Recent from talks

Nothing was collected or created yet.

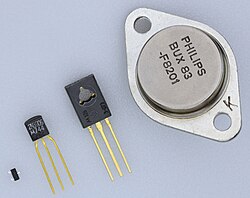

TO-92

View on WikipediaThe TO-92 is a widely used style of semiconductor package mainly used for transistors. The case is often made of epoxy or plastic, and offers compact size at a very low cost.

History and origin

[edit]The JEDEC TO-92 descriptor is derived from the original full name for the package: Transistor Outline Package, Case Style 92.[1] The package is also known by the designation SOT54. By 1966 the package was being used by Motorola for their 2N3904 devices among others.[2]

Construction and orientation

[edit]

The case is molded around the transistor elements in two parts; the face is flat, usually bearing a machine-printed part number (some early examples had the part number printed on the top surface instead). The back is semi-circularly-shaped. A line of moulding flash from the injection-moulding process can be seen around the case.

The leads protrude from the bottom of the case. When looking at the face of the transistor, the leads are commonly configured from left-to-right as the emitter, base, and collector for 2N series (JEDEC) transistors, however, other configurations are possible, such as emitter, collector, and base commonly used for 2S series (Japanese) transistors or collector, base, and emitter for many of the BC series (Pro Electron) types.

If the face has a part name made up of only one letter and a few numbers, it can be either a Japanese or a Pro Electron part number. Thus, "C1234" would likely be a 2SC1234 device, but "C547" is usually short for "BC547".

The leads coming out of the case are spaced 0.05" (1.27 mm) apart. It is often convenient to bend them outward to a 0.10" (2.54 mm) spacing to make more room for wiring.[3] Units with their leads pre-bent may be ordered to fit specific board layouts, depending on the application. Otherwise, the leads may be bent manually; however, care must be taken as they can break easily, as with any other device that is manually configured.

The physical dimensions of the TO-92 housing may vary slightly depending on the manufacturer, however, the 1.27mm lead spacing must be respected.

Advantages

[edit]- Transistors of this type can be made very inexpensively and take up very little board space. Most models are readily available in large quantities from wholesale distributors.

- They are easy to find in small electronics stores because of their wide usefulness, making them a popular choice for hobby work and prototyping.

Disadvantages

[edit]The main disadvantage of this style of case is the lack of heat sinking.

- Transistors and ICs of these types cannot handle as much power as higher-power equivalents, such as the TO-220, and can burn out quickly if they dissipate excessive power.

- There is no standard pinout for the TO-92. The American BJTs use the E-B-C pinout while their Japanese counterparts use the E-C-B pinout and some RF devices use the B-E-C pinout.[citation needed]

Voltage and current

[edit]Although TO-92 devices are mainly used in low-voltage / low-current (<30 V; <1 A) applications, high-voltage (600 Volt Vce) and high-current (5 A Ic) devices are available. Nominal maximum power dissipation is less than one watt (600 mW).

Variants

[edit]For diodes or integrated circuits with two connections (e.g. temperature sensors) the middle lead is either not connected or omitted entirely.

In the late 1960s, Ferranti introduced a smaller package with a compatible footprint, called "E-Line".[4][5] This package was later standardized as a British Standard (but not by JEDEC) and remained in production with Ferranti Semiconductors' successor companies (Plessey, Zetex Semiconductors, Diodes Incorporated[6]). In East Germany the E-Line package was known as the "Miniplast" package and widely used by Kombinat Mikroelektronik Erfurt.

Standards

[edit]| Standards organization | Standard | Designation for | ||

|---|---|---|---|---|

| TO-92 | E-Line/Miniplast | |||

| 3-lead | 2-lead | |||

| IEC | IEC 60191[7] | A68 | ||

| DIN | DIN 41868[8] | 10B3[a] | ||

| EIAJ / JEITA | ED-7500A[9][10] | SC-43A | ||

| British Standards | BS 3934[11] | SO-94[b] | ||

| Gosstandart | GOST 18472—88[12] | KT-26[c] | — | KD-129[d] |

| Rosstandart | GOST R 57439—2017[13] | |||

| Kombinat Mikroelektronik Erfurt | TGL 200-8380[14] | — | — | L2 |

| TGL 11811[7] | — | L3 | — | |

| TGL 26713/07[7] | F2 | F3 | F4 | |

- ^ DIN 41868 also defines variants with the leads bent to emulate the footprint of other packages: 10A3 (TO-18 footprint).

- ^ BS-3934 also defines variants with the leads bent to emulate the footprint of other packages: SO-95 (TO-5 footprint), SO-96 (for flat mounting), and SO-97 (TO-18 footprint).

