Recent from talks

Nothing was collected or created yet.

Deep drawing

View on Wikipedia

Deep drawing is a sheet metal forming process in which a sheet metal blank is radially drawn into a forming die by the mechanical action of a punch.[1] It is thus a shape transformation process with material retention. The process is considered "deep" drawing when the depth of the drawn part exceeds its diameter. This is achieved by redrawing the part through a series of dies.

The flange region (sheet metal in the die shoulder area) experiences a radial drawing stress and a tangential compressive stress due to the material retention property. These compressive stresses (hoop stresses) result in flange wrinkles (wrinkles of the first order). Wrinkles can be prevented by using a blank holder, the function of which is to facilitate controlled material flow into the die radius. Deep drawing presses, especially in the Aerospace and Medical industries, require unparalleled accuracy and precision. Sheet hydroforming presses do complex draw work. Bed size, tonnage, stroke, speed, and more can be tailored to your specific draw forming application.

Process

[edit]The total drawing load consists of the ideal forming load and an additional component to compensate for friction in the contacting areas of the flange region and bending forces as well as unbending forces at the die radius. The forming load is transferred from the punch radius through the drawn part wall into the deformation region (sheet metal flange). In the drawn part wall, which is in contact with the punch, the hoop strain is zero whereby the plane strain condition is reached. In reality, mostly the strain condition is only approximately plane. Due to tensile forces acting in the part wall, wall thinning is prominent and results in an uneven part wall thickness, such that the part wall thickness is lowest at the point where the part wall loses contact with the punch, i.e., at the punch radius.

The thinnest part thickness determines the maximum stress that can be transferred to the deformation zone. Due to material volume constancy, the flange thickens and results in blank holder contact at the outer boundary rather than on the entire surface. The maximum stress that can be safely transferred from the punch to the blank sets a limit on the maximum blank size (initial blank diameter in the case of rotationally symmetrical blanks). An indicator of material formability is the limiting drawing ratio (LDR), defined as the ratio of the maximum blank diameter that can be safely drawn into a cup without flange to the punch diameter. Determination of the LDR for complex components is difficult and hence the part is inspected for critical areas for which an approximation is possible. During severe deep drawing the material work hardens and it may be necessary to anneal the parts in controlled atmosphere ovens to restore the original elasticity of the material.

Commercial applications of this metal shaping process often involve complex geometries with straight sides and radii. In such a case, the term stamping is used in order to distinguish between the deep drawing (radial tension-tangential compression) and stretch-and-bend (along the straight sides) components. Deep drawing is always accompanied by other forming techniques within the press. These other forming methods include:[2]

- Beading: Material is displaced to create a larger, or smaller, diameter ring of material beyond the original body diameter of a part, often used to create O-ring seats.

- Bottom Piercing: A round or shaped portion of metal is cut from the drawn part.

- Bulging: In the bulging process a portion of the part's diameter is forced to protrude from the surrounding geometry.

- Coining: Material is displaced to form specific shapes in the part. Typically coining should not exceed a depth of 30% of the material thickness.

- Curling: Metal is rolled under a curling die to create a rolled edge.

- Extruding: After a pilot hole is pierced, a larger diameter punch is pushed through, causing the metal to expand and grow in length.

- Ironing / Wall Thinning: Ironing is a process to reduce the wall thickness of parts. Typically ironing should not exceed a depth of 30% of the material thickness.

- Necking: A portion of the part is reduced in diameter to less than the major diameter.

- Notching: A notch is cut into the open end of the part. This notch can be round, square, or shaped.

- Rib Forming: Rib forming involves creating an inward or outward protruding rib during the drawing process.

- Side Piercing: Holes are pierced in the side wall of the drawn part. The holes may be round or shaped according to specifications.

- Stamping / Marking: This process is typically used to put identification on a part, such as a part number or supplier identification.

- Threading: Using a wheel and arbor, threads are formed into a part. In this way threaded parts can be produced within the stamping press.

- Trimming: In the Trimming process, excess metal that is necessary to draw the part is cut away from the finished part.

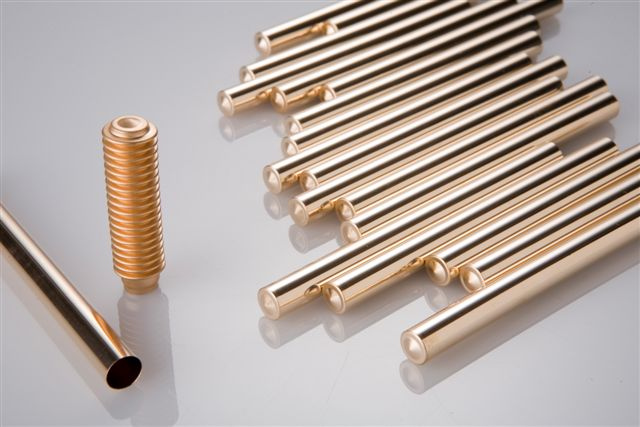

Often components are partially deep drawn in order to create a series of diameters throughout the component (as in the image of the deep draw line). It common use to consider this process as a cost saving alternative to turned parts which require much more raw material.

