Recent from talks

Nothing was collected or created yet.

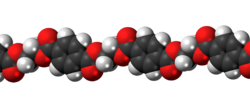

Polyethylene terephthalate

View on Wikipedia

| |

| |

| |

| Names | |

|---|---|

| IUPAC name

Poly(ethylene terephthalate)

| |

| Systematic IUPAC name

Poly(oxyethyleneoxyterephthaloyl) | |

| Other names

Terylene (trademark);

Dacron (trademark).

| |

| Identifiers | |

| Abbreviations | PET, PETE |

| ChEBI | |

| ChemSpider |

|

| ECHA InfoCard | 100.121.858 |

| UNII | |

CompTox Dashboard (EPA)

|

|

| Properties | |

| (C10H8O4)n[1] | |

| Molar mass | 10–50 kg/mol, varies |

| Density |

|

| Melting point | > 250 °C (482 °F; 523 K)[2] 260 °C[1] |

| Boiling point | > 350 °C (662 °F; 623 K) (decomposes) |

| Practically insoluble[2] | |

| log P | 0.94540[3] |

| Thermal conductivity | 0.15[4] to 0.24 W/(m·K)[1] |

Refractive index (nD)

|

1.57–1.58,[4] 1.5750[1] |

| Thermochemistry | |

Heat capacity (C)

|

1.0 kJ/(kg·K)[1] |

| Related compounds | |

Related Monomers

|

Terephthalic acid Ethylene glycol |

Except where otherwise noted, data are given for materials in their standard state (at 25 °C [77 °F], 100 kPa).

| |

Polyethylene terephthalate (or poly(ethylene terephthalate),[5] PET, PETE, or the obsolete PETP or PET-P), is the most common thermoplastic polymer resin of the polyester family and is used in fibres for clothing, containers for liquids and foods, and thermoforming for manufacturing, and in combination with glass fibre for engineering resins.[6]

In 2013, annual production of PET was 56 million tons.[7] The biggest application is in fibres (in excess of 60%), with bottle production accounting for about 30% of global demand.[8] In the context of textile applications, PET is referred to by its common name, polyester, whereas the acronym PET is generally used in relation to packaging. PET used in non-fiber applications (i.e. for packaging) makes up about 6% of world polymer production by mass. Accounting for the >60% fraction of polyethylene terephthalate produced for use as polyester fibers, PET is the fourth-most-produced polymer after polyethylene (PE), polypropylene (PP) and polyvinyl chloride (PVC).[8][5]

PET consists of repeating (C10H8O4) units. PET is commonly recycled, and has the digit 1 (♳) as its resin identification code (RIC). The National Association for PET Container Resources (NAPCOR) defines PET as: "Polyethylene terephthalate items referenced are derived from terephthalic acid (or dimethyl terephthalate) and mono ethylene glycol, wherein the sum of terephthalic acid (or dimethyl terephthalate) and mono ethylene glycol reacted constitutes at least 90 percent of the mass of monomer reacted to form the polymer, and must exhibit a melting peak temperature between 225 °C and 255 °C, as identified during the second thermal scan in procedure 10.1 in ASTM D3418, when heating the sample at a rate of 10 °C/minute."[9]

Depending on its processing and thermal history, polyethylene terephthalate may exist both as an amorphous (transparent) and as a semi-crystalline polymer. The semicrystalline material might appear transparent (particle size less than 500 nm) or opaque and white (particle size up to a few micrometers) depending on its crystal structure and particle size.

One process for making PET uses bis(2-hydroxyethyl) terephthalate, which can be synthesized by the esterification reaction between terephthalic acid and ethylene glycol with water as a byproduct (this is also known as a condensation reaction), or by transesterification reaction between ethylene glycol and dimethyl terephthalate (DMT) with methanol as a byproduct. It can also be obtained by recycling of PET itself.[10] Polymerization is through a polycondensation reaction of the monomers (done immediately after esterification/transesterification) with water as the byproduct.[6]

| Young's modulus, E | 2800–3100 MPa |

| Tensile strength, σt | 55–75 MPa |

| Elastic limit | 50–150% |

| Notch test | 3.6 kJ/m2 |

| Glass transition temperature, Tg | 67–81 °C |

| Vicat B | 82 °C |

| Linear expansion coefficient, α | 7×10−5 K−1 |

| Water absorption (ASTM) | 0.16 |

| Source[1] | |

|---|---|

Uses

[edit]Textiles

[edit]Polyester fibres are widely used in the textile industry. The invention of the polyester fibre is attributed to J. R. Whinfield.[11] It was first commercialized in the 1940s by ICI, under the brand 'Terylene'.[12] Subsequently E. I. DuPont launched the brand 'Dacron'. As of 2022, there are many brands around the world, mostly Asian.

Polyester fibres are used in fashion apparel often blended with cotton, as heat insulation layers in thermal wear, sportswear and workwear and automotive upholstery.

Rigid packaging

[edit]Plastic bottles made from PET are widely used for soft drinks, both still and sparkling. For beverages that are degraded by oxygen, such as beer, a multilayer structure is used. PET sandwiches an additional polyvinyl alcohol (PVOH) or polyamide (PA) layer to further reduce its oxygen permeability.

Non-oriented PET sheet can be thermoformed to make packaging trays and blister packs.[13] Both amorphous PET and BoPET are transparent to the naked eye. Color-conferring dyes can easily be formulated into PET sheet.

PET is permeable to oxygen and carbon dioxide and this imposes shelf life limitations of contents packaged in PET.[14]: 104

In the early 2000s, the global PET packaging market grew at a compound annual growth rate of 9% to €17 billion in 2006.[15]

Flexible packaging

[edit]Biaxially oriented PET (BOPET) film (including brands like "Mylar") can be aluminized by evaporating a thin film of metal onto it to reduce its permeability, and to make it reflective and opaque (MPET). These properties are useful in many applications, including flexible food packaging and thermal insulation (such as space blankets).

Photovoltaic modules

[edit]BOPET is used in the backsheet of photovoltaic modules. Most backsheets consist of a layer of BOPET laminated to a fluoropolymer or a layer of UV stabilized BOPET.[16]

PET is also used as a substrate in thin film solar cells.

Thermoplastic resins

[edit]PET can be compounded with glass fibre and crystallization accelerators, to make thermoplastic resins. These can be injection moulded into parts such as housings, covers, electrical appliance components and elements of the ignition system.[17]

Nanodiamonds

[edit]PET is stoichiometrically a mixture of carbon and H2O, and therefore has been used in an experiment involving laser-driven shock compression which created nanodiamonds and superionic water. This could be a possible way of producing nanodiamonds commercially.[18][19]

Other applications

[edit]- A waterproofing barrier in undersea cables.

- As a film base.

- As a fibre, spliced into bell rope tops to help prevent wear on the ropes as they pass through the ceiling.

- Since late 2014 as liner material in type IV composite high pressure gas cylinders. PET works as a much better barrier to oxygen than earlier used (LD)PE.[20]

- As a 3D printing filament, as well as in the 3D printing plastic PETG (polyethylene terephthalate glycol). In 3D printing PETG has become a popular material[21] - used for high-end applications like surgical fracture tables[22] to automotive and aeronautical sectors, among other industrial applications.[23] The surface properties can be modified to make PETG self-cleaning for applications like the fabrication of traffic signs for the manufacture of light-emitting diode LED spotlights.[24]

- As one of three layers for the creation of glitter; acting as a plastic core coated with aluminum and topped with plastic to create a light reflecting surface,[25] although as of 2021 many glitter manufacturing companies have begun to phase out the use of PET after calls from organizers of festivals to create bio-friendly glitter alternatives.[25][26]

- Film for tape applications, such as the carrier for magnetic tape or backing for pressure-sensitive adhesive tapes. Digitalization has caused the virtual disappeance of the magnetic audio and videotape application.

- Water-resistant paper.[27]

-

PET preform for injection stretch blow moulding of a bottle

-

A finished PET bottle

-

A PET bottle which has been heated by a candle and has recrystallized, making it opaque.

-

PET clamshell packaging, used to sell fruit, hardware, etc.

-

Polyester yarn

-

Microfiber towels and cleaning cloths

-

Aluminized Mylar balloons filled with helium

History

[edit]PET was patented in 1941 by John Rex Whinfield, James Tennant Dickson and their employer the Calico Printers' Association of Manchester, England. E. I. DuPont de Nemours in Delaware, United States, first produced Dacron (PET fiber) in 1950 and used the trademark Mylar (boPET film) in June 1951 and received registration of it in 1952.[28][29] It is still the best-known name used for polyester film. The current owner of the trademark is DuPont Teijin Films.[30]

In the Soviet Union, PET was first manufactured in the laboratories of the Institute of High-Molecular Compounds of the USSR Academy of Sciences in 1949, and its name "Lavsan" is an acronym thereof (лаборатории Института высокомолекулярных соединений Академии наук СССР).[31]

The PET bottle was invented in 1973 by Nathaniel Wyeth[32] and patented by DuPont.[33]

Physical properties

[edit]

PET in its most stable state is a colorless, semi-crystalline resin. However it is intrinsically slow to crystallize compared to other semicrystalline polymers. Depending on processing conditions it can be formed into either non-crystalline (amorphous) or crystalline articles. Its amenability to drawing in manufacturing makes PET useful in fibre and film applications. It is strong and impact-resistant. PET is hygroscopic and absorbs water.[34]

