Recent from talks

Nothing was collected or created yet.

Leaky feeder

View on Wikipedia

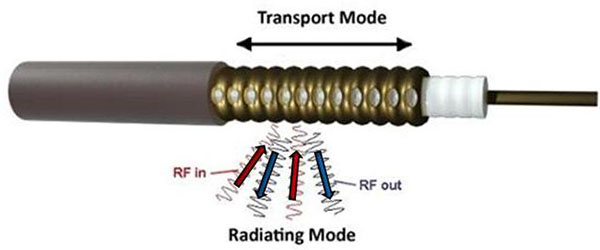

A leaky feeder is a kind of antenna used for communication in mines, tunnels, and other enclosed spaces.[1] The commercial name radiating cable[2][3][better source needed][4] emphasizes that it is designed to radiate, unlike most cables.

Principle

[edit]A leaky feeder communication system consists of a cable run along tunnels which emits and receives radio waves, functioning as an extended antenna. The cable is "leaky" in that it has gaps or slots in its outer conductor to allow the radio signal to leak into or out of the cable along its entire length. Because of this leakage, line amplifiers are inserted at regular intervals, typically every 350 to 500 metres, to boost the signal. The signal is usually picked up by portable transceivers carried by personnel. Transmissions from the transceivers are picked up by the feeder and carried to other parts of the tunnel, allowing two-way radio communication throughout the tunnel system.

The system has a limited range and because of the frequency it uses (typically VHF or UHF), transmissions cannot pass through solid rock, which limits the system to a line-of-sight application. It does, however, allow two-way mobile communication.

Due to the signal loss, a leaky feeder is usually used for frequencies under 1 GHz. Above that frequency, the losses require too many repeaters, thus making other options more effective. Antennae (omni, panel or bi-directional) or even distributed antenna systems are more often used for higher frequency bands.

Applications

[edit]Mining

[edit]Leaky feeders are used in the mining industry for wireless communication between miners. The system is used as a primary communication system with a transceiver small enough to be comfortably worn for an entire shift.[5]

Underground railways

[edit]The leaky feeder system is used for underground mobile communication in mass transit railways. In Delhi, Hong Kong, and Copenhagen, leaky feeders were installed during construction.[citation needed][clarification needed] This gives emergency services seamless mobile communication from underground to the surface.

The London Underground uses a leaky feeder system for its internal communication network Connect.[6] However, the communication used by the emergency services, Airwave, was not compatible and did not work below ground. The fact that this situation continued to exist after the 1987 King's Cross fire was criticised in the reports from the 7 July 2005 London bombings, where it hampered rescue efforts.[7] In March 2020, two additional leaky feeder cables were brought online in the Jubilee line extension tunnels between Canning Town and Westminster. One of these cables provided commercial 4G coverage for passengers, both in the tunnels and on station platforms,[8] whilst the second cable provided coverage for the Home Office's Emergency Services Network (ESN),[9] which is currently being rolled out to replace the ageing Airwave network.[10] This trial section is the first to be brought online as part of a project to provide both commercial 4G coverage and ESN coverage across the entire Tube network.

Tyne and Wear Metro was the first railway in the UK to use leaky feeder cables for public mobile phone connectivity, in its city-centre underground tunnels. Initially this was a 2G signal, but then mobile operator EE upgraded this to 4G for their customers. As of 2023, operator Nexus are planning a comprehensive upgrade to mobile data coverage, including in the tunnels.[11]

An alternative to using leaky feeder in underground railways is to use Distributed Antenna System (DAS). A DAS system was deployed in some New York City Subway stations by Transit Wireless to provide Wi‑Fi and mobile phone and data coverage for customers.[12]

In-flight wireless networks

[edit]Leaky feeder antenna systems can also be used to allow use of onboard mobile phones and Wi‑Fi on passenger aircraft.[13][14] The weight and space requirements of leaky feeder systems are usually lower than comparable antenna systems, thus saving space and fuel. The even field strengths produced by runs of leaky feeders spanning the entire fuselage improve coverage while requiring less transmitting power.

Industrial buildings

[edit]Leaky feeders are used in hotels, warehouses and other industrial buildings where it is difficult to get Wi‑Fi coverage using normal access points. Some installations have 50–75 meters of leaky wire connected to the antenna output of each access point.[15]

RFID

[edit]A leaky feeder modified with metallic strips can be used as a radio-frequency identification (RFID) antenna.[16][17]

See also

[edit]References

[edit]- ^ "Improvements coming soon to mine communications". Kentucky New Era. Associated Press. 19 February 2007. Retrieved 6 March 2012.

