Recent from talks

Contribute something

Nothing was collected or created yet.

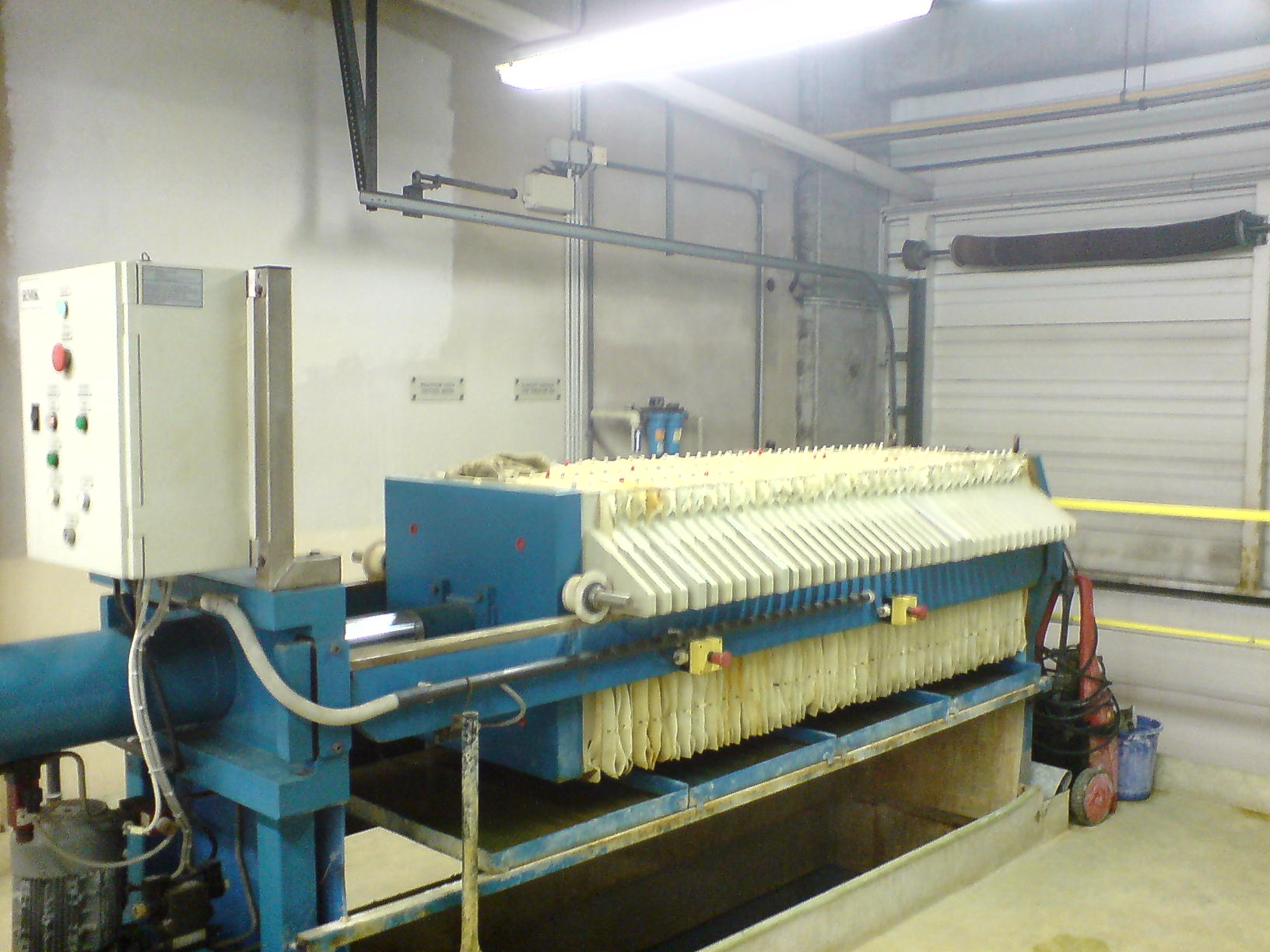

Filter press

View on Wikipedia

An industrial filter press is a tool used in separation processes, specifically to separate solids and liquids. The machine stacks many filter elements and allows the filter to be easily opened to remove the filtered solids, and allows easy cleaning or replacement of the filter media.

Filter presses cannot be operated in a continuous process but can offer very high performance, particularly when low residual liquid in the solid is desired. Among other uses, filter presses are utilised in marble factories in order to separate water from mud in order to reuse the water during the marble cutting process.

Concept behind filter press technology

[edit]Generally, the slurry that will be separated is injected into the centre of the press and each chamber of the press is filled. Optimal filling time will ensure the last chamber of the press is loaded before the mud in the first chamber begins to cake. As the chambers fill, pressure inside the system will increase due to the formation of thick sludge. Then, the liquid is strained through filter cloths by force using pressurized air, but the use of water could be more cost-efficient in certain cases, such as if water was re-used from a previous process.

History

[edit]

The first form of filter press was invented in the United Kingdom in 1853, used in obtaining seed oil through the use of pressure cells. However, there were many disadvantages associated with them, such as high labour requirement and discontinuous process. Major developments in filter press technology started in the middle of 20th century. In Japan in 1958, Kenichiro Kurita and Seiichi Suwa succeeded in developing the world's first automatic horizontal-type filter press to improve the cake removal efficiency and moisture absorption. Nine years later, Kurita Company began developing flexible diaphragms to decrease moisture in filter cakes. The device enables optimisation of the automatic filtration cycle, cake compression, cake discharge and filter-cloth washing leading to the increment in opportunities for various industrial applications. A detailed historical review, dating back to when the Shang Dynasty used presses to extract tea from camellia the leaves and oil from the hips in 1600 BC, was compiled by K. McGrew.[1]

Types of filter presses

[edit]There are four main basic types of filter presses: plate and frame filter presses, recessed plate and frame filter presses, membrane filter presses and (fully) automatic filter presses.

Plate and frame filter press

[edit]A plate and frame filter press is the most fundamental design, and may be referred to as a "membrane plate filter." This type of filter press consists of many alternating plates and frames assembled with the supports of a pair of rails, with filter membranes inserted between each plate-frame pair.[citation needed]

- Plates provide support to the filter membranes under pressure, and have narrow slots to allow the filtrate to flow through the membrane into the plate, then out into a collection system.

- Frames provide a chamber between the membranes and plates into which the slurry is pumped and the filter cake accumulates.

The stack is compressed with sufficient force to provide a liquid-tight seal between each plate and frame, the filter membrane may have an integrated seal around the edge or the filter material itself may act as a gasket when compressed.

As the slurry is pumped through the membranes, the filter cake accumulates and becomes thicker. The filter resistance increases as well, and the process is stopped when the pressure differential reaches a point where the plates are considered full enough.

To remove the filter cake and clear the filters, the stack of plates and frames are separated and the cake either falls off or is scraped from the membranes to be collected in a tray below.[2] The filter membranes are then cleaned using wash liquid and the stack is re-compressed ready to start the next cycle.[3]

An early example of this is the Dehne filter press, developed by A L G Dehne (1832–1906) of Halle, Germany, and commonly used in the late 19th and early 20th century for extracting sugar from sugar beet and from sugar cane, and for drying ore slurries. Its great disadvantage was the amount of labor involved in its operation.[4]

(Fully) Automatic filter press

[edit]An automatic filter press has the same concept as the manual filter and frame filter, except that the whole process is fully automated.[5] It consists of larger plate and frame filter presses with mechanical "plate shifters".[citation needed] The function of the plate shifter is to move the plates and allow rapid discharge of the filter cakes accumulated in between the plates. It also contains a diaphragm compressor in the filter plates which aids in optimizing the operating condition by further drying the filter cakes.[citation needed]

Fully automatic filter presses provide a high degree of automation while providing uninterrupted operation at the same time. The option of the simultaneous filter plate opening system, for example, helps to realise a particularly fast cake release reducing the cycle time to a minimum. The result is a high-speed filter press that allows increased production per unit area of filter. For this reason, these machines are used in applications with highly filterable products where high filtration speeds are required. These include, e.g. mining concentrates and residues. There are different systems for fully automatic operation. These include, e.g. the vibration/shaking devices, spreader clamp/spreader cloth version or scraping devices. The unmanned operating time of a fully automatic filter press is 24/7.[citation needed]

