Recent from talks

Contribute something

Nothing was collected or created yet.

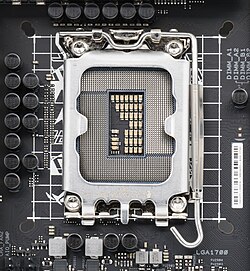

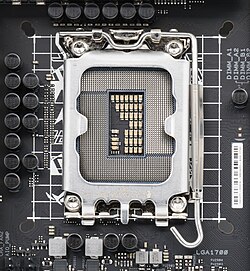

Land grid array

View on WikipediaThis article needs additional citations for verification. (November 2007) |

The land grid array (LGA) is a type of surface-mount packaging for integrated circuits (ICs) that is notable for having the pins on the socket (when a socket is used) — as opposed to pins on the integrated circuit, known as a pin grid array (PGA).[1] An LGA can be electrically connected to a printed circuit board (PCB) either by the use of a socket or by soldering directly to the board.

Description

[edit]The land grid array is a packaging technology with a grid of contacts, 'lands', on the underside of a package. The contacts are to be connected to a grid of contacts on the PCB. Not all rows and columns of the grid need to be used. The contacts can either be connected by using an LGA socket, or by surface-mount soldering using solder paste.[2] The grid elements found in use can be e.g. circular, triangular or other polygonal shapes and might have even different sizes. Grids might sometimes appear like honey comb patterns. Designs are often optimized for factors like contact likeliness despite tolerances, electrical gap to neighboring contacts and for allowing best shapes for counterpart spring contacts including their outgoing electric connectivity to e.g. a backplane PCB.

LGA packaging is related to ball grid array (BGA) and pin grid array (PGA) packaging. Like pin grid arrays, land grid array packages are designed to fit either in a socket or be soldered directly to a circuit board, although PGA packages cannot be soldered using surface mount technology. In contrast with a BGA, land grid array packages in unsocketed configurations have no balls, and use flat contacts which are soldered directly to the PCB.

Use in microprocessors

[edit]

LGA has been used for high-end microprocessors and similar applications since the 1990s, primarily in Unix workstations. These early uses predate the availability of modern LGA sockets, and instead used land grid arrays on both the processor package and the motherboard. An array of slightly compressible conductive columns held in a frame is then sandwiched between the two LGA surfaces and compressed using the heatsink. This was considered field upgradable by technicians at the time. Care had to be taken to not touch the conductive columns to avoid contamination.[3]

LGA is currently used as a physical interface for microprocessors of the Intel Pentium, Intel Xeon, Intel Core and AMD Opteron, Threadripper, Epyc, and newer Ryzen families. Unlike the pin grid array (PGA) interface found on older Intel and current AMD desktop processors, there are no pins on the chip; in place of the pins are pads of bare gold-plated copper that touch protruding pins on the microprocessor's socket on the motherboard. Compared to PGA CPUs, LGA reduces the likelihood of the chip being damaged either before or during installation as there are no pins that can be accidentally bent. By transferring the pins to the motherboard, it is possible to design the socket to physically shield the pins from damage, and the costs of installation damage can be mitigated as motherboards tend to be significantly cheaper than CPUs.[4]

While LGA sockets have been in use as early as 1996 by the MIPS R10000, HP PA-8000, and Sun UltraSPARC II[5] processors, the interface did not gain mainstream use until Intel introduced their LGA platform, starting with the 5x0 and 6x0 sequence Pentium 4 (Prescott) in 2004.[6] All Pentium D and Core 2 desktop processors use LGA 775 socket. As of Q1 2006, Intel switched the Xeon server platform to LGA, starting with the 5000-series models. AMD introduced their server LGA platform starting with the 2000-series Opteron in Q2 2006. AMD offered the Athlon 64 FX series on socket 1207FX through ASUS's L1N64-SLI WS motherboards. It was the only desktop LGA solution offered by AMD at the time until the release of Socket AM5 in 2022.