- ^ "Times Microwave Radiating Cable Catalogue" (PDF). Times Microwave. Archived from the original (PDF) on 23 February 2017. Retrieved 12 March 2017.

- ^ "Radiating Cable". CommScope. Retrieved 13 September 2014.

- ^ "Radiating cable revealed". Radio Frequency Systems. Archived from the original on 30 August 2017. Retrieved 13 September 2014.

- ^ "Basic Tutorial on Wireless Communication and Electronic Tracking: Technology Overview". Centers for Disease Control and Prevention. Retrieved 8 March 2014.

- ^ "Victoria line heads Metronet renewal". Railway Gazette International. 1 August 2003. Retrieved 6 March 2012.[permanent dead link]

- ^ "Communications blamed in London bomb response". PC Advisor. 23 February 2012. Retrieved 6 March 2012.

- ^ "4G on Jubilee line tunnel section from March 2020". Transport for London (Press release). Retrieved 2021-03-12.

- ^ Kobie, Nicole (2020-02-05). "Inside the messy mission to bring 4G to the London Underground". Wired UK. ISSN 1357-0978. Retrieved 2021-03-12.

- ^ "Emergency Services Network: overview". GOV.UK. Retrieved 2021-03-12.

- ^ "Nexus announces plan to improve digital connectivity on Tyne and Wear Metro | nexus.org.uk". Archived from the original on 2023-07-07. Retrieved 2025-09-05.

- ^ Nally, Jonathan (30 September 2013). "Tunnel vision: getting New York talking". CriticcalComms. Archived from the original on 1 October 2013. Retrieved 8 March 2014.

- ^ ETSI White Paper No. 4 GSM operation onboard aircraft (PDF), January 2007

- ^ W. L. Gore & Associates (15 October 2013), "Leaky Feeder Antennas for Airborne Wi-Fi", Microwave Journal

- ^ "Leaky Feeder Communication and Installation Guide for Business". Wall to Wall Communications. 11 February 2019. Retrieved 12 March 2019.

- ^ Putaala, Jussi; Myllymäki, Sami; Kokkonen, Mikko; Jantunen, Heli (July 2021). "Resonator-enhanced radiating cable for UHF RFID readers" (PDF). Microwave and Optical Technology Letters. 63 (7): 1842–1847. doi:10.1002/mop.32844. S2CID 233392835.

- ^ Kokkonen, Mikko; Myllymaki, Sami; Putaala, Jussi; Jantunen, Heli (2022). "A Resonator Enhanced UHF RFID Antenna Cable for Inventory and Warehouse Applications" (PDF). IEEE Journal of Radio Frequency Identification. 6 (1): 128–133. Bibcode:2022IJRFI...6..128K. doi:10.1109/jrfid.2021.3135047. S2CID 245218056.

External links

[edit]Leaky feeder

View on GrokipediaHistory

Invention and Patenting

The leaky feeder principle, involving the intentional radiation of radio frequency signals from a transmission line to enable communications in enclosed environments such as tunnels, was first systematically described and experimentally validated in 1956 by N. Monk and H.S. Winbigler. In their work, published in the IRE Transactions on Vehicular Communications, they demonstrated two-way VHF communication with moving trains inside the North River tunnel using an open-wire transmission line or twin-lead cable laid parallel to the tracks, which allowed signal leakage to couple with the tunnel's conductive walls for propagation. This approach addressed the limitations of direct radio propagation in long, shielded spaces by treating the tunnel as part of an artificial waveguide, with the leaky line compensating for attenuation through controlled field leakage.[8] While the 1956 disclosure established the foundational concept without a specific patent, practical implementations evolved toward coaxial designs for improved shielding and efficiency. In the early 1970s, as applications expanded to mining and underground facilities, George Brownell, an American engineer, developed a leaky coaxial cable featuring periodic slots or apertures in the outer conductor to facilitate uniform signal radiation. Brownell filed a patent application for this "leaky coaxial cable" on October 29, 1971, which was granted as U.S. Patent No. 3,945,006 on September 21, 1976, describing a structure optimized for broadband leakage while minimizing external interference. This patent marked a key advancement in commercial viability, enabling rugged, low-loss cables suitable for harsh environments, though earlier non-coaxial leaky lines had already seen limited deployment.[9] Subsequent patents built on these foundations, such as those for integrated amplifiers and slot geometries, but Brownell's work is credited with pioneering the modern coaxial leaky feeder form factor widely adopted in the 1970s for mine safety communications. Historical reviews confirm that pre-1970s systems relied more on simpler twin-lead configurations, with coaxial variants proliferating after patent protections facilitated manufacturing scalability.[10]Initial Deployments and Evolution