Recessed plate filter press

[edit]A recessed plate filter press does not use frames and instead has a recess in each plate with sloping edges in which the filter cloths lie, the filter cake builds up in the recess directly between two plates and when the plates are separated the sloping edges allow the cake to fall out with minimal effort.[6] To simplify construction and usage the plates typically have a hole through the centre, passing through the filter cloth and around which it is sealed so that the slurry flows through the centre of each plate down the stack rather than inward from the edge of each plate. Although easier to clean, there are disadvantages to this method, such as longer cloth changing time, inability to accommodate filter media that cannot conform to the curved recess such as paper, and the possibility of forming uneven cake.[7]

Membrane filter press

[edit]Membrane filter presses have a great influence on the dryness of the solid by using an inflatable membrane in the filter plates to compress remaining liquid from the filter cake before the plates are opened. Compared to conventional filtration processes, it achieves the lowest residual moisture values in the filter cake. This makes the membrane filter press a powerful and widely used system. Depending on the degree of dewatering, different dry matter contents (dry matter content – percentage by weight of dry material in the filter cake) can be achieved in the filter cake by squeezing with membrane plates. The range of achievable dry matter contents extends from 30 to over 80 percent. Membrane filter presses not only offer the advantage of an extremely high degree of dewatering; they also reduce the filtration cycle time by more than 50 percent on average, depending on the suspension. This results in faster cycle and turnaround times, which lead to an increase in productivity. The membrane inflation medium consists either of compressed air or a liquid medium (e.g. water).

Applications

[edit]Filter presses are used in a huge variety of different applications, from dewatering of mineral mining slurries to blood plasma purification.[3] At the same time, filter press technology is widely established for ultrafine coal dewatering as well as filtrate recovery in coal preparation plants. According to G.Prat, the "filter press is proven to be the most effective and reliable technique to meet today's requirement".[8] One of the examples is Pilot scale plate filter press, which is specialized in dewatering coal slurries. In 2013 the Society for Mining, Metallurgy and Exploration published an article highlighting this specific application.[9] It was mentioned that the use of the filter press is very beneficial to plant operations, since it offers dewatering ultraclean coal as product, as well as improving quality of water removed to be available for equipment cleaning.[10]

Other industrial uses for automatic membrane filter presses include municipal waste sludge dewatering,[11] ready mix concrete water recovery,[12] metal concentrate recovery, and large-scale fly ash pond dewatering.[13]

Many specialized applications are associated with different types of filter press that are currently used in various industries. Plate filter press is extensively used in sugaring operations such as the production of maple syrup in Canada, since it offers very high efficiency and reliability. According to M.Isselhardt, "appearance can affect the value of maple syrup and customer's perception of quality".[14] This makes the raw syrup filtration process extremely crucial in achieving desired product with high quality and appealing form, which again suggested how highly appreciated filter press methods are in industry.

Assessment of important characteristics

[edit]Here are some typical filter press calculation used for handling operation applied in waste water treatment:

Solids loading rate

[edit]S=(B x 8.34 lb/gal x s)⁄A

Where,

S is the solid loadings rate in lb+h⁄ft2.<r /> B is biosolids in gal⁄h

s is the % solids/ 100.

A is the plate area in ft2.

Net filter yield

[edit]

Where:

- NFY is the net filter yield in kg/h/m2.

- S is the solids loadings rate in kg/h/m2.

- P is the period in h.

- TCT is the total cycle time in h.

(S × P) gives the filter run time.[15]

Flow rate of filtrate

[edit]

Where:

- u is flow rate of filtrate through cloth and cake (m/s),

- dV/dt is volumetric filtration rate (m3/s),

- Rc is the resistance of the filter cake (m-1),

- Rf is the initial resistance of the filter (resistance of an initial layer of cake, filter cloths, plate and channel) (m-1),

- μ is the viscosity of the filtrate (N·s/m2),

- ΔP is the applied pressure difference (N/m2) one side to another side of the filter medium,

- A is the filtration area (m2).

Those are the most important factors that affect the rate of filtration. When filtrate pass through the filter plate, deposition of solids are formed and increases the cake thickness, which also increase Rc while Rf is assumed to be constant.[16] The flow resistance from cake and filter medium can be studied by calculating the flow rate of filtration through them.

If the flow rate is constant, the relationship between pressure and time can be obtained. The filtration must be operated by increasing pressure difference to cope with the increase in flow resistance resulting from pore clogging.[16] The filtration rate is mainly affected by viscosity of the filtrate as well as resistance of the filter plate and cake.

Optimum time cycle

[edit]High filtration rate can be obtained from producing thin cake. However, a conventional filter press is a batch system and the process must be stopped to discharge the filter cake and reassemble the press, which is time-consuming. Practically, maximum filtration rate is obtained when the filtration time is greater than the time taken to discharge the cake and reassemble the press to allow for cloth's resistance.[16] Properties of the filter cake affect the filtration rate, and it is desirable for the particle's size to be as large as possible to prevent pore blockage by using a coagulant. From experimental work, flow rate of liquid through the filter medium is proportional to the pressure difference.[17] As the cake layer forms, pressure applies to the system increases and the flow rate of filtrate decreases.[7] If the solid is desired, the purity of the solid can be increased by cake washing and air drying.[18] Sample of filter cake can be taken from different locations and weighed to determine the moisture content by using overall material balance.[9]

Possible heuristics to be used during design of the process

[edit]The selecting of filter press type depends on the value of liquid phase or the solid phase. If extracting liquid phase is desired, then filter press is among the most appropriate methods to be used.[19]

Materials

[edit]Nowadays, filter plates are made from polymers or steel coated with polymer. They give good drainage surface for filter cloths. The plate sizes are ranged from 10 by 10 cm to 2.4 by 2.4 m and 0.3 to 20 cm for the frame thickness.[18]

Filter medium

[edit]Typical cloth areas can range from 1 m2 or less on laboratory scale to 1000 m2 in a production environment, even though plates can provide filter areas up to 2000 m2. Normally, plate and frame filter press can form up to 50 mm of cake thickness, however, it can be push up to 200 mm for extreme cases. Recessed plate press can form up to 32 mm of cake thickness.[7]

In the early days of press use in the municipal waste biosolids treatment industry, issues with cake sticking to the cloth was problematic and many treatment plants adopted less effective centrifuge or belt filter press technologies. Since then, there have been great enhancements in fabric quality and manufacturing technology that have made this issue obsolete.[20] Unlike the US, automatic membrane filter technology is the most common method to dewater municipal waste biosolids in Asia. Moisture is typically 10-15% lower and less polymer is required—which saves on trucking and overall disposal cost.

Operating condition

[edit]The operating pressure is commonly up to 7 bars for metal.[18] The improvement of the technology makes it possible to remove large amount of moisture at 16 bar of pressure and operate at 30 bars.[3] However, the pressure is 4-5 bars for wood or plastic frames.[18] If the concentration of solids in the feed tank increase until the solid particles are attached to each other. It is possible to install moving blades in the filter press to reduce resistance to flow of liquid through the slurry.[21] For the process prior to cake discharge, air blowing is used for cakes that have permeability of 10−11 to 10−15 m2.[9]

Pre-treatment

[edit]Pre-treatment of the slurries before filtration is required if the solid suspension has settled down. Coagulation as pre-treatment can improve the performance of filter press because it increases the porosity of the filter cake leading to faster filtration. Varying the temperature, concentration and pH can control the size of the flocs. Moreover, if the filter cake is impermeable and difficult for the flow of filtrate, filter aid chemical can be added to the pre-treatment process to increase the porosity of the cake, reduce the cake resistance and obtain thicker cake. However, filter aids need to be able to remove from the filter cake either by physical or chemical treatment. A common filter aid is Kieselguhr, which give 0.85 voidage.[21]

In terms of cake handling, batch filter press requires large discharge tray size in order to contain large amount of cake and the system is more expensive compared to continuous filter press with the same output.[3]

Washing

[edit]There are two possible methods of washing that are being employed, the "simple washing" and the "thorough washing". For simple washing, the wash liquor flows through the same channel as the slurry with high velocity, causing erosion of the cakes near the point of entry. Thus the channels formed are constantly enlarged and therefore uneven cleaning is normally obtained. A better technique is by thorough washing in which the wash liquor is introduced through a different channel behind the filter cloth called washing plates. It flows through the whole thickness of the cakes in opposite direction first and then with the same direction as the filtrate. The wash liquor is normally discharged through the same channel as the filtrate. After washing, the cakes can be easily removed by supplying compressed air to remove the excess liquid.[18]

