energy consumption than conventional copper pot stills through insulated stainless steel construction and ultrasonic cleaning capabilities that utilize residual alcohol for post-run sanitization, thereby minimizing water usage and manual intervention.[204][202][205] Hybrid still designs have proliferated in the 21st century, particularly among artisan producers, offering flexibility to switch between batch pot-still congeners for flavor depth and continuous column operation for higher throughput. Models like the iStill 2000 and Genio Still series incorporate programmable logic controllers (PLCs) for unmanned operation, with sensors monitoring alcohol vapor composition to automate cuts between heads, hearts, and tails, improving yield consistency to over 95% in rectified spirits. These systems, often scaled from 500L to 2000L capacities, have enabled craft distilleries to reduce labor by 70-80% while maintaining product quality comparable to traditional methods.[206][207][208] Sustainability-driven innovations include the adoption of renewable energy integration for still heating. In 2023, Annandale Distillery in Scotland initiated trials of a £3.6 million thermal energy storage system developed by Exergy3, which converts excess renewable electricity into stored heat for steam generation, powering a 4MW boiler without fossil fuels. This technology, set for full implementation by 2025, targets net-zero carbon emissions in whisky distillation by storing 36MWh of energy to run operations for up to seven days on intermittent renewables, potentially cutting distillery energy costs by 50% and emissions by over 90% compared to gas-fired systems.[209][210][211] Further automation trends post-2010 include continuous stills with AI-assisted predictive controls, as seen in the Prospero Supreme launched in 2024, which uses fractional distillation columns with automated valve sequencing to minimize manpower while producing consistent high-proof spirits at rates exceeding 100 liters per hour. These advancements, supported by stainless steel-copper hybrid materials for corrosion resistance and flavor neutrality, reflect a shift toward scalable, data-driven distillation that prioritizes empirical process metrics over artisanal variability.[212][213]Sustainability and Efficiency Improvements