Recent from talks

Nothing was collected or created yet.

Plowshare

View on WikipediaThis article needs additional citations for verification. (July 2024) |

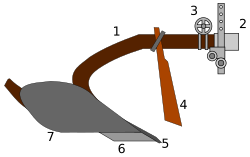

- beam

- three point hitch

- height regulator

- coulter or knife

- chisel

- plowshare

- moldboard

In agriculture, a plowshare (US) or ploughshare (UK; /ˈplaʊʃɛər/) is a component of a plow (or plough). It is the cutting or leading edge, preceding the moldboard, and it closely follows the coulter (one or more ground-breaking spikes) when plowing.

The plowshare itself is often a hardened blade dressed into an integral moldboard (by the blacksmith) so making a unified combination of plowshare and moldboard, the whole being responsible for entering the cleft in the earth (made by the coulter's first cutting-through) and turning the earth over.

In well-tilled terrain the plowshare may do duty without a preceding coulter.

In modern plows both coulter and plowshare are detachable for easy replacement when worn or broken.

History

[edit]

Triangular-shaped stone plowshares are found at the sites of Chinese Majiabang culture dated to 3500 BC around Lake Tai. Plowshares have also been discovered at the nearby Liangzhu and Maqiao sites roughly dated to the same period. The British archaeologist David R. Harris says this indicates that more intensive cultivation in fixed, probably bunded, fields had developed by this time. According to Mu Yongkang and Song Zhaolin's classification and methods of use, the triangular plow assumed many kinds and were the departure from the Hemudu and Luojiajiao spade, with the Songze small plow in mid-process. The post-Liangzhu plows used draft animals.[1][2]

In heraldry

[edit]Plowshares are often used in heraldry.

In ancient cultures

[edit]The ancient phrase from the biblical Book of Isaiah, "to turn swords into ploughshares," is still in common use today. These plowshares represent peaceful use of wartime capabilities. On the other hand, the Book of Joel uses the phrase in reverse, "Beat your plowshares into swords".

However, in classical antiquity during the Battle of Marathon, many Persians were slain by a deadly plowshare-wielding ally who appeared suddenly on the side of the ancient Athenians. After their victory and his disappearance, an oracle told the Athenians to worship the hero under the name Echetlaeus: the hero with the "echetlon", or plowshare.[3]

References

[edit]- ^ Harris (1996), 427–428.

- ^ You Archived 2011-07-06 at the Wayback Machine (1999), 1–8.

- ^ Lloyd, W. Watkiss (1881). "The Battle of Marathon: 490 B. C." The Journal of Hellenic Studies. 2: 380–395. doi:10.2307/623580. ISSN 0075-4269.

External links

[edit]Plowshare

View on GrokipediaDefinition and Function

Etymology

The term "plowshare" entered English in the late 14th century as a compound of "plow" and "share," denoting the cutting blade of the plow that slices through the soil.[2] The component "share" derives from Old English scear, meaning "plowshare" or "that which cuts," rooted in Proto-Germanic skeraz ("cutter") and ultimately tracing to the Proto-Indo-European root sker-, signifying "to cut." This etymological lineage emphasizes the implement's fundamental role as a sharp, dividing tool. In American English, the spelling "plowshare" predominates, while British English favors "ploughshare," a variant reflecting historical orthographic differences in the word for the full implement.[4] Across other languages, equivalent terms highlight similar conceptual origins tied to cutting or slicing. In Latin, the plowshare is termed vōmer, literally meaning "plowshare," evoking the shape and function of a blade that parts the earth like a knife.[5] In ancient Chinese contexts, archaeological evidence from the Han dynasty and earlier reveals the term sì (耜), referring to the iron or bronze cutting share in the traditional leisi (耒耜) plow, a wooden-handled device.[6] This plow is credited in legendary accounts to the agricultural deity Shennong. Historical naming evolved alongside plow designs, particularly in medieval Europe, where the "share" specifically designated the horizontal cutting edge that preceded the moldboard.[7] This terminology adapted to describe its integration in heavier, wheeled plows like the carruca for turning sod in northern soils.Role in Soil Turning