The initial deployments of leaky feeder systems occurred in underground coal mines in the United Kingdom during the late 1960s, driven by the need for reliable radio communication in wet and confined environments where traditional wiring failed. The National Coal Board began evaluating leaky transmission lines in 1967 as a superior alternative to twin feeders, with early trials conducted at the Longannet colliery to extend VHF signal coverage along roadways.[11] These systems utilized coaxial cables with intentional apertures in the outer conductor to radiate signals uniformly, enabling two-way voice communication between mobile radios and fixed base stations over distances previously unattainable without excessive infrastructure.[10] By the 1970s, leaky feeder technology had proliferated to North American underground mines, where it addressed similar challenges in extending radio range for safety and operational coordination.[5] Early installations typically employed analog VHF frequencies, with line-powered amplifiers spaced every 300-500 meters to offset attenuation and maintain signal strength up to several kilometers.[3] This era marked the shift from rudimentary open-braided cables—first conceptualized in 1956—to engineered radiating cables optimized for mine environments, incorporating periodic boosters for consistent coverage. Evolution in the subsequent decades involved enhancements for broader applications and improved performance. In underground railways, leaky feeders were adapted for train traffic control, with systems like those in UK metros providing bidirectional communication by the 1980s.[3] Technical refinements included better shielding materials to minimize interference and support higher frequencies, enabling integration with data telemetry for monitoring equipment and personnel tracking.[10] By the 2000s, deployments expanded beyond mining to tunnels and urban subways, while hybrid digital-analog variants emerged to handle voice, low-bandwidth data, and eventually compatibility with fiber optic backhauls, though initial costs—often exceeding $800,000 for comprehensive mine setups—limited adoption to high-risk sites.[3] Recent advancements focus on broadband capabilities for autonomous vehicles, yet core principles of controlled leakage persist from early mine trials.[12]Technical Principles

Core Mechanism of Signal Leakage

A leaky feeder cable functions as a specialized coaxial transmission line designed to intentionally radiate radio frequency (RF) signals along its length, unlike standard coaxial cables that confine electromagnetic waves within the inner conductor, dielectric, and outer shield. The core mechanism relies on periodic apertures, such as slots or perforations, introduced into the outer conductor, which disrupt the shielding and permit controlled leakage of the guided TEM (transverse electromagnetic) mode into the surrounding environment.[13][1] Signal propagation begins with an RF transmitter injecting energy into the cable, where it travels as a coaxial mode wave supported by currents on the inner and outer conductors separated by the dielectric insulator. At each aperture in the outer conductor—typically longitudinal slots spaced at intervals matching the wavelength—the discontinuity causes a portion of the electric and magnetic fields to couple externally, converting part of the guided energy into radiated waves or evanescent fields that extend radially from the cable. This leakage manifests as an intentional attenuation of the forward-propagating signal, typically engineered to values between 3 and 15 dB per 100 meters depending on frequency and design, ensuring uniform coverage without excessive loss over long runs.[14][13][15] The external coupling to mobile transceivers occurs primarily through two mechanisms: direct radiation for farther distances, where slots act as distributed slot antennas emitting omnidirectional or directional fields, and near-field coupling for close-range devices, where diffracted leakage fields from the coaxial mode interact with the mobile antenna within a "congestion radius" of approximately 3-5 meters. This dual-mode behavior—radiation-dominated at higher frequencies and coupling at lower—arises from the physics of mode conversion at the slots, where the outer conductor's incomplete shielding reduces lateral attenuation, allowing electromagnetic energy to penetrate the environment while maintaining primary signal integrity along the cable axis. Inline amplifiers, spaced every 300-500 meters, counteract cumulative leakage losses to sustain signal strength.[14][15][1]Design Features and Materials

