Recent from talks

Nothing was collected or created yet.

Static electricity

View on Wikipedia

| Electromagnetism |

|---|

|

Static electricity is an imbalance of electric charges within or on the surface of a material. The charge remains until it can move away as an electric current or by electrical discharge. The word "static" is used to differentiate it from current electricity, where an electric charge flows through an electrical conductor.[2]

A static electric charge can be created whenever two surfaces contact and/or slide against each other and then separate. The effects of static electricity are familiar to most people because they can feel, hear, and even see sparks if the excess charge is neutralized when brought close to an electrical conductor (for example, a path to ground), or a region with an excess charge of the opposite polarity (positive or negative). The familiar phenomenon of a static shock – more specifically, an electrostatic discharge – is caused by the neutralization of a charge.

Causes

[edit]Materials are made of atoms that are normally electrically neutral because they contain equal numbers of positive charges (protons in their nuclei) and negative charges (electrons in "shells" surrounding the nucleus). The phenomenon of static electricity requires a separation of positive and negative charges. When two materials are in contact, electrons may move from one material to the other, which leaves an excess of positive charge on one material, and an equal negative charge on the other. When the materials are separated, they retain this charge imbalance. It is also possible for ions to be transferred.

Contact-induced charge separation

[edit]

Electrons or ions can be exchanged between materials on contact or when they slide against each other, which is known as the triboelectric effect and results in one material becoming positively charged and the other negatively charged. The triboelectric effect is the main cause of static electricity as observed in everyday life, and in common high-school science demonstrations involving rubbing different materials together (e.g., fur against an acrylic rod). Contact-induced charge separation causes one's hair to stand up and causes "static cling" (for example, a balloon rubbed against the hair becomes negatively charged; when near a wall, the charged balloon is attracted to positively charged particles in the wall, and can "cling" to it, suspended against gravity).[3]

Pressure-induced charge separation

[edit]Applied mechanical stress generates an electric polarization and in turn this can lead to separation of charge in many types of materials. The free carriers at the surface of a material compensate for the polarization induced by the strains.[4][5]

Heat-induced charge separation

[edit]Heating can generate electric polarization, which in turn can lead a separation of charge in certain materials. All pyroelectric materials are also piezoelectric and do not have inversion symmetry.[6]

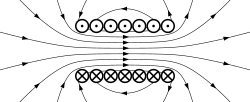

Charge-induced charge separation

[edit]A charged object brought close to an electrically neutral conductive object causes a separation of charge within the neutral object. This is called electrostatic induction. Charges of the same polarity are repelled and move to the side of the object away from the external charge, and charges of the opposite polarity are attracted and move to the side facing the charge. As the force due to the interaction of electric charges falls off rapidly with increasing distance, the effect of the closer (opposite polarity) charges is greater and the two objects feel a force of attraction. Careful grounding of part of an object can permanently add or remove electrons, leaving the object with a global, permanent charge.

Removal and prevention

[edit]

Removing or preventing a buildup of static charge can be as simple as opening a window or using a humidifier, to increase the moisture content of the air, making the atmosphere more conductive. Air ionizers can perform the same task.[7]

Items that are particularly sensitive to static discharge may be treated with the application of an antistatic agent, which adds a conducting surface layer that ensures any excess charge is evenly distributed. Fabric softeners and dryer sheets used in washing machines and clothes dryers are an example of an antistatic agent used to prevent and remove static cling.[8]

Many semiconductor devices used in electronics are particularly sensitive to static discharge. Conductive antistatic bags are commonly used to protect such components. People who work on circuits that contain these devices often ground themselves with a conductive antistatic strap.[9][10]

In the industrial settings such as paint or flour plants as well as in hospitals, antistatic safety boots are sometimes used to prevent a buildup of static charge due to contact with the floor. These shoes have soles with good conductivity. Anti-static shoes should not be confused with insulating shoes, which provide exactly the opposite benefit – some protection against serious electric shocks from the mains voltage.[11]

Within medical cable assemblies and lead wires, random triboelectric noise is generated when the various conductors, insulation, and fillers rub against each other as the cable is flexed during movement. Noise generated within a cable is often called handling noise or cable noise, but this type of unwanted signal is more accurately described as triboelectric noise. When measuring low-level signals, noise in cable or wire may present a problem. For example, the noise in an ECG or another medical signal may make accurate diagnosis difficult or even impossible. Keeping triboelectric noise at acceptable levels requires careful material selection, design, and processing as cable material is manufactured.[12]

Static discharge

[edit]This section needs additional citations for verification. (September 2010) |

The spark associated with static electricity is caused by electrostatic discharge, or simply static discharge, as excess charge is neutralized by a flow of charges from or to the surroundings.

The feeling of an electric shock is caused by the stimulation of nerves as the current flows through the human body. The energy stored as static electricity on an object varies depending on the size of the object and its capacitance, the voltage to which it is charged, and the dielectric constant of the surrounding medium. For modelling the effect of static discharge on sensitive electronic devices, a human being is represented as a capacitor of 100 picofarads, charged to a voltage of 4,000 to 35,000 volts. When touching an object this energy is discharged in less than a microsecond.[13] While the total energy is small, on the order of millijoules, it can still damage sensitive electronic devices. Larger objects will store more energy, which may be directly hazardous to human contact or which may give a spark that can ignite flammable gas or dust.