The most recent[when?] Intel desktop LGA socket is dubbed LGA 1851 (Socket V1), which is used with Intel's Arrow Lake series Core Ultra 5, 7, and 9 families. Their Skylake-X Core i7 and Core i9 families use the LGA 2066 socket. The LGA setup provides higher pin densities, allowing more power contacts and thus a more stable power supply to the chip.

AMD introduced its first consumer LGA socket, called Socket TR4 (LGA 4094) for its high end desktop platform Ryzen Threadripper processors. This socket is physically identical to their Socket SP3 for their Epyc server CPUs even though SP3 CPUs are not compatible with the desktop X399 chipset and vice versa.

The previous AMD server LGA socket was designated Socket G34 (LGA 1944). Like Intel, AMD decided to use LGA sockets for their higher pin densities, as a 1944-pin PGA would simply be too large for most motherboards.

AMD

[edit]- Socket F (LGA 1207)

- Socket C32 (LGA 1207) (replaces Socket F)

- Socket G34 (LGA 1944)

- Socket SP3 (LGA 4094)

- Socket TR4 (LGA 4094)

- Socket sTRX4 (LGA 4094)

- Socket sWRX8 (LGA 4094)

- Socket AM5 (LGA 1718)

- Socket SP5 (LGA 6096)

- Socket SP6 (LGA 4844)

- Socket sTR5 (LGA 4844)

Intel

[edit]- LGA 771 (Socket J) – Note that Socket 771 is the server counterpart of LGA 775 and with a bus compatible motherboard, an adapter for LGA 775 to LGA 771 can be used to get a Xeon on a consumer motherboard with Socket 775.

- LGA 775 (Socket T)

- LGA 1366 (Socket B)

- LGA 1356 (Socket B2)

- LGA 1156 (Socket H)

- LGA 1155 (Socket H2)

- LGA 1150 (Socket H3)

- LGA 1151 (Socket H4) – note that two discrete revisions of LGA 1151 exist; the first revision is only compatible with Skylake and Kaby Lake CPUs while the second revision is only compatible with Coffee Lake CPUs.

- LGA 1200 (Socket H5)

- LGA 1700 (Socket V)

- LGA 1851 (Socket V1)

- LGA 1954 (Codename "NVL-S") – note that it is an upcoming socket.

- LGA 2011 (Socket R)

- LGA 2011-3 (Socket R3) – note that LGA 2011-3 is incompatible with LGA 2011 and is used for Haswell-E and Broadwell-E Intel Core i7 extreme processors and the Intel X99 chipset. It does, however have the same pin count and design as LGA 2011. Also used for Xeon E5 processors and Intel C612 chipset.

- LGA 2066 (Socket R4) – for Intel's X299 Chipset and i5, i7 and i9 X processors from Skylake-X and Kaby Lake-X lines. There are Xeons also available for this socket.

- LGA 3647 (Socket P, also P0 and P1) – two mechanically incompatible versions for different products, 6ch memory

- LGA 4189 (Socket P+) - Intel Xeon Scalable (Ice Lake-SP) socket, 8ch memory

- LGA 4677 (Socket E) - Intel Xeon Scalable (Sapphire Rapids and Emerald Rapids) socket

- LGA 7529 - Intel E-core Xeon (Sierra Forest) socket

See also

[edit]- Chip carrier

- Dual in-line package (DIP)

- Pin grid array (PGA)

- Ball grid array (BGA)

- Compression Attached Memory Module (CAMM), a memory module form factor using a land grid array connection

References

[edit]- ^ "Definition of:LGA". PC Magazine. Retrieved October 1, 2015.

- ^ "Land Grid Array (LGA) Socket and Package Technology" (PDF). Intel. Retrieved October 1, 2015.

- ^ "LGA Socket Application Guide - Recommended information for LGA socketing applications". tyco Electronics. 2004-03-15.

- ^ Prices of the most expensive Intel Core i7 and AMD Threadripper CPUs vs their most expensive corresponding motherboards on eBuyer as of 16th of Feb 2018

- ^ "English: Sun UltraSPARC-II 64-bit RISC microprocessor, back". 19 May 2009.