Leaky feeder cables are coaxial transmission lines engineered with deliberate imperfections in the outer conductor to enable controlled electromagnetic signal leakage along their length, providing radio frequency coverage in enclosed environments such as tunnels and mines.[16] The primary design feature is the incorporation of slots, apertures, or loose braiding in the shielding, which allows a portion of the guided wave energy to radiate externally as a leakage field, typically achieving coupling losses of around 60 dB at distances of 6 meters from the cable at 450 MHz.[17] These imperfections contrast with standard coaxial cables, where the outer conductor is designed to minimize leakage; in leaky feeders, the slots are often arranged in a periodic or continuous pattern, such as a single continuous slot or zig-zag configurations, to balance attenuation and radiation efficiency across frequencies up to 2.5 GHz.[17][16] Common diameters include 1/2 inch (13 mm) and 7/8 inch (22 mm) for underground applications, with characteristic impedance standardized at 50 ohms to match typical radio equipment.[17] Materials selection prioritizes low loss, flexibility, and environmental durability, particularly flame retardancy for mining use. The inner conductor is typically solid oxygen-free copper or bare copper-covered aluminum for reduced attenuation, surrounded by a gas-injected foam polyethylene dielectric to achieve propagation velocities of 85-88%.[17] The outer conductor employs a bonded aluminum or copper tape with integrated slots or a braided copper wire configuration featuring intentional gaps, enabling the surface transfer impedance necessary for leakage while maintaining structural integrity.[17] [16] The outermost jacket is usually polyvinyl chloride (PVC) or flame-retardant polyethylene (FRPE), often low-smoke zero-halogen (LSZH) formulations compliant with standards like MSHA for underground safety, with operating temperatures ranging from -40°C to +85°C.[17] These materials ensure the cable's attenuation remains manageable, such as 2.22 dB per 100 feet at 450 MHz for mid-sized variants, supporting long runs with periodic amplification.[17]Propagation Characteristics

Leaky feeder cables propagate radio frequency signals as guided transverse electromagnetic (TEM) waves along the coaxial transmission line, with controlled leakage through periodic slots or apertures in the outer conductor enabling radiation to proximate receivers. This dual function results in higher longitudinal attenuation than sealed coaxial cables, as energy is intentionally dissipated for coverage, balanced by design parameters optimizing transmission over distances of 1-2 km per segment. Propagation velocity is determined by the dielectric constant of the insulating material, while the phase constant maintains coherence along the cable, supporting applications in VHF to UHF bands from approximately 30 MHz to 1 GHz.[16] The longitudinal attenuation constant, representing signal loss per unit length, increases with frequency due to greater radiative efficiency at shorter wavelengths and is influenced by conductor size, dielectric losses, and environmental interactions such as proximity to tunnel walls or moisture accumulation. For a typical 1-5/8 inch RF feeder leaky cable, attenuation values are as follows:| Frequency (MHz) | Attenuation (dB/100 m) |

|---|---|

| 75 | 0.60 |

| 150 | 0.90 |

| 300 | 1.30 |

| 450 | 1.60 |

| 900 | 2.70 |

| Frequency (MHz) | Coupling Loss 50% (dB) | Coupling Loss 95% (dB) |

|---|---|---|

| 75 | 63 | 72 |

| 150 | 66 | 76 |

| 300 | 68 | 72 |

| 450 | 67 | 70 |

| 900 | 58 | 60 |

System Components

Cable Construction

Leaky feeder cables consist of a coaxial structure modified to enable intentional radio frequency (RF) signal radiation along their length. The core components include a central conductor, a dielectric insulator, an outer conductor with engineered apertures, and an external protective jacket. This design allows most of the signal to propagate internally while a controlled portion leaks outward to provide distributed coverage.[1][17] The inner conductor is typically a solid or stranded annealed copper wire or bare copper-clad aluminum (BCCAI) tube, selected for high conductivity and mechanical strength to minimize transmission losses. Surrounding this is a low-loss dielectric, often gas-injected foamed polyethylene, which supports the characteristic impedance—usually 50 ohms—and reduces attenuation while maintaining flexibility.[17][20] The outer conductor, critical for leakage, differs from standard coaxial cables by incorporating slots, gaps, or perforations rather than a continuous shield. Common implementations include a bonded aluminum tape or copper foil with a continuous single slot, periodic non-uniformly spaced slots, or zig-zag apertures, which control coupling loss and radiation pattern—often directing emission over approximately 180 degrees with slots positioned on one side. In flexible variants, a loosely woven braid serves as the outer conductor to permit RF escape, while rigid types may use corrugated copper tubing with intentional discontinuities. These features balance shielding against external interference with uniform signal leakage, typically achieving coupling losses around 60 dB at frequencies like 2.4 GHz.[17][1][16] An outer jacket, usually polyethylene (PE), polyvinyl chloride (PVC), or low-smoke zero-halogen (LSZH) materials, encases the assembly for environmental protection, flame retardancy, and mechanical durability in harsh settings like mines. Specialized jackets may include dual layers for water blocking in direct-buried applications or enhanced UV and cold resistance. Cable diameters vary, such as 0.350 inches for smaller flexible models, enabling installation around curves without kinking. Manufacturing emphasizes precision in slot geometry and spacing to ensure consistent attenuation—e.g., 1.34 dB per 100 feet at 150 MHz for larger sizes—and broadband operation from VHF to 2.5 GHz.[17][21][22]