Lightning

[edit]

Lightning is a dramatic natural example of static discharge. While the details are unclear and remain a subject of debate, the initial charge separation is thought to be associated with contact between ice particles within storm clouds. In general, significant charge accumulations can only persist in regions of low electrical conductivity (very few charges free to move in the surroundings), hence the flow of neutralizing charges often results from neutral atoms and molecules in the air being torn apart to form separate positive and negative charges, which travel in opposite directions as an electric current, neutralizing the original accumulation of charge. The static charge in air typically breaks down in this way at around 10,000 volts per centimeter (10 kV/cm) depending on humidity.[14] The discharge superheats the surrounding air causing the bright flash, and produces a shock wave causing the booming sound. A lightning bolt is simply a scaled-up version of the sparks seen in more domestic occurrences of static discharge. The flash occurs because the air in the discharge channel is heated to such a high temperature that it emits light by incandescence. The clap of thunder is the result of the shock wave created as the superheated air expands.

Electronic components

[edit]Many semiconductor devices used in electronics are very sensitive to the presence of static electricity and can be damaged by a static discharge. The use of an antistatic strap is mandatory for researchers manipulating nanodevices. Further precautions can be taken by taking off shoes with thick rubber soles and permanently staying with a metallic ground.

Static build-up in flowing flammable and ignitable materials

[edit]

Discharge of static electricity can create severe hazards in those industries dealing with flammable substances, where a small electrical spark might ignite explosive mixtures.[15]

The flowing movement of finely powdered substances or low conductivity fluids in pipes or through mechanical agitation can build up static electricity.[16] The flow of granules of material such as sand down a plastic chute can transfer charge, which can be measured using a multimeter connected to metal foil lining the chute at intervals, and can be roughly proportional to particulate flow.[17] Dust clouds of finely powdered substances can become combustible or explosive. When there is a static discharge in a dust or vapor cloud, explosions have occurred. Among the major industrial incidents that have occurred due to static discharge are the explosion of a grain silo in southwest France, a paint plant in Thailand, a factory making fiberglass moldings in Canada, a storage tank explosion in Glenpool, Oklahoma in 2003, and a portable tank filling operation and a tank farm in Des Moines, Iowa and Valley Center, Kansas in 2007.[18][19][20]

The ability of a fluid to retain an electrostatic charge depends on its electrical conductivity. When low conductivity fluids flow through pipelines or are mechanically agitated, contact-induced charge separation called flow electrification occurs.[21][22] Fluids that have low electrical conductivity (below 50 picosiemens per meter), are called accumulators. Fluids having conductivity above 50 pS/m are called non-accumulators. In non-accumulators, charges recombine as fast as they are separated and hence electrostatic charge accumulation is not significant. In the petrochemical industry, 50 pS/m is the recommended minimum value of electrical conductivity for adequate removal of charge from a fluid.

Kerosines may have conductivity ranging from less than 1 picosiemens per meter to 20 pS/m. For comparison, deionized water has a conductivity of about 10,000,000 pS/m or 10 μS/m.[23]

Transformer oil is part of the electrical insulation system of large power transformers and other electrical apparatus. Re-filling of large apparatus requires precautions against electrostatic charging of the fluid, which may damage sensitive transformer insulation.

An important concept for insulating fluids is the static relaxation time. This is similar to the time constant τ (tau) of an RC circuit. For insulating materials, it is the ratio of the static dielectric constant divided by the electrical conductivity of the material. For hydrocarbon fluids, this is sometimes approximated by dividing the number 18 by the electrical conductivity of the fluid. Thus a fluid that has an electrical conductivity of 1 pS/m has an estimated relaxation time of about 18 seconds. The excess charge in a fluid dissipates almost completely after four to five times the relaxation time, or 90 seconds for the fluid in the above example.

Charge generation increases at higher fluid velocities and larger pipe diameters, becoming quite significant in pipes 8 inches (200 mm) or larger. Static charge generation in these systems is best controlled by limiting fluid velocity. The British standard BS PD CLC/TR 50404:2003 (formerly BS-5958-Part 2) Code of Practice for Control of Undesirable Static Electricity prescribes pipe flow velocity limits. Because water content has a large impact on the fluids dielectric constant, the recommended velocity for hydrocarbon fluids containing water should be limited to 1 meter per second.

Bonding and earthing are the usual ways charge buildup can be prevented. For fluids with electrical conductivity below 10 pS/m, bonding and earthing are not adequate for charge dissipation, and anti-static additives may be required. [citation needed]

Fueling operations

[edit]The flowing movement of flammable liquids like gasoline inside a pipe can build up static electricity. Non-polar liquids such as gasoline, toluene, xylene, diesel, kerosene and light crude oils exhibit significant ability for charge accumulation and charge retention during high velocity flow. Electrostatic discharges can ignite the fuel vapor.[24] When the electrostatic discharge energy is high enough, it can ignite a fuel vapor and air mixture. Different fuels have different flammable limits and require different levels of electrostatic discharge energy to ignite.

