Recent from talks

Contribute something

Nothing was collected or created yet.

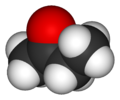

Butanone

View on Wikipedia | |||

| |||

| |||

| Names | |||

|---|---|---|---|

| Preferred IUPAC name

Butan-2-one[2] | |||

Other names

| |||

| Identifiers | |||

3D model (JSmol)

|

|||

| 741880 | |||

| ChEBI | |||

| ChEMBL | |||

| ChemSpider | |||

| ECHA InfoCard | 100.001.054 | ||

| EC Number |

| ||

| 25656 | |||

| KEGG | |||

PubChem CID

|

|||

| RTECS number |

| ||

| UNII | |||

| UN number | 1193 | ||

CompTox Dashboard (EPA)

|

|||

| |||

| |||

| Properties | |||

| C4H8O | |||

| Molar mass | 72.107 g·mol−1 | ||

| Appearance | Colorless liquid | ||

| Odor | Mint or acetone-like[3] | ||

| Density | 0.8050 g/mL | ||

| Melting point | −86 °C (−123 °F; 187 K) | ||

| Boiling point | 79.64 °C (175.35 °F; 352.79 K) | ||

| 27.5 g/100 mL | |||

| log P | 0.37[4] | ||

| Vapor pressure | 78 mmHg (20 °C)[3] | ||

| Acidity (pKa) | 14.7 | ||

| −45.58·10−6 cm3/mol | |||

Refractive index (nD)

|

1.37880 | ||

| Viscosity | 0.43 cP | ||

| Structure | |||

| 2.76 D | |||

| Hazards | |||

| GHS labelling: | |||

[5] [5]

| |||

| Danger[5] | |||

| H225, H319, H336[5] | |||

| P210, P233, P240, P241, P242, P243, P261, P264, P271, P280, P303+P361+P353, P304+P340, P305+P351+P338, P312, P337+P313, P370+P378, P403+P233, P403+P235, P405, P501[5] | |||

| NFPA 704 (fire diamond) | |||

| Flash point | −9 °C (16 °F; 264 K) | ||

| 505 °C (941 °F; 778 K) | |||

| Explosive limits | 1.4–11.4%[3] | ||

| Lethal dose or concentration (LD, LC): | |||

LD50 (median dose)

|

| ||

LC50 (median concentration)

|

| ||

| NIOSH (US health exposure limits): | |||

PEL (Permissible)

|

TWA 200 ppm (590 mg/m3)[3] | ||

REL (Recommended)

|

TWA 200 ppm (590 mg/m3) ST 300 ppm (885 mg/m3)[3] | ||

IDLH (Immediate danger)

|

3000 ppm[3] | ||

| Safety data sheet (SDS) | Safety Data Sheet | ||

| Related compounds | |||

Related ketones

|

|||

| Supplementary data page | |||

| Butanone (data page) | |||

Except where otherwise noted, data are given for materials in their standard state (at 25 °C [77 °F], 100 kPa).

| |||

Butanone, also known as methyl ethyl ketone (MEK) or ethyl methyl ketone,[a] is an organic compound with the formula CH3C(O)CH2CH3. This colorless liquid ketone has a sharp, sweet odor reminiscent of acetone. It is produced industrially on a large scale, but occurs in nature only in trace amounts.[7] It is partially soluble in water, and is commonly used as an industrial solvent.[8] It is an isomer of another solvent, tetrahydrofuran.

Production

[edit]Butanone may be produced by oxidation of 2-butanol. The dehydrogenation of 2-butanol is catalysed by copper, zinc, or bronze:

- CH3CH(OH)CH2CH3 → CH3C(O)CH2CH3 + H2

This is used to produce approximately 700 million kilograms yearly. Other syntheses that have been examined but not implemented include Wacker oxidation of 2-butene and oxidation of isobutylbenzene, which is analogous to the industrial production of acetone.[7] The cumene process can be modified to produce phenol and a mixture of acetone and butanone instead of only phenol and acetone in the original.[9]