Transparent products can be produced by rapidly cooling molten polymer below the glass transition temperature (Tg) to form a non-crystalline amorphous solid.[35] Like glass, amorphous PET forms when its molecules are not given enough time to arrange themselves in an orderly, crystalline fashion as the melt is cooled. While at room temperature the molecules are frozen in place, if enough heat energy is put back into them afterward by heating the material above Tg, they can begin to move again, allowing crystals to nucleate and grow. This procedure is known as cold crystallization.[36] Amorphous PET also crystallizes and becomes opaque when exposed to solvents, such as chloroform or toluene.[37]

A more crystalline product can be produced by allowing the molten polymer to cool slowly. Rather than forming one large single crystal, this material has a number of spherulites (crystallized areas) each containing many small crystallites (grains). Light tends to scatter as it crosses the boundaries between crystallites and the amorphous regions between them, causing the resulting solid to be translucent.[38] Orientation also renders polymers more transparent.[clarification needed] This is why BOPET film and bottles are both crystalline, to a degree, and transparent.[citation needed]

Flavor absorption

[edit]PET has an affinity for hydrophobic flavors, and drinks sometimes need to be formulated with a higher flavor dosage, compared to those going into glass, to offset the flavor taken up by the container.[39]: 115 While heavy gauge PET bottles returned for re-use, as in some EU countries, the propensity of PET to absorb flavors makes it necessary to conduct a "sniffer test" on returned bottles to avoid cross-contamination of flavors.[39]: 115

Intrinsic viscosity

[edit]Different applications of PET require different degrees of polymerization, which can be obtained by modifying the process conditions. The molecular weight of PET is measured by solution viscosity. Viscosity is highly dependent on molecular parameters such as chain length and molecular weight. Due to the structural complexity of branched polymers, viscosity-based determination of molecular weight is best used with linear polymers. With dilute solutions, an empirical relationship can be derived between the viscosity and the hydrodynamic volume and molecular weight distribution.[40] The preferred method to measure this viscosity is the intrinsic viscosity (IV) of the polymer.[41] Intrinsic viscosity is a dimensionless measurement found by extrapolating the relative viscosity (measured in (dℓ/g)) to zero concentration. Shown below are the IV ranges for common applications:[42]

| Application | IV |

|---|---|

| Textile fibers | 0.40–0.70 |

| Technical fibers (e.g. tire cord) | 0.72–0.98 |

| Biaxially oriented PET film (BOPET) | 0.60–0.70 |

| Sheet grade film for thermoforming | 0.70–1.00 |

| General purpose bottles | 0.70–0.78 |

| Carbonated drink bottles | 0.78–0.85 |

| Monofilaments and engineering plastics | 1.00–2.00 |

Copolymers

[edit]PET is often copolymerized with other diols or diacids to optimize the properties for particular applications.[43][44]

PETG

[edit]

For example, cyclohexanedimethanol (CHDM) can be added to the polymer backbone, replacing some of the ethylene glycol. Since this building block is much larger (six additional carbon atoms) than the ethylene glycol unit it replaces, it does not fit in with the neighboring chains the way an ethylene glycol unit would. This interferes with crystallization and lowers the polymer's melting temperature. In general, such PET is known as PETG or PET-G (polyethylene terephthalate glycol-modified). It is a clear amorphous thermoplastic that can be injection-molded, sheet-extruded or extruded as filament for 3D printing. PETG can be colored during processing. Replacing all of the ethylene glycol with CHDM gives PCT.

Isophthalic acid

[edit]

Another common modifier is isophthalic acid, replacing some of the 1,4-(para-) linked terephthalate units. The 1,2-(ortho-) or 1,3-(meta-) linkage produces an angle in the chain, which also disturbs crystallinity.

Advantages

[edit]Such copolymers are advantageous for certain molding applications, such as thermoforming, which is used for example to make tray or blister packaging from co-PET film, or amorphous PET sheet (A-PET/PETA) or PETG sheet. On the other hand, crystallization is important in other applications where mechanical and dimensional stability are important, such as seat belts. For PET bottles, the use of small amounts of isophthalic acid, CHDM, diethylene glycol (DEG) or other comonomers can be useful: if only small amounts of comonomers are used, crystallization is slowed but not prevented entirely. As a result, bottles are obtainable via stretch blow molding ("SBM"), which are both clear and crystalline enough to be an adequate barrier to aromas and even gases, such as carbon dioxide in carbonated beverages.

Production

[edit]Polyethylene terephthalate is produced largely from purified terephthalic acid (PTA), as well as to a lesser extent from (mono-)ethylene glycol (MEG) and dimethyl terephthalate (DMT).[45][6] As of 2022, ethylene glycol is made from ethene found in natural gas, while terephthalic acid comes from p-xylene made from crude oil. Typically an antimony or titanium compound is used as a catalyst, a phosphite is added as a stabilizer and a bluing agent such as cobalt salt is added to mask any yellowing.[46]

Processes

[edit]Dimethyl terephthalate process

[edit]

In the dimethyl terephthalate (DMT) process, DMT and excess ethylene glycol (MEG) are transesterified in the melt at 150–200 °C with a basic catalyst. Methanol (CH3OH) is removed by distillation to drive the reaction forward. Excess MEG is distilled off at higher temperature with the aid of vacuum. The second transesterification step proceeds at 270–280 °C, with continuous distillation of MEG as well.[45]

The reactions can be summarized as follows:

- First step

- C6H4(CO2CH3)2 + 2 HOCH2CH2OH → C6H4(CO2CH2CH2OH)2 + 2 CH3OH

- Second step

- n C6H4(CO2CH2CH2OH)2 → [(CO)C6H4(CO2CH2CH2O)]n + n HOCH2CH2OH

Terephthalic acid process

[edit]

In the terephthalic acid process, MEG and PTA are esterified directly at moderate pressure (2.7–5.5 bar) and high temperature (220–260 °C). Water is eliminated in the reaction, and it is also continuously removed by distillation:[45]

- n C6H4(CO2H)2 + n HOCH2CH2OH → [(CO)C6H4(CO2CH2CH2O)]n + 2n H2O

Bio-PET

[edit]Bio-PET is the bio-based counterpart of PET.[47][48] Essentially in Bio-PET, the MEG is manufactured from ethylene derived from sugar cane ethanol. A better process based on oxidation of ethanol has been proposed,[49] and it is also technically possible to make PTA from readily available bio-based furfural.[50]

Bottle processing equipment

[edit]

There are two basic molding methods for PET bottles, one-step and two-step. In two-step molding, two separate machines are used. The first machine injection molds the preform, which resembles a test tube, with the bottle-cap threads already molded into place. The body of the tube is significantly thicker, as it will be inflated into its final shape in the second step using stretch blow molding.

In the second step, the preforms are heated rapidly and then inflated against a two-part mold to form them into the final shape of the bottle. Preforms (uninflated bottles) are now also used as robust and unique containers themselves; besides novelty candy, some Red Cross chapters distribute them as part of the Vial of Life program to homeowners to store medical history for emergency responders. The two-step process lends itself to third party production remote from the user site. The preforms can be transported and stored by the thousand in a much smaller space than would finished containers, for the second stage to be carried out on the user site on a 'just in time' basis. In one-step machines, the entire process from raw material to finished container is conducted within one machine, making it especially suitable for molding non-standard shapes (custom molding), including jars, flat oval, flask shapes, etc. Its greatest merit is the reduction in space, product handling and energy, and far higher visual quality than can be achieved by the two-step system.[citation needed]

Degradation

[edit]PET is subject to degradation during processing. If the moisture level is too high, hydrolysis will reduce the molecular weight by chain scission, resulting in brittleness. If the residence time and/or melt temperature (temperature at melting) are too high, then thermal degradation or thermooxidative degradation will occur resulting in discoloration and reduced molecular weight, as well as the formation of acetaldehyde, and the formation "gel" or "fish-eye" formations through cross-linking. Mitigation measures include copolymerisation with other monomers like CHDM or isophthalic acid, which lower the melting point and thus the melt temperature of the resin, as well as the addition of polymer stabilisers such as phosphites.[51]

Acetaldehyde

[edit]Acetaldehyde, which can form by degradation of PET after mishandling of the material, is a colorless, volatile substance with a fruity smell. Although it forms naturally in some fruit, it can cause an off-taste in bottled water. As well as high temperatures (PET decomposes above 300 °C or 570 °F) and long barrel residence times, high pressures and high extruder speeds (which cause shear raising the temperature), can also contribute to the production of acetaldehyde. Photo-oxidation can also cause the gradual formation acetaldehyde over the object's lifespan. This proceeds via a Type II Norrish reaction.[52]

When acetaldehyde is produced, some of it remains dissolved in the walls of a container and then diffuses into the product stored inside, altering the taste and aroma. This is not such a problem for non-consumables (such as shampoo), for fruit juices (which already contain acetaldehyde), or for strong-tasting drinks like soft drinks. For bottled water, however, low acetaldehyde content is quite important, because if nothing masks the aroma, even extremely low concentrations (10–20 parts per billion in the water) of acetaldehyde can produce an off-taste.[53]

Safety and environmental concerns

[edit]Commentary published in Environmental Health Perspectives in April 2010 suggested that PET might yield endocrine disruptors under conditions of common use and recommended research on this topic.[54] Proposed mechanisms include leaching of phthalates as well as leaching of antimony. An article published in Journal of Environmental Monitoring in April 2012 concludes that antimony concentration in deionized water stored in PET bottles stays within EU's acceptable limit even if stored briefly at temperatures up to 60 °C (140 °F), while bottled contents (water or soft drinks) may occasionally exceed the EU limit after less than a year of storage at room temperature.[55][56]