Electrostatic discharge while fueling with gasoline is a present danger at gas stations.[25] Fires have also been started at airports while refueling aircraft with kerosene. New grounding technologies, the use of conducting materials, and the addition of anti-static additives help to prevent or safely dissipate the buildup of static electricity. Customers who need to fill containers at gas stations are advised to set them on the ground first so that any static buildup will dissipate without risk of fire or explosion.

The flowing movement of gases in pipes alone creates little, if any, static electricity.[26] It is envisaged that a charge generation mechanism only occurs when solid particles or liquid droplets are carried in the gas stream.

In space exploration

[edit]Due to the extremely low humidity in extraterrestrial environments, very large static charges can accumulate, causing a major hazard for the complex electronics used in space exploration vehicles. Static electricity is thought to be a particular hazard for astronauts on planned missions to the Moon and Mars. Walking over the extremely dry terrain could cause them to accumulate a significant amount of charge; reaching out to open the airlock on their return could cause a large static discharge, potentially damaging sensitive electronics.[27]

Ozone cracking

[edit]

A static discharge in the presence of air or oxygen can create ozone, which can degrade rubber parts. Many elastomers are sensitive to ozone cracking. Exposure to ozone creates deep penetrative cracks in critical components like gaskets and O-rings. Fuel lines are also susceptible to the problem unless preventive action is taken. Preventive measures include adding anti-ozonants to the rubber mix, or using an ozone-resistant elastomer. Fires from cracked fuel lines have been a problem on vehicles, especially in the engine compartments where ozone can be produced by electrical equipment.

Energies involved

[edit]The energy released in a static electricity discharge may vary over a wide range. The energy in joules can be calculated from the capacitance (C) of the object and the static potential V in volts (V) by the formula E = ½CV2.[28] One experimenter estimates the capacitance of the human body as high as 400 picofarads, and a voltage of 50,000 volts, discharged e.g. during touching a charged car, creating a spark with energy of 500 millijoules.[29] Another estimate is 100–300 pF and 20,000 volts, producing a maximum energy of 60 mJ.[30] IEC 479-2:1987 states that a discharge with energy greater than 5000 mJ is a direct serious risk to human health. IEC 60065 states that consumer products cannot discharge more than 350 mJ into a person.

The maximal potential is limited to about 35–40 kV, due to corona discharge dissipating the charge at higher potentials. Potentials below 3000 volts are not typically detectable by humans. Maximal potential commonly achieved on human body range between 1 and 10 kV, though in optimal conditions as high as 20–25 kV can be reached. Low relative humidity increases the charge buildup; walking 20 feet (6 m) on vinyl floor at 15% relative humidity causes buildup of voltage up to 12 kV, while at 80% humidity the voltage is only 1.5 kV.[31]

As little as 0.2 millijoules may present an ignition hazard; such low spark energy is often below the threshold of human visual and auditory perception.

Typical ignition energies are:

- 0.017 mJ for hydrogen,

- 0.2–2 mJ for hydrocarbon vapors,

- 1–50 mJ for fine flammable dust,

- 40–1000 mJ for coarse flammable dust.

The energy needed to damage most electronic devices[specify] is between 2 and 1000 nanojoules.[32]

A relatively small energy, often as little as 0.2–2 millijoules, is needed to ignite a flammable mixture of a fuel and air. For the common industrial hydrocarbon gases and solvents, the minimum ignition energy required for ignition of vapor–air mixture is lowest for the vapor concentration roughly in the middle between the lower explosive limit and the upper explosive limit, and rapidly increases as the concentration deviates from this optimum to either side. Aerosols of flammable liquids may be ignited well below their flash point. Generally, liquid aerosols with particle sizes below 10 micrometers behave like vapors, particle sizes above 40 micrometers behave more like flammable dusts. Typical minimal flammable concentrations of aerosols lay between 15 and 50 g/m3. Similarly, presence of foam on the surface of a flammable liquid significantly increases ignitability. Aerosol of flammable dust can be ignited as well, resulting in a dust explosion; the lower explosive limit usually lies between 50 and 1000 g/m3; finer dusts tend to be more explosive and requiring less spark energy to set off. Simultaneous presence of flammable vapors and flammable dust can significantly decrease the ignition energy; a mere 1 vol.% of propane in air can reduce the required ignition energy of dust by 100 times. Higher than normal oxygen content in atmosphere also significantly lowers the ignition energy.[33]

There are five types of electrical discharges:

- Spark, responsible for the majority of industrial fires and explosions where static electricity is involved. Sparks occur between objects at different electric potentials. Good grounding of all parts of the equipment and precautions against charge buildups on equipment and personnel are used as prevention measures.