Both liquid-phase oxidation of heavy naphtha and the Fischer–Tropsch reaction produce mixed oxygenate streams, from which 2-butanone is extracted by fractionation.[10]

Applications

[edit]Solvent

[edit]Butanone is an effective and common solvent[8] and is used in processes involving gums, resins, cellulose acetate and nitrocellulose coatings and in vinyl films.[11] For this reason it finds use in the manufacture of plastics, textiles, in the production of paraffin wax, and in household products such as lacquer, varnishes, paint remover, a denaturing agent for denatured alcohol, glues, and as a cleaning agent. It is a prime component of plumbers' priming fluid, used to clean PVC materials. It has similar solvent properties to acetone but boils at a higher temperature and has a significantly slower evaporation rate.[12] Unlike acetone, it forms an azeotrope with water,[13][14] making it useful for azeotropic distillation of moisture in certain applications. Butanone is also used in dry erase markers as the solvent of the erasable dye.

The hydroxylamine derivative of butanone is methylethyl ketone oxime (MEKO), which also find use in paints and varnishes as an anti-skinning agent.

Plastic welding

[edit]As butanone dissolves polystyrene and many other plastics, it is sold as "model cement" for use in connecting parts of scale model kits. Though often considered an adhesive, it is functioning as a welding agent in this context.

Other uses

[edit]Butanone is the precursor to methyl ethyl ketone peroxide, which is a catalyst for some polymerization reactions such as crosslinking of unsaturated polyester resins. Dimethylglyoxime can be prepared from butanone first by reaction with ethyl nitrite to give diacetyl monoxime followed by conversion to the dioxime:[15]

In the peroxide process on producing hydrazine, the starting chemical ammonia is bonded to butanone, oxidized by hydrogen peroxide, bonded to another ammonia molecule.

In the final step of the process, hydrolysis produces the desired product, hydrazine, and regenerates the butanone.

- Me(Et)C=NN=C(Et)Me + 2 H2O → 2 Me(Et)C=O + N2H4

Safety

[edit]Flammability

[edit]Butanone can react with most oxidizing materials and can produce fires.[8] It is moderately explosive, requiring only a small flame or spark to cause a vigorous reaction.[8] The vapor is heavier than air, so it can accumulate at low points. It is explosive at concentrations between 1.4 and 11.4%.[16] Concentrations in the air high enough to be flammable are intolerable to humans due to the irritating nature of the vapor.[12] Butanone fires should be extinguished with carbon dioxide, dry agents, or alcohol-resistant foam.[8]

The ignition of butanone vapor was the proximate cause of the 2007 Xcel Energy Cabin Creek fire, resulting in the deaths of five workers in a hydroelectric penstock. After the incident, the U.S. Chemical Safety and Hazard Investigation Board specifically noted the danger posed by butanone in confined spaces, and suggested 1,1,1-trichloroethane or limonene as safer alternatives.[17]

Health effects

[edit]Butanone is a constituent of tobacco smoke.[18] It is an irritant, causing irritation to the eyes and nose of humans.[12] Serious animal health effects have been seen only at very high levels. There are no long-term studies with animals breathing or drinking it,[19] and no studies for carcinogenicity in animals breathing or drinking it.[20]: 96 There is some evidence that butanone can potentiate the toxicity of other solvents, in contrast to the calculation of mixed solvent exposures by simply adding exposures.[21]

As of 2010[update], the United States Environmental Protection Agency (EPA) listed butanone as a toxic chemical. There are reports of neuropsychological effects. It is rapidly absorbed through undamaged skin and lungs. It contributes to the formation of ground-level ozone, which is toxic in low concentrations.[16]

Regulation

[edit]Butanone is listed as a Table II precursor under the United Nations Convention Against Illicit Traffic in Narcotic Drugs and Psychotropic Substances.[22]

Emission of butanone was regulated in the US as a hazardous air pollutant, because it is a volatile organic compound contributing to the formation of tropospheric (ground-level) ozone. In 2005, the US Environmental Protection Agency removed butanone from the list of hazardous air pollutants (HAPs).[23][24][25]

See also

[edit]Notes

[edit]- ^ The international standards group IUPAC has deprecated the term methyl ethyl ketone, and now recommends using ethyl methyl ketone instead.[2]

References

[edit]- ^ Merck Index, 11th Edition, 5991.