Waste

[edit]Nowadays filter presses are widely used in many industries, they would also produce different types of wastes. Harmful wastes such as toxic chemical from dye industries, as well as pathogen from waste stream might accumulate in the waste cakes; hence the requirement for treating those wastes would be different. Therefore, before discharge waste stream into the environment, application of post-treatment would be an important disinfection stage. It is to prevent health risks to the local population and the workers that are dealing with the waste (filter cakes) as well as preventing negative impacts to our ecosystem. Since filter press would produce large amount of waste, if it was to be disposed by land reclamation, it is recommended to dispose to the areas that are drastically altered like mining areas where development and fixation of vegetation are not possible. Another method is by incineration, which would destroy the organic pollutants and decrease the mass of the waste. It is usually done in a closed device by using a controlled flame.[2]

Advantages and disadvantages compared to other competitive methods

[edit]Many debates have been discussed about whether or not filter presses are sufficient to compete with modern equipment currently as well as in the future, since filter presses were one of the oldest machine-driven dewatering devices. Efficiency improvements are possible in many applications where modern filter presses have the best characteristics for the job, however, despite the fact that many mechanical improvements have been made, filter presses still remain to operate on the same concept as when first invented. A lack of progress in efficiency improvements as well as a lack of research on conquering associated issues surrounding filter presses have suggested a possibility of performance inadequacy. At the same time, many other types of filter could do the same or better job as press filters. In certain cases, it is crucial to compare characteristics and performances.[22]

Batch filter press versus a continuous vacuum belt filter

[edit]Filter presses offer a wide range of application, one of its main propositions is the ability to provide a large filter area in a relatively small footprint. Surface area available is one of the most important dimensions in any filtering process, since it maximises filter flow rate and capacity. A standard size filter press offers a filter area of 216 m2, whereas a standard belt filter only offers approximately 15 m2.[22]

High-solids slurries: continuous pressure operation

[edit]Filter presses are commonly used to dewater high-solids slurries in metal processing plants, one of the press filter technology that could deliver the job is the Rotary Pressure Filter method, which provides continuous production in a single unit, where filtration is directed via pressure. However, in cases where solids concentration in high-solids slurries is too high (50%+), it is better to handle these slurries using vacuum filtration, such as a continuous Indexing Vacuum Belt Filter, since high concentration of solids in slurries will increase pressure and if pressure is too high, the equipment might be damaged and/or less efficient operation.[22]

References

[edit]- ^ McGrew, Kent. "Historical Development of the Automated Filter Press" (PDF). Archived from the original (PDF) on 2019-02-14. Retrieved 2016-03-14.

- ^ a b Von Sperling, M (January 2007). Biological Wastewater Treatment: Wastewater Characteristics Treatment and Disposal. IWA PUBLISHING. ISBN 9781843391616. Retrieved June 10, 2013.

- ^ a b c d SUTHERLAND, K (2008). Filters and Filtration Handbook (5th ed.). Elsevier.

- ^ "Last Tribute to a Kalgoorlie Mining Man". Western Mail. Vol. 61, no. 3, 240. Western Australia. 3 October 1946. p. 8. Retrieved 8 February 2019 – via National Library of Australia.

- ^ "Tons Per Hour Product Guide" (PDF). Archived from the original (PDF) on 2019-02-09. Retrieved 2016-03-04.

- ^ EPA. "Biosolids technology fact sheet : Recessed-plate filter press, washington, D.C." Retrieved 5 October 2013.

- ^ a b c Tarleton, E. S. W., R. J (2007). Solid/liquid separation - equipment selection and process design. Elsevier. ISBN 978-0-080-46717-7.

{{cite book}}: CS1 maint: multiple names: authors list (link) - ^ Kilma, M. S.; Arnold, Barbara J.; Bethell, Peter J. (2012). Challenges in Fine Coal Processing, Dewatering, and Disposal (Chapter 10). Society for Mining, Metallurgy, and Exploration (SME). ISBN 978-0-87335-363-2. Retrieved 21 April 2015.

- ^ a b c Kilma, M. S.; Arnold, Barbara J.; Munjack, J.; Barry, B. (2013). Application of a Pilot-Scale Plate Filter Press in Dewatering Coal Slurries. Society for Mining, Metallurgy and Exploration (SME). pp. 42–50. ISBN 978-1-62198-038-4.

- ^ Lessard, Paul. "Filter Press Doubles Coal Production" (PDF).

- ^ "Municipal Waste Dewatering with a Filter Press" (PDF).

- ^ Lessard, Paul. "Concrete Ready Mix Wash-Out Water" (PDF).

- ^ Lessard, Paul. "Large-Scale Fly Ash Pond Dewatering" (PDF). Archived from the original (PDF) on 2016-03-05. Retrieved 2016-03-04.

- ^ Isselhardt, M.; Williams, S.; Stowe, B.; Perkins, T. "Recommendations for Proper Plate Filter Press Operation" (PDF). Proctor Maple Research Center. University of Vermont Extension. Retrieved 21 April 2015.

- ^ F.R. Spellman (2008). Handbook of water and waste water treatment plant operations (second ed.).

- ^ a b c CHEREMISINOFF, N. P. (1998). Liquid Filtration (2nd ed.). Elsevier. ISBN 978-0-0805-1036-1.

- ^ J H HARKER; J. R. B.; J.F. RICHARDSON. Coulson & Richardson Chemical Engineering Particle Technology & Separation Processes. Oxford, Butterworth-Heinemann. ISBN 0750644451.

- ^ a b c d e Perry, R. H.; Green, D.W. (2008). Perry's Chemical Engineers' Handbook (8th ed.). pp. 2022, 2036, 2023.

- ^ ALEJANDRO ANAYA DURAND; JOSSELINE ALARID MIGUEL; GABRIEL GALLEGOS DIEZ BARROSO; LEON GARCIA, M. A. J. P. S. A. (2006). Heuristics Rules for Process Equipment. Chemical Engineering. pp. 113, 44–47.

- ^ "Jingjin Filter Cloth Manufacture and Quality Control".

- ^ a b CHEREMISINOFF, N. P. (1998). Liquid Filtration (2nd ed.). Elsevier. ISBN 978-0-0805-1036-1.

- ^ a b c PERLMUTTER, B. "A REVIEW OF FILTER PRESS BASICS AND ISSUES VERSUS ALTERNATIVE BATCH OR CONTINUOUS REPLACEMENT TECHNOLOGIES".

Filter press

View on GrokipediaIntroduction and Fundamentals

Overview of Filter Press Technology

A filter press is an industrial tool designed for solid-liquid separation, utilizing pressure to process slurries by stacking filter chambers formed by plates covered in permeable media such as filter cloths.[1] The basic mechanism involves pumping the slurry into these sealed chambers, where applied pressure—typically from a hydraulic system—forces the liquid portion (filtrate) through the filter media, while solid particles are retained and build up as a compact filter cake on the plate surfaces.[4] This pressure-driven process, originally invented in 1853 for applications like seed oil extraction, enables effective dewatering across various industries.[6] The general operation follows a batch cycle with key steps: filling, where the slurry is introduced into the chambers under low pressure; filtration, during which increasing pressure expels the filtrate; pressing to further consolidate and dewater the cake; cake release, achieved by opening the plate assembly to discharge the solids; and cleaning, involving rinsing or washing the media to prepare for reuse.[7] These steps ensure thorough separation without continuous flow, making the technology adaptable for intermittent processing needs.[1] Key benefits of filter press technology include producing filter cakes with high solids concentrations, typically ranging from 30% to 70% dry matter depending on slurry characteristics, which minimizes liquid content and facilitates downstream handling or disposal.[8] It offers efficient batch processing with low energy consumption compared to continuous alternatives, while providing clear filtrate for reuse.[4] Visually, a standard setup features a robust frame supporting a pack of alternating plates and frames, a hydraulic ram for compression, and integrated channels or ports for filtrate collection and slurry feed.[1] Various configurations, such as plate and frame designs, build on this core structure to suit specific applications.[7]Historical Development