- Brush discharge occurs from a nonconductive charged surface or highly charged nonconductive liquids. The energy is limited to roughly 4 millijoules. To be hazardous, the voltage involved must be above about 20 kilovolts, the surface polarity must be negative, a flammable atmosphere must be present at the point of discharge, and the discharge energy must be sufficient for ignition. Further, because surfaces have a maximal charge density, an area of at least 100 cm2 has to be involved. This is not considered to be a hazard for dust clouds.

- Propagating brush discharge is high in energy and dangerous. Occurs when an insulating surface of up to 8 mm thick (e.g. a teflon or glass lining of a grounded metal pipe or a reactor) is subjected to a large charge buildup between the opposite surfaces, acting as a large-area capacitor.

- Cone discharge, also called bulking brush discharge, occurs over surfaces of charged powders with resistance above 1010 ohms, or also deep through the powder mass. Cone discharges are not usually observed in dust volumes below 1 m3. The energy involved depends on the grain size of the powder and the charge magnitude, and can reach up to 20 mJ. Larger dust volumes produce higher energies.

- Corona discharge, considered non-hazardous.

See also

[edit]References

[edit]- ^ phi6guy (July 3, 2025). Coulomb's law | Electrostatics | Electric Charges and Fields | NCERT Class 12 Physics |. Retrieved July 15, 2025 – via YouTube.

{{cite AV media}}: CS1 maint: numeric names: authors list (link) - ^ Dhogal (1986). Basic Electrical Engineering, Volume 1. Tata McGraw-Hill. p. 41. ISBN 978-0-07-451586-0.

- ^ Harper, Wallace Russel (1998). Contact and frictional electrification. The Laplacian Press Series on Electrostatics. Morgan Hill, California: Laplacian Press. ISBN 978-1-885540-06-5.

- ^ Fisher, L. H. (February 1, 1951). "On the Representation of the Static Polarization of Rigid Dielectrics by Equivalent Charge Distributions". American Journal of Physics. 19 (2): 73–78. Bibcode:1951AmJPh..19...73F. doi:10.1119/1.1932714. ISSN 0002-9505.

- ^ Griffiths, David J. (June 29, 2017). "Introduction to Electrodynamics". Higher Education from Cambridge University Press. doi:10.1017/9781108333511.008. Retrieved January 13, 2025.

- ^ Ashcroft, Neil W.; Mermin, N. David (2012). Solid state physics (Repr ed.). South Melbourne: Brooks/Cole Thomson Learning. ISBN 978-0-03-083993-1.

- ^ "Ionizers and Static Eliminators". GlobalSpec. 2009. Archived from the original on February 10, 2009. Retrieved April 13, 2009.

- ^ "Fabric Softener and Static". Ask a Scientist, General Science Archive. US Department of Energy. 2003. Retrieved April 13, 2009.

- ^ "Antistatic Bags for Parts". PC Chop Shop. John Wiley and Sons. 2004. ISBN 978-0-7821-4360-7. Retrieved April 13, 2009.

- ^ "Antistatic Wrist Strap". PC Chop Shop. John Wiley and Sons. 2004. ISBN 978-0-7821-4360-7. Retrieved April 13, 2009.

- ^ "Safetoes: Safety Footwear". Safetoes. Trojan Tooling. 2004. Archived from the original on November 27, 2022. Retrieved April 13, 2009.

- ^ "Triboelectric Noise in Medical Cables and Wires". August 29, 2014.

- ^ Carlos Hernando Díaz, Sung-Mo Kang, Charvaka Duvvury, Modeling of electrical overstress in integrated circuits Springer, 1995 ISBN 0-7923-9505-0 page 5

- ^ J. J. Lowke (1992). "Theory of electrical breakdown in air". Journal of Physics D: Applied Physics. 25 (2): 202–210. Bibcode:1992JPhD...25..202L. doi:10.1088/0022-3727/25/2/012. S2CID 250794264.

- ^ Kassebaum, J. H. & Kocken, R. A. (1995). "Controlling static electricity in hazardous (Classified) locations". Industry Applications Society 42nd Annual Petroleum and Chemical Industry Conference. pp. 105–113. doi:10.1109/PCICON.1995.523945. ISBN 0-7803-2909-0. S2CID 110221915.

- ^ Wagner, John P.; Clavijo, Fernando Rangel Electrostatic charge generation during impeller mixing of used transformer oil Department of Nuclear Engineering, Safety Engineering and Industrial Hygiene Program, Texas A&M University, College Station, online 21 August 2000; accessed Jan 2009 doi:10.1016/S0304-3886(00)00019-X

- ^ Downie, Neil A., Exploding Disk Cannons, Slimemobiles and 32 Other Projects for Saturday Science (Johns Hopkins University Press (2006), ISBN 978-0-8018-8506-8, chapter 33, pages 259-266 "Electric Sand"

- ^ Hearn, Graham (1998). "Static electricity: concern in the pharmaceutical industry?". Pharmaceutical Science & Technology Today. 1 (7): 286–287. doi:10.1016/S1461-5347(98)00078-9.