- ^ Shimpi, Anand Lal (June 21, 2004). "Intel's 925X & LGA-775: Are Prescott 3.6 and PCI Express Graphics any Faster?". AnandTech. Archived from the original on May 5, 2010. Retrieved November 12, 2022.

External links

[edit]Land grid array

View on GrokipediaFundamentals

Definition and Design

A land grid array (LGA) is a surface-mount packaging technology for integrated circuits (ICs) in which the electrical contacts consist of flat metal "lands" arranged in a two-dimensional grid pattern on the bottom surface of the package. These lands mate directly with corresponding contact pads on a printed circuit board (PCB) through soldering or via a socket interface, enabling reliable electrical connections without the need for protruding pins or solder balls on the package itself.[2][3] This design contrasts with other grid array types by positioning the interconnection elements flush with the package substrate, facilitating easier handling and integration in automated assembly processes.[1] The core design elements of an LGA include the shape, size, and spacing of the lands, as well as the overall package footprint. Land shapes are typically circular, square, or rectangular, with dimensions optimized for solder joint formation and mechanical stability; for instance, square lands often measure 0.4–0.6 mm per side in fine-pitch applications. The grid pitch, or center-to-center spacing between adjacent lands, generally ranges from 0.4 mm to 1.27 mm, allowing for dense packing while accommodating manufacturing tolerances and signal integrity requirements. Package footprints are usually square or rectangular, supporting array configurations from a few dozen to thousands of contacts, such as in high-density ICs where the substrate may span up to 27 mm per side for many general applications, with larger formats used in high-performance processors.[2][3] Functionally, LGA enables high-density interconnections by providing a planar interface that supports both electrical signaling and thermal dissipation through direct land-to-pad contact, often enhanced by thermal vias on the PCB. This flat structure minimizes height and avoids the fragility of protruding elements, making it suitable for compact, high-performance applications. For example, LGA packages can accommodate pin counts exceeding 2000, as seen in the LGA 4094 configuration with 4094 lands, which supports advanced processors requiring extensive I/O and power delivery.[3][1][7]Key Components

The substrate in a Land Grid Array (LGA) package serves as the foundational interposer, typically constructed from organic materials such as bismaleimide-triazine (BT) resin reinforced with glass fibers for standard applications, providing a balance of electrical performance, thermal stability, and cost-effectiveness.[3] In high-reliability or power-intensive scenarios, ceramic substrates like alumina (Al₂O₃, with CTE ~7-8 ppm/°C) or low-temperature co-fired ceramic (LTCC, which can be tailored to ~12 ppm/°C for CTE matching to PCBs at 12-18 ppm/°C) are employed, offering superior thermal conductivity.[8][9] The lands, which form the contact grid on the underside of the package, are patterned from copper traces using lithographic techniques to achieve precise array layouts, often in a fully populated or peripheral matrix configuration.[3] These copper lands are finished with a thin layer of nickel followed by immersion gold (Ni/Au plating, typically 0.1-0.5 μm gold over nickel) to enhance conductivity, prevent oxidation, and ensure reliable electrical contact; electroless nickel immersion gold (ENIG) is a common specification that promotes uniform solderability without bridging risks during assembly.[1][9][2] The die is attached to the substrate via epoxy-based adhesives or solder for mechanical and thermal bonding, followed by interconnection methods such as gold wire bonding for simpler designs or flip-chip techniques using solder bumps or copper pillars with underfill encapsulation to minimize stress and improve reliability.[3] Thermal interface materials (TIMs), often polymer pastes or metal alloys like indium, are integrated between the die (or integrated heat spreader) and the external heatsink to facilitate efficient heat dissipation, addressing the high thermal densities in LGA packages.[10] Assembly of the LGA package to the PCB emphasizes socket-based mating for removable applications, where spring-loaded contacts—commonly known as pogo pins—within the socket compress against the lands to form electrical connections without soldering, enabling easier upgrades and testing.[11][12] Direct soldering is an alternative for permanent mounts, using solder paste reflow on matching PCB pads. Alignment is achieved through fiducial marks or corner identifiers (e.g., Pin A1 markers) on the package and board, often aided by optical recognition systems to ensure precise grid registration and prevent misalignment during placement.[2][3]Historical Development