Antimony

[edit]Antimony (Sb) is a metalloid element that is used as a catalyst in the form of compounds such as antimony trioxide (Sb2O3) or antimony triacetate in the production of PET. After manufacturing, a detectable amount of antimony can be found on the surface of the product. This residue can be removed with washing. Antimony also remains in the material itself and can, thus, migrate out into food and drinks. Exposing PET to boiling or microwaving can increase the levels of antimony significantly, possibly above US EPA maximum contamination levels.[57] The drinking water limit assessed by WHO is 20 parts per billion (WHO, 2003), and the drinking water limit in the United States is 6 parts per billion.[58] Although antimony trioxide is of low toxicity when taken orally,[59] its presence is still of concern. The Swiss Federal Office of Public Health investigated the amount of antimony migration, comparing waters bottled in PET and glass: The antimony concentrations of the water in PET bottles were higher, but still well below the allowed maximum concentration. The Swiss Federal Office of Public Health concluded that small amounts of antimony migrate from the PET into bottled water, but that the health risk of the resulting low concentrations is negligible (1% of the "tolerable daily intake" determined by the WHO). A later (2006) but more widely publicized study found similar amounts of antimony in water in PET bottles.[60] The WHO has published a risk assessment for antimony in drinking water.[59]

Fruit juice concentrates (for which no guidelines are established), however, that were produced and bottled in PET in the UK were found to contain up to 44.7 μg/L of antimony, well above the EU limits for tap water of 5 μg/L.[61]

Shed microfibres

[edit]Clothing sheds microfibres in use, during washing and machine drying. Plastic litter slowly forms small particles. Microplastics which are present on the bottom of the river or seabed can be ingested by small marine life, thus entering the food chain. As PET has a higher density than water, a significant amount of PET microparticles may be precipitated in sewage treatment plants. PET microfibers generated by apparel wear, washing or machine drying can become airborne, and be dispersed into fields, where they are ingested by livestock or plants and end up in the human food supply. A study published in the journal Science of the Total Environment found PET accounted for 18% of microplastics in human lung tissue samples, and that there were 0.69 ± 0.84 microplastics per gram of lung tissue.[62] SAPEA have declared that such particles 'do not pose a widespread risk'.[63] PET is known to degrade when exposed to sunlight and oxygen.[64] As of 2016, scarce information exists regarding the life-time of the synthetic polymers in the environment.[65]

Polyester recycling

[edit]This section needs additional citations for verification. (April 2011) |

While most thermoplastics can, in principle, be recycled, PET bottle recycling is more practical than many other plastic applications because of the high value of the resin and the almost exclusive use of PET for widely used water and carbonated soft drink bottling.[66][67] PET bottles lend themselves well to recycling (see below). In many countries PET bottles are recycled to a substantial degree,[66] for example about 75% in Switzerland.[68] The term rPET is commonly used to describe the recycled material, though it is also referred to as R-PET or post-consumer PET (POSTC-PET).[69][70]

The prime uses for recycled PET are polyester fiber, strapping, and non-food containers.[citation needed] Because of the recyclability of PET and the relative abundance of post-consumer waste in the form of bottles, PET is also rapidly gaining market share as a carpet fiber.[71] PET, like many plastics, is also an excellent candidate for thermal disposal (incineration), as it is composed of carbon, hydrogen, and oxygen, with only trace amounts of catalyst elements (but no sulfur).[citation needed] In general, PET can either be chemically recycled into its original raw materials (PTA, DMT, and EG), destroying the polymer structure completely;[citation needed] mechanically recycled into a different form, without destroying the polymer;[citation needed] or recycled in a process that includes transesterification and the addition of other glycols, polyols, or glycerol to form a new polyol. The polyol from the third method can be used in polyurethane (PU foam) production,[72][73][74][75] or epoxy-based products, including paints.[76]

In 2023 a process was announced for using PET as the basis for supercapacitor production. PET, being stoichiometrically carbon and H2O, can be turned into a form of carbon containing sheets and nanospheres, with a very high surface area. The process involves holding a mixture of PET, water, nitric acid, and ethanol at a high temperature and pressure for eight hours, followed by centrifugation and drying.[77][78]

Significant investments were announced in 2021 and 2022 for chemical recycling of PET by glycolysis, methanolysis,[79][80] and enzymatic recycling[81] to recover monomers. Initially these will also use bottles as feedstock but it is expected that fibres will also be recycled this way in future.[82]

PET is also a desirable fuel for waste-to-energy plants, as it has a high calorific value which helps to reduce the use of primary resources for energy generation.[83]

Biodegradation

[edit]At least one species of bacterium in the genus Nocardia can degrade PET with an esterase enzyme.[84] Esterases are enzymes able to cleave the ester bond between two oxygens that links subunits of PET.[84] The initial degradation of PET can also be achieved esterases expressed by Bacillus, as well as Nocardia.[85] Japanese scientists have isolated another bacterium, Ideonella sakaiensis, that possesses two enzymes which can break down the PET into smaller pieces digestible by the bacteria. A colony of I. sakaiensis can disintegrate a plastic film in about six weeks.[86][87] French researchers report developing an improved PET hydrolase that can depolymerize (break apart) at least 90 percent of PET in 10 hours, breaking it down into individual monomers.[88][89][90] Also, an enzyme based on a natural PET-ase was designed with the help of a machine learning algorithm to be able to tolerate pH and temperature changes by the University of Texas at Austin. The PET-ase was found to able to degrade various products and could break them down as fast as 24 hours.[91][92]

See also

[edit]- BoPET (biaxially oriented PET)

- Bioplastic

- PET bottle recycling

- Plastic recycling

- Polycyclohexylenedimethylene terephthalate—a polyester with a similar structure to PET

- Polyester

- Solar water disinfection—a method of disinfecting water using only sunlight and plastic PET bottles

References

[edit]- ^ a b c d e f g h van der Vegt, A. K.; Govaert, L. E. (2005). Polymeren, van keten tot kunstof. VSSD. ISBN 978-90-71301-48-3.[page needed]

- ^ a b c Record of Polyethylenterephthalat in the GESTIS Substance Database of the Institute for Occupational Safety and Health, accessed on 7 November 2007.

- ^ "poly(ethylene terephthalate) macromolecule_msds".

- ^ a b Speight, J. G.; Lange, Norbert Adolph (2005). McGraw-Hill (ed.). Lange's Handbook of Chemistry (16th ed.). pp. 2807–2758. ISBN 0-07-143220-5.

- ^ a b "Plastics - the Facts 2022 • Plastics Europe". Plastics Europe. Retrieved 15 March 2025.

- ^ a b c De Vos, Lobke; Van de Voorde, Babs; Van Daele, Lenny; Dubruel, Peter; Van Vlierberghe, Sandra (December 2021). "Poly(alkylene terephthalate)s: From current developments in synthetic strategies towards applications". European Polymer Journal. 161 110840. Bibcode:2021EurPJ.16110840D. doi:10.1016/j.eurpolymj.2021.110840. hdl:1854/LU-8730084.

- ^ Saxena, Shalini (19 March 2016). "Newly identified bacteria cleans up common plastic". Ars Technica. Retrieved 21 March 2016.

- ^ a b Ji, Li Na (February 2013). "Study on Preparation Process and Properties of Polyethylene Terephthalate (PET)". Applied Mechanics and Materials. 312: 406–410. Bibcode:2013AMM...312..406J. doi:10.4028/www.scientific.net/AMM.312.406.

- ^ "What is PET? - NAPCOR". NAPCOR. Retrieved 8 July 2020.

- ^ "Polyethylene terephthalate is an often-recycled plastic, but industry is still seeking major improvements". Chemical & Engineering News. Retrieved 15 March 2025.

- ^ Whinfield, J.R. (May 1953). "The Development of Terylene". Textile Research Journal. 23 (5): 289–293. doi:10.1177/004051755302300503.

- ^ The name Terylene was formed by inversion of (polyeth)ylene ter(ephthalate) and dates to the 1940s. Oxford Dictionary. Terylene was first registered as a UK trademark in April 1946.[citation needed] UK Intellectual Property Office UK00000646992

- ^ Pasbrig, Erwin (29 March 2007), Cover film for blister packs, retrieved 20 November 2016

- ^ Ashurst, P.; Hargitt, R. (26 August 2009). Soft Drink and Fruit Juice Problems Solved. Elsevier. ISBN 978-1-84569-706-8.

- ^ Patton, Dominique (16 January 2008). "Salzgitter to buy SIG Beverages unit". Beverage Daily. Retrieved 1 November 2023.

- ^ "COVEME PHOTOVOLTAIC Backsheets and Frontsheets for PV modules" (PDF). Retrieved 4 March 2022.

- ^ "Rynite PET Design Guide" (PDF). DuPont. Retrieved 4 March 2022.

- ^ He, Jhiyu; et al. (2 September 2022). "Diamond formation kinetics in shock-compressed C─H─O samples recorded by small-angle x-ray scattering and x-ray diffraction". Science Advances. 8 (35) eabo0617. Bibcode:2022SciA....8O.617H. doi:10.1126/sciadv.abo0617. hdl:10852/101445. PMC 10848955. PMID 36054354.

- ^ Leah Crane (10 September 2022). "Blasting plastic with powerful lasers turns it into tiny diamonds". New Scientist.

- ^ SIPA: Lightweight compressed gas cylinders have plastic liners / PET provides high oxygen barrier https://www.plasteurope.com, 18 November 2014, retrieved 16 May 2017.