Amplifiers and Accessories

In leaky feeder systems, bidirectional amplifiers (BDAs) are essential components that compensate for the longitudinal signal loss in radiating cables, typically spaced every 300 to 500 meters depending on cable attenuation and frequency band. These amplifiers boost both transmit and receive signals to ensure uniform coverage over extended distances, with models like the PBE BDA-4 providing up to 20 dB gain in VHF bands while operating on a wide supply voltage range of 6 to 24 VDC for flexible underground deployment.[23][24] VHF BDAs, such as those from Becker Mining Systems, are designed specifically to counter cable losses in mining environments, supporting voice and data communications by amplifying signals bidirectionally without introducing significant noise or distortion.[25] UHF and LTE-compatible BDAs extend functionality to broadband applications, with devices like the MB-UBDA-01-WW operating in the 435-455 MHz uplink band to integrate voice and data services in a single unit.[26] Line amplifiers, such as the Digital Drift DDLFS-LA-V75, incorporate features like Ethernet monitoring for remote diagnostics, passing broadband data with minimal loss while providing selectable gain levels for VHF signals at 75 Ohm impedance.[27] These amplifiers must comply with safety standards, as evidenced by MSHA approval for the PBE BDA-4 in 2014, ensuring reliability in hazardous locations by preventing signal degradation through rock, equipment, and cable leakage.[23] Accessories complement amplifiers by facilitating connections, termination, and power distribution. Coupling units or taps connect portable radios to the cable, injecting or extracting signals at access points with minimal insertion loss, often using 75 Ohm impedance matching to avoid reflections.[28] Line splices join cable segments, such as the Sigma Communication Systems VHF splice, which maintains 75 Ohm integrity with low loss for seamless extension.[28] Terminators at cable ends prevent standing waves by absorbing residual signals, while power inserters supply DC voltage to amplifiers along the line, typically via the cable's center conductor.[29] Backup power systems, including DC UPS units with remote monitoring, ensure continuous operation during outages by charging batteries and delivering 30 VDC to the network.[29] Connectors and adapters, customized for corrugated copper designs, secure joints against environmental stresses like moisture and vibration in tunnels.[30]Integration with Transmitters and Receivers

Leaky feeder systems integrate with transmitters by connecting the proximal end of the cable to the output port of a base station or repeater transmitter via coaxial connectors, such as N-type or BNC, to inject radiofrequency (RF) signals into the cable for propagation and leakage along its length.[4] This setup treats the cable as an extended antenna, with signal attenuation typically managed at 5-10 dB per 100 meters depending on frequency and cable design, necessitating inline amplifiers spaced every 300-500 meters to maintain output power levels up to 50 watts.[31][3] Receiver integration occurs similarly, with the cable's signal output coupled to the receiver input, enabling the capture of RF signals leaked into the cable from portable transceivers within proximity (usually 10-50 meters radially).[4] In two-way systems, a single bidirectional cable connects to a duplexer or circulator at the base station transceiver to separate transmit and receive paths, preventing interference while supporting frequencies in VHF (30-300 MHz) or UHF (300-3000 MHz) bands common in mining applications.[32][33] Impedance matching, typically at 50 or 75 ohms, is critical during integration to minimize reflections and standing waves, achieved through matching transformers or stubs if the transmitter/receiver impedance differs from the cable's characteristic impedance.[3] Portable radios interface wirelessly with the cable via electromagnetic coupling, relaying signals to the base receiver without direct wired connection, as demonstrated in underground evaluations where received signal strength indicators (RSSI) remain viable up to 2-3 km along the cable with proper amplification.[31][34] Systems often incorporate automatic gain control in receivers to handle varying leakage levels, ensuring consistent performance in environments with multipath interference.[3]Applications