Early Innovations

The development of land grid array (LGA) packaging emerged in the early 1990s as part of broader advancements in surface-mount technology aimed at high-density interconnects for integrated circuits. For example, in 1992, Matsushita Electronics began mass-producing LGA-type CSPs using gold-wire stud bumps for flip-chip connections in cellular phone microprocessors.[13] Early prototypes focused on using flat conductive pads or short columns on the package underside instead of protruding pins, which reduced overall height, minimized mechanical stress, and enhanced scalability for denser pin arrangements compared to traditional pin grid array (PGA) designs. This shift addressed limitations in earlier soldered packages by enabling more reliable connections in compact form factors suitable for demanding environments like Unix workstations and mainframes.[13] A key innovation was the introduction of socketable LGA designs, allowing for removable connections that facilitated easier upgrades and maintenance without full desoldering, marking a transition from permanent soldered packages to modular systems. Early LGA designs prioritized reliability over extreme density, typically featuring pin counts under 1000, such as the 587-pin configuration in prototypes.[14] Initial commercial applications appeared in non-x86 processors for Unix-based systems around 1995–2000, driven by needs for better thermal management through direct heat sink attachment via compression sockets. For instance, Sun Microsystems' UltraSPARC-IIi, introduced in 1998 for workstations like the Netra i 1, utilized a ceramic 587-pin LGA package with flip-chip attachment, enabling efficient power delivery and cooling in server environments. Similarly, IBM's Power4 processor, developed for high-end RS/6000 Unix servers and announced in 1999, employed an LGA-style package to support its multichip module design, allowing socketed installation that enhanced thermal dissipation in mainframe-like scalability. These early adoptions in SPARC and PowerPC architectures demonstrated LGA's viability for enterprise computing, where low-profile sockets reduced system height while maintaining robust electrical performance.[14][15]Adoption by Major Manufacturers

Intel pioneered the mass-market adoption of Land Grid Array (LGA) sockets in 2004 with the launch of LGA 775 alongside the Pentium 4 processor featuring the Prescott core, transitioning from Pin Grid Array (PGA) designs to accommodate increasing power requirements and pin counts for desktop processors.[16] This introduction marked a key milestone in enabling higher I/O integration and improved mechanical reliability for consumer and enthusiast systems. Intel's commitment to LGA continued through the evolution of the LGA 115x series from 2008 to 2015, including LGA 1156 for Nehalem-based Core i7 processors, LGA 1155 for Sandy Bridge, LGA 1150 for Haswell, and LGA 1151 for Skylake and later generations, supporting a broad range of desktop and mobile platforms.[17] Building on this foundation, Intel advanced LGA implementations for newer architectures, introducing LGA 1200 in 2020 for 10th- and 11th-generation Core processors based on Comet Lake and Rocket Lake, followed by LGA 1700 in 2021 for the hybrid Alder Lake design with performance and efficiency cores.[18] In 2024, LGA 1851 debuted with Arrow Lake processors, featuring 1,851 contacts to enhance power delivery and PCIe 5.0 support while maintaining compatibility dimensions with prior sockets.[19] For server applications, Intel deployed LGA 4677 in 2023 with Sapphire Rapids Xeon processors, optimized for high-core-count workloads and advanced memory configurations.[20] This progression reflects Intel's strategy to leverage LGA for scalable electrical interfaces amid escalating transistor densities and thermal demands. AMD integrated LGA technology starting with server-oriented Opteron processors on Socket G34 (LGA 1944) in 2010, following an earlier LGA exploration with Socket F (LGA 1207) in 2006, to support multi-socket configurations and higher bandwidth needs.[21] The company expanded LGA adoption in high-end desktop segments with Socket TR4 (LGA 4094) in 2017 for the initial Ryzen Threadripper series, enabling up to 64 cores and extensive PCIe lanes for content creation and compute tasks.[22] Mainstream desktop sockets remained PGA until the shift to AM5 (LGA 1718) in 2022 with the Ryzen 7000 series based on Zen 4 architecture.[23] This platform received updates through 2025 for Zen 5 processors, emphasizing long-term socket longevity and integration of DDR5 and PCIe 5.0+.[24] The widespread shift to LGA by both Intel and AMD post-2004 was primarily driven by the need for enhanced upgradability and to manage rising power densities in processors, as designs like Intel's Prescott core demanded robust power distribution across more contacts without compromising CPU integrity.[25] By 2025, LGA sockets underpinned the majority of desktop and server CPU platforms from these manufacturers, facilitating higher I/O counts essential for modern features like PCIe 5.0+ integration and multi-channel memory.[26]Technical Comparisons