The plowshare functions as the principal cutting component of the moldboard plow, positioned immediately after the coulter to horizontally slice through the soil layer, typically to a depth of 9 to 12 inches, thereby initiating the soil disruption process.[8] This slicing action creates a clean furrow bottom and enables the lifted soil slice to be directed toward the moldboard for inversion, which aerates the subsurface, loosens compacted layers, and prepares a friable seedbed conducive to root growth and water infiltration.[8] Within the plow assembly, the plowshare integrates seamlessly with adjacent components, preceding the moldboard to ensure soil flow from cutting to turning. In contemporary plow designs, the plowshare is typically detachable, facilitating straightforward replacement when abrasion from soil contact diminishes its sharpness, thereby preserving overall tillage efficiency and reducing operational downtime. The plowshare's interaction with soil promotes inversion of the topsoil layer, effectively burying weed seeds, crop residues, and surface pathogens—achieving up to 80-90% incorporation at standard depths—to suppress competition for new plantings and enhance nutrient cycling through decomposition.[8] Adjustments to the plow's angle, such as variations in rake or suction, directly modulate the cutting depth and furrow width, optimizing soil turnover for specific conditions like clay-heavy or sandy profiles while minimizing draft force on the implement.Design and Types

Traditional Structures

Early tests in Project Plowshare focused on fundamental designs for contained underground detonations and cratering to assess containment and excavation potential, using relatively low-yield devices buried at specific depths to minimize fallout while studying cavity formation and earth displacement. The Rainier test on September 19, 1957, involved a 1.7-kiloton device detonated 274 meters underground in a horizontal tunnel at the Nevada Test Site, marking the first fully contained explosion that produced no visible fallout and validated subsurface containment for peaceful uses.[9] Subsequent early experiments refined these structures, such as the Gnome test in December 1961, where a 3.1-kiloton plutonium device was placed 361 meters deep in a salt formation near Carlsbad, New Mexico, to create a subsurface cavity for potential storage or stimulation applications, resulting in a chimney extending to the surface due to unexpected fracturing. The Sedan cratering test on July 6, 1962, employed a larger 104-kiloton device buried 194 meters deep, designed to simulate massive excavation by forming a crater 390 meters wide and 100 meters deep, displacing 12 million tons of earth for projects like canal digging.[9][10] These initial designs typically featured spherical or cylindrical implosion-type devices with yields ranging from 1 to 100 kilotons, optimized for geological containment in tuff, salt, or alluvium, with burial depths calculated to balance energy release against surface venting risks. Key components included tamper materials for efficiency and instrumentation arrays to measure seismic effects, gas leakage, and cavity radius, informing scalability for civil engineering.[11]Modern Adaptations

As the program progressed into the late 1960s and 1970s, Plowshare tests adapted to specialized applications like natural resource stimulation, incorporating tailored device placements and yields to enhance permeability in reservoirs while addressing environmental concerns through deeper burials and multi-stage configurations. The Gasbuggy test on December 10, 1967, collaborated with the El Paso Natural Gas Company, detonating a 3.1-kiloton device at 1,286 meters depth in a San Juan Basin well, temporarily increasing gas flow by a factor of 6-8 despite later tritium contamination issues.[9] Further adaptations included the Rulison test in September 1969, which used a 40-kiloton device at 2,560 meters in Colorado's Piceance Basin to stimulate tight gas sands, achieving initial production boosts but deemed uneconomical due to radioactivity; and the Rio Blanco test on May 17, 1973, featuring three 30-kiloton devices stacked at depths of 1,848, 2,124, and 2,399 meters in a single well, aimed at multi-zone fracturing for enhanced recovery.[11][12] Technological refinements involved improved diagnostics for fallout prediction, such as pre-test hydrological modeling and post-shot sampling, alongside hybrid designs combining low-yield primaries for precise energy coupling to rock formations. These adaptations prioritized industrial viability, with adjustable yields (up to 100 kilotons) and emplacement techniques like vertical shafts or hydraulic emplacement to suit varied geologies, though persistent contamination challenges limited commercial adoption.[9]Materials and Construction