- ^ Santana, Leonardo; Alves, Jorge Lino; Sabino Netto, Aurélio da Costa; Merlini, Claudia (6 December 2018). "Estudo comparativo entre PETG e PLA para Impressão 3D através de caracterização térmica, química e mecânica". Matéria (Rio de Janeiro) (in Portuguese). 23 (4): e12267. doi:10.1590/S1517-707620180004.0601.

- ^ Bow, J. K.; Gallup, N.; Sadat, S. A.; Pearce, J. M. (15 July 2022). "Open source surgical fracture table for digitally distributed manufacturing". PLOS ONE. 17 (7) e0270328. Bibcode:2022PLoSO..1770328B. doi:10.1371/journal.pone.0270328. PMC 9286293. PMID 35839177.

- ^ Valvez, Sara; Silva, Abilio P.; Reis, Paulo N. B. (2022). "Optimization of Printing Parameters to Maximize the Mechanical Properties of 3D-Printed PETG-Based Parts". Polymers. 14 (13): 2564. doi:10.3390/polym14132564. PMC 9269443. PMID 35808611.

- ^ Barrios, Juan M.; Romero, Pablo E. (January 2019). "Improvement of Surface Roughness and Hydrophobicity in PETG Parts Manufactured via Fused Deposition Modeling (FDM): An Application in 3D Printed Self–Cleaning Parts". Materials. 12 (15): 2499. Bibcode:2019Mate...12.2499B. doi:10.3390/ma12152499. PMC 6696107. PMID 31390834.

- ^ a b Green, Dannielle Senga; Jefferson, Megan; Boots, Bas; Stone, Leon (January 2021). "All that glitters is litter? Ecological impacts of conventional versus biodegradable glitter in a freshwater habitat". Journal of Hazardous Materials. 402 124070. Bibcode:2021JHzM..40224070G. doi:10.1016/j.jhazmat.2020.124070. PMID 33254837.

- ^ Street, Chloe (6 August 2018). "61 UK festivals are banning glitter - make the switch to eco sparkle". Evening Standard. Retrieved 25 March 2023.

- ^ Teijin. "Teijin Develops Eco-friendly Wet-strong Printing Paper Made 100% with Recycled Polyester Derived from Used PET Bottles". Teijin Group. Archived from the original on 25 August 2013. Retrieved 12 March 2013.

- ^ "The Complete History Of Polyester". Quality Nylon Rope. 14 December 2016. Retrieved 2 November 2024.

- ^ Whinfield, John Rex and Dickson, James Tennant (1941) "Improvements Relating to the Manufacture of Highly Polymeric Substances", UK Patent 578,079; "Polymeric Linear Terephthalic Esters", U.S. patent 2,465,319 Publication date: 22 March 1949; Filing date: 24 September 1945; Priority date: 29 July 1941

- ^ TEIJIN: Trademarks Archived 2 May 2013 at the Wayback Machine "Mylar and Melinex are the registered trademarks or trademarks of Dupont Teijin Films U.S. Limited Partnership and have been licensed to Teijin DuPont Films Japan Limited"

- ^ Ryazanova-Clarke, Larissa; Wade, Terence (31 January 2002). The Russian Language Today. Taylor & Francis. pp. 49–. ISBN 978-0-203-06587-7.

- ^ "Nathaniel Wyeth – Got a lot of bottle". www.thechemicalengineer.com. Retrieved 3 March 2022.

- ^ Wyeth, N.; Roseveare, R. (15 May 1973). "US patent US3733309 "Biaxially oriented poly(ethylene terephthalate) bottle"".

- ^ Margolis, James M. (28 October 2020). Engineering Thermoplastics: Properties and Applications. CRC Press. ISBN 978-1-000-10411-0.

- ^ Scheirs, John; Long, Timothy E. (2003). Modern polyesters: chemistry and technology of polyesters and copolyesters. Hoboken, N.J.: John Wiley & Sons. ISBN 0-471-49856-4. OCLC 85820031.

- ^ Pingping, Zhu; Dezhu, Ma (1999). "Study on the double cold crystallization peaks of poly(ethylene terephthalate) (PET): 2. Samples isothermally crystallized at high temperature". European Polymer Journal. 35 (4): 739–742. doi:10.1016/S0014-3057(98)00179-7. Retrieved 28 May 2025.

- ^ NPCS Board of Consultants & Engineers (2014) Chapter 6, p. 56 in Disposable Products Manufacturing Handbook, NIIR Project Consultancy Services, Delhi, ISBN 978-9-381-03932-8

- ^ Jabarin, Saleh A. (1982). "Optical properties of thermally crystallized poly(ethylene terephthalate)". Polymer Engineering & Science. 22 (13): 815–820. doi:10.1002/pen.760221305. ISSN 0032-3888. Retrieved 28 May 2025.

- ^ a b Ashurst, P.; Hargitt, R. (26 August 2009). Soft Drink and Fruit Juice Problems Solved. Elsevier. ISBN 978-1-84569-706-8.

- ^ Sanches, N.B.; Dias, M.L.; Pacheco, E.B.A.V. (2005). "Comparative techniques for molecular weight evaluation of poly (ethylene terephthalate) (PET)". Polymer Testing. 24 (6): 688–693. doi:10.1016/j.polymertesting.2005.05.006. Retrieved 28 May 2025.

- ^ Thiele, Ulrich K. (2007) Polyester Bottle Resins, Production, Processing, Properties and Recycling, Heidelberg, Germany, pp. 85 ff, ISBN 978-3-9807497-4-9

- ^ Gupta, V.B. and Bashir, Z. (2002) Chapter 7, p. 320 in Fakirov, Stoyko (ed.) Handbook of Thermoplastic Polyesters, Wiley-VCH, Weinheim, ISBN 3-527-30113-5.

- ^ "What is PETG? (Everything You Need To Know)". China: Wankai New Materials Co., Ltd. 18 July 2024. Retrieved 28 October 2024.

- ^ "What is PETG? (Everything You Need To Know)". TWI Ltd. Archived from the original on 4 April 2025.

- ^ a b c "Polyesters". Ullmann's Encyclopedia of Industrial Chemistry. Vol. A21. Weinheim: Wiley-VCH. pp. 233–238. doi:10.1002/14356007.a21_227. ISBN 978-3-527-30673-2.

- ^ MacDonald, W A (October 2002). "New advances in poly(ethylene terephthalate) polymerization and degradation". Polymer International. 51 (10): 923–930. doi:10.1002/pi.917.

- ^ Bio-based drop-in, smart drop-in and dedicated chemicals

- ^ Duurzame bioplastics op basis van hernieuwbare grondstoffen

- ^ Alex Tullo (20 November 2017). "New route planned to biobased ethylene glycol". C&EN Global Enterprise. 95 (46): 10. doi:10.1021/cen-09546-notw6.

- ^ Tachibana, Yuya; Kimura, Saori; Kasuya, Ken-ichi (4 February 2015). "Synthesis and Verification of Biobased Terephthalic Acid from Furfural". Scientific Reports. 5 (1): 8249. Bibcode:2015NatSR...5.8249T. doi:10.1038/srep08249. PMC 4316194. PMID 25648201.

- ^ F Gugumus (1996). Gaechter and Mueller (ed.). Plastics additives handbook: stabilizers, processing aids, plasticizers, fillers, reinforcements, colorants for thermoplastics (4th ed.). Munich: Hanser. p. 92. ISBN 978-3-446-17571-6.

- ^ Day, M.; Wiles, D. M. (January 1972). "Photochemical degradation of poly(ethylene terephthalate). III. Determination of decomposition products and reaction mechanism". Journal of Applied Polymer Science. 16 (1): 203–215 BHET. doi:10.1002/app.1972.070160118.

- ^ Nawrocki, J; Dąbrowska, A; Borcz, A (November 2002). "Investigation of carbonyl compounds in bottled waters from Poland". Water Research. 36 (19): 4893–4901. Bibcode:2002WatRe..36.4893N. doi:10.1016/S0043-1354(02)00201-4. PMID 12448533.

- ^ Sax, Leonard (2010). "Polyethylene Terephthalate May Yield Endocrine Disruptors". Environmental Health Perspectives. 118 (4): 445–8. Bibcode:2010EnvHP.118..445S. doi:10.1289/ehp.0901253. PMC 2854718. PMID 20368129.

- ^ Tukur, Aminu; Sharp, Liz; Stern, Ben; Tizaoui, Chedly; Benkreira, Hadj (2012). "PET bottle use patterns and antimony migration into bottled water and soft drinks: the case of British and Nigerian bottles". Journal of Environmental Monitoring. 14 (4): 1237–1247. doi:10.1039/c2em10917d. PMID 22402759.

- ^ Sax, Leonard (April 2010). "Polyethylene Terephthalate May Yield Endocrine Disruptors". Environmental Health Perspectives. 118 (4): 445–448. Bibcode:2010EnvHP.118..445S. doi:10.1289/ehp.0901253. PMC 2854718. PMID 20368129.

- ^ Cheng, Xiaoliang; Shi, Honglan; Adams, Craig D.; Ma, Yinfa (August 2010). "Assessment of metal contaminations leaching out from recycling plastic bottles upon treatments". Environmental Science and Pollution Research. 17 (7): 1323–1330. Bibcode:2010ESPR...17.1323C. doi:10.1007/s11356-010-0312-4. PMID 20309737.