With Ball Grid Array

The land grid array (LGA) and ball grid array (BGA) packages differ fundamentally in their interconnection structures. LGA employs flat, exposed metal lands—typically nickel-gold plated pads arranged in a grid on the package underside—for electrical contact, eliminating protruding elements and enabling compatibility with removable sockets that press the package against spring-loaded pins on the motherboard.[3] In contrast, BGA features solder balls attached to the package substrate, which are reflow-soldered directly to the printed circuit board (PCB), creating a permanent attachment without the need for intermediary sockets.[27] This structural distinction in LGA allows for repeated insertions and removals when used with sockets, facilitating upgrades, while BGA's ball-based design prioritizes a low-profile, direct bond that enhances compactness but limits field serviceability.[2] Assembly processes for LGA and BGA highlight trade-offs in precision and reliability. LGA assembly involves applying solder paste to PCB pads, followed by accurate component placement using optical alignment tools to ensure initial positioning within tight tolerances (e.g., ±50 μm), and subsequent reflow soldering; this method supports easier field replacement in socketed configurations but demands meticulous alignment to prevent joint voids or misalignment.[3] BGA assembly, however, leverages the solder balls for self-alignment during reflow, where surface tension corrects offsets up to 50% of the pad size, simplifying placement but introducing risks of defects such as solder bridging, open joints, or voids if reflow parameters are suboptimal.[27] While LGA's flat lands reduce the complexity of handling protruding features, BGA's process benefits from the balls' ability to accommodate minor placement errors, though both require controlled reflow profiles to achieve reliable interconnections.[2] In terms of suitability, LGA is favored for upgradable consumer central processing units (CPUs) where socket-based designs enable processor swaps without resoldering, and its configuration minimizes mechanical stress on the die by distributing loads more evenly across the flat lands during thermal cycling or vibration.[2] BGA, conversely, excels in mobile and embedded integrated circuits, such as graphics processing units (GPUs) and memory chips, due to its compact form factor and ability to support higher I/O densities in space-constrained environments.[27] Notably, both BGA and LGA packages can achieve fine pitches down to 0.4 mm and 0.35 mm respectively, enabling high I/O densities, though LGA's design inherently lowers die stress in mechanically demanding scenarios.[3][2][28]With Pin Grid Array

The primary mechanical distinction between the Land Grid Array (LGA) and Pin Grid Array (PGA) lies in their interface design: PGA packages feature protruding pins on the underside of the integrated circuit that insert into matching holes or sockets on the printed circuit board (PCB), enabling a direct mechanical lock, whereas LGA packages use flat, recessed conductive lands on the package that mate with protruding spring-loaded pins located on the PCB socket, relying on compressive force for connection.[27][29] This inversion shifts the structural load from the package to the socket in LGA, reducing stress on the chip during installation and removal.[30] Electrically, PGA pins establish direct compression contacts for signal transmission, but their extended length introduces higher parasitic inductance and greater risk of bending during handling or insertion, which can compromise contact reliability.[30] In contrast, LGA's flat lands paired with short socket pins minimize inductance through shorter contacts, supporting higher data rates with improved signal integrity.[30] Furthermore, LGA enables higher contact density in comparable package areas by using smaller, non-protruding lands, avoiding the fragility constraints of PGA pins.[31][29] PGA found suitability in older, lower-density computing systems, such as early Intel Pentium processors using Socket 7, where simpler pin-based connections sufficed for moderate pin counts and frequencies below 5 GHz.[32] LGA, however, dominates modern high-core-count CPUs from Intel and AMD— with AMD transitioning to LGA via the AM5 socket in 2022—providing superior signal integrity for multi-gigahertz operations and complex interconnects in processors like Core and EPYC series.[30] Intel's transition from PGA to LGA in 2004, marked by the LGA 775 socket launch, reduced overall package height and enhanced manufacturing yields by mitigating pin-related defects, facilitating scalability for future generations.[30]Applications in Computing