Mining and Underground Extraction

Leaky feeder systems provide essential two-way radio communication in underground mining operations, where rock formations and tunnel geometries severely attenuate conventional wireless signals. These systems employ a coaxial cable intentionally designed with apertures or slots to radiate and receive radio frequencies along its length, enabling uniform coverage over distances exceeding several kilometers when amplified.[35] In mining contexts, the cable is typically suspended from tunnel roofs, connecting portable radios used by workers to a surface base station for voice dispatch, emergency alerts, and coordination.[36] Deployment began in the 1970s as a hybrid wired-wireless solution to overcome propagation challenges in confined subterranean spaces.[5] Regulatory mandates have solidified their role in safety protocols, particularly following the U.S. Mine Improvement and New Emergency Response (MINER) Act of 2006, enacted after disasters like Sago and Darby where communication failures hindered evacuations.[34] The Act requires wireless two-way communication and electronic tracking systems capable of functioning post-accident, with leaky feeders approved by the Mine Safety and Health Administration (MSHA) for compliance, such as VHF models like the MCA 1000 with MSHA approval 23-A090003-0 supporting minimum RFI distances of 8 feet.[37][38] Systems must maintain integrity during emergencies, including separation from blasting operations up to 50 feet as permitted in emergency response plans.[39] Beyond voice, leaky feeders facilitate data transport for mine monitoring, such as integrating Internet Protocol over land mobile radio for sensor networks tracking ventilation, gas levels, and equipment status.[40] In coal mines, VHF leaky feeders predominate due to their penetration in dusty, methane-prone environments, often interfacing with tracking tags for personnel location.[34] Empirical assessments indicate reliable performance in active workings, though susceptibility to cable damage from roof falls or machinery necessitates redundant segments and regular testing.[3] Adoption extends to metal and hard-rock mines globally, enhancing productivity by enabling remote control of machinery and real-time fault reporting.[41]Tunneling and Underground Rail Systems

Leaky feeder systems provide essential radio coverage in tunneling projects, where concrete and earth walls severely attenuate signals and conventional antennas cannot maintain consistent propagation over extended distances. These systems utilize radiating cables installed along tunnel lengths to enable voice, data, and emergency communications for workers and equipment. According to evaluations by the U.S. Centers for Disease Control and Prevention, leaky feeders are deployed in tunnels too long for standard antennas, supporting land mobile radio services in such confined environments.[3] In underground rail systems like subways and metros, leaky feeders facilitate bidirectional communication for train control, passenger mobile connectivity, and public safety networks, addressing challenges posed by curved tunnels, station platforms, and signal blockage from metal structures. For example, in the London Underground, two dedicated leaky feeder cables were installed by early 2020—one for commercial 4G mobile services and a second for the U.K. Home Office's emergency services network—to deliver in-tunnel coverage across multiple lines.[42] Technical assessments in metro tunnels have compared broadband and radiating-mode leaky feeders, measuring coupling losses as low as 50-70 dB under dry conditions to optimize signal leakage for VHF/UHF frequencies.[43] International standards, such as those from the International Telecommunication Union, endorse leaky feeders for land mobile applications in tunnels, recommending designs that handle moisture and mounting difficulties while ensuring uniform attenuation rates of 5-10 dB per 100 meters.[4] In high-speed rail and metro expansions, secure cable clamping prevents sagging and maintains impedance matching, critical for minimizing reflections in linear topologies exceeding several kilometers.[44] These deployments often integrate with TETRA or LTE protocols, providing scalable solutions that outperform distributed antenna systems in cost and reliability for deep underground rail corridors.[45]Industrial Facilities and Large Structures

Leaky feeder systems provide essential radio frequency coverage in industrial facilities where conventional antennas struggle due to signal attenuation from metal machinery, reinforced concrete walls, and expansive layouts. In factories and refineries, these systems connect sensors, cameras, and control equipment across large sites, enabling real-time data transmission for operational monitoring and safety protocols.[46] [47] This application is particularly valuable in hazardous areas, such as flammable gas plants, where intrinsically safe communication prevents ignition risks from traditional wireless devices.[47] In chemical plants and petrochemical refineries, leaky feeders support two-way radio communications for worker coordination and emergency response, radiating signals uniformly along cable runs installed parallel to production lines or piping corridors. These installations mitigate multipath fading and shadowing effects common in environments with dense metallic infrastructure, ensuring consistent coverage without the need for numerous discrete antennas.[48] Systems often integrate with existing SCADA networks for remote control of valves, pumps, and alarms, as documented in evaluations of radiating cable performance in complex industrial settings.[48] Warehouses and other large enclosed structures utilize leaky feeders for paging, maintenance dispatching, and wireless inventory systems, where high shelving and stacked goods create propagation dead zones. Cables are typically suspended from ceiling joists or routed along structural beams to deliver contoured indoor RF distribution, as per manufacturer guidelines for such deployments.[3] [1] In utility buildings and sprawling industrial complexes, they extend coverage to underground or semi-enclosed service areas, supporting voice and data links over distances exceeding several kilometers when amplified.[49] International standards recognize their efficacy in large buildings with inadequate natural propagation, emphasizing self-contained setups for reliable in-building networks.[14]Military and Security Environments