- ^ a b c d Nomenclature of Organic Chemistry : IUPAC Recommendations and Preferred Names 2013 (Blue Book). Cambridge: The Royal Society of Chemistry. 2014. p. 725. doi:10.1039/9781849733069-FP001. ISBN 978-0-85404-182-4.

- ^ a b c d e f NIOSH Pocket Guide to Chemical Hazards. "#0069". National Institute for Occupational Safety and Health (NIOSH).

- ^ "butan-2-one_msds".

- ^ a b c d "Safety Data Sheet - Klean Strip - Methyl Ethyl Ketone (MEK)" (PDF). Kleanstrip.com. Klean Strip. 15 April 2015. Archived from the original (PDF) on 17 April 2018. Retrieved 5 November 2019.

- ^ a b "2-Butanone". Immediately Dangerous to Life or Health Concentrations (IDLH). National Institute for Occupational Safety and Health (NIOSH).

- ^ a b Wilhelm Neier, Guenter Strehlke "2-Butanone" in Ullmann's Encyclopedia of Industrial Chemistry, Wiley-VCH, Weinheim, 2002.

- ^ a b c d e Turner, Charles F.; McCreery, Joseph W. (1981). The Chemistry of Fire and Hazardous Materials. Boston, Massachusetts: Allyn and Bacon, Inc. p. 118. ISBN 0-205-06912-6.

- ^ "Direct Routes to Phenol". Archived from the original on 2007-04-09. Retrieved 2017-12-13.

- ^ Ashford's Dictionary of Industrial Chemicals, Third edition, 2011, ISBN 978-0-9522674-3-0, pages 6013-4

- ^ Apps, E. A. (1958). Printing Ink Technology. London: Leonard Hill [Books] Limited. pp. 101.

- ^ a b c Fairhall, Lawrence T. (1957). Industrial Toxicology. Baltimore: The Williams and Wilkins Company. pp. 172–173.

- ^ Lange's Handbook of Chemistry, 10th ed. pp1496-1505

- ^ CRC Handbook of Chemistry and Physics, 44th ed. pp 2143-2184

- ^ Semon, W. L.; Damerell, V. R. (1943). "Dimethylglyoxime". Organic Syntheses; Collected Volumes, vol. 2, p. 204.

- ^ a b Simon B.N. Thompson (Winter 2010). "Implications for cognitive rehabilitation and brain injury from exposure to Methyl Ethyl Ketone (MEK): a review" (PDF). Journal of Cognitive Rehabilitation. 28(Winter): 4–14. Archived from the original (PDF) on 2022-01-21.

- ^ U.S. Chemical Safety and Hazard Investigation Board (August 2010). "Investigation Report: Xcel Energy Hydroelectric Plant Penstock Fire". U.S. Chemical Safety and Hazard Investigation Board.

- ^ Talhout, Reinskje; Schulz, Thomas; Florek, Ewa; Van Benthem, Jan; Wester, Piet; Opperhuizen, Antoon (2011). "Hazardous Compounds in Tobacco Smoke". International Journal of Environmental Research and Public Health. 8 (12): 613–628. doi:10.3390/ijerph8020613. ISSN 1660-4601. PMC 3084482. PMID 21556207.

- ^ "Methyl ethyl ketone (MEK) (CASRN 78-93-3)". Integrated Risk Information System (IRIS). EPA. 26 September 2003. Archived from the original on August 23, 2000. Retrieved 16 March 2015.

- ^ "US Toxicological review of Methyl ethyl ketone In Support of Summary Information on the Integrated Risk Information System (IRIS)" (PDF). US Environmental Protection Agency. September 2003. p. 152. Archived from the original (PDF) on April 3, 2010. Retrieved 16 March 2015.