Intel Microprocessors

Intel's adoption of Land Grid Array (LGA) sockets began with the LGA 775 in 2004, which supported processors from the Pentium 4 series through the Core 2 Duo, remaining in use until 2010 for desktop and entry-level server applications. This socket marked a shift from pin grid array designs, offering improved thermal and electrical performance for mid-range computing. Subsequent consumer-oriented sockets evolved to the LGA 1156 (2008), LGA 1155 (2011), LGA 1150 (2013), and LGA 1151 (2015–2018), all accommodating the Core i series processors, with pin counts increasing to handle higher core densities and power requirements in mainstream desktops. The LGA 1200 followed in 2020 for 10th-generation Comet Lake and 11th-generation Rocket Lake CPUs, emphasizing compatibility within those generations but requiring motherboard updates for prior sockets.[16][33] More recent advancements include the LGA 1700 socket, introduced in 2021 for 12th-generation Alder Lake and extending through 13th- and 14th-generation Raptor Lake processors until 2024 and into 2025 with the Bartlett Lake refresh, which supports hybrid architectures combining performance (P-cores) and efficiency (E-cores) with dedicated land allocations for at least 16 PCIe 5.0 lanes plus additional connectivity. The LGA 1851 socket, launched in 2024 for Arrow Lake (Core Ultra 200 series), features 1851 lands to enhance PCIe 5.0 support and DDR5 memory integration, enabling higher bandwidth for gaming and productivity workloads. In server environments, Intel utilized the LGA 2011 socket starting in 2012 for Xeon E5 processors, providing multi-channel memory and expanded I/O for enterprise scalability. For advanced AI and data center tasks, the LGA 4677 socket debuted in 2023 with 5th-generation Xeon Scalable (Emerald Rapids and later Sapphire Rapids variants), incorporating 4677 lands to manage elevated power densities in high-performance computing.[34][19][35][36][37] LGA designs in Intel microprocessors integrate dedicated power delivery zones within the land grid to ensure voltage regulator module (VRM) stability, distributing current efficiently across phases to mitigate thermal hotspots and support transient loads up to several hundred amps. This zoning is critical for maintaining signal integrity in high-frequency operations. However, Intel's LGA sockets exhibit backward incompatibility across generations, necessitating new motherboards for each major socket change, such as from LGA 1700 to LGA 1851, to align with evolving pinouts and power specifications.[38][39]AMD Microprocessors