- ^ Storage Tank Explosion and Fire in Glenpool, Oklahoma April 7, 2003 National Transportation Safety Board

- ^ Static Spark Ignites Flammable Liquid during Portable Tank Filling Operation Archived 2009-01-17 at the Wayback Machine Chemical Safety Board October 29, 2007

- ^ Egorov, V.N. (1970). "Electrification of petroleum fuels" (PDF). Khimiya I Tekhnologiya Topliv I Masel. 6 (4): 20–25. Bibcode:1970CTFO....6..260E. doi:10.1007/BF00723571.

- ^ Touchard, Gérard (2001). "Flow electrification of liquids". Journal of Electrostatics. 51–52: 440–447. doi:10.1016/S0304-3886(01)00081-X.

- ^ Chevron Corporation Aviation Fuels Technical Review Archived 2009-03-19 at the Wayback Machine 2006, accessed Dec 2008

- ^ Hearn, Graham Static electricity – guidance for Plant Engineers – Wolfson Electrostatics University of Southampton 2002; accessed Dec 2008

- ^ "CarCare – Auto Clinic" Popular Mechanics, April 2003, p. 163.

- ^ Kinzing, G.E., 'Electrostatic Effects in Pneumatic Transport: Assessment, Magnitudes and Future Direction', Journal Pipelines, 4, 95–102, 1984

- ^ "NASA – Crackling Planets". Retrieved February 23, 2021.

- ^ Nomograms for capacitive electrostatic discharge risk assessment Archived 2021-03-01 at the Wayback Machine. Ece.rochester.edu. Retrieved on 2010-02-08.

- ^ "High voltage safety: VandeGraaff Electrostatic Generator". amasci.com. Retrieved January 27, 2010.

- ^ Index Archived 2021-02-27 at the Wayback Machine. Wolfsonelectrostatics.com. Retrieved on 2011-03-17.

- ^ M. A. Kelly, G. E. Servais, T. V. Pfaffenbach An Investigation of Human Body Electrostatic Discharge, ISTFA ’93: The 19th International Symposium for Testing & Failure Analysis, Los Angeles, California, USA/15–19 November 1993.

- ^ "ESD Terms". eed.gsfc.nasa.gov. Archived from the original on September 17, 2004. Retrieved January 27, 2010.

- ^ Static Electricity Guidance for Plant Engineers. Graham Hearn – Wolfson Electrostatics, University of Southampton.

External links

[edit] Media related to Static electricity at Wikimedia Commons

Media related to Static electricity at Wikimedia Commons The dictionary definition of static electricity at Wiktionary

The dictionary definition of static electricity at Wiktionary

Static electricity

View on GrokipediaFundamental Concepts

Electric Charge and Electrostatic Forces

Electric charge is a fundamental physical property of matter that determines the strength and direction of the electromagnetic force exerted on other matter. There are two types of electric charge: positive charge, carried by protons, and negative charge, carried by electrons.[5] In atoms, protons reside in the nucleus while electrons orbit around it, maintaining electrical neutrality in neutral matter.[5] Electric charge is quantized, meaning it occurs only in discrete multiples of the elementary charge C, the charge of a single proton or electron (with opposite signs).[6] This quantization implies that charge cannot exist in arbitrarily small amounts but rather as integer multiples of .[6] The earliest recorded observation of electrostatic effects dates to around 600 BCE, when Thales of Miletus noted that amber (Greek: elektron), when rubbed with fur, attracted lightweight objects like feathers.[4] This discovery laid the groundwork for understanding static electricity, culminating in Benjamin Franklin's 1752 kite experiment, which demonstrated that lightning involves the same electrical fluid by collecting atmospheric charge in a Leyden jar during a storm.[7] The law of conservation of charge states that the net electric charge in any isolated system remains constant over time, regardless of internal processes.[5] Static electricity buildup occurs when there is a local imbalance between positive and negative charge carriers—excess electrons creating negative charge or a deficit creating positive charge—without net charge creation or destruction.[5] This conservation principle ensures that charge separation in insulators leads to electrostatic forces without violating overall neutrality in isolated systems. The electrostatic force between two stationary point charges and separated by distance is described by Coulomb's law: where N m²/C² is Coulomb's constant, and is the unit vector from one charge to the other.[8] The force magnitude follows an inverse-square law, meaning it decreases with the square of the distance, and the force is repulsive for like charges and attractive for unlike charges.[8] In vector form, the direction aligns along the line connecting the charges, pointing away from positive charges and toward negative ones. The electric field at a point due to a point charge is defined as the electrostatic force per unit positive test charge: with units of N/C or V/m.[9] Electric field lines visualize the field's direction and strength, originating from positive charges and terminating on negative charges, with line density proportional to field magnitude.[9] For multiple charges, the total electric field is the vector superposition of individual fields, allowing complex field patterns from charge distributions.[9] This field concept mediates electrostatic interactions, providing a framework for understanding forces without direct charge contact.Triboelectric Series and Material Properties