The filter press was invented in the United Kingdom in 1853 by engineers William Needham and James Kite, who patented a mechanical device using pressurized cells to separate solids from liquids in semi-fluid materials. This early design was primarily applied in industries such as ceramics manufacturing for expelling water from clay slip and in brewing for clarifying liquids, marking a significant advancement over manual filtration methods.[9][10] By the early 20th century, filter presses had become integral to the mining and chemical industries, where they were employed for dewatering mineral slurries and recovering valuable solids from process streams. The plate and frame configuration emerged as the predominant design during this period, offering improved handling of larger volumes and corrosive materials compared to the original models; for instance, the Eimco plate and frame press was used extensively in gold mining to recover zinc dust from cyanide solutions, demonstrating its durability over decades of operation.[11] Mid-20th-century innovations transformed filter press operations from labor-intensive processes to automated systems. In 1958, Japanese engineers Kenichiro Kurita and Seiichi Suwa developed the world's first fully automatic filter press at Kurita Machinery Mfg. Co., introducing hydraulic pressing and automatic plate shifting to streamline cake discharge and reduce cycle times, with patents secured in Japan, the U.S., U.K., and Germany. This RF-type model paved the way for broader industrial adoption, and by 1959, further refinements by the same team introduced the recessed chamber style, which enhanced cake formation and moisture reduction without requiring separate frames.[12][13][11] From the late 20th century through the early 21st, the technology evolved toward more efficient variants, including recessed plate and membrane designs that integrated inflatable diaphragms to apply secondary pressure, achieving drier cakes and shorter filtration cycles. Hydraulic systems became standard, enabling operations at pressures up to 25 bar and facilitating integration with upstream processes in chemical and mining sectors. Influential companies like Larox, established in 1977 in Finland, advanced these iterations through innovative pressure filter presses, later becoming part of Metso in 2010 and contributing over 1,300 units worldwide known for reliability in demanding environments.[14][15] Post-2010 developments have emphasized sustainability and intelligence, with modular filter press designs allowing scalable configurations for fluctuating production demands in industries like wastewater treatment and mining tailings management. AI-driven automation, incorporating IoT sensors and predictive analytics, has enabled real-time monitoring and maintenance forecasting, reducing downtime by up to 30% in some systems. Energy-efficient models, such as ANDRITZ's MiningMaster ME4 introduced in 2025, feature optimized hydraulic drives and low-power pressing mechanisms, cutting energy use while enhancing dewatering performance for eco-friendly operations.[16][17][18]Types of Filter Presses

Plate and Frame Filter Press

The plate and frame filter press is a classic design featuring alternating flat solid plates and hollow frames arranged on a support structure, with filter cloths draped over both sides of each plate to form sealed chambers. The hollow frames create the space for slurry containment and cake formation, while the plates provide drainage channels for the filtrate to exit. This configuration allows for pressure-driven filtration where slurry is introduced into the frames, solids are retained on the cloths to build a cake, and liquid passes through to the plate surfaces.[19][20] Operationally, the plate and frame filter press functions as a batch or semi-automatic process, typically manual in smaller setups, where slurry is pumped into the frames under pressure until the cake fills the frame depth, limiting thickness to 25-50 mm. After filtration, the press is opened by separating the plates and frames, allowing manual or mechanical removal of the cakes, followed by cloth cleaning and reassembly for the next cycle. This design supports operating pressures up to 5-7 bar, making it suitable for moderate-pressure applications in industries like chemical processing and wastewater treatment.[19][21] Key advantages of this type include its simple construction, which results in low initial costs and straightforward maintenance, particularly for small-scale operations requiring flexibility in cake thickness adjustments via frame selection. It also provides a large filtration area within a compact footprint and efficient cake washing capabilities due to the separated plate and frame setup.[19][20] However, limitations arise from its labor-intensive cake removal process, which increases operational downtime and costs in high-volume settings, and its unsuitability for highly compressible cakes that may blind the filter cloth or unevenly distribute pressure. Typical configurations feature plate areas ranging from 0.1 to 2 m² per plate, with overall press sizes scaling from small units with a few plates to larger assemblies handling up to several cubic feet of slurry per cycle.[19][21]Recessed Plate Filter Press

The recessed plate filter press utilizes plates featuring recessed chambers on both sides, which eliminates the need for separate frames and allows filter cloths to cover the entire plate face, forming sealed filtration chambers when the plates are clamped together. These plates are typically constructed from durable materials such as polypropylene, cast iron, or stainless steel to withstand operating pressures of 100 to 225 psi. A key design element is the large center feed hole, which enables rapid and uniform slurry distribution into the chambers, thereby reducing clogging risks and extending plate life. Feed channels are commonly positioned along the plate edges or through the center for efficient slurry entry.[22][23][24][25] In operation, slurry is pumped directly into the recessed chambers, where solids are retained on the filter cloths to form cakes up to 50 mm thick, while filtrate passes through the media. The process builds pressure over 30 to 45 minutes until maximum is reached, completing the filtration phase in a batch cycle that typically lasts 1 to 4 hours. Upon cycle completion, the plates are hydraulically separated, allowing the cakes to release easily by gravity into a hopper or drum, often with minimal manual assistance such as light spatula use if adhesion occurs. This direct filling and separation mechanism simplifies cake handling compared to frame-dependent designs.[23][24][26][25] The recessed plate design offers several advantages, including reduced labor for cake discharge due to effortless plate separation and gravity release, higher throughput from efficient chamber filling and support for thicker cakes, and enhanced suitability for non-compressible solids, yielding cake solids concentrations of 35% to 55% without chemical additives in many cases. It also provides lower operating costs through part-time operator needs and minimal maintenance from fewer moving parts, while achieving drier cakes that lower disposal expenses. These benefits make it an improvement over plate and frame presses by streamlining assembly and discharge.[23][22][26][25] Common applications include wastewater treatment for biosolids dewatering and mining for slurry dewatering, where high solids capture and clear filtrate recovery are critical. Plate configurations accommodate diverse scales, with sizes ranging from 250 mm x 250 mm for pilot and small operations to up to 2.4 m x 2.4 m for large industrial setups, enabling adaptability to varying throughput demands.[23][22][24]Membrane Filter Press

The membrane filter press is a specialized type of filter press that incorporates flexible membranes, typically made of rubber or synthetic polymers, integrated into the filter plates on one or both sides to enable enhanced dewatering through mechanical compression. These membranes are mounted within the plate structure, often in a core feed configuration where slurry is introduced through a central port in the plates, allowing even distribution into the filtration chambers formed between alternating fixed and membrane plates. The design builds upon recessed plate technology by adding inflatable diaphragms that remain flat during initial filtration but can expand to apply uniform pressure across the formed filter cake.[27][28] Operation of the membrane filter press occurs in a two-stage process: first, the slurry is pumped into the chambers under pressure, typically up to 8 bar, where solids form a cake against the filter cloth while filtrate drains through the plates. In the second stage, after initial dewatering, the membranes are inflated using compressed air or water at pressures up to 15-16 bar, squeezing the cake to expel additional liquid and achieve higher dryness levels, with the squeeze phase lasting approximately 5-10 minutes depending on the slurry characteristics. This inflation compresses the cake uniformly, preventing channeling and maximizing liquid removal, after which the plates are separated for cake discharge. The process is particularly suited for compressible materials, as the mechanical squeeze applies static pressure without relying solely on feed pump force.[28][27][29] Key advantages of the membrane filter press include the production of significantly drier cakes, often reaching 50-80% solids content or higher depending on the application, representing a 20-50% improvement in dryness (higher solids percentage) compared to standard recessed plate presses and reduces the need for downstream thermal drying processes. It is ideal for applications involving compressible sludges, such as in mining tailings or wastewater treatment, where the enhanced dewatering lowers disposal volumes and costs while maintaining filtrate clarity. The technology also shortens overall filtration cycles by up to 50% through efficient squeezing, optimizing throughput without excessive energy use.[27][29][30][31] Variants of the membrane filter press include full membrane configurations, where both sides of the plates feature inflatable diaphragms for maximum compression, and mixed packs that alternate standard fixed plates with membrane plates to balance cost and performance. These options allow customization based on slurry volume and desired cake dryness, with full membrane setups often used for high-dewatering demands in chemical processing.[28][27]Automatic and Advanced Filter Presses