- ^ Dick, F. D. (2006). "Solvent neurotoxicity". Occupational and Environmental Medicine. 63 (3): 221–226. doi:10.1136/oem.2005.022400. PMC 2078137. PMID 16497867.

- ^ List of Precursors and Chemicals Frequently Used in the Illicit Manufacture of Narcotic Drugs and Psychotropic Substances Under International Control Archived February 27, 2008, at the Wayback Machine, International Narcotics Control Board

- ^ Federal Register Volume 70, Issue 242 (December 19, 2005)

- ^ Barbara Kanegsberg (n.d.). "MEK No Longer a HAP". Bfksolutions newsletter. Archived from the original on 2 April 2015. Retrieved 2 April 2015. After technical review and consideration of public comments, EPA concluded that potential exposures to butanone emitted from industrial processes may not reasonably be anticipated to cause human health or environmental problems.[citation needed]

- ^ "EPA De-Lists MEK from CAA HAP List". www.pcimag.com. Retrieved 2016-07-30.

External links

[edit]Butanone

View on GrokipediaProperties

Physical properties

Butanone, also known as methyl ethyl ketone (MEK), is a colorless liquid with a sweet, acetone-like odor.[1] Its molecular formula is C₄H₈O, and it has a molecular weight of 72.11 g/mol.[7] The compound exhibits a boiling point of 79.6 °C and a melting point of −86.3 °C.[7] At 20 °C, its vapor pressure is 78 mmHg.[1] Key physical properties of butanone are summarized in the following table:| Property | Value | Conditions | Source |

|---|---|---|---|

| Density | 0.8049 g/cm³ | 20 °C | https://www.sigmaaldrich.com/US/en/product/sigald/360473 |

| Refractive index | 1.3788 | 20 °C (n_D) | https://webbook.nist.gov/chemistry/silmarils-liquids-n-k/docs/META.MIR.PUR.2-Butanone.LIQ.SIGMA-ALDRICH.PNNL515381.pdf |

| Viscosity | 0.41 cP | 20 °C | https://trc.nist.gov/ThermoML/10.1021/je050110r.html |

| Flash point | −9 °C | Closed cup | https://www.sigmaaldrich.com/US/en/sds/Aldrich/W217018 |

| Solubility in water | 27.5 g/100 mL | 20 °C | https://pubchem.ncbi.nlm.nih.gov/compound/Methyl-Ethyl-Ketone |

| Miscibility | Miscible with ethanol, ether | N/A | https://pubchem.ncbi.nlm.nih.gov/compound/Methyl-Ethyl-Ketone |

| Specific heat capacity | 2.20 J/g·K | 25 °C | https://webbook.nist.gov/cgi/cbook.cgi?ID=C78933&Mask=7 |

| Heat of vaporization | 31.3 kJ/mol | Boiling point | https://webbook.nist.gov/cgi/cbook.cgi?ID=C78933&Mask=4 |