- ^ Consumer Factsheet on: Antimony Archived 7 June 2014 at the Wayback Machine, EPA archive 2003-06-23

- ^ a b Guidelines for drinking – water quality. who.int

- ^ Shotyk, William; et al. (2006). "Contamination of Canadian and European bottled waters with antimony from PET containers". Journal of Environmental Monitoring. 8 (2): 288–92. doi:10.1039/b517844b. PMID 16470261.

- ^ Hansen, Claus; et al. (2010). "Elevated antimony concentrations in commercial juices". Journal of Environmental Monitoring. 12 (4): 822–4. doi:10.1039/b926551a. PMID 20383361.

- ^ Jenner, Lauren C.; Rotchell, Jeanette M.; Bennett, Robert T.; Cowen, Michael; Tentzeris, Vasileios; Sadofsky, Laura R. (July 2022). "Detection of microplastics in human lung tissue using μFTIR spectroscopy". Science of the Total Environment. 831 154907. Bibcode:2022ScTEn.83154907J. doi:10.1016/j.scitotenv.2022.154907. PMID 35364151.

- ^ "SAPEA report: Evidence on microplastics does not yet point to widespread risk - ALLEA". 10 January 2019. Retrieved 5 March 2022.

- ^ Chamas, Ali; Moon, Hyunjin; Zheng, Jiajia; Qiu, Yang; Tabassum, Tarnuma; Jang, Jun Hee; Abu-Omar, Mahdi; Scott, Susannah L.; Suh, Sangwon (9 March 2020). "Degradation Rates of Plastics in the Environment". ACS Sustainable Chemistry & Engineering. 8 (9): 3494–3511. doi:10.1021/acssuschemeng.9b06635.

- ^ Ioakeimidis, C.; Fotopoulou, K. N.; Karapanagioti, H. K.; Geraga, M.; Zeri, C.; Papathanassiou, E.; Galgani, F.; Papatheodorou, G. (22 March 2016). "The degradation potential of PET bottles in the marine environment: An ATR-FTIR based approach". Scientific Reports. 6 (1) 23501. Bibcode:2016NatSR...623501I. doi:10.1038/srep23501. PMC 4802224. PMID 27000994.

- ^ a b Malik, Neetu; Kumar, Piyush; Shrivastava, Sharad; Ghosh, Subrata Bandhu (June 2017). "An overview on PET waste recycling for application in packaging". International Journal of Plastics Technology. 21 (1): 1–24. doi:10.1007/s12588-016-9164-1.

- ^ Imran, Muhammad; Kim, Do Hyun; Al-Masry, Waheed A.; Mahmood, Asif; Hassan, Azman; Haider, Sajjad; Ramay, Shahid M. (April 2013). "Manganese-, cobalt-, and zinc-based mixed-oxide spinels as novel catalysts for the chemical recycling of poly(ethylene terephthalate) via glycolysis". Polymer Degradation and Stability. 98 (4): 904–915. doi:10.1016/j.polymdegradstab.2013.01.007.

- ^ "RAPPORT DE GESTION 2019" (PDF) (in French). Swiss PET Recycling Association. p. 5. Retrieved 5 March 2022.

- ^ Awaja, Firas; Pavel, Dumitru (July 2005). "Recycling of PET". European Polymer Journal. 41 (7): 1453–1477. Bibcode:2005EurPJ..41.1453A. doi:10.1016/j.eurpolymj.2005.02.005.

- ^ "PET and its eco-friendly alternative: rPET". Prevented Ocean Plastic. 8 May 2020. Retrieved 9 October 2022.

- ^ "R-PET: Schweizer Kreislauf – PET-Recycling". www.petrecycling.ch (in French). Retrieved 6 March 2022.

- ^ Makuska, Ricardas (2008). "Glycolysis of industrial poly(ethylene terephthalate) waste directed to bis(hydroxyethylene) terephthalate and aromatic polyester polyols" (PDF). Chemija. 19 (2): 29–34.

- ^ "Arropol | Arropol Chemicals". Retrieved 2 January 2019.

- ^ Shirazimoghaddam, Shadi; Amin, Ihsan; Faria Albanese, Jimmy A; Shiju, N. Raveendran (15 February 2023). "Chemical Recycling of Used PET by Glycolysis Using Niobia-Based Catalysts". ACS Engineering Au. 3 (1): 37–44. doi:10.1021/acsengineeringau.2c00029. PMC 9936547. PMID 36820227.

- ^ Jehanno, Coralie; Pérez-Madrigal, Maria M.; Demarteau, Jeremy; Sardon, Haritz; Dove, Andrew P. (2019). "Organocatalysis for depolymerisation". Polymer Chemistry. 10 (2): 172–186. doi:10.1039/C8PY01284A. hdl:2117/365711.

- ^ Bal, Kevser; Ünlü, Kerim Can; Acar, Işıl; Güçlü, Gamze (May 2017). "Epoxy-based paints from glycolysis products of postconsumer PET bottles: synthesis, wet paint properties and film properties". Journal of Coatings Technology and Research. 14 (3): 747–753. doi:10.1007/s11998-016-9895-0.

- ^ Karmela Padavic-Callaghan (23 August 2023). "Plastic bottles can be recycled into energy-storing supercapacitors". New Scientist.

- ^ Wang, Shengnian; et al. (2023). "Upcycling drink bottle waste to ball-sheet Intercalated carbon structures for supercapacitor applications". ACS Fall 2023 - Sessions. American Chemical Society.

- ^ Laird, Karen (18 January 2022). "Loop, Suez select site in France for first European Infinite Loop facility". Plastics News. Retrieved 11 March 2022.

- ^ Toto, Deanne (1 February 2021). "Eastman invests in methanolysis plant in Kingsport, Tennessee". Recycling Today. Retrieved 11 March 2022.

- ^ Page Bailey, mary (24 February 2022). "Carbios and Indorama to build first-of-its-kind enzymatic recycling plant for PET in France". Chemical Engineering. Retrieved 11 March 2022.

- ^ Shojaei, Behrouz; Abtahi, Mojtaba; Najafi, Mohammad (December 2020). "Chemical recycling of PET: A stepping-stone toward sustainability". Polymers for Advanced Technologies. 31 (12): 2912–2938. doi:10.1002/pat.5023.

- ^ Palacios-Mateo, Cristina; van der Meer, Yvonne; Seide, Gunnar (6 January 2021). "Analysis of the polyester clothing value chain to identify key intervention points for sustainability". Environmental Sciences Europe. 33 (1): 2. doi:10.1186/s12302-020-00447-x. PMC 7787125. PMID 33432280.

- ^ a b Samak, Nadia A.; Jia, Yunpu; Sharshar, Moustafa M.; Mu, Tingzhen; Yang, Maohua; Peh, Sumit; Xing, Jianmin (December 2020). "Recent advances in biocatalysts engineering for polyethylene terephthalate plastic waste green recycling". Environment International. 145 106144. Bibcode:2020EnInt.14506144S. doi:10.1016/j.envint.2020.106144. PMID 32987219.

- ^ Smith, Matthew R.; Cooper, Sharon J.; Winter, Derek J.; Everall, Neil (July 2006). "Detailed mapping of biaxial orientation in polyethylene terephthalate bottles using polarised attenuated total reflection FTIR spectroscopy". Polymer. 47 (15): 5691–5700. doi:10.1016/j.polymer.2005.07.112.

- ^ Yoshida, S.; Hiraga, K.; Takehana, T.; Taniguchi, I.; Yamaji, H.; Maeda, Y.; Toyohara, K.; Miyamoto, K.; Kimura, Y.; Oda, K. (11 March 2016). "A bacterium that degrades and assimilates poly(ethylene terephthalate)". Science. 351 (6278): 1196–9. Bibcode:2016Sci...351.1196Y. doi:10.1126/science.aad6359. PMID 26965627.

- ^ "Could a new plastic-eating bacteria help combat this pollution scourge?". The Guardian. 10 March 2016. Retrieved 11 March 2016.

- ^ Ong, Sandy (24 August 2023). "The living things that feast on plastic". Knowable Magazine. doi:10.1146/knowable-082423-1.

- ^ Tournier, V.; Topham, C. M.; Gilles, A.; David, B.; Folgoas, C.; Moya-Leclair, E.; Kamionka, E.; Desrousseaux, M.-L.; Texier, H.; Gavalda, S.; Cot, M.; Guémard, E.; Dalibey, M.; Nomme, J.; Cioci, G.; Barbe, S.; Chateau, M.; André, I.; Duquesne, S.; Marty, A. (9 April 2020). "An engineered PET depolymerase to break down and recycle plastic bottles". Nature. 580 (7802): 216–219. Bibcode:2020Natur.580..216T. doi:10.1038/s41586-020-2149-4. PMID 32269349.

- ^ Tournier, Vincent; Duquesne, Sophie; Guillamot, Frédérique; Cramail, Henri; Taton, Daniel; Marty, Alain; André, Isabelle (10 May 2023). "Enzymes' Power for Plastics Degradation". Chemical Reviews. 123 (9): 5612–5701. doi:10.1021/acs.chemrev.2c00644. PMID 36916764.

- ^ "Scientists Engineer New Plastic-Eating Enzyme | Sci-News.com". Breaking Science News | Sci-News.com. 28 April 2022. Retrieved 2 June 2022.

- ^ Lu, Hongyuan; Diaz, Daniel J.; Czarnecki, Natalie J.; Zhu, Congzhi; Kim, Wantae; Shroff, Raghav; Acosta, Daniel J.; Alexander, Bradley R.; Cole, Hannah O.; Zhang, Yan; Lynd, Nathaniel A.; Ellington, Andrew D.; Alper, Hal S. (28 April 2022). "Machine learning-aided engineering of hydrolases for PET depolymerization". Nature. 604 (7907): 662–667. Bibcode:2022Natur.604..662L. doi:10.1038/s41586-022-04599-z. PMID 35478237.