Ancient Materials

In the prehistoric era, early plowshares were crafted from polished stone materials, marking the initial advancements in soil cultivation tools. These implements, often shaped for basic cutting and turning, were essential for Neolithic farming communities. Stone plowshares were used in Neolithic China for agriculture, including rice cultivation. Similarly, in Neolithic Europe, flint was a primary material for ard tips—the cutting edges of light scratch plows—sourced from extensive regional mines such as those at Spiennes in Belgium or Grimes Graves in England, dating to approximately 4000–3000 BCE.[13] These stone materials allowed for rudimentary agriculture but were limited by their brittleness; flint and basalt plowshares frequently broke upon hitting rocks or compacted earth, necessitating frequent replacement and restricting use to softer soils.[14] The transition to metal during the Bronze Age significantly enhanced plowshare performance, beginning around 2000 BCE in Mesopotamia. Bronze, an alloy of copper and tin, enabled the production of more resilient shares with sharper, more durable edges than stone, facilitating deeper soil penetration and broader cultivation in the Fertile Crescent's alluvial plains.[15] These early bronze plowshares improved efficiency in barley and wheat fields. However, bronze's relative softness compared to later metals meant it dulled quickly under heavy use, requiring regular sharpening with whetstones, which increased labor demands. By the Iron Age, approximately 1000 BCE, a further shift occurred across Europe and Asia to wrought iron plowshares, which offered superior hardness and edge retention for sustained soil turning. In Europe, iron shares appeared in Celtic and Hallstatt contexts, such as those unearthed in La Tène sites, allowing for heavier plowing in forested or clay-heavy regions.[16] In Asia, similar developments are evident in early Iron Age China and India, where wrought iron implements supported expanded wet-rice and dry-crop farming.[17] Despite these improvements, early wrought iron was impure and prone to bending or chipping without advanced forging techniques, still demanding periodic maintenance; regional variations, like flint supplementation in northern European ards, persisted due to iron's scarcity in some areas. Overall, these ancient materials' limitations—breakage in stone, dulling in bronze, and variability in early iron—shaped agricultural practices, emphasizing localized sourcing and tool repair as key factors in tool durability up to the medieval period.[18]Industrial Materials

In the modern era, plowshares are primarily constructed from advanced steel variants designed to withstand the abrasive demands of mechanized farming. High-carbon steels, such as 1080-grade, provide essential hardness and edge retention, enabling effective soil penetration while maintaining structural integrity under repeated stress.[19] These materials evolved from earlier iron-based designs, incorporating higher carbon content to enhance durability for large-scale operations. Alloy steels with boron additions, introduced in the early 20th century, further improve wear resistance by promoting hardenability during heat treatment, resulting in martensitic structures that resist abrasion from soil particles.[20] Boron-alloyed variants, like those from SSAB's boron steel line, achieve up to 500-600 HB hardness post-quenching and tempering, extending service life in tillage equipment.[21] Contemporary plowshare innovations incorporate hardened tungsten carbide inserts to bolster edge durability, particularly in high-wear zones exposed to rocky or compacted soils. These inserts, bonded to steel bases, offer wear resistance up to ten times greater than traditional high-carbon steel, reducing replacement frequency and operational downtime in intensive farming.[22] For conservation tillage practices that minimize soil inversion and erosion, plastic composites—such as fiber-reinforced polymers or thermoplastic coatings—have emerged as alternatives or supplements to metal components, providing low-friction surfaces that lessen soil disturbance and compaction.[23] These composites, applied in tools like chisels and sweeps akin to plowshares, promote residue retention on the surface while maintaining lightweight profiles for fuel-efficient machinery.[24] As of 2025, ongoing research explores bio-based composites and advanced nano-coatings to further enhance sustainability and reduce environmental impact in tillage tools.[23] Manufacturing processes for industrial plowshares emphasize precision and sustainability to meet performance standards. Steel plowshares are often produced via hot forging followed by precision casting for complex geometries, ensuring uniform material distribution and minimal defects.[25] Heat treatment, including quenching and tempering, is applied to achieve targeted hardness levels, with boron steels requiring controlled cooling to optimize microstructure and abrasion resistance.[26] Final shaping involves CNC machining for tight tolerances on cutting edges, enhancing compatibility with modern tractor systems. To address environmental concerns, manufacturers increasingly recycle scrap steel—with up to 97% recycled content in some steels like those from Ovako—reducing energy consumption and waste in production cycles.[27]Historical Development