Chemical properties

Butanone, also known as methyl ethyl ketone, has the molecular formula C₄H₈O and the structural formula CH₃C(O)CH₂CH₃, featuring a carbonyl group (C=O) at the 2-position of a four-carbon chain, classifying it as a simple aliphatic ketone.[1] The carbonyl carbon in butanone is sp² hybridized, resulting in bond angles approximately 120° around this atom due to the trigonal planar geometry of the C=O unit. The alpha hydrogens in butanone exhibit moderate acidity, with a pKa value of approximately 20, enabling deprotonation to form enolate ions under basic conditions.[8] The carbonyl oxygen acts as a weak base, with the pKa of its protonated form around -7, allowing coordination with Lewis acids in catalytic processes.[8] Butanone undergoes several characteristic reactions typical of ketones. Under extremely vigorous conditions, such as prolonged heating with hot concentrated alkaline KMnO₄, butanone can be oxidized with cleavage of the C-C bond adjacent to the carbonyl, yielding acetic acid and propanoic acid.[9] Reduction with sodium borohydride (NaBH₄) or catalytic hydrogenation selectively converts the carbonyl to a secondary alcohol, producing butan-2-ol.[10] In acid-catalyzed halogenation, butanone reacts with bromine (Br₂) at the alpha position to form 3-bromobutanone, with the reaction proceeding via the enol tautomer and potentially leading to polyhalogenation if uncontrolled. Butanone also participates in aldol condensation reactions, where it acts as a nucleophile (via its enolate) toward aldehydes, forming β-hydroxy ketones or α,β-unsaturated ketones upon dehydration, as exemplified in crossed aldol reactions with non-enolizable carbonyls like benzaldehyde.[11] Butanone demonstrates good stability under both acidic and basic conditions at moderate temperatures, resisting hydrolysis or decomposition, though prolonged exposure to strong bases can promote side reactions via enolate formation.[1] It exhibits a tendency for enolization, equilibrating with its enol form (but-1-en-2-ol) in trace amounts under acidic or basic catalysis, driven by the acidity of its alpha hydrogens and stabilized by resonance in the enol tautomer. Spectroscopic characterization of butanone includes a characteristic infrared (IR) absorption for the carbonyl stretch at 1715 cm⁻¹, indicative of an unconjugated aliphatic ketone.[12] In ¹H NMR spectroscopy, the methyl group attached to the carbonyl (CH₃C=O) appears as a singlet at δ 2.1 ppm, the methylene group (CH₂) as a quartet at δ 2.4 ppm, and the terminal methyl (CH₃) as a triplet at δ 1.0 ppm, reflecting the deshielding effect of the carbonyl on adjacent protons.[13]Production

Industrial production

Butanone, also known as methyl ethyl ketone (MEK), is primarily produced industrially through the catalytic dehydrogenation of 2-butanol. This gas-phase process employs catalysts such as brass, zinc-copper alloys, or zinc oxide at temperatures ranging from 400 to 500 °C and atmospheric pressure, yielding butanone alongside hydrogen gas. The reaction proceeds as 2-butanol is vaporized and passed over the catalyst bed, with subsequent cooling and separation of the product stream. This method accounts for the majority of global production due to its efficiency and reliance on readily available petrochemical feedstocks from refinery C4 streams.[14][15][16] A secondary industrial route produces butanone as a by-product from the liquid-phase oxidation of n-butane to acetic acid. This process uses catalysts such as cobalt or manganese acetates at 150–225 °C and pressures around 5.5 MPa, yielding butanone alongside other products like ethanol, ethyl acetate, and formic acid. While less dominant than dehydrogenation, it utilizes refinery streams from petroleum processing and accounts for approximately 14% of production in regions like the U.S.[3] Historically, butanone was largely obtained as a byproduct from the modified cumene process for phenol and acetone production, involving the oxidation of cumene (isopropylbenzene) derived from benzene and propylene. However, since the 1960s, there has been a shift toward dedicated direct synthesis methods like those described above, driven by increasing demand and process optimizations that improved yields and reduced dependency on phenol coproduction. In modern facilities, the crude product from either route undergoes purification via multistage distillation to achieve greater than 99% purity, removing water, unreacted alcohols or alkenes, and light impurities such as acetone.[17][18] Global production of butanone was approximately 1.1 million metric tons annually as of 2022 and reached about 1.17 million tons in 2024, with projections indicating steady growth to around 1.45 million tons by 2030, primarily fueled by demand in coatings and adhesives. As of 2024, Asia-Pacific accounts for over 45% of global production, with ongoing investments in energy-efficient processes to reduce the ~11.6 GJ/ton energy intensity. China leads as the largest producer, contributing approximately 35% of worldwide output, supported by its expansive petrochemical infrastructure. The process is energy-intensive, requiring about 11.6 GJ per ton in optimized setups, encompassing reaction, distillation, and utilities. Economic factors, including feedstock costs from propylene and butene, influence pricing, which averaged around $1,200 per metric ton in 2024 amid fluctuations in oil prices and regional supply dynamics.[4][19][20][21][22]Laboratory synthesis