Automatic filter presses represent an evolution of recessed plate and membrane designs, incorporating advanced automation to minimize human intervention while enhancing efficiency in industrial dewatering processes. These systems typically feature fully automatic plate shifters that use hydraulic or chain-driven mechanisms to separate plates sequentially, often controlled by programmable logic controllers (PLCs) for precise sequencing of operations such as feeding, filtration, and discharge.[32][33] Robotic or load-sensing carriages further automate cake handling by gripping and shifting plates, allowing for safe, rapid emptying without manual labor.[33][34] In operation, these presses enable 24/7 unmanned cycles through integrated PLC programming that orchestrates plate opening, cake release via gravity or vibration, and automatic cloth washing with high-pressure sprays (60–80 bar).[32][16] Filtration cycles are shortened to 10–30 minutes per stage, depending on slurry characteristics and pressure (up to 16 bar), with overall cycle times reduced by up to 50% compared to semi-automatic models, facilitating higher throughput.[35][34] Advancements in the 2020s have introduced modular designs for scalable configurations, such as the MiningMaster ME4 with up to 240 chambers and 60,000-liter filtration volume, allowing easy adaptation to varying production needs.[16] Artificial intelligence (AI) enables real-time optimization of pressure and timing by analyzing sensor data on flow rates and moisture levels, while Internet of Things (IoT) sensors support predictive maintenance through anomaly detection and cloud-based remote monitoring, integrating seamlessly with Industry 4.0 frameworks.[36] These innovations build operational intelligence on membrane or recessed bases, focusing on data-driven adjustments rather than mechanical squeezing alone. Key advantages include up to 30% higher productivity over semi-automatic systems, with throughput increases of 20–30% versus manual operations, and labor cost reductions of up to 80% due to autonomous cake discharge methods like air-assisted blowback or integrated scrapers.[35][32] Energy efficiency is enhanced in recent models through variable frequency drives (VFDs) on hydraulic pumps, which adjust motor speeds to demand and cut consumption by 30–50%.[35][37] Hybrid systems combining pressure filtration with low-amplitude vibration for faster cake release further optimize energy use per ton processed, particularly in wastewater and mining applications.[37]Components and Materials

Filter Plates and Frames

Filter plates and frames are the core structural components of a filter press, designed to withstand high pressures while facilitating the separation of solids from liquids. Filter plates typically come in three primary types: flat plates used in plate-and-frame designs, recessed plates that form built-in chambers, and membrane plates equipped with inflatable diaphragms for enhanced cake dewatering.[38] These plates are commonly constructed from corrosion-resistant materials such as polypropylene (PP) or reinforced polypropylene for chemical compatibility and durability, while steel or cast iron variants are employed in applications requiring greater mechanical strength.[39] Plate dimensions vary widely to suit different scales, with laboratory units featuring small sizes around 150 mm x 150 mm providing approximately 0.02 m² of filtration area per plate, and industrial models scaling up to 2000 mm x 2000 mm plates contributing to total press areas exceeding 2000 m² in large installations.[40][41] In classic plate-and-frame configurations, frames are hollow structures positioned between flat plates to create the filtration chambers, allowing slurry to enter and solids to accumulate.[42] Each frame and plate includes feed ports for slurry introduction, typically located at the center or corners to promote even distribution, along with filtrate channels—often grooved pathways on the plate surfaces—that direct clarified liquid to outlet ports.[1] Stay bosses, raised integral protrusions on the plates, provide mechanical support to prevent flexing or deformation under operational pressures up to several bars.[43] Filter press configurations generally fall into side-bar designs, which use parallel beams along the sides for plate support and are suitable for smaller setups with up to 100 plates, or overhead beam designs that suspend plates from above for easier access and can accommodate 100 to 175 or more plates in high-capacity systems.[44] Together, the plates and frames form sealed chambers when compressed hydraulically, ensuring uniform slurry distribution across the filter area to achieve consistent cake formation and efficient filtration.[1] Proper maintenance of filter plates and frames is essential for longevity and performance, with corrosion resistance achieved through material selection and protective coatings to mitigate uniform, pitting, or crevice corrosion from aggressive slurries.[45] Plate alignment must be regularly checked and maintained—often following a 1-3-1-3 pattern for port matching—to prevent leaks, uneven pressure distribution, or operational failures.[46]Filter Media

Filter media in filter presses primarily consist of filter cloths, which are flexible, permeable fabrics that capture solids from slurry while allowing filtrate to pass through. These cloths are essential for achieving effective separation, and their performance directly influences filtration efficiency and cake quality. Common materials include woven polypropylene, nylon, and cotton, selected for their balance of retention, flow, and durability.[47][48][49] Woven polypropylene cloths are the most widely used due to their excellent chemical resistance to acids and bases, low moisture absorption, and good cake release properties, making them suitable for a broad range of industrial slurries. Nylon cloths offer high tensile strength and abrasion resistance, ideal for handling abrasive particles, though they have limited compatibility with strong acids. Cotton cloths, often used in food-grade applications, provide biodegradability and natural filtration but are less resistant to chemicals and moisture compared to synthetics. Other materials like polyester may be employed for specific thermal or mechanical needs. Pore sizes typically range from 1 to 100 microns, with finer pores for smaller particles and coarser for higher flow rates.[47][50][48][49] Key properties of filter cloths include permeability, which governs filtrate flow and is influenced by yarn type (e.g., monofilament for higher permeability) and weave pattern (e.g., satin for smooth surfaces); ease of cake release, enhanced by non-stick finishes like singeing or specific weaves to prevent adhesion; and chemical resistance, which ensures longevity in corrosive environments. Typical cloths cover an area of 1-2 m² per plate, matching the filter press design for optimal coverage.[47][51][49] Selection of filter media depends on slurry characteristics such as particle size and distribution, which dictate pore size to ensure retention without excessive blinding; corrosiveness and temperature, favoring materials like polypropylene for acidic conditions or nylon for alkaline ones; and cake dryness requirements, where smoother cloths promote drier, easier-to-release cakes. For slurries with fine or colloidal particles, filter aids such as diatomaceous earth are applied to form a precoat layer, improving permeability and preventing rapid clogging.[47][52][48][50] Installation involves draping the cloths over filter plates and securing them with gaskets to seal edges and prevent slurry bypass. In advanced systems, automatic washing mechanisms clean the cloths during cycles to mitigate blinding and extend usability. Lifespan typically ranges from 500 to 2000 cycles, varying by material, slurry abrasiveness, and maintenance. Replacement is indicated by significant flow reduction, increased pressure differentials, or visible damage, signaling reduced permeability.[51][49][47]Construction Materials

Filter presses are constructed using a variety of materials selected for their ability to withstand mechanical stresses, chemical exposures, and operational pressures while ensuring longevity and safety in industrial applications.[21] The primary materials for filter plates include polypropylene, which is widely used due to its excellent corrosion resistance and suitability for pressures up to 16 bar (225 psi), making it ideal for standard industrial dewatering processes.[53][54] Cast iron and steel plates, on the other hand, support higher pressures up to 25 bar in heavy-duty applications, offering robust structural integrity for demanding environments like mining and chemical processing.[55] Stainless steel plates, particularly grades 304 and 316, are preferred for food and pharmaceutical industries because of their hygienic properties, non-reactivity with sensitive slurries, and compliance with FDA standards.[56][57] Frames and hydraulic components are typically made from carbon steel, often coated with epoxy-based paints to enhance corrosion resistance and durability against environmental factors.[45] For applications involving acidic slurries, rubber linings are applied to frames and components to provide superior acid resistance and prevent degradation.[58][59] Material selection is guided by the slurry's pH, temperature (typically up to 100°C for polypropylene and higher for cast iron), and required operating pressure to ensure compatibility and prevent failures like warping or leaks.[60][61] Cost considerations play a key role, with polypropylene plates being more economical for moderate-pressure operations but limited in extreme conditions, whereas metal alternatives like stainless steel or cast iron incur higher upfront costs yet provide value in high-pressure, long-term use.[21][42] In recent trends during the 2020s, manufacturers have incorporated lightweight composites, such as carbon fiber-reinforced materials, into modular press designs to reduce weight by up to 40% while maintaining strength, facilitating easier installation and transport.[62] Additionally, sustainable options like recycled polymers have gained traction in plate and frame construction, lowering environmental impact and aligning with circular economy principles in modern filter press production.[63][64]Operation and Process