The triboelectric series is a qualitative ranking of materials based on their tendency to gain or lose electrons during contact and separation, with materials at the positive end acting as electron donors (acquiring a net positive charge) and those at the negative end as electron acceptors (acquiring a net negative charge).[10] This ordering predicts the direction of charge transfer when two materials interact: a material higher in the series will charge positively relative to one lower in the series. Representative examples include glass and human hair near the positive end, followed by wool, nylon, cotton, silk, and wood in the middle, and amber, hard rubber, polyvinyl chloride (PVC), and polytetrafluoroethylene (Teflon) toward the negative end.[11][10] The position of a material in the triboelectric series is influenced by intrinsic properties such as surface chemistry, which determines the availability of electron-donating or -accepting sites like functional groups; work function, the minimum energy required to remove an electron from the surface; and electron affinity, the energy change associated with adding an electron to the material.[12][13] For instance, materials with low work functions and high electron affinities, such as fluoropolymers like Teflon, tend to rank more negatively because they readily accept electrons, while insulators like glass with higher work functions rank positively.[12] Experimentally, the series was established through early systematic studies involving rubbing dissimilar materials together and measuring the resulting charge transfer using sensitive electrometers to detect voltage differences.[11] Modern validations employ similar contact-separation cycles with Faraday cups or electrostatic voltmeters to quantify charge densities, confirming the relative ordering while highlighting its qualitative nature.[10][14] However, the triboelectric series is not absolute and can shift due to environmental factors like humidity, which promotes charge dissipation through water adsorption on surfaces; increased surface roughness, which alters contact area and traps charges; or contamination, which introduces foreign electron-trapping sites.[10][13] These variations make the series a predictive tool rather than a fixed hierarchy, useful for anticipating static buildup in specific conditions. For example, human hair often charges positively against plastics like PVC during combing, leading to attraction of dust or, upon contact with a grounded metal doorknob, an electrostatic discharge perceived as a shock.[10][13]Generation Mechanisms

Contact and Friction-Induced Charging

Contact and friction-induced charging primarily occurs through the triboelectric effect, where physical contact between two dissimilar materials leads to electron transfer at their interface due to differences in their work functions. The work function represents the minimum energy required to remove an electron from the material's surface; when materials with differing work functions contact, electrons migrate from the lower work function material (becoming positively charged) to the higher work function material (becoming negatively charged) until their Fermi levels equilibrate. Upon separation, this charge redistribution persists, creating a net electrostatic imbalance that manifests as static electricity.[15][16] Although termed "triboelectric" from the Greek for rubbing, friction is not strictly necessary for charging, as simple contact can initiate electron transfer; however, friction amplifies the process by increasing the effective contact area through surface deformation and prolonging interaction time, thereby facilitating greater charge exchange.[17] This enhancement is particularly evident in scenarios involving relative motion, where frictional forces promote more intimate molecular interactions at the interface. The magnitude of charge separation in this process is influenced by several key factors, including the applied contact force, which expands the contact area and thus the sites available for electron transfer; the duration of contact, allowing equilibrium to be approached more closely; relative velocity between the materials, which can intensify frictional effects and surface cleaning; and environmental conditions such as low relative humidity, which reduces charge leakage through adsorbed water layers on surfaces.[18][19] These variables collectively determine the extent of charging, with empirical observations showing that charge buildup is more pronounced under dry conditions and with moderate velocities that optimize contact without excessive wear. In everyday scenarios, this mechanism is observed when a person walks across a carpet, where repeated contact and friction between shoe soles and carpet fibers transfer electrons to the body, accumulating charge that discharges as a visible spark upon touching a conductive object like a door handle. Another common example is combing dry hair, which generates charge separation between the plastic comb and hair strands, causing the hair to repel and stand upright due to like-charge interactions. The direction and extent of charging in such pairs align with rankings in the triboelectric series, which orders materials by their electron-donating or -accepting tendencies.[20]Induction and Charge Separation