One common laboratory method for synthesizing butanone involves the oxidation of 2-butanol, a secondary alcohol, using Jones reagent, which consists of chromium trioxide in aqueous sulfuric acid.[23] The reaction proceeds at room temperature or slightly above, typically requiring 30 minutes to 1 hour, and yields butanone in 70–95% depending on reaction scale and workup conditions.[24] This method selectively converts the secondary alcohol to the corresponding ketone without over-oxidation. A milder alternative is the use of pyridinium chlorochromate (PCC) in dichloromethane as the solvent.[25] The oxidation of 2-butanol with PCC occurs at room temperature over 1–2 hours, providing butanone in 80–90% yield while minimizing side products.[26] To optimize yield, the reaction mixture is stirred under anhydrous conditions, and excess PCC (1.5 equivalents) is employed to ensure complete conversion. Butanone can also be prepared via the hydrolysis of gem-dichlorides, such as 2,2-dichlorobutane, using aqueous alkali (e.g., KOH or NaOH) under reflux.[27] The gem-dichloride undergoes nucleophilic substitution to form a gem-diol intermediate, which spontaneously dehydrates to the ketone, typically affording 70–85% yield after 2–4 hours of heating.[28] This route is useful when starting from readily available alkyl halides but requires careful control to avoid elimination side reactions. A historical laboratory approach involves the dry distillation of a mixture of calcium acetate and calcium propionate in a 1:1 molar ratio at 400–500°C.[29] This ketonization reaction decarboxylates the salts to produce butanone along with calcium carbonate, with yields around 60–80% based on the propionate content.[30] The distillate is collected and separated from byproducts like acetone formed from excess acetate. Following synthesis, butanone is purified by solvent extraction with diethyl ether to remove aqueous impurities, followed by fractional distillation at atmospheric pressure (boiling point 79.6°C).[24] This process achieves >95% purity for analytical use, with extraction efficiencies improved by multiple washes and drying over anhydrous sodium sulfate. In laboratory settings, safety precautions are essential when handling oxidants; for instance, chromic acid and PCC generate toxic chromium(VI) waste, requiring fume hood operation and proper disposal, while potassium permanganate (an alternative oxidant for 2-butanol) poses risks as a strong oxidizer and must be used in cooled conditions to prevent runaway reactions.[31]Uses

Solvent applications

Butanone, also known as methyl ethyl ketone (MEK), serves as an effective solvent in numerous industrial applications due to its moderate polarity, characterized by a dielectric constant of 18.5 at 20°C. This property enables it to dissolve a range of polar and semi-polar substances, including resins, adhesives, and components in paints, facilitating their formulation and application.[32][33] In the coatings industry, butanone is widely employed in nitrocellulose lacquers for wood finishing and automotive paints, where it provides rapid drying and good solvency for nitrocellulose polymers. It is also used in the production of vinyl films for packaging and flooring, as well as in manufacturing magnetic tapes, where it aids in dispersing magnetic particles and binding them to the substrate. Additionally, butanone functions as an extraction solvent in the pharmaceutical industry for isolating active compounds and in oil refining processes for dewaxing lubricating oils by selectively dissolving waxes. As a diluent in polymer processing, it dissolves polystyrene at concentrations typically ranging from 10% to 20% by weight, enabling casting and molding operations.[34][35][36][37][38][15] One key advantage of butanone over more hazardous alternatives like benzene is its lower toxicity profile; benzene is classified as a Class 1 residual solvent due to its carcinogenic potential, whereas butanone falls into Class 3, indicating minimal toxicological concern at typical exposure levels. Its evaporation rate, approximately 3.8 relative to n-butyl acetate, contributes to efficient drying in solvent-based systems without excessive residue. In 2023, solvent applications accounted for approximately 50% of global butanone consumption, underscoring its dominant role in industrial formulations.[39][40][41]Other industrial uses