External links

[edit]Polyethylene terephthalate

View on GrokipediaChemical Structure and Properties

Molecular Composition and Synthesis Basics

Polyethylene terephthalate (PET) consists of repeating monomeric units formed by the polycondensation of terephthalic acid (1,4-benzenedicarboxylic acid) and ethylene glycol, resulting in the structural formula -[O-CH₂-CH₂-O-CO-C₆H₄-CO]-_n, where C₆H₄ denotes the para-phenylene ring.[7][8] The empirical formula of the repeating unit is C₁₀H₈O₄, with a molar mass of 192.2 g/mol.[9] This composition features ester linkages that connect the aliphatic ethylene glycol segments to the rigid aromatic terephthalate units, conferring the polymer its polyester classification and key attributes like thermal stability arising from the benzene ring's conjugation.[10] The synthesis of PET primarily occurs through two-step polycondensation processes. In the direct esterification route, purified terephthalic acid (PTA) reacts with excess ethylene glycol (EG) at elevated temperatures (around 250–260°C) to form bis(2-hydroxyethyl) terephthalate (BHET) monomer and water, followed by a second-stage polycondensation under vacuum to remove EG and extend the chain, achieving high molecular weight (typically 10–50 kg/mol).[7][11] Alternatively, the transesterification method employs dimethyl terephthalate (DMT) with EG, initially producing BHET and methanol at lower temperatures (150–200°C), then proceeding to polycondensation similar to the PTA process, though the DMT route has declined due to PTA's cost advantages and purity.[7] Catalysts such as antimony trioxide or titanium compounds facilitate these reactions by lowering activation energies and promoting ester interchange or dehydration.[11] These synthesis basics ensure PET's linear, semi-crystalline structure, with the para-oriented terephthalate units enabling efficient chain packing and hydrogen bonding interactions that underpin its mechanical integrity.[10] The processes operate under controlled conditions to minimize side reactions like diethylene glycol formation, which can degrade properties if exceeding 1–2% of the glycol content.[9]Intrinsic Physical and Thermal Properties

Polyethylene terephthalate (PET) is a semi-crystalline thermoplastic polymer characterized by a density of approximately 1.38 g/cm³ in its amorphous form, increasing to about 1.455 g/cm³ in highly crystalline states due to denser molecular packing.[8][12] The degree of crystallinity typically ranges from 0% in quenched amorphous PET to 30-40% in oriented films or fibers, influencing optical clarity, stiffness, and barrier performance, with amorphous PET appearing transparent and crystalline forms more opaque or hazy.[13][14] The glass transition temperature (Tg) of PET lies between 65°C and 80°C, marking the onset of segmental chain mobility and a shift from glassy to rubbery behavior, with values varying based on crystallinity and processing history—lower for amorphous samples and slightly higher for crystalline ones.[8][15] The melting temperature (Tm) ranges from 240°C to 270°C, reflecting the disruption of crystalline lamellae, though practical processing often targets 250-260°C to avoid degradation.[8][16] Key thermal properties include a coefficient of linear thermal expansion (CTE) of 20-80 × 10⁻⁶ K⁻¹, exhibiting anisotropy in oriented forms where machine-direction expansion is lower than transverse.[12][17] Specific heat capacity is approximately 1.0-1.35 kJ/kg·K near room temperature, increasing with temperature due to enhanced vibrational modes.[17] Thermal conductivity remains low at 0.15-0.24 W/m·K, typical of insulating polymers, limiting heat dissipation in applications.[17][13]| Property | Typical Value | Notes/Source Dependence |

|---|---|---|

| Density (amorphous) | 1.38 g/cm³ | Increases with crystallinity[16] |

| Glass Transition Temp. | 65-80°C | Crystallinity-dependent[8] |

| Melting Temperature | 250-260°C | Process-oriented range[16] |

| CTE | 20-80 × 10⁻⁶ K⁻¹ | Anisotropic in films[12] |

| Specific Heat Capacity | 1.0-1.35 kJ/kg·K | At ambient conditions[17] |

| Thermal Conductivity | 0.15-0.24 W/m·K | Low, polymer-typical[17] |

Barrier and Mechanical Characteristics

Polyethylene terephthalate exhibits robust mechanical properties derived from its semi-crystalline structure, which provides stiffness and dimensional stability. The ultimate tensile strength ranges from 60 to 140 MPa, with a Young's modulus of 3.5 to 11 GPa, enabling resistance to deformation under load.[18] Biaxially oriented PET films demonstrate enhanced performance, achieving tensile strengths of 190–260 MPa and elongation at break of 60–165%, which contribute to toughness in thin applications.[12] Notched Izod impact strength varies from 13 to 85 J/m, reflecting moderate energy absorption before fracture.[12][18]| Mechanical Property | Typical Range |

|---|---|

| Ultimate Tensile Strength | 60–140 MPa[18] |

| Young's Modulus | 3.5–11 GPa[18] |

| Elongation at Break (oriented film) | 60–165%[12] |

| Notched Izod Impact Strength | 13–85 J/m[18][12] |

Production Processes

Conventional Chemical Routes

Polyethylene terephthalate (PET) is produced industrially via step-growth polycondensation polymerization of purified terephthalic acid (PTA) or dimethyl terephthalate (DMT) with excess ethylene glycol (EG), requiring high-purity monomers exceeding 99% to achieve suitable polymer properties.[20][1] The PTA route, which dominates modern production, begins with mixing solid PTA and liquid EG in a paste preparation tank using counter-rotating kneading elements, followed by esterification to form bis(2-hydroxyethyl) terephthalate (BHET) monomers and low-molecular-weight oligomers while removing water.[21] Primary esterification occurs at 230–260°C under 30–50 psig pressure, with secondary esterification at 250–270°C under atmospheric pressure, venting water via a reflux column.[21] Subsequent polycondensation builds chain length through transesterification and EG elimination, conducted in staged reactors under progressive vacuum and elevated temperatures: initial stages at 270–300°C and 20–40 mm Hg, advancing to final high polymerizers at 280–300°C and 0.1–1.0 mm Hg, often using catalysts such as antimony trioxide.[21][1] The molten polymer is extruded, quenched, and pelletized; for high-viscosity applications like bottles, solid-state polymerization follows under inert gas at 200–240°C to further increase intrinsic viscosity without melting.[20] This direct esterification avoids methanol handling, offering economic and process efficiency advantages over the older DMT route, which gained prevalence until the mid-1960s but declined with high-purity PTA availability.[20] The DMT-based transesterification route, historically significant, involves melting DMT with EG and catalysts at 170–230°C under atmospheric pressure to interchange esters and distill methanol, yielding BHET, followed by analogous prepolymerization (230–285°C, 1–760 mm Hg) and polymerization (260–300°C, <5 mm Hg) steps with EG removal.[21][1] While both routes produce PET exceeding 4 billion pounds annually in the U.S., the PTA process now accounts for the majority due to simplified byproduct recovery and faster esterification kinetics enabled by innovations like Amoco's PTA purification.[1][20] Vacuum systems, typically steam jet ejectors, facilitate byproduct distillation to minimize defects like acetaldehyde formation.[21]Bio-Based and Alternative Methods

Bio-based production of polyethylene terephthalate (PET) replaces petroleum-derived monomers with biomass-sourced alternatives, primarily targeting ethylene glycol (EG) and terephthalic acid (TPA), which constitute the polymer's core components. EG, accounting for approximately 30% of PET's mass, is commercially produced via bioethanol from sugarcane fermentation, dehydration to ethylene, and subsequent conversion through ethylene oxide hydrolysis; Braskem has manufactured bio-EG at scale in Brazil since 2011, with annual capacities exceeding 200,000 metric tons.[22][23] TPA, the remaining ~70%, remains challenging for full bio-derivation due to its aromatic structure, but routes include microbial fermentation of glucose to cis,cis-muconic acid followed by catalytic dehydrogenation and oxidation, or bio-isobutanol dehydration to isobutene and aromatization to paraxylene (PX), then oxidation to TPA.[24][25] Partially bio-based PET, using bio-EG with petrochemical TPA, has achieved commercial viability; Coca-Cola's PlantBottle, introduced in 2009, incorporates up to 30% bio-content and has been used in over 35 billion units by 2020, reducing reliance on fossil EG without altering polymer properties.[26] Fully bio-based PET emerged commercially in 2024 via bio-PX routes, where Indorama Ventures and partners produced ISCC+-certified bio-paraxylene from plant-based feedstocks, enabling Suntory's launch of 45 million PET bottles with 100% bio-derived monomers, matching virgin PET's mechanical strength (tensile modulus ~3-4 GPa) and barrier performance.[27] Global bio-PET market volume reached an estimated 3.74 billion USD in 2025, driven by demand in packaging, though scalability is limited by bio-TPA costs (20-50% higher than petrochemical equivalents due to fermentation yields <90%).[28][29] Alternative production methods emphasize recycling-derived feedstocks to circumvent virgin monomer synthesis. Chemical recycling depolymerizes post-consumer PET via glycolysis (using ethylene glycol at 180-240°C to yield bis(hydroxyethyl) terephthalate, BHET), methanolysis (to dimethyl terephthalate and EG), or hydrolysis (to TPA and EG under acidic/basic conditions at 200-300°C), followed by repolymerization; these yield high-purity rPET comparable to virgin material, with glycolysis achieving >95% monomer recovery in industrial plants like those operated by Eastman Chemical since 2019.[30][31] Biological alternatives employ enzymes such as PETase and MHETase from Ideonella sakaiensis or engineered variants, hydrolyzing PET at ambient conditions (30-70°C, pH 7-9) to TPA and EG with efficiencies up to 90% crystallinity degradation; CARBIOS scaled this to pilot in 2020 and plans a 50,000-ton/year commercial plant by 2026, reducing energy use by 70% versus mechanical recycling.[32][33] Electrocatalytic methods, such as anodic oxidation of PET waste in alkaline media, convert it to formate and TPA at potentials of 1.5-2.0 V, offering potential for integrated upcycling but remaining lab-scale as of 2021 with faradaic efficiencies ~80%.[34] These routes enhance circularity, with chemical methods dominating ~20% of Europe's PET supply in 2025, though biological processes face enzyme stability challenges under industrial conditions.Quality Control and Degradation Issues