- ^ Russian: КТ-26

- ^ Russian: КД-129

Common components in a TO-92 package

[edit]Common transistors:

- BC548, general purpose NPN transistor

- BC558, general purpose PNP transistor

- 2N3904, general purpose NPN transistor

- 2N3906, general purpose PNP transistor

- 2N7000, N-channel FET

- PN2222A, a "plastic" version of the original 2N2222 NPN transistor which came in a TO-18 package

Other common components:

- MK484, AM radio integrated circuit

- 78Lxx series, voltage regulator integrated circuits

- TL431, voltage regulator integrated circuit

References

[edit]- ^ a b c "JEDEC TO-92 package specification" (PDF). JEDEC. Archived from the original (PDF) on June 18, 2017.

- ^ The semiconductor data book. Motorola. August 1966. Retrieved 2021-07-09.

- ^ Bourns. "Package Mechanical Information, TO-92" (PDF). Retrieved 28 February 2016.

- ^ Applications of the E-Line Plastic Encapsulated Transistor. Oldham: Ferranti Ltd. June 1969. Retrieved 2021-07-10.

- ^ "E-Line – The ultimate TO-92". Quick Reference Guide (PDF). Ferranti Semiconductors. February 1983. p. E2. Retrieved 2021-07-10.

- ^ "E-Line Package Information" (PDF). Diodes Incorporated. March 2017. Retrieved 2021-07-10.

- ^ a b c "TGL 26713/07: Gehäuse für Halbleiterbauelemente - Bauform F" [Outline drawings for semiconductor devices; Type F] (PDF) (in German). Leipzig: Verlag für Standardisierung. June 1988. Retrieved 2021-06-15.

- ^ "Semiconductor Databook" (PDF). Heilbronn: AEG-Telefunken. pp. 17, 19. Retrieved 2021-08-20.

- ^ "EIAJ ED-7500A Standards for the Dimensions of Semiconductor Devices" (PDF). JEITA. 1996. p. 120. Retrieved 2021-06-14.

- ^ "TO-92 (SOT54)". Nexperia. 2004-11-16. Archived from the original on 2017-12-13. Retrieved 2021-07-12.

- ^ "Package Outlines". Quick Reference Guide (PDF). Ferranti Semiconductors. February 1983. p. PO14. Retrieved 2021-07-10.

- ^ "ГОСТ 18472—88 ПРИБОРЫ ПОЛУПРОВОДНИКОВЫЕ - Основные размеры" [GOST 18472—88 Semiconductor devices - basic dimensions] (PDF) (in Russian). Rosstandart. 1988. p. 33-34,55. Retrieved 2021-06-17.

- ^ "ГОСТ Р 57439—2017 ПРИБОРЫ ПОЛУПРОВОДНИКОВЫЕ - Основные размеры" [GOST R 57439—2017 Semiconductor devices - basic dimensions] (PDF) (in Russian). Gosstandart. 2017. p. 41-42,68-69. Retrieved 2021-06-17.

- ^ "TGL 200-8380: Halbleiterbauelemente - Halbleiterdioden Verlustleistung unter 1 Watt - Bauformen" [Semiconductor Devices - Designs for Semiconductor Diodes - Dissipation power less 1 Watt] (PDF) (in German). Leipzig: Verlag für Standardisierung. 1981. Retrieved 2021-07-12.

External links

[edit]- TO-92 Package, EESemi.com

- [1] Essay about TO92 housings (German) by Dipl.-Ing. Bernd Wiebus at German national library server.

TO-92

View on GrokipediaHistory and Development

Origins in Semiconductor Packaging

The TO-92 package, formally designated as the JEDEC Transistor Outline Package, Case Style 92, was developed specifically for encapsulating low-power discrete semiconductors such as bipolar junction transistors and diodes, providing a compact, cost-effective plastic housing suitable for through-hole mounting.[5] This standardization emerged as part of the broader Transistor Outline (TO) series, which defined consistent physical outlines to facilitate manufacturing and assembly in electronic devices. Following World War II, the Joint Electron Device Engineering Council (JEDEC), originally formed in 1944 as the Joint Electron Tube Engineering Council (JETEC) and restructured in 1958 to encompass solid-state devices, took on a pivotal role in the U.S. semiconductor industry by establishing uniform standards for component packaging and specifications.[6] These efforts addressed the growing need for interoperability among manufacturers, reducing fragmentation in the rapidly expanding post-war electronics sector and enabling scalable production of transistors and integrated circuits. JEDEC's focus on outline registrations, including the TO series, helped solidify a common framework that supported the transition from vacuum tubes to solid-state technology. The TO-92 package saw its first commercial application in 1966 when Motorola introduced it for the 2N3904 NPN general-purpose transistor, signifying the onset of mass production for this versatile low-power device.[7] This debut highlighted the package's advantages in affordability and ease of handling compared to earlier metal-can enclosures, quickly establishing it as a staple for consumer and industrial electronics. In European markets, the package was alternatively referred to as SOT54 under Pro-Electron and EIAJ nomenclature, reflecting parallel standardization efforts.[8]Early Adoption and Evolution