Leaky feeder systems provide essential radio coverage in military underground facilities, such as bunkers and tunnels, where line-of-sight propagation is obstructed by reinforced structures and earth, ensuring bi-directional VHF and UHF communications for command and control operations.[50][51] In these environments, the cable's intentional signal leakage along its length maintains uniform coverage without dead zones, penetrating obstacles like concrete walls that attenuate conventional antennas.[52] This reliability supports secure voice, data, and telemetry links in confined spaces, reducing risks during emergencies or sustained operations.[51] In security applications, leaky feeders enable perimeter surveillance and border monitoring by extending radio networks along linear installations, such as fences or patrol routes, where terrain or foliage disrupts standard signals.[50] Their design offers resistance to electronic jamming and interference, minimizing detectability through a reduced RF signature compared to point-source antennas, which is critical for stealthy operations in electronic warfare scenarios.[52] Systems like those integrated with mesh radio technologies further enhance adaptability, allowing low-latency reconfiguration in dynamic threats.[50] For field deployments and urban combat, leaky feeders facilitate communications in complex terrains, including subways or building interiors repurposed for defense, by combining wired backbone stability with wireless mobility.[53][50] This setup has been adapted for military use since at least the early 2000s, with advancements in software-defined radios improving integration with existing defense networks.[50] Overall, these systems prioritize operational continuity in high-stakes environments over broader-area coverage, outperforming alternatives in signal consistency through physical infrastructure.[52]Specialized Uses

In correctional facilities, leaky feeder systems provide controlled wireless communication to mitigate security risks from unauthorized signals. These systems leverage near-field signal propagation to limit coverage to specific zones, enabling selective access for staff or monitored inmate devices while preventing external interference or organized crime coordination. A 2014 analysis of mobile systems in socially sensitive environments highlights how leaky feeders' intentional signal leakage supports such applications without compromising containment.[54] Commercial implementations, such as those integrated with entertainment systems, further adapt leaky feeders for vandal-prone areas, distributing RF signals along cable runs to cover cell blocks or common areas with minimal infrastructure.[55] In aviation, leaky feeder antennas enable in-flight wireless connectivity for passenger devices. These specialized cables, designed for aircraft interiors, support broadband Wi-Fi by uniformly distributing signals across cabins where traditional antennas face multipath challenges from metallic structures. W.L. Gore & Associates developed such antennas operating from 400 MHz to 6 GHz, facilitating seamless integration with onboard systems for voice, data, and internet access as of 2013.[56][57] Connectors tailored for aerospace applications ensure durability under vibration and pressure changes, with Type N variants supporting high-frequency operations in confined airborne spaces.[58] Leaky feeders also serve niche indoor environments like airport terminals and multi-level parking garages, where RF signals attenuate due to concrete and steel. Deployments in these structures use the cable's slotted design to create linear coverage along corridors or ramps, supporting public safety radios or emergency paging without extensive antenna arrays. Technical literature notes their use in such commercial complexes for consistent signal strength over extended runs, dating back to adaptations for non-underground linear paths.[59][60]Advantages