Origins in Prehistory

The earliest evidence of plowshares emerges from the Neolithic period in East Asia, particularly within China's Songze culture (ca. 4000–3300 BCE), where triangular-shaped stone plowshares have been unearthed at sites in the Lake Tai region. These implements, crafted from durable stone, were attached to simple wooden ards—lightly constructed frames that scratched rather than inverted the soil—and were primarily powered by human effort to prepare small, irregular rice fields measuring from a few square meters to around 30 m². Earlier Majiabang culture sites (ca. 4300–4000 BCE), such as Caoxieshan and Chuodun, show similar small fields (1–32 m²) supported by water management but likely tilled using wooden or bone spades rather than plows. This innovation facilitated the transition from slash-and-burn horticulture to more systematic wet-rice cultivation in the Yangtze Delta's alluvial lowlands, supported by integrated water management features like bunds, ditches, and ponds.[28] By the subsequent Songze culture and further into the Liangzhu culture (ca. 3300–2300 BCE), stone plowshares evolved in size and sophistication, with examples including assembled variants discovered at sites like Maoshan and Shi’ao in the Taihu Lake basin and Ningshao Plain. These tools continued to pair with wooden ards for human-powered tilling of increasingly larger fields, up to 100–2000 m², enabling intensified rice farming amid rising population pressures and environmental adaptations in the region. Concurrently, plow technology spread westward, with archaeological records from the Near East—such as ard marks and tool remnants in Mesopotamia and the Levant—indicating similar human-powered stone or wooden plowshares in use by around 4000 BCE, aiding the expansion of cereal-based agriculture in semi-arid zones.[28][29] A pivotal shift occurred after 2500 BCE, as the harnessing of draft animals like oxen was integrated into plowing practices across both East Asia and the Near East, transforming the plowshare's role from a scratching tool to one capable of deeper soil disruption. This animal traction, evidenced in Indus Valley artifacts from around 2500 BCE and broader Near Eastern contexts by the late third millennium BCE, permitted cultivation of expansive fields and reduced labor intensity, fostering surplus production and societal complexity in early agricultural communities. In China, oxen enhanced the efficacy of stone shares in the post-Neolithic era, setting the stage for bronze-age advancements.[30]Evolution in Agricultural Societies

In the classical era, plowshares evolved significantly with the adoption of iron components, enhancing their durability and effectiveness over earlier wooden or stone designs derived from Greek symmetrical ard plows. Roman agricultural innovations, particularly in the 1st century CE, incorporated heavy iron plowshares into the carruca, a wheeled plow suited for turning denser soils in regions like Britain and Gaul.[31] This design featured an asymmetrical share that sliced soil more efficiently, often paired with a coulter for vertical cutting, marking an improvement on the lighter Greek bow ard used for Mediterranean gravelly terrains.[31] Concurrent developments in Asia during the Han Dynasty (206 BCE–220 CE) advanced plowshare technology through widespread use of cast-iron shares in animal-drawn plows. By the Early Western Han period (ca. 202–140 BCE), iron plowshares measuring 40–50 cm in length were produced via blast furnaces at sites like Taicheng ironworks, enabling oxen to pull them effectively for tilling the Central Plains' loess soils.[32] These shares, depicted in Han pictorial bricks alongside traction cattle showing wear from prolonged use, facilitated deeper soil penetration and supported intensified rice and millet cultivation, contrasting with the lighter wooden plows of prior dynasties.[32] Medieval Europe saw further refinements in plowshares with the integration of moldboards into heavy plows around the 9th century, particularly in northern regions with heavy clay soils. The carruca, evolving from Roman precedents, combined an iron plowshare, coulter, and curved moldboard to invert soil fully, improving drainage and weed burial on damp, fertile lands unsuitable for lighter ards.[31] This innovation, evidenced in Viking Age Scandinavia (9th–10th centuries) and widespread by the 11th century in Denmark and Britain, required teams of up to eight oxen and enabled the cultivation of high-backed ridges, boosting productivity in areas like the Po Valley and northern Germany.[31] Lynn White Jr. highlighted this as a pivotal shift, linking the heavy plow's adoption to population growth and manorial expansion between AD 900 and 1300.[33] The global diffusion of European-style plowshares accelerated after Columbus's voyages in the late 15th century, with adoption in the Americas beginning in the 16th century through Spanish and Portuguese colonists introducing iron shares and draft animals like oxen. These models transformed indigenous slash-and-burn systems into plow-based farming for crops such as wheat, though limited by unfamiliar soils until hybrid techniques emerged.[29] In Africa and Asia, colonial expansions from the 16th century onward prompted adaptations for tropical soils, such as lighter wooden beams with metal shares in sub-Saharan regions to avoid compacting fragile laterites, as seen in Ethiopian and Ugandan ox-drawn plows for cotton on humid terrains.[34]Cultural and Symbolic Roles