In PET manufacturing, quality control emphasizes monitoring intrinsic viscosity (IV), which serves as a proxy for molecular weight and mechanical strength, with targets typically ranging from 0.60 to 0.80 dL/g for bottle-grade resin to ensure adequate processability and tensile properties.[35] [36] Acetaldehyde (AA) content, a volatile byproduct, is strictly limited to below 1 ppm in food-contact grades to prevent off-flavor migration into beverages.[37] Diethylene glycol (DEG) incorporation, arising from side reactions in ethylene glycol, is controlled under 1.5 mol% to maintain crystallinity and thermal stability, as higher levels promote amorphous regions and reduce barrier performance.[36] Carboxyl end-group concentration is titrated to detect early degradation, with levels rising from baseline 12 meq/kg at optimized conditions (e.g., 272°C) to 18 meq/kg under excessive heat (285°C), signaling chain scission.[36] Moisture content in pellets is reduced to under 50 ppm prior to melt processing via drying, as residual water initiates hydrolysis.[36] Degradation issues in PET production stem mainly from thermal, hydrolytic, and thermo-oxidative pathways during polymerization, extrusion, and solid-state polymerization (SSP). Thermal degradation at 280–300°C induces random ester bond scission, lowering IV and forming acetaldehyde alongside cyclic oligomers like trimers, which can reach 366 ppm after prolonged residence times (e.g., 65 minutes).[36] This process has an activation energy of approximately 129 kJ/mol for homopolymer PET, exacerbated by shear in extruders, leading to yellowing and reduced melt strength.[36] Hydrolytic degradation accelerates above 100°C in the presence of moisture or acidic impurities, cleaving ester links autocatalytically to yield carboxyl and hydroxyl ends, with rates up to 10,000 times faster than pure thermal degradation at 100–120°C; the number-average molecular weight (Mn) post-hydrolysis follows Mn' = Mn [1 + x × (Mn/1800)], where x is exposure factor.[36] Thermo-oxidative effects involve hydroperoxide formation at methylene sites, promoting chain branching or scission under air exposure during melt phases.[36] Mitigation relies on process optimization, such as vacuum devolatilization to remove volatiles, inert atmospheres to curb oxidation, and additives like phosphoric acid (at 150 ppm) to enhance stability and tensile strength from 2.61 g/d to 3.0 g/d.[36] Impurities from catalysts, such as antimony trioxide residues, can catalyze further degradation if not minimized, while in recycled PET streams, cumulative defects like gels or colorants compound quality loss, necessitating advanced sorting and purification.[38] [30] Benzene formation from polymer impurity breakdown during reprocessing poses additional risks, as it exceeds safe thresholds in poorly controlled recycled feeds.[39]Historical Development

Invention and Initial Research

Polyethylene terephthalate (PET) was first synthesized in 1941 by British chemists John Rex Whinfield and James Tennant Dickson at the Calico Printers' Association in Accrington, England, during research into thermoplastic polyesters suitable for fiber production.[40] Their experiments built on prior investigations into polyesters, particularly the work of Wallace Carothers at DuPont in the 1930s, which had produced aliphatic polyesters with inadequate melting points for practical textile applications; Whinfield and Dickson shifted to aromatic diacids like terephthalic acid combined with aliphatic diols such as ethylene glycol to yield a polymer with enhanced thermal stability.[41] [42] The synthesis involved polycondensation via esterification of terephthalic acid with ethylene glycol or transesterification with dimethyl terephthalate, resulting in a linear polymer chain that could be melt-spun into strong fibers.[43] This process addressed wartime needs for synthetic alternatives to imported natural fibers and silk, as the United Kingdom sought domestic production capabilities amid supply disruptions.[44] Initial tests confirmed PET's high tensile strength and resistance to stretching, properties derived from its semi-crystalline structure formed during polymerization.[45] Whinfield and Dickson filed a British patent (No. 578,079) for the polymer in November 1941, marking the formal invention of PET as a viable material for industrial use.[41] Early research emphasized optimizing reaction conditions to achieve high molecular weight, which was critical for fiber drawability and durability, though full-scale development was delayed by World War II resource constraints.[40]Commercialization and Industry Growth

Commercial production of polyethylene terephthalate (PET) began in the mid-20th century, initially focused on textile fibers. Imperial Chemical Industries (ICI) in the United Kingdom achieved the first mass production of PET fiber in 1946, marketing it under the brand Terylene for apparel and industrial applications.[46] DuPont, having acquired U.S. rights to the technology in 1945, launched commercial PET fiber production as Dacron in 1953, rapidly expanding its use in clothing and tire cords due to superior strength and durability compared to natural fibers.[42] Concurrently, DuPont introduced PET film under the Mylar trademark in 1952 for electrical insulation and packaging, establishing early industrial markets.[47] The 1970s marked a pivotal shift toward packaging applications, catalyzing explosive industry growth. In 1973, DuPont engineer Nathaniel Wyeth patented the single-use PET bottle capable of withstanding carbonation pressures, enabling replacement of heavier glass containers.[48] Commercial rollout followed swiftly, with PepsiCo introducing PET soft drink bottles in 1975 and Coca-Cola in 1977, followed by 2-liter sizes in 1978, which slashed shipping costs and boosted consumer convenience.[49] This innovation drove PET demand, as bottles offered shatter resistance, transparency, and recyclability, propelling annual global PET bottle production from negligible volumes in the early 1970s to over 10 million metric tons by the 1990s.[50] Subsequent decades saw sustained expansion, fueled by packaging dominance and emerging uses in films and strapping. Global PET production capacity reached approximately 36.23 million tonnes per annum by 2023, reflecting an average annual growth rate exceeding 3% since the 2000s, with Asia accounting for over 70% of output due to cost advantages in terephthalic acid feedstock.[51] Market value stood at USD 39.12 billion in 2024, projected to grow at a compound annual growth rate of 5.6% through 2030, driven primarily by beverage packaging (over 50% of consumption) amid rising global soft drink and bottled water demand.[52] Key producers evolved to include integrated firms like Indorama Ventures and Alpek, but early pioneers DuPont and ICI laid the foundation for PET's role as the dominant polyester resin, comprising about 20% of total plastics production worldwide.[53]Recent Technological Advances

In the field of polyethylene terephthalate (PET) recycling, enzymatic depolymerization has advanced markedly since 2020, with engineered PETase enzymes enabling more efficient hydrolysis of PET into monomers like terephthalic acid and ethylene glycol. A 2025 study detailed improvements in enzyme variants, achieving up to 90% depolymerization rates under mild conditions (50–70°C), surpassing wild-type enzymes from bacteria such as Ideonella sakaiensis by factors of 10–100 in catalytic turnover.[54] These modifications, including directed evolution and computational design, target the ester bonds in PET's backbone, reducing energy inputs compared to traditional chemical methods that require high temperatures above 200°C.[54] Similarly, the U.S. National Renewable Energy Laboratory (NREL) reported in June 2025 optimized enzymatic processes that integrate pretreatment, hydrolysis, and repolymerization, yielding recycled PET with purity exceeding 95% and minimizing byproduct formation.[55] Chemical recycling techniques have also progressed, particularly neutral hydrolysis and glycolysis variants that avoid harsh acids or bases, preserving monomer integrity for closed-loop production. Research published in 2025 highlighted scalable neutral hydrolysis systems achieving 98% monomer recovery from post-consumer PET at atmospheric pressure, with catalysts like metal-organic frameworks enhancing selectivity and reducing wastewater by 70% relative to alkaline methods.[56] Upcycling pathways have emerged, such as geography-guided microbial consortia converting PET hydrolysates into high-value chemicals like muconic acid, demonstrated at industrial scales in a May 2025 study with yields of 85% from waste streams, supporting circular economy applications by diverting PET from landfills.[57] Innovations like moisture-harvesting catalysis, reported in March 2025, use ambient humidity to facilitate PET bond cleavage without external solvents, potentially lowering operational costs by 50% in humid environments.[58] Bio-based PET production has seen incremental technological refinements, focusing on renewable sourcing of monomers to reduce fossil fuel dependence. Advances include fermentation-derived terephthalic acid from biomass, with pilot-scale processes achieving 100,000 tons/year capacity by 2023, enabling PET with 30–100% bio-content while maintaining mechanical properties equivalent to petroleum-based variants (tensile strength ~60 MPa).[59] Hybrid methods combining bio-ethylene glycol from sugarcane with recycled terephthalic acid have scaled commercially, as evidenced by facilities operational since 2022 that produce food-grade rPET bottles with lifecycle carbon footprints 50–70% lower than virgin PET.[60] These developments prioritize empirical metrics like monomer yield and impurity levels (<1% for FDA compliance) over unsubstantiated sustainability claims, though scalability remains constrained by feedstock volatility.[61]Applications and Economic Importance