Butanone, commonly known as methyl ethyl ketone (MEK), plays a vital role in plastic welding by cleaning and softening the surfaces of thermoplastics such as polyvinyl chloride (PVC) and acrylics, enabling effective bonding without heat. This process is widely applied in the automotive sector for repairing dashboards, bumpers, and interior components, as well as in the signage industry for assembling durable acrylic displays and letters.[42][43] As a chemical intermediate, MEK is essential for producing methyl ethyl ketone peroxide (MEKP), a catalyst that initiates the polymerization of unsaturated polyester resins used in fiberglass-reinforced plastics for boat hulls, automotive parts, and construction materials. MEKP is synthesized by oxidizing MEK with hydrogen peroxide under controlled conditions to ensure stability and efficacy in resin curing.[44][45] MEK is incorporated into flexographic printing inks as a solvent to dissolve resins and control viscosity, supporting high-speed printing on flexible packaging, labels, and corrugated materials. In anti-corrosion coatings, it facilitates uniform film formation on metal substrates, enhancing adhesion and barrier properties to prevent rust in marine and industrial environments.[46][47] In household products, MEK appears in glues and sealants for bonding plastics and metals, as well as in paint removers to dissolve cured coatings, often at concentrations of 5–40% to balance solvency and safety in commercial formulations.[48][49] Niche applications include lube oil dewaxing, where MEK acts as a selective solvent to extract wax crystals from lubricating oils, improving viscosity and cold-flow performance in petroleum refining. It is also used in synthetic rubber processing to dissolve and blend polymers, aiding the production of tires, hoses, and seals.[3][50] As of 2023, chemical intermediates account for approximately 15% of global MEK use, while adhesives and related applications represent around 20%, reflecting steady demand in manufacturing sectors.[21]Safety and regulation

Flammability hazards

Butanone, also known as methyl ethyl ketone (MEK), is classified as a Class IB flammable liquid according to the National Fire Protection Association (NFPA), characterized by a flash point below 22.8 °C (73 °F) and a boiling point above 37.8 °C (100 °F).[51] This classification underscores its high volatility and potential for ignition under ambient conditions, with an NFPA flammability rating of 3, indicating that it can be ignited under almost all ambient temperatures and produces hazardous atmospheres when vapors are present in air.[1] The autoignition temperature of butanone is 515 °C (959 °F), meaning it can spontaneously ignite in air without an external spark or flame at this threshold.[52] Additionally, its explosive limits in air range from 1.4% to 11.4% by volume, allowing vapor-air mixtures within this concentration to form explosive atmospheres if ignited.[53] The vapor density of butanone is 2.5 (relative to air at 1), which causes its vapors to be heavier than air and prone to accumulation in low-lying areas, basements, or confined spaces, thereby increasing the risk of flash-back ignition from distant sources.[54] This behavior heightens explosion risks in poorly ventilated environments where vapors can travel along the ground to ignition sources such as open flames, sparks, or hot surfaces. In terms of firefighting, suitable extinguishing agents include alcohol-resistant foam, carbon dioxide, or dry chemical extinguishers, as these suppress vapors effectively without exacerbating the fire; however, direct water streams should be avoided, as they can spread the flammable liquid and vapors rather than contain the blaze.[51] Safe storage practices for butanone mandate the use of grounded metal containers to prevent static electricity buildup, maintained at temperatures below 27 °C (80 °F) in well-ventilated areas distant from ignition sources, heat, or incompatible materials like strong oxidizers.[55] A notable incident illustrating these hazards occurred on October 2, 2007, at the Xcel Energy Cabin Creek hydroelectric plant near Georgetown, Colorado, where MEK vapors accumulated in a confined space during equipment cleaning, ignited, and caused a flash fire that resulted in five fatalities due to inadequate hazard preparation and ventilation.[56] Such events highlight the critical need for rigorous controls to mitigate butanone's flammability risks in industrial settings.[57]Health and toxicity effects