Electrostatic induction is the process by which an external electric field from a charged object causes a redistribution of charges in a nearby neutral material, resulting in charge separation without direct physical contact.[21] This phenomenon occurs because the external field exerts a force on the charges within the material, attracting opposite charges and repelling like charges to create regions of net positive and negative charge. For instance, when a positively charged object is brought near a neutral conductor, electrons within the conductor migrate toward the side closest to the inducer, leaving the far side positively charged.[22] In conductors, such as metals, free electrons are highly mobile and respond readily to the external field, leading to the formation of induced charge layers on the surface. The electrons accumulate on the near side, creating a layer of negative induced charge, while the far side develops a corresponding positive layer due to the deficit of electrons; this separation ensures the electric field inside the conductor remains zero in electrostatic equilibrium.[21] If the conductor is grounded during this process, electrons can flow to or from the ground, allowing the removal of the opposite charges and leaving the conductor with a net permanent charge opposite to that of the inducer.[22] In dielectrics, or insulators, charge separation arises from the alignment of molecular dipoles rather than free charge movement, producing bound charges that cannot flow freely. An applied electric field causes the positive and negative ends of polar molecules to orient toward the field lines, resulting in a net polarization where bound positive charges accumulate on one side and bound negative charges on the other.[23] This polarization in dielectrics reduces the overall electric field strength within the material compared to vacuum, a key factor in their use in capacitors.[24] One practical application of induction is in the electrophorus, a historical device invented by Alessandro Volta in 1775 that generates static charge through repeated induction cycles. The electrophorus consists of a dielectric plate charged by friction and a metal disk; the charged plate induces an opposite charge on the grounded disk, which retains the charge after separation, allowing the process to be repeated multiple times to accumulate significant charge.[25] This method demonstrates how induction can amplify charge without ongoing frictional input, relying solely on the initial charge on the dielectric.[22] The magnitude of the induced charge on a conductor due to an external inducer can be expressed as , where is the capacitance of the system and is the potential difference induced by the external charge.[26] This relation derives from Gauss's law, which states that the electric flux through a closed surface enclosing the conductor is proportional to the enclosed charge: .[27] For a conductor in equilibrium, the field inside is zero, so any Gaussian surface within the conductor encloses zero net charge; the induced surface charge must therefore cancel the field from the external charge, leading to balancing the potential to maintain equipotentiality, equivalent to charging a capacitor to voltage .[26]Pressure and Heat-Induced Charging

Pressure-induced charging occurs through the piezoelectric effect, a phenomenon in which certain crystalline materials generate an electric charge in response to applied mechanical stress. This effect arises from the displacement of internal charges within the crystal lattice when stress deforms the structure, leading to a buildup of voltage across the material. The relationship is described by the equation for electric displacement , where is the electric displacement, is the piezoelectric coefficient specific to the material, and is the applied stress.[28] Common examples include quartz crystals and biological materials like bone, where the effect enables applications such as sensors that convert mechanical vibrations into electrical signals.[29] The piezoelectric effect was first experimentally demonstrated in 1880 by brothers Pierre and Jacques Curie, who observed charge generation in crystals like quartz under compression.[30] Heat-induced charging is mediated by the pyroelectric effect, observed in polar crystals that exhibit a spontaneous electric polarization. A change in temperature alters this polarization, producing a temporary electric charge on the material's surfaces as the dipoles realign. This is quantified by , where is the change in polarization, is the pyroelectric coefficient, and is the temperature change. Materials such as tourmaline demonstrate this effect prominently, with heating causing the crystal to attract lightweight particles like ash due to the generated charge.[31] Pyroelectricity has been noted since ancient times; the Greek philosopher Theophrastus described tourmaline's attraction of straw and ash upon heating around 314 BCE, though the electrical nature was not understood until later observations in the 18th century.[31] In practical contexts, pressure-induced charging manifests in fluid flow scenarios, such as the streaming potential generated when an electrolyte is forced through charged porous media or pipes, where shear at the solid-liquid interface separates charges to create a measurable voltage. For heat-induced charging, thermal gradients in pyroelectric materials can produce charges in devices like infrared detectors, though the effect is transient and requires ongoing temperature variation. Both piezoelectric and pyroelectric effects are limited to non-centrosymmetric crystals, lacking inversion symmetry that would otherwise cancel charge separation, making them material-specific and less common than other charging mechanisms.[32][33]Manifestations and Effects

Electrostatic Discharge Processes

Electrostatic discharge (ESD) occurs when the electric potential difference between two objects exceeds the dielectric breakdown strength of the intervening medium, typically air, leading to the formation of a conductive plasma channel that rapidly neutralizes the charge imbalance. In air at standard conditions, this breakdown happens at an electric field strength of approximately 3 MV/m (or 3 kV/mm), where free electrons are accelerated to ionize gas molecules, initiating an avalanche process that creates the plasma pathway.[34][35] The primary types of ESD include sparks, brush discharges, and arcs, each characterized by distinct propagation and duration influenced by electrode geometry, humidity, and charge levels. A spark is a short-duration, visible discharge forming a brief arc-like channel through the gas without sustained stabilization, often occurring across small gaps.[36] Brush discharge, resembling a corona from blunt or irregular electrodes, produces a diffuse, fan-like ionization without a fully developed channel, typically at lower energies and higher humidities that suppress full breakdown.[37] An arc is a sustained, high-current discharge maintained by thermal ionization once initiated, common in larger gaps or with continuous charge supply, though less typical in isolated static scenarios.[38] The onset of breakdown is governed by Paschen's law, which states that the breakdown voltage is a function of the product of gas pressure and electrode gap distance , expressed as . This relationship yields a characteristic curve with a minimum breakdown voltage in air of approximately 327 V, occurring at Torr·cm (corresponding to a gap of about 7.5 μm at atmospheric pressure).[39] The law, empirically derived by Friedrich Paschen in 1889, highlights how deviations from optimal values increase the required voltage, with higher pressures or larger gaps demanding progressively stronger fields.[39] The energy released during an ESD event is given by the formula for stored electrostatic energy in a capacitor: where is the capacitance between the charged objects and is the potential difference, typically ranging from millijoules to several joules depending on the charge accumulation.[40] In human-generated ESD, such as from triboelectric charging, the maximum releasable energy is often limited to around 30 mJ due to body capacitance constraints.[41] A common example is the spark discharge from a charged human body, where potentials build up to 10–35 kV through activities like walking on carpet, leading to a visible spark upon touching a grounded conductor like a doorknob. In dry conditions, similar shocks commonly occur when touching houseplants, as the plant's water-rich tissues and connection to soil (acting as a ground) provide a conductive path, enabling rapid discharge of accumulated charge on the body.[42] This discharge can damage sensitive electronic circuits, as many components fail at voltages below 100 V, with the rapid current pulse causing thermal or lattice damage in semiconductors.[42]Lightning and Atmospheric Phenomena