Operating Conditions

Filter presses operate under controlled pressure, temperature, and cycle conditions to ensure efficient separation of solids from liquids while maintaining equipment integrity. Feed pressures typically range from 2 to 7 bar, allowing slurry to fill the chambers without excessive stress on the plates. For the squeezing phase, pressures can reach 15 to 30 bar depending on the filter press type, which compresses the filter cake to expel residual filtrate. The basic hydraulic ram force required is calculated as Force = Pressure × Area, where pressure is in Pascals and area is the effective plate surface in square meters, ensuring uniform compression across the press. Temperature limits for operation generally fall between 20°C and 80°C for standard filter presses, accommodating most industrial slurries without degrading the filter media or causing thermal expansion issues in the plates. Specialized designs using heat-resistant materials, such as stainless steel or polymer composites, can handle temperatures up to 120°C for applications involving hot process streams like in chemical or food processing. Cycle parameters are optimized for throughput and cake dryness, with filling times ranging from 5 to 15 minutes to allow complete chamber saturation, followed by pressing durations of 10 to 30 minutes to achieve desired dewatering. Slurry feed rates vary from 1 to 10 m³/h, influenced by slurry viscosity and solids content, to prevent overloading the system. Recent advancements as of 2025, including AI-driven monitoring and automated systems from manufacturers like ANDRITZ, enable real-time optimization of these parameters, reducing overall energy use and improving sustainability.[65][17] Safety features are integral to mitigate risks during operation, including pressure relief valves that automatically vent excess pressure to prevent plate deformation or rupture, and interlock systems that halt the cycle if anomalies like plate misalignment occur. Continuous monitoring for leaks via sensors on filtrate outlets and hydraulic lines ensures early detection of seal failures, maintaining operator safety and process reliability. Operational variations exist by filter press type: plate and frame models typically use lower pressures (up to 10-15 bar) due to their simpler construction, while membrane filter presses require higher squeeze pressures (20-30 bar) to inflate diaphragms for enhanced cake compression. These parameters must align with material compatibility to avoid corrosion or fatigue, as detailed in construction guidelines.Filtration Cycle and Timing

The filtration cycle of a filter press is a sequential process comprising several key phases to separate solids from liquids efficiently. It begins with slurry filling, where the conditioned slurry is pumped into the chambers formed between filter plates and cloths at a low pressure and high flow rate, allowing initial free water to drain while solids start accumulating on the cloth surface. This phase typically lasts a few minutes, depending on the press size and slurry volume.[23][7] Following filling, pressure filtration occurs as hydraulic pressure is applied (typically 100-225 psi), forcing the liquid filtrate through the cloth while building a compact filter cake of solids within the chamber recesses. This dewatering phase continues until filtrate flow reaches a low set-point, indicating sufficient cake formation. In membrane filter presses, an optional membrane squeeze phase follows, where flexible diaphragms inflate to apply additional pressure, further consolidating the cake and reducing its moisture content to as low as 20-30%.[23][7] The cycle then proceeds to cake release and plate shifting, where the press opens, and plates are mechanically separated—either manually or automatically—to discharge the cake. Discharge methods include gravity drop, where dry cakes fall into collection bins below the press, or mechanical aids like scrapers for sticky materials to ensure complete removal. Finally, cloth washing rinses the filter media with water sprays to remove residual particles, preparing the press for the next cycle; pressure settings for washing are adjusted post-filtration as needed.[23][66] Optimum timing for the filtration phase is governed by cake resistance, with a heuristic for filtration time derived from Darcy's law under constant pressure:where is the filtrate viscosity, is the specific cake resistance, is the mass of solids per unit volume of filtrate, is the filtrate volume, is the applied pressure, and is the filter area (neglecting medium resistance for thick cakes). Total cycle times typically range from 20-60 minutes for standard industrial operations, encompassing all phases, though this can vary to 2-8 hours depending on slurry type and application; modern automated systems as of 2025 can shorten effective cycle times by 20-30% through optimized plate shifting and monitoring.[67][68][69] Factors influencing cycle timing include slurry concentration, with higher solids density (e.g., >3% dry solids) accelerating filling and dewatering, and cake compressibility, where fine or compressible particles increase resistance and extend filtration duration. Automation in modern presses, such as automatic plate shifting and cloth washing, significantly reduces downtime between cycles, achieving availability over 98%. The primary efficiency goal is to minimize non-filtration time—such as plate opening (1-10 minutes) and washing—to less than 10% of the total cycle, thereby maximizing throughput.[66][69]

Pre-treatment of Slurry

Pre-treatment of slurry is essential in filter press operations to enhance filtration efficiency by modifying the physical and chemical properties of the feed, particularly for challenging slurries with fine particles or high viscosity. This preparation step aggregates suspended solids, reduces viscosity, and prevents filter media clogging, leading to improved cake formation and higher throughput. Common techniques involve chemical and physical adjustments tailored to the slurry's composition, such as solids content exceeding 10%, where pre-treatment becomes critical to manage flow resistance and achieve optimal dewatering.[66][70] Coagulation and flocculation are primary chemical techniques used to aggregate fine particles in the slurry. Coagulation employs inorganic agents like ferric chloride, polyferric sulfate, or calcium hydroxide to destabilize colloidal particles, promoting their initial clustering, while flocculation follows with organic polymers such as polyacrylamide (typically dosed at 0.1-0.5% by weight) to form larger, settleable flocs. Cationic polymers are preferred for organic-rich sludges, whereas anionic types suit inorganic feeds. These processes improve solid-liquid separation by creating a more permeable cake structure.[71][70] pH adjustment complements coagulation and flocculation by optimizing slurry stability, typically targeting a range of 6-9 to enhance particle aggregation without compromising filtrate quality or system integrity. This is achieved using the same inorganic coagulants, with careful monitoring to avoid corrosion or adverse effects on downstream processes.[71][70] Filter aids, such as diatomaceous earth or perlite, are added to the slurry (0.5-2% by weight, depending on the application) to increase cake porosity and prevent fine particles from blinding the filter media. Perlite, being lighter than diatomaceous earth, requires half the weight for equivalent performance, often applied at 2-4% solids concentration in the slurry for body feed or as a pre-coat layer on filter cloths (500-1200 g/m² of filter area) to form a protective, permeable barrier before introducing the main slurry. These aids trap fines within their structure, maintaining open flow paths.[72][73][74] Other physical methods include dilution for viscous slurries, where water or recycled filtrate is added (e.g., 200-800 mm equivalent volume) to lower concentration and improve pumpability; heating to 20-60°C, which can reduce viscosity from 150 cP to 35 cP in clay-based slurries; and screening to remove oversized particles (>1-2 mm) that could damage equipment or unevenly distribute solids. These approaches are selected based on slurry rheology and are often combined for high-solids feeds (>10%).[71][70][75] The benefits of slurry pre-treatment include reduced filter blinding, enhanced cake permeability, and increased flow rates, with chemical conditioning and filter aids capable of shortening filtration time by over 50% in high-viscosity cases, equating to 20-50% higher effective throughput for solids contents above 10%. For instance, thermal treatment alone can reduce relative filtration time to 0.23 at 60°C compared to ambient conditions. These improvements minimize operational downtime and optimize resource use in industrial settings.[70][76][66] However, considerations include balancing the cost of chemicals and energy against performance gains—polymer dosing and heating add operational expenses—along with environmental impacts from chemical disposal, such as sludge toxicity or effluent pH shifts, necessitating proper selection and waste management to ensure sustainability. Empirical testing is recommended to determine optimal dosages and methods for specific slurries.[70][71]Washing and Cake Discharge