The TO-92 package saw rapid adoption in the late 1960s among U.S. manufacturers like Motorola and General Electric for general-purpose transistors, driven by the need for robust, low-cost plastic encapsulation amid the burgeoning electronics industry. This shift from metal-can packages to plastic ones enabled more compact and affordable designs, aligning with the era's explosive growth in semiconductor production. The package's inclusion in Motorola's 1966 Semiconductor Data Book marked a pivotal milestone, featuring it as Case 29 for devices such as the 2N3904 NPN transistor and facilitating global standardization efforts.[9][10] Demand surged due to the proliferation of consumer electronics, particularly portable radios and televisions, where the TO-92's small footprint and ease of assembly proved ideal for mass-market applications. Japanese manufacturers, including Toshiba, quickly incorporated similar plastic transistor packages into their production lines during this period, contributing to the package's international uptake as transistor radios became ubiquitous household items. By the end of the decade, the TO-92 had become a staple for low-power amplification and switching in these devices, supporting the transition from germanium to silicon transistors.[11][12] Through the 1970s and 1980s, the TO-92 evolved primarily through refinements in epoxy molding compounds, enhancing moisture resistance, thermal stability, and overall reliability without altering the core design. In 1970, Dexter Chemical introduced the first transfer-moldable epoxy specifically for TO-92 packages, allowing for optically clear encapsulation and improved manufacturing efficiency. Subsequent advancements in the 1980s focused on low-alpha emission and higher thermal conductivity formulations, addressing reliability concerns in increasingly dense circuits, though the package remained through-hole oriented until the rise of surface-mount alternatives in the late 1980s.[13][14]Design and Construction

Physical Structure and Materials

The TO-92 package employs a semi-cylindrical molded epoxy resin case that encapsulates the semiconductor die, offering electrical insulation and mechanical protection. This case typically measures approximately 5 mm in diameter and 4.6 mm in height, featuring a flat face for printing part numbers, date codes, and manufacturer logos, while the opposite side is rounded.[15][16] Internally, the package is constructed using a stamped metal lead frame, typically composed of three tin-plated copper alloy leads that protrude from the base of the case. These leads have a straight-line spacing of 1.27 mm (0.05 inches) in their unformed state, which is often pre-bent by manufacturers to a 2.54 mm (0.1 inch) pitch to align with standard printed circuit board (PCB) hole spacing for easier insertion and soldering.[17][15] The primary material for the case is a thermoset epoxy resin, which provides robust environmental resistance and is sometimes reinforced with glass fillers in variants to improve mechanical strength and dimensional stability. Package color is commonly black to minimize light sensitivity in certain devices, though variations exist depending on the manufacturer.[18][16] For assembly, the TO-92 supports through-hole mounting directly into PCB vias, with the leads soldered on the opposite side. Automated production is facilitated by optional tape-and-reel packaging, where components are aligned in carrier tape with 2,000 units per reel for high-volume pick-and-place operations.[19]Lead Configuration and Pinouts

The TO-92 package employs a three-lead configuration primarily for bipolar junction transistors (BJTs), with the leads corresponding to the emitter, base, and collector terminals. However, unlike some semiconductor packages, the TO-92 lacks a universal pinout standard, as it defines only the physical enclosure rather than the internal device wiring. This variability stems from differing regional and manufacturer practices, requiring users to consult specific datasheets for accurate identification. Pin numbering conventionally proceeds from left to right (1, 2, 3) when viewing the package with the flat face toward the observer and leads pointing downward. In the United States, the JEDEC standard—commonly applied to 2N-series transistors—assigns pin 1 to the emitter, pin 2 to the base, and pin 3 to the collector (E-B-C configuration). Japanese manufacturers, following EIAJ conventions, frequently adopt an emitter-collector-base (E-C-B) arrangement, as seen in 2S-series (e.g., 2SC) devices like the 2SC945, where pin 1 is the emitter, pin 2 the collector, and pin 3 the base. European-style BC-series transistors, such as the BC547, typically use a collector-base-emitter (C-B-E) pinout, with pin 1 as the collector, pin 2 the base, and pin 3 the emitter. These differences reflect historical manufacturing conventions rather than a deliberate design choice.| Series/Standard | Pin 1 (Left) | Pin 2 (Middle) | Pin 3 (Right) | Example Device | Source |

|---|---|---|---|---|---|

| JEDEC (U.S.) | Emitter | Base | Collector | 2N3904 | onsemi 2N3904 Datasheet |

| EIAJ (Japanese) | Emitter | Collector | Base | 2SC945 | Components101 2SC945 Guide |

| European (BC) | Collector | Base | Emitter | BC547 | onsemi BC550 Datasheet |