AMD's adoption of land grid array (LGA) sockets for microprocessors began in the server segment with Socket F (LGA 1207) in 2006, supporting early Opteron processors in multi-socket systems. This was followed by Socket G34 (LGA 1944), introduced in 2010 for the Opteron 6100 and 6200 series based on the Magny-Cours and Interlagos architectures, respectively. The G34 socket facilitated scalability in dual- and quad-socket configurations, emphasizing power efficiency and high-performance computing workloads until its phase-out around 2016.[40] In 2017, AMD launched the EPYC processor family on Socket SP3 (LGA 4094), a design tailored for Zen-based architectures that supported up to 64 cores per socket with eight-channel DDR4 memory. The SP3 socket, used across the first three generations of EPYC (Naples, Rome, and Milan), incorporates dedicated land contacts to enable the Infinity Fabric interconnect, which provides high-bandwidth, low-latency communication between on-package chiplets in AMD's multi-chiplet layouts. This approach allowed for modular scaling, with EPYC processors delivering up to 128 PCIe 3.0/4.0 lanes depending on the generation, powering data center applications. AMD transitioned to Socket SP5 (LGA 6096) for the 4th generation EPYC (9004 series, Genoa and Bergamo, launched 2022) and 5th generation (9005 series, Turin, launched 2024), supporting up to 192 cores, eight-channel DDR5 memory, CXL 2.0, and up to 128 PCIe 5.0 lanes for enhanced AI and cloud workloads.[7][41][42][43] For high-end desktop and workstation microprocessors, AMD introduced LGA with Socket sTRX4 (LGA 4094) in 2019 alongside the third-generation Ryzen Threadripper processors on the Zen 2 architecture. Paired with the TRX40 chipset, sTRX4 supported up to 64 cores, quad-channel DDR4, and 88 PCIe 4.0 lanes total, highlighting AMD's shift to LGA for enhanced thermal and electrical efficiency in multi-chiplet designs where Infinity Fabric links connect core complex dies (CCDs) and an I/O die. This socket remained in use through 2022 for Zen 3-based Threadripper 5000 series, before evolving to Socket sTR5 (LGA 6096) for the 7000 series (Zen 4, launched 2023) with PCIe 5.0 support and extending to the 9000 series (Zen 5, launched July 2025), offering up to 96 cores, 80 PCIe 5.0 lanes, and octa-channel DDR5 for demanding content creation and AI tasks.[44][45] AMD's consumer desktop transition to LGA occurred in 2022 with Socket AM5 (LGA 1718) for the Ryzen 7000 series on the Zen 4 architecture, featuring integrated graphics, dual-channel DDR5 memory, and 28 PCIe 5.0 lanes from the processor for graphics and storage. The AM5 design accommodates multi-chiplet configurations with land zones optimized for Infinity Fabric interconnects between CCDs and the I/O die, supporting thermal design powers up to 170W in high-end models like the Ryzen 9 7950X. This platform continued with the Ryzen 9000 series (Zen 5, launched 2024), delivering improved instructions per clock and AI acceleration. Unlike more frequent socket changes elsewhere, AMD has committed to AM5 platform support through at least 2027, enabling forward compatibility across Zen 4, Zen 5, and potentially future generations without requiring motherboard upgrades.[46][47][48][49][50]Other Integrated Circuits

Land grid array (LGA) packaging finds applications in various integrated circuits beyond microprocessors, particularly in embedded systems where compact form factors and reliable connections are essential. In field-programmable gate arrays (FPGAs), LGA packages enable reconfigurability and high-density I/O in space-constrained environments, such as radiation-tolerant designs for aerospace and military applications. For instance, Microchip Technology (formerly Actel) offers LGA options for its RTAX-S FPGA family, which supports mission-critical operations by providing robust packaging for harsh conditions.[51] Power management integrated circuits (PMICs) also utilize LGA packaging to achieve efficient thermal dissipation and integration in portable devices like laptops. Analog Devices employs LGA in its power modules, which feature flat land contacts for direct PCB mounting, facilitating low-profile designs with improved power delivery and heat transfer. These packages typically support pin counts ranging from hundreds to over a thousand lands, balancing compactness with performance in battery-powered systems.[6] In embedded systems for automotive and telecommunications, LGA packages are adopted for their leadless construction and high pin density, suitable for networking processors and microcontrollers. Infineon's CG-LGA package family, used in power semiconductors, provides bottom-terminated lands for enhanced electrical and thermal performance in automotive electronics, such as motor control and infotainment systems. Similarly, LGA is prevalent in telecom networking ICs, where it supports high-speed data interfaces in compact modules for base stations and routers.[52][53] A notable trend involves socketless LGA variants in mobile system-on-chips (SoCs) and IoT devices, where the elimination of protruding pins reduces overall Z-height for thinner profiles. This approach is increasingly used in cellular IoT modules, enabling seamless integration of processors and connectivity ICs while maintaining signal integrity and manufacturability.[54]Advantages and Limitations