Lightning in thunderstorms arises from the electrification of clouds, where charge separation occurs primarily through collisions between ice particles and graupel in convective updrafts. In these processes, supercooled water droplets freeze onto graupel pellets, and subsequent collisions with lighter ice crystals lead to triboelectric charging, transferring negative charge to the denser graupel, which then falls toward the cloud base, while positively charged ice crystals are carried upward by updrafts to the cloud top.[43][44] This separation establishes a dipole structure with positive charges at higher altitudes and negative charges lower in the cloud, often extending to induce opposite charges on the Earth's surface below.[43] The buildup of this charge separation can create enormous electric potentials, reaching up to 100 million volts between the cloud and ground, sufficient to ionize air and initiate a lightning discharge. The process begins with a stepped leader—a faint, branching channel of ionized air that propagates intermittently from the cloud toward the ground in steps of about 50 meters, at speeds around 200 km/s. When the leader nears the ground, an upward streamer from a tall object or the surface connects, triggering the luminous return stroke that neutralizes the charge by surging back to the cloud at nearly one-third the speed of light, releasing vast energy in the process.[45][46] Lightning manifests in several types, with cloud-to-ground (CG) flashes being the most hazardous to life and property due to their direct connection to the surface, accounting for about 25% of all discharges but causing most injuries and fires. Intra-cloud lightning, the most common type comprising roughly 75-80% of flashes, occurs between oppositely charged regions within the same cloud, while cloud-to-cloud lightning connects separate storm cells. Each typical CG flash consists of multiple strokes, dissipating approximately 1 gigajoule of energy, primarily as heat and light.[47][48] The effects of lightning are profound: the return stroke heats the surrounding air to around 30,000 K almost instantaneously, causing explosive expansion that produces thunder as a shock wave propagates outward. This discharge also generates powerful electromagnetic pulses that can induce currents in nearby conductors, potentially disrupting electronics, and frequently ignites wildfires by heating surfaces to combustion temperatures. Globally, thunderstorms produce about 100 lightning flashes per second, totaling over 8 million strikes daily, and these events play a key ecological role by fixing atmospheric nitrogen—estimated at 3-10 teragrams annually—into oxides that deposit as fertilizers for soil nutrients.[49][50][51][52]Corona Discharge and Material Degradation

Corona discharge refers to the partial electrical breakdown and localized ionization of air around a conductor exposed to a non-uniform electric field, occurring at voltages below the threshold for complete dielectric breakdown. This phenomenon is particularly pronounced in geometries with sharp points or edges, where electrostatic field gradients are intensified, leading to accelerated electron avalanches and streamer formation. Visually, it appears as a faint bluish or violet glow due to excited nitrogen and oxygen species, accompanied by an audible hissing or buzzing sound from the rapid recombination of ions.[53][54][55] A key byproduct of corona discharge is ozone production, initiated when high-energy electrons and ultraviolet radiation dissociate oxygen molecules (O₂) into atomic oxygen, which then recombines to form ozone (O₃) via the reactionIn ambient air near high-voltage conductors, ozone concentrations can accumulate to several parts per million, depending on discharge intensity and environmental conditions. This process not only alters local air chemistry but also contributes to oxidative stress on nearby materials.[56][57][58] The ozone generated attacks unsaturated double bonds in polymeric materials, particularly elastomers like natural rubber and synthetic variants used in tires, cables, and insulators, resulting in ozone cracking—deep, fissures that propagate perpendicular to the stress direction. In the presence of static electric fields from ongoing corona activity, this degradation accelerates, as the reactive species penetrate surface layers more readily, leading to embrittlement and mechanical failure. For instance, prolonged exposure in high-voltage environments can cause surface erosion and reduced tensile strength in rubber insulation.[59][60][61] Detection of corona discharge typically involves ultraviolet cameras, which capture the emission spectrum in the 200–400 nm range for visual localization, or ozone sensors that measure concentrations in real-time, especially along high-voltage transmission lines where such activity is common. These methods enable early identification to mitigate associated risks. Health-wise, the ozone acts as a potent respiratory irritant, causing symptoms such as throat irritation, coughing, and shortness of breath in exposed individuals, while industrially, the resulting material degradation can significantly shorten the service life of polymers in affected systems.[62][63][64]

.jpg/250px-Static_on_the_playground_(48616367).jpg)

.jpg)