Butanone exposure can cause acute irritation to the eyes and skin, with mild eye discomfort and slight nose and throat irritation reported in humans at concentrations of 100 ppm for 6 hours.[35] At 200 ppm, some individuals experience mild eye irritation and symptoms of central nervous system (CNS) depression, such as headache, dizziness, and a feeling of intoxication after 4 hours of exposure.[58] Higher concentrations, above 10,000 ppm, lead to severe respiratory and ocular irritation in animals, including lacrimation and labored breathing.[59] Chronic exposure to butanone has been associated with potential liver and kidney damage in animal studies, with increased liver weights observed in female rats exposed to 3,000 ppm for 15 days, though no histopathological lesions were noted.[35] In rats, oral doses around 1,080 mg/kg caused mild renal tubule necrosis, indicating kidney effects at elevated levels, while the OSHA permissible exposure limit (PEL) is set at 200 ppm to prevent such risks.[33] Potential neurotoxicity, including ataxia and lethargy, has been observed in animals at chronic high doses, though human data suggest minimal long-term neurological impacts below occupational limits.[60] The median lethal dose (LD50) for butanone in rats is approximately 2,737 mg/kg orally and 11,700 ppm via inhalation for 4 hours.[33] Butanone is rapidly metabolized in the liver primarily via cytochrome P450 2E1 (CYP2E1) to 3-hydroxy-2-butanone, which is further reduced to 2,3-butanediol; these metabolites are excreted in urine, with rapid elimination preventing significant accumulation.[60][33] Studies on reproductive and developmental effects show no teratogenicity in rats and mice exposed to up to 3,000 ppm during gestation, though slight fetotoxicity, such as reduced fetal body weight, occurred at this level without embryotoxic or teratogenic outcomes.[35] Regarding carcinogenicity, butanone is not classifiable as to its carcinogenicity to humans by the International Agency for Research on Cancer (IARC Group 3), due to inadequate evidence in humans and animals.[62]Environmental and regulatory aspects

Butanone exhibits favorable environmental fate characteristics, being readily biodegradable in aerobic conditions. According to OECD Test Guideline 301D, it achieves 98% biodegradation within 28 days, meeting the criteria for ready biodegradability.[63] Its low octanol-water partition coefficient (log Kow of 0.29) indicates minimal potential for bioaccumulation in aquatic organisms.[33] In the atmosphere, butanone primarily undergoes photodegradation via reaction with hydroxyl (OH) radicals, with an estimated half-life of about 1 day (approximately 21 hours) under typical conditions.[33] As a volatile organic compound (VOC), it contributes to the formation of photochemical smog by participating in reactions that generate ground-level ozone and other secondary pollutants.[33] Butanone demonstrates low acute toxicity to aquatic life. The 96-hour LC50 for fish (e.g., bluegill sunfish) is 2480 mg/L, indicating moderate tolerance, while concentrations below 100 mg/L show no significant adverse effects on algae growth.[64] These toxicity thresholds inform regulatory limits on environmental releases to protect ecosystems.[33] Regulatory frameworks address butanone's environmental releases due to its VOC status and potential ecological impacts. Under the U.S. Clean Air Act, the Environmental Protection Agency (EPA) classifies butanone as a VOC subject to emission controls, though it receives exemptions or reduced reactivity weighting in certain architectural coatings to limit smog formation.[6] In the European Union, butanone is registered under REACH with no specific Annex XVII restrictions, but its use in mixtures is monitored for environmental hazards, including aquatic chronic toxicity classifications.[65] The Occupational Safety and Health Administration (OSHA) sets a permissible exposure limit of 200 ppm as an 8-hour time-weighted average for workplace air to mitigate inhalation risks during handling.[66] For spill response, butanone releases should be contained using absorbent materials such as vermiculite or sand, followed by proper disposal as hazardous waste; entry into waterways must be prevented to avoid diluting aquatic habitats.[67] Global regulatory trends emphasize reducing butanone emissions to curb air pollution. In California, post-2020 amendments to the Aerosol Coatings Regulation under the Air Resources Board limit VOC content and reactivity in consumer aerosol products, effectively phasing out high-butanone formulations to combat smog, with methyl ethyl ketone assigned a maximum incremental reactivity of 1.48.[68] Production facilities worldwide are increasingly required to monitor and report emissions under frameworks like the EPA's Toxics Release Inventory.References

- https://pubchem.ncbi.nlm.nih.gov/compound/Methyl-Ethyl-Ketone