In filter presses, washing the filter cake is a critical post-filtration step to remove residual mother liquor and soluble impurities, ensuring product purity especially in pharmaceutical and food applications where contaminant levels must be minimized to below 1%.[77] Common methods include simple displacement washing, where high-velocity wash water flushes through the cake in a single direction to displace impurities, and thorough multi-channel washing, such as countercurrent systems that route fresh wash liquid through multiple stages for up to 99% purity by reusing partially contaminated effluent.[78][77] Displacement washing is suitable for uniform cakes with soluble contaminants, while countercurrent approaches optimize water usage in resource-intensive processes like pigment salt removal or sugar de-sweetening.[78][77] The washing process typically requires 1-3 times the press volume of water, delivered at pressures of 6-8 bar to prevent cake cracking or slumping, with durations of 2-5 minutes per cycle to balance efficiency and thoroughness.[77] In membrane filter presses, pre-squeezing the cake before washing enhances uniformity, reducing short-circuiting and improving impurity extraction.[79] Following washing, filter cloths must be cleaned to prevent clogging in subsequent cycles; methods include high-pressure power spraying at 800-1200 PSI to flush particles from the weave or acid washing with 25% hydrochloric acid recirculated for 1-2 hours, ensuring restored porosity and drier cakes.[80] Cake discharge removes the dewatered solids from the plates after washing and drying, with methods varying by automation level and cake properties. Manual scraping involves operators using tools to dislodge cakes, a labor-intensive process taking up to 45 minutes per cycle and posing safety risks, while automatic tilting plates shift chambers open in 15 minutes, boosting throughput by 25% for non-sticky materials.[34] For sticky cakes, vibration systems apply pneumatic pulses to release solids in seconds, and air blowback uses compressed air bursts for dry, quick detachment, though it consumes significant energy.[34][81] Automation integrates features like spray bars for in-situ cloth rinsing during discharge and conveyor systems to transport cakes to storage, reducing total discharge time to 10 minutes and minimizing residual moisture that can cause adhesion issues.[34] Challenges include incomplete cake release due to high moisture content (up to 20-30% in some slurries), addressed by extended air blowing, and cloth blinding from unremoved fines, necessitating regular acid dips or sprays to maintain operational efficiency.[34][80] These steps integrate into the overall filtration cycle to ensure consistent performance across industrial uses.[7]Performance and Assessment

Solids Loading Rate and Net Filter Yield

The solids loading rate (SLR) in a filter press quantifies the mass of dry solids applied per unit filter area per unit time, typically in units of kg/m²/h, serving as a key indicator of the equipment's capacity during the active filtration phase. It is calculated as where is the solids concentration in the feed slurry (kg/m³), is the volumetric slurry flow rate (m³/h), and is the total effective filter area (m²).[82] The net filter yield (Y), also known as net solids yield, measures the overall effective rate of dry solids recovery per unit area over the complete filtration cycle, accounting for non-filtration periods like cake discharge and plate reconfiguration, with units of kg/h/m². This yield provides a more practical assessment of long-term performance, as it reflects operational efficiency including downtime. Both SLR and net filter yield are influenced by operating pressure, which enhances dewatering by compressing the cake and reducing resistance, and by slurry properties such as particle size distribution, concentration, and compressibility; for instance, slurries with high fines content exhibit lower rates due to increased cake resistance. In mining applications, typical net filter yields range from 40 to 100 kg/m²/h for conventional sidebar plate-and-frame presses handling mineral tailings, though advanced membrane types can exceed 350 kg/m²/h with optimized flocculation and pressure up to 16 bar.[83][84] These metrics are primarily used to size filter presses by estimating the required area for a target solids throughput, ensuring economic viability; automatic filter presses generally achieve higher net yields—up to 1.5–2 times those of manual variants—through faster cycle times enabled by hydraulic or pneumatic automation.[83]Filtrate Flow Rate and Efficiency Metrics

The filtrate flow rate in a filter press represents the volume of liquid passing through the filter medium per unit time per unit filter area, typically expressed in cubic meters per hour per square meter (m³/h/m²) or meters per hour (m/h). This rate is governed by principles of pressure-driven cake filtration, where flow declines as cake resistance increases with solids buildup.[85] As filtration progresses, the flow rate declines nonlinearly until the cycle ends.[86] Pre-treatment of the slurry, such as flocculation or coagulation, enhances the initial flow rate by forming more permeable cakes in applications like mining tailings dewatering.[87] Key efficiency metrics for filtrate production include recovery rate, which measures the percentage of input liquid recovered as clear filtrate, typically exceeding 95% for applications yielding clean effluents, such as in mineral processing where water recycling is prioritized.[88] Filtrate clarity is assessed using turbidity measurements (in NTU) to detect residual particulates, with effective filtration achieving <1 NTU for potable or process reuse, or conductivity (in µS/cm) to monitor dissolved ions if salinity affects quality.[89] These metrics confirm efficiency, as pre-treatment directly impacts clarity by minimizing fines passage, thereby supporting higher recovery without secondary polishing.[87]Design and Optimization

Heuristics for Process Design

Selection of the appropriate filter press type depends on the operational volume, desired cake characteristics, and throughput requirements. Plate and frame filter presses are typically recommended for low-volume applications, such as small-scale mining or pharmaceutical processing, where versatility and ease of maintenance are prioritized over speed.[90] Membrane filter presses are preferred for applications requiring drier cakes, as the elastomeric membranes allow for additional squeezing under high pressure, commonly used in wastewater treatment and mineral processing to achieve moisture contents below 20%.[90] For high-throughput operations exceeding 1000 kg/h of solids, automatic filter presses are ideal, incorporating hydraulic automation for rapid plate shifting and cake discharge to minimize downtime.[44] Sizing a filter press begins with calculating the total filtration area required, using the formula , where SLR is the solids loading rate (typically 10-50 kg/m²/h depending on slurry properties) and the safety factor ranges from 1.2 to 1.5 to account for variations in feed consistency or fouling.[91] The number of plates is then determined based on the expected cake volume per chamber, ensuring each plate's capacity (often 20-50 L for standard sizes) aligns with the batch solids load while maintaining even distribution across the press.[92] Process design rules emphasize adapting to slurry behavior; for compressible cakes, such as those from biological sludges, pressure should be limited to 5-10 bar initially to prevent excessive consolidation and increased specific resistance, gradually ramping up to avoid cloth blinding.[44] To accommodate the batch nature of filter presses in continuous processes, incorporating buffer tanks for slurry storage ensures steady feed rates, reducing pump strain and improving cycle consistency.[92] Scale-up from laboratory to industrial systems relies on pilot testing to measure specific resistance (often 10^9 to 10^12 m/kg for typical slurries), which informs pressure drop predictions and area requirements under full-scale conditions.[93] Economic analysis is crucial, balancing capital expenditures (CAPEX) for larger presses against operational expenditures (OPEX) from energy and maintenance, with payback periods typically 2-5 years for high-solids applications.[44] Modern design heuristics include hybrid integrations, such as pre-dewatering with centrifuges to thicken slurries to 10-20% solids before filter press feeding, enhancing overall efficiency in tailings management.[94] Additionally, AI-driven systems enable dynamic adjustments to parameters like pressure profiles and cycle times based on real-time slurry data, improving throughput in automated setups. As of 2025, advancements in predictive analytics, such as those from Roxia and ANDRITZ, further optimize filtration cycles and moisture prediction.[95][96]Energy Consumption and Sustainability Factors

Filter presses exhibit varying energy consumption depending on the slurry characteristics, cake dryness targets, and system design, typically ranging from 1 to 5 kWh per ton of dry solids processed.[97] In many systems, the feed pump alone accounts for 90-95% of the total energy due to its continuous operation during filling.[97] This distribution highlights pumping as the dominant energy demand, influenced by factors like slurry viscosity and required filtration pressure.[97] Reduction strategies have advanced significantly in recent models, incorporating variable speed drives (VSDs) on pumps and motors to match energy input to operational needs, potentially cutting consumption by 20-40% compared to fixed-speed systems.[98] Regenerative hydraulics, which recover and reuse energy from pressure release cycles in the hydraulic power unit, further enhance efficiency by minimizing waste heat and power losses, with some 2020s-era designs achieving up to 30% lower overall energy use through optimized pump sizing and slower feed cycles.[97] These approaches not only lower operational costs but also extend equipment lifespan by reducing mechanical stress.[98] Sustainability in filter press operations is bolstered by features like closed-loop water recycling, which recovers 80-95% of process water for reuse in subsequent cycles, significantly reducing freshwater intake and wastewater discharge.[99] The use of biodegradable filter aids, such as cellulose-based materials, supports eco-friendly filtration by enabling compostable waste streams and minimizing environmental persistence of residues.[100] Compared to continuous centrifuges, filter presses in batch operations often yield a lower carbon footprint due to reduced energy intensity and simpler mechanics.[94] Regulatory compliance plays a key role in sustainable deployment, with filter presses supporting adherence to U.S. Environmental Protection Agency (EPA) standards for biosolids management under 40 CFR Part 503, which governs the use or disposal of sewage sludge to protect public health and the environment. Considerations for odors and potential sulfide emissions during cake storage and handling are managed through enclosure and ventilation systems.[101] Life-cycle assessments (LCAs) of filter press materials emphasize durable, recyclable components like polypropylene cloths and steel frames to minimize embodied carbon, guiding selections that lower overall environmental impact across manufacturing, use, and disposal phases.[102] Innovations in the field include solar-powered auxiliary systems, such as photovoltaic integration for hydraulic pumps and controls, which offset grid dependency in remote or off-grid installations.[103] Additionally, filter presses are increasingly integrated with renewable energy processes, like biomass dewatering in biofuel production, where efficient solids separation enhances yield while aligning with zero-waste goals.[104] These developments underscore the technology's evolution toward greener industrial practices.Applications and Comparisons