Benefits

One of the primary advantages of Land Grid Array (LGA) technology is its ability to achieve higher pin density compared to alternatives like Pin Grid Array (PGA), enabling more input/output (I/O) connections in a compact package. For instance, LGA packages can support over 2000 lands, such as the 2011 contacts in Intel's LGA 2011 socket, without expanding the overall footprint, which facilitates advanced features like multi-channel memory controllers in modern processors.[55][56] The absence of protruding pins on the LGA package significantly reduces the risk of damage during handling, shipping, and installation. Flat contact lands on the processor protect the die from bending or breakage that can occur with PGA designs, while the socket's pins simplify insertion and minimize alignment errors.[57][29] This design has been credited with improving overall system reliability by lowering the incidence of CPU-related failures during assembly. LGA also offers enhanced thermal and electrical performance due to its flat land structure, which allows for uniform pressure application across contacts, resulting in low contact resistance—typically below 20 mΩ per land—and efficient heat spreading. The larger contact area with the PCB promotes better thermal conductivity, aiding in heat dissipation for high-power applications.[55][58][59] Furthermore, LGA's socket-based design enhances upgradability, extending product lifecycles by allowing processor swaps without replacing the motherboard, as exemplified by AMD's commitment to support the AM5 socket through at least 2027, with further extensions to Zen 6 in 2026–2027 and potential Zen 7 support as of 2025.[48][60] This feature reduces electronic waste and provides cost-effective paths for performance improvements over time.Challenges

Manufacturing land grid array (LGA) packages involves significant complexities, particularly in the precise plating of land pads to ensure reliable solder joints and prevent defects such as oxidation or voids. Electroless nickel/electroless palladium/immersion gold (ENEPIG) is the preferred surface finish for these lands, as it provides robust protection against oxidation during assembly processes like reflow soldering, where excessive soak times or slow ramp rates can otherwise lead to solder paste oxidation and subsequent void formation. Voids in LGA thermal pads are typically limited to a maximum of 25% area per manufacturer guidelines and IPC-A-610J standards, often mitigated through optimized stencil designs that achieve 50-70% solder paste coverage on exposed pads.[1][1][1] Additionally, socket production for LGA interfaces contributes to higher costs, with high-end CPU sockets estimated at $10-15 per unit in large volumes due to the intricate manufacturing of spring-loaded contacts.[61] Operationally, LGA assemblies are susceptible to poor electrical contact if the socket's normal force is unevenly distributed, which can result from stress relaxation in stamped metal contacts and lead to increased contact resistance or intermittent failures. This issue is exacerbated by LGA's higher sensitivity to thermal expansion mismatches between the package and printed circuit board (PCB), where differential coefficients of thermal expansion (CTE) during reflow or operational temperature cycling can induce residual stresses, warpage, or solder joint cracking. Rapid cooling post-reflow, for instance, amplifies these CTE-related stresses, potentially compromising long-term joint integrity.[62][1][63] Recent studies, however, indicate that LGA solder joints can exhibit 1.5 times longer fatigue life than BGA in thermal cycling due to larger pads and reduced solder volume.[64][65] Reliability concerns in LGA designs include land wear from repeated insertions and removals, as the friction between package lands and socket contacts degrades over multiple mating cycles, typically limiting durability to dozens of operations before contact resistance rises. In high-vibration environments such as server applications, LGA sockets face additional risks of fretting wear, where micro-movements at contact interfaces accelerate material loss and electrical degradation, often modeled through simulated field scenarios to predict failure thresholds. Gold plating on lands, as used in components from manufacturers like Key Components, helps mitigate some oxidation-related wear but does not eliminate cycle-induced degradation.[58][66]References

- https://en.wikichip.org/wiki/amd/packages/socket_sp3

- https://en.wikichip.org/wiki/amd/List_of_AMD_CPU_sockets

- https://en.wikichip.org/wiki/amd/packages/socket_g34

- https://en.wikichip.org/wiki/amd/ryzen_threadripper