In Heraldry

In heraldry, the plowshare serves as a charge symbolizing agricultural labor and reliance on providence for sustenance.[35] It represents hard work in tilling the soil, often denoting families, guilds, or municipalities connected to farming or rural life.[36] This emblem underscores themes of productivity and the earth's bounty, distinguishing it from more martial symbols in traditional armorial designs.[37] Historically, the plowshare appears in European coats of arms from the late medieval and early modern periods, particularly in contexts tied to agrarian economies or craftsmanship. For instance, the arms of the Kremer Guild in Aschaffenburg, Germany, from 1588, feature a plowshare to signify the blacksmiths' role in forging agricultural tools.[38] Municipal examples include the coat of arms of Waldbroel, where the plowshare highlights the region's agricultural heritage in a post-medieval context.[39] Similarly, Lascheid's arms incorporate a plowshare to evoke the area's farming character.[40] These usages reflect the plowshare's association with rural nobility and trade guilds, rather than high nobility, emphasizing communal labor over conquest.[41] The plowshare is typically blazoned in simple terms, such as "a plowshare argent," indicating a silver or white blade oriented with its point to chief unless specified otherwise.[37] In the arms of Csernely, Hungary, it is described as "a plough share points downward Argent" positioned between architectural elements, showcasing its integration into balanced compositions.[42] Over time, from the 16th to 19th centuries, depictions evolved from detailed, realistic renderings—often showing the blade's ferule for attachment to the plow—to more abstract, stylized forms that prioritized heraldic clarity and tincture contrast.[37] Sheaves of wheat or other crops sometimes accompany the plowshare, reinforcing its agricultural motif without altering the core charge.[43]Mythological and Religious Symbolism

In the Hebrew Bible, the plowshare emerges as a potent symbol of transformation and eschatological peace. The prophet Isaiah, writing in the 8th century BCE, envisions a future era where nations repurpose instruments of war for agriculture: "They shall beat their swords into plowshares, and their spears into pruning hooks; nation shall not lift up sword against nation, neither shall they learn war any more" (Isaiah 2:4). This prophecy, rooted in the context of Judah's geopolitical tensions, portrays the plowshare as an emblem of divine judgment leading to universal harmony and the cessation of conflict.[44][45] Conversely, the Book of Joel inverts this imagery to signify impending divine judgment and mobilization for war. In Joel 3:10, the text commands: "Beat your plowshares into swords, and your pruning hooks into spears; let the weakling say, 'I am a warrior.'" This reversal underscores the plowshare's dual role in biblical symbolism, shifting from peace to preparation for apocalyptic confrontation, reflecting the cyclical tensions between agrarian stability and martial upheaval in ancient Near Eastern thought.[46] Greek mythology further elevates the plowshare through the legend of Echetlaeus, a mysterious hero at the Battle of Marathon in 490 BCE. As described by Pausanias in the 2nd century CE, Echetlaeus appeared as a rustic figure wielding a plow (or its beam, echetle) to slay numerous Persian invaders before disappearing into the earth, interpreted as an epiphany of a chthonic deity like Demeter or the earth itself. The Athenians honored him with a hero cult, viewing the plowshare as a divine tool bridging agriculture and heroic defense, symbolizing the land's protective fertility against foreign threats.[47][48] The plowshare's symbolic resonance extends to idiomatic expressions and cultural motifs emphasizing peace and fertility. The biblical phrase "swords into plowshares" has influenced modern diplomacy, most notably in the United Nations' bronze sculpture Let Us Beat Swords into Plowshares (1959) outside its New York headquarters, which depicts a figure forging a sword into a plow to represent humanity's aspiration to end war and foster productive endeavors. In ancient Mesopotamian art, the plow frequently appears as a fertility emblem linked to gods like Ningirsu, who embodied both agricultural abundance and martial prowess, as seen in pictorial sources where it signifies the renewal of the land. Similarly, in ancient Egyptian iconography, plowing scenes tied to the Nile's annual inundation symbolize cosmic fertility and the regeneration of life, invoking deities of agriculture to ensure bountiful harvests.[49][50][51]References

- https://commons.wikimedia.org/wiki/File:Wappen-waldbroel.jpg