Industrial and Traditional Applications

Filter presses play a central role in the mining and minerals sector, where they are employed for dewatering tailings and ore concentrates to manage waste and recover process water. In tailings management, these devices process slurries from mineral extraction, producing a stackable filter cake that minimizes environmental impact and reduces the volume of wet waste stored in impoundments. For ore concentrates, such as those from copper, zinc, or gold processing, filter presses separate valuable solids from liquids, enabling efficient drying and transport; for instance, they can elevate solids content from feed slurries around 20-40% to cakes exceeding 60% solids, depending on material properties and operating conditions.[103][105][106][107] In wastewater treatment, particularly at municipal plants, filter presses are utilized for sludge thickening and dewatering to produce biosolids suitable for disposal or reuse. They apply high pressure to conditioned sludge, squeezing out water to form a semi-solid cake, which reduces hauling costs and volume by up to 90% compared to untreated sludge. This process aids in biosolids recovery, allowing for nutrient-rich material that can be land-applied as fertilizer after stabilization, while clarifying the filtrate for further treatment or discharge. Recessed-plate designs are especially effective for municipal applications, achieving cake solids contents of 25-40% and high capture rates over 98%.[101][108][109] The chemical and pharmaceutical industries rely on filter presses for precise solid-liquid separation in processes like crystal separation and pigment filtration. In pharmaceutical production, they isolate active pharmaceutical ingredients or crystals from reaction mixtures, ensuring high purity and yield while complying with Good Manufacturing Practice (GMP) standards through sanitary designs and validated cleaning protocols. For pigments in the chemical sector, filter presses handle slurries of inorganic or organic colorants, such as iron oxides or titanium dioxide, to produce dry cakes for further processing into paints, inks, or coatings, with filter media selected to retain fine particles down to 1 micron. GMP-compliant models feature stainless steel construction and automated controls to prevent contamination.[110][111][112][113] In food processing, filter presses contribute to product clarification by removing solids from liquids, enhancing quality and shelf life. For maple syrup production, they filter hot syrup to eliminate nitre, sugar sand, and other impurities, using diatomaceous earth pre-coats for optimal clarity without affecting flavor; the process involves stacking filter papers between plates and applying pressure to yield bright, debris-free syrup at rates suitable for small to medium producers. Similarly, in fruit juice processing, filter presses separate pulp solids and sediments from apple, berry, or citrus juices, producing clear filtrate for packaging while compacting waste as a filter cake; this step follows enzymatic treatment and ensures high throughput with minimal product loss.[114][115] Additional traditional applications include coal washing and marble slurry dewatering in ceramics manufacturing. In coal washeries, membrane filter presses dewater fine coal tailings from cleaning operations, reducing moisture to 15-25% to produce transportable cakes and recycle water, thereby improving efficiency in fine particle recovery. For ceramics, filter presses treat marble and granite cutting slurries, separating stone dust from water to achieve cakes with residual moisture below 25%, allowing solids reuse in production and clean effluent discharge.[116][117] Case studies illustrate the scalability of filter presses in these industries, with typical installations processing 5-50 tons of solids per day in smaller operations, such as regional mining sites or municipal treatment facilities, where cycle times and automation balance throughput with energy use. For example, a compact model might handle 5 tons per cycle in pigment filtration, enabling daily outputs in this range for batch chemical processes. Larger systems scale up significantly, but these mid-range capacities represent common traditional setups.[118][119]Emerging Applications and Specialized Uses

In the realm of battery materials recovery, filter presses have gained prominence in the 2020s for processing spent lithium-ion batteries from electric vehicles (EVs), enabling the separation of valuable metals such as lithium and cobalt from leachates and residues. These systems facilitate high-purity filtrate production by compressing slurries to extract clean liquids while concentrating solids for further metal reclamation, supporting scalable recycling operations. For instance, multi-plant filter press installations have been deployed specifically for EV battery recycling, achieving efficient solid-liquid separation to recover cobalt and lithium with minimal environmental impact. As of 2025, with global EV battery waste projected to reach 1 million tons annually, filter presses support recycling rates over 95% for key metals, driven by regulations in the EU and US.[120][121][122] Emerging uses in renewables leverage filter presses for dewatering biomass slurries in biofuel production, where plate-and-frame designs coated with diatomaceous earth enhance microalgae harvesting efficiency by up to 20%, yielding biomass with water content as low as 22% for downstream biofuel conversion. Chamber filter presses are also applied in algal biomass processing, concentrating flocculated microalgae post-sedimentation to produce dry cakes suitable for lipid extraction in renewable fuel pathways. This approach addresses the high water content in algal cultures, streamlining the transition from cultivation to biofuel feedstock preparation.[123][124] Specialized applications include pharmaceutical waste treatment, where filter presses separate solids from liquid effluents generated during drug manufacturing, reducing waste volume and ensuring compliance with stringent purity standards through automated cake discharge. Portable and mobile filter press units have been developed for remote sites, such as mining or field environmental remediation, offering on-site dewatering of slurries without reliance on fixed infrastructure, thus enabling flexible operations in isolated locations.[125][126] By 2025, key trends involve advancements in membrane filter presses with enhanced plate designs for finer particle retention in research and development settings. Modular, containerized filter press designs are increasingly adopted for R&D prototyping, allowing scalable testing of novel slurries while minimizing footprint and setup time. These advancements promote a circular economy by facilitating metal recycling from battery wastes, closing loops in supply chains for critical materials and reducing reliance on virgin resources.[127][64][121]Advantages, Disadvantages, and Comparisons to Alternatives

Filter presses provide several key advantages in solid-liquid separation processes. They produce highly dry filter cakes, often achieving 70-80% solids content in industrial applications like mining and chemical processing, which minimizes waste volume and associated handling costs. Operating costs are relatively low, typically ranging from $0.5 to $2 per ton of dry solids, due to efficient energy use (0.03-0.05 kWh/kg dry solids) and minimal polymer requirements in optimized setups. Their compact design requires a smaller footprint compared to many continuous systems, making them ideal for batch operations with intermittent or variable feed streams.[31][128][129][26] Despite these benefits, filter presses have notable disadvantages. Their inherent batch operation necessitates downtime for cake discharge and cloth cleaning, limiting applicability in high-throughput, continuous production environments and extending cycle times to 1.5-4 hours per batch. Initial capital costs are high, frequently surpassing $100,000 for basic units and up to several million for large-scale installations, alongside mechanically complex designs that demand regular maintenance. Manual variants also require significant labor for plate handling and odor exposure during operations.[23][23][130][131] When compared to alternative filtration methods, filter presses excel in scenarios requiring high-pressure dewatering for intermittent processing but lag in continuous efficiency. Versus vacuum belt filters, filter presses deliver superior cake dryness (up to 60% solids versus 19-30%) and are preferable for feeds with high solids content (>15%), though their batch mode contrasts with the continuous operation of belts, which offer lower energy use but reduced yield for fines. Against centrifuges, filter presses yield drier cakes (40-55% solids versus 20-25%) and lower energy consumption, but centrifuges provide faster, continuous processing with better automation, albeit at higher power costs (0.07 kWh/kg dry solids). Relative to rotary vacuum drum filters, filter presses apply higher pressures for better fine particle retention and drier outputs (versus up to 35% solids), making them suitable for challenging slurries, while drums support higher capacities in continuous flows but with more moisture retention. Quantitative metrics highlight these trade-offs, as shown below:| Metric | Filter Press | Vacuum Belt Filter | Centrifuge | Rotary Vacuum Drum |

|---|---|---|---|---|

| Cake Solids (%) | 40-55 (up to 80 in mining) | 19-30 | 20-25 | Up to 35 |

| Yield (kg/m²/h) | 20-50 | 10-30 | N/A (volume-based) | 300-450 kg DS/h·m² |

| Energy (kWh/kg DS) | 0.03-0.05 | Lower overall | 0.07 | Moderate |

| Operation Mode | Batch | Continuous | Continuous | Continuous |