Reliability in Challenging Environments

Leaky feeder systems excel in environments characterized by high RF attenuation, multipath fading, and physical obstructions, such as underground mines and tunnels, where conventional antennas fail to maintain consistent coverage. These systems propagate signals along the cable length, minimizing dead zones and enabling bidirectional communication over distances up to 1-2 km per segment with appropriate amplification.[16] In Rayleigh fading channels typical of confined spaces, leaky feeders demonstrate lower bit error rates (BER) compared to single-antenna setups at equivalent signal-to-noise ratios, supporting modulation schemes like QPSK and M-QAM for reliable data transmission.[61] ![Leaky feeder cable deployment][float-right] Empirical assessments confirm stable received power levels, ranging from -15 to -25 dBm over 50 m in tunnel tests, versus the more variable -5 to -50 dBm from point-source antennas, reducing outage risks in dynamic settings like expanding mine workings.[61] Coupling loss between 60-90 dB, adjustable via cable design and mounting, ensures predictable signal leakage despite environmental factors like moisture or proximity to conductive surfaces, with bifilar cables offering lower loss (as low as 30 dB) in optimal underground conditions.[16] Systems incorporate repeaters to extend range and mitigate longitudinal attenuation, maintaining integrity amid interference from machinery or geological shifts, thus supporting critical applications like vehicle-to-infrastructure (V2I) links in tunnels.[16][61] Durability is enhanced by the cable's rugged construction, tolerant of harsh exposures including vibration, dust, and water ingress, allowing scalable deployment that adapts to evolving infrastructure without frequent signal degradation.[33] Optimal slot spacing, such as 20 mm at 3 GHz frequencies, further optimizes performance by minimizing BER and enabling gigabit-per-second rates with reduced RF power needs, lowering interference in dense, enclosed areas.[61] While sensitive to installation specifics, proper empirical site tuning—accounting for multipath variations up to 20 dB—yields high uptime, positioning leaky feeders as a primary solution for safety-critical voice and data in non-line-of-sight scenarios.[16][61]Coverage Uniformity and Scalability

Leaky feeder systems deliver uniform coverage by radiating radio signals continuously along the cable length, resulting in consistent signal strength proximate to the cable with variations typically below 5 dB in tested environments.[62] This contrasts with discrete antenna deployments, which exhibit greater signal fluctuations and dead zones in confined spaces like tunnels or indoor areas.[63] The design ensures reliable two-way communication within 3-10 meters radially from the cable, minimizing nulls and supporting portable radios without line-of-sight dependencies.[1] Scalability is achieved through modular extension via inline amplifiers or repeaters, spaced every 350-500 meters to offset attenuation and maintain signal integrity over extended runs.[64] Unamplified segments cover 300-450 meters, but amplified configurations enable deployments spanning tens of kilometers, such as over 40 km in long tunnels with multiple boosters.[65] [66] This approach facilitates incremental expansion in dynamic settings like expanding mines, integrating with base stations and fiber backhauls for larger networks without compromising uniformity.[67]Empirical Performance Metrics

Leaky feeder systems are characterized by longitudinal attenuation, which measures signal loss along the cable length, typically ranging from 2 to 4 dB per 100 meters in VHF frequencies depending on cable construction and environmental factors such as mounting proximity to walls or contamination.[16] Coupling loss, representing the power loss between the feeder and a mobile antenna, commonly falls between 60 and 90 dB, with short-distance variations up to 20 dB following a Rayleigh distribution in tunnel or mine environments; design values of at least 90 dB are recommended for system stability to account for these fluctuations.[16] These metrics apply across frequencies from 3 MHz to 1,000 MHz, with lower VHF bands preferred for economic viability despite higher frequencies offering better propagation in tunnels but increased sensitivity to external influences.[16] Field tests demonstrate achievable coverage distances of 1 to 2 km per segment with repeaters, though practical limits in mines often require amplifiers every 300 to 500 meters to maintain reliable voice or data links.[16] In coaxial cable evaluations at 60 MHz, attenuation rates varied from 0.6 to 1.1 dB per 100 feet (approximately 2 to 3.6 dB per 100 meters), with coupling losses of 71 to 83 dB measured at 20 feet from the cable.[68] Environmental moisture, such as rain or snow, can degrade sensitivity by 10 to 15 dB on average, with profile variations up to 22 dB, though slight ground moisture may enhance coupling by 1 to 2 dB; these effects underscore the need for weather-resistant designs in outdoor or damp underground applications.[68]| Parameter | Typical Value | Frequency/Context | Notes/Source |

|---|---|---|---|

| Longitudinal Attenuation | 2–4 dB/100 m | VHF (30–300 MHz) | Varies with cable type and mounting[16] |

| Coupling Loss (50%) | 50–60 dB or higher | General leaky cables | Exceeded by 50% of measurement points[69] |

| Coverage per Segment | 1–2 km with repeaters | 3 MHz–1 GHz | Achievable in tests; shorter in practice[16] |

| Moisture Impact | 10–15 dB sensitivity reduction | 60 MHz, coaxial tests | Average; up to 22 dB variation[68] |