Packaging and Consumer Goods

Polyethylene terephthalate (PET) dominates the packaging industry, comprising about 75% of global PET demand in 2025, with beverage bottles representing the largest segment at 60%.[62] Its adoption stems from properties including high transparency, mechanical strength, gas barrier capabilities, and low density, enabling lightweight containers that reduce shipping costs while maintaining product integrity.[63] In 2024, PET bottle production volume reached 26.3 million metric tons globally, supporting applications in carbonated soft drinks, water, and other beverages.[64] In the United States, PET accounted for 44.7% of single-serve beverage packaging in 2021, underscoring its market leadership in this category.[60] Bottled water specifically consumed 34.6% of global PET packaging in 2019, driven by consumer preferences for portable, shatter-resistant alternatives to glass.[65] Beyond bottles, PET serves in thermoformed consumer goods such as trays, clamshells, and blister packs for retail items like produce, hardware, and pharmaceuticals, where its formability and clarity facilitate product visibility and protection.[66] PET films find application in flexible packaging for food and non-food items, leveraging excellent tensile strength, chemical resistance, and barrier performance to extend shelf life and prevent contamination.[5] These films are often used in lidding, pouches, and wraps, contributing to efficient consumer goods distribution.[67] Recycled PET variants are increasingly integrated into these formats, including post-consumer resin for thermoformed trays and clamshells, aligning with demands for sustainable packaging without compromising functionality.[68]Textiles and Fibers

Polyethylene terephthalate (PET) is melt-spun into continuous filaments to produce polyester fibers, which constitute the majority of synthetic textile fibers due to their favorable mechanical properties.[69] The process involves extruding molten PET through spinnerets, followed by drawing to align polymer chains and enhance tensile strength, typically achieving fiber tenacities of 4-8 g/denier.[5] These fibers exhibit high durability, resistance to stretching and shrinkage, and low moisture absorption (around 0.4%), making them suitable for apparel, upholstery, and carpets.[8] Polyester fibers from PET were first commercialized in the mid-20th century, with British chemists John Rex Whinfield and James Tennant Dickson patenting PET in 1941, leading to Imperial Chemical Industries' Terylene production in 1946 and DuPont's Dacron launch in 1950.[41] By the 1960s, polyester had captured significant market share in textiles, valued for wrinkle resistance and ease of care, which reduced ironing needs in garments.[70] In apparel, polyester blends with cotton or wool improve dimensional stability and dyeability, while staple fibers are used in nonwovens for filters and hygiene products.[71] In 2024, polyester accounted for 57% of global fiber production, totaling approximately 60 million metric tons annually, with PET-derived fibers dominating synthetic segments due to cost-effectiveness and versatility.[72] The polyester fiber market reached USD 77.07 billion in 2024, driven by demand in fast fashion and technical textiles like geotextiles and tire cords.[73] Microfiber variants, often PET-based, enable high surface area for absorbency in cleaning cloths and sportswear, though they contribute to microplastic shedding during laundering.[74] Recycled PET fibers, comprising up to 20% of production in some segments, maintain comparable strength to virgin material but require sorting to avoid property degradation.[75]Industrial and Emerging Uses

Polyethylene terephthalate (PET) serves as an engineering thermoplastic in industrial machinery, where its high strength-to-weight ratio, dimensional stability, and wear resistance enable use in components such as gears, bearings, bushings, valve parts, filler pistons, and wear pads.[76][77] These properties allow PET to withstand mechanical stresses and moderate temperatures up to approximately 120°C in continuous service.[77] In the automotive industry, PET resins contribute to lightweight structural parts, including interior components and under-hood elements, supporting reduced vehicle weight and improved fuel efficiency without compromising durability.[30][78] PET films provide essential electrical insulation in electronics manufacturing, functioning as substrates for flexible printed circuits, wire sleeving, and dielectric layers due to their high breakdown voltage exceeding 100 kV/mm and low dielectric loss.[79][80] In photovoltaic systems, PET-based backsheets encapsulate solar modules, delivering moisture and UV resistance alongside electrical isolation to safeguard cells from environmental degradation; field studies in desert conditions reveal gradual hydrolysis and cracking after 5–10 years of exposure, informing material enhancements.[81][82] Emerging industrial applications leverage PET's versatility for advanced energy technologies, including lightweight flexible solar modules where PET films replace glass covers, achieving weights under 1 kg/m² and enabling integration into portable or conformable devices with efficiencies around 20%.[83] Recycled PET is also being upcycled into functional adsorbents for CO₂ capture, converting waste via sulfonation to materials with adsorption capacities up to 2.5 mmol/g under ambient conditions, offering a pathway for integrating plastic recycling into carbon management infrastructure.[84] In construction, recycled PET fibers reinforce cement composites, enhancing tensile strength by 20–30% and reducing crack propagation in experimental mixes.[85]Material Variants and Modifications

Copolymers and Blends

Copolymers of polyethylene terephthalate (PET) are synthesized by incorporating comonomers such as diols (e.g., cyclohexanedimethanol or CHDM) or diacids (e.g., isophthalic acid) during polycondensation, which disrupts the regular chain structure to alter crystallinity, glass transition temperature, and mechanical properties.[86] For instance, PETG, a copolyester of terephthalic acid, ethylene glycol, and CHDM, remains amorphous due to the bulky CHDM units that hinder chain packing, resulting in higher impact strength, shatter resistance, and transparency compared to semicrystalline PET.[87] This copolymerization lowers the melting point and enhances processability for applications like thermoformed trays and medical packaging, where clarity and toughness are prioritized over PET's barrier properties.[88] Other PET copolyesters, such as those incorporating 4-hydroxybenzoic acid, exhibit thermotropic liquid crystalline behavior in the melt phase, enabling oriented processing for high-modulus fibers or films with improved tensile strength and thermal stability.[86] These modifications can also facilitate foaming technologies, as seen in PET copolyesters with adjusted sorption properties for physical foaming using carbon dioxide, yielding lightweight structures for insulation or packaging.[89] Commercial examples include flame-retardant PET copolyesters enhanced with phosphorus additives, which maintain mechanical integrity while meeting fire safety standards in electronics and textiles, though inherent flammability of PET necessitates such interventions.[90] Blends of PET with other polymers address limitations like brittleness or cost by combining properties, but PET's polarity often leads to immiscibility and poor interfacial adhesion, requiring compatibilizers to refine phase morphology and boost performance.[91] For example, polypropylene (PP)/recycled PET (r-PET) blends, where r-PET replaces up to a proportion of virgin PP, reduce material costs and enhance stiffness, with compatibilizers like polypropylene grafted with maleic anhydride improving tensile strength and elongation by reducing droplet size in the dispersed phase.[92] [91] In PET/polyethylene (PE) blends, addition of carbon fibers as reinforcements upgrades mechanical properties, achieving tensile moduli exceeding those of neat polymers through fiber bridging of immiscible phases, suitable for upcycled automotive or structural composites.[93] PET blends with bio-based terpolyesters, such as ethylene 2,6-naphthalate modified variants, provide high dimensional stability under thermal stress, with low shrinkage rates enabling use in high-temperature films or molded parts.[94] Fiber blends incorporating PET with natural fibers like cotton or wool leverage PET's wrinkle resistance and durability for durable-press textiles, though blending ratios must balance dyeability and comfort.[95]Performance Enhancements and Special Formulations

Special formulations of polyethylene terephthalate (PET) incorporate additives to enhance mechanical, thermal, and barrier properties without fundamentally altering the base polymer structure through copolymerization. Nucleating agents, such as sodium or lithium salts, accelerate crystallization kinetics, enabling faster processing cycles in injection molding and thermoforming while improving dimensional stability and reducing warpage in applications like trays and containers.[96] For recycled PET (rPET), chemical chain extenders—typically multifunctional epoxides or pyromellitic dianhydride—react with hydroxyl and carboxyl end groups to increase intrinsic viscosity from 0.6-0.7 dL/g to over 0.8 dL/g, restoring melt strength for blow molding and extrusion without depolymerization losses exceeding 5%.[97] Flame-retardant grades achieve UL-94 V-0 ratings through incorporation of 5-10 wt% phosphorus-based compounds like ammonium polyphosphate or melamine derivatives, which promote char formation and suppress ignition temperatures below 300°C during combustion testing. These additives maintain tensile strengths above 50 MPa while limiting oxygen index to over 28%, suitable for electrical housings and automotive components. UV-resistant formulations include hindered amine light stabilizers (HALS) at 0.5-2 wt%, extending weathering durability to 2000 hours under ASTM G155 xenon arc exposure with less than 10% property degradation, as verified in outdoor simulations for films and sheets.[90][98] Impact modification employs core-shell elastomers or block copolymers at 5-15 wt%, raising notched Izod impact from 20 J/m to over 100 J/m at 23°C by dispersing rubber phases that absorb fracture energy, particularly effective in low-temperature environments down to -20°C. High-strength variants use nanoscale fillers like 1-3 wt% montmorillonite clay, boosting modulus to 5-6 GPa via intercalation that reinforces matrix stiffness without sacrificing transparency below 5% haze increase. These enhancements, grounded in empirical rheological and mechanical testing, prioritize causal mechanisms like phase separation control over unsubstantiated claims of universal superiority.[99][8]Health and Safety Assessments

Potential Human Exposure Risks