The sequence of deep drawn components is referred to as a "deep draw line". The numbers of components that form the deep draw line is given by the quantity of "stations" available in the press. In the case of mechanical presses this is determined by the number of cams on the top shaft.

For high precision mass productions, it is always advisable to use a transfer press also known as eyelet press. The advantage of this type of press, in respect to conventional progressive presses, is that the parts are transferred from one die to the next by means of so-called "fingers". Not only do the fingers transfer the parts but they also guide the component during the process. This allows parts to be drawn to the deepest depths with the tightest tolerances.

Other types of presses:[3]

- Die-Set Transfer Press: Part is transferred via transfer fingers as the part progresses through the forming process. Tooling components attached to die plates enable the die to be installed in the press as one unit.

- ICOP (Individually Cam Operated Press): The part is transferred via transfer fingers as the part progresses through the forming process. Die components are installed in the press one station at a time.

- Progressive Die Press: The part is carried on the steel webbing as it progresses through the forming process.

Variations

[edit]Deep drawing has been classified into conventional and unconventional deep drawing. The main aim of any unconventional deep drawing process is to extend the formability limits of the process. Some of the unconventional processes include hydromechanical deep drawing, Hydroform process, Aquadraw process, Guerin process, Marform process and the hydraulic deep drawing process to name a few.

The Marform process, for example, operates using the principle of rubber pad forming techniques. Deep-recessed parts with either vertical or sloped walls can be formed. In this type of forming, the die rig employs a rubber pad as one tool half and a solid tool half, similar to the die in a conventional die set, to form a component into its final shape. Dies are made of cast light alloys and the rubber pad is 1.5-2 times thicker than the component to be formed. For Marforming, single-action presses are equipped with die cushions and blank holders. The blank is held against the rubber pad by a blank holder, through which a punch is acting as in conventional deep drawing. It is a double-acting apparatus: at first the ram slides down, then the blank holder moves: this feature allows it to perform deep drawings (30-40% transverse dimension) with no wrinkles.[4][5][6][7][8]

Industrial uses of deep drawing processes include automotive body and structural parts, aircraft components, utensils and white goods. Complex parts are normally formed using progressive dies in a single forming press or by using a press line.

Workpiece materials and power requirements

[edit]Softer materials are much easier to deform and therefore require less force to draw. The following is a table demonstrating the draw force to percent reduction of commonly used materials.

| Material | Percent reduction | |||

|---|---|---|---|---|

| 39% | 43% | 47% | 50% | |

| Aluminium | 88 | 101 | 113 | 126 |

| Brass | 117 | 134 | 151 | 168 |

| Cold-rolled steel | 127 | 145 | 163 | 181 |

| Stainless steel | 166 | 190 | 214 | 238 |

Tool materials

[edit]Punches and dies are typically made of tool steel, however cheaper (but softer) carbon steel is sometimes used in less severe applications. It is also common to see cemented carbides used where high wear and abrasive resistance is present. Alloy steels are normally used for the ejector system to kick the part out and in durable and heat resistant blank holders.[10]

Lubrication and cooling

[edit]Lubricants are used to reduce friction between the working material and the punch and die. They also aid in removing the part from the punch. Some examples of lubricants used in drawing operations are heavy-duty emulsions, phosphates, white lead, and wax films. Plastic films covering both sides of the part while used with a lubricant will leave the part with a fine surface.

See also

[edit]References

[edit]- ^ DIN 8584-3

- ^ "Deep Draw Process for Precision Metal Components". Trans-Matic Manufacturing Co. Archived from the original on 2018-04-28.

- ^ "Deep Drawing Presses". Trans-Matic Manufacturing Co. Archived from the original on 8 February 2014. Retrieved 20 January 2014.

- ^ Totten, Funatani & Xie 2004, p. 30

- ^ Narayanan et al. 2006, p. 306

- ^ Wick & Veilleux 1984, pp. 5–78

- ^ Sala 2001

- ^ Morovvati, Mollaei-Dariani & Asadian-Ardakani 2010, pp. 1738–1747

- ^ Todd, Allen & Alting 1994, p. 288.

- ^ Todd, Allen & Alting 1994

Bibliography

[edit]- Narayanan, S.; Kumar, K. Gokul; Reddy, K. Janardhan; Kuppan, P. (2006), CAD/CAM Robotics and Factories of the Future: 22nd International Conference, Alpha Science International Ltd., ISBN 978-81-7319-792-5

- Sala, Giuseppe (June 2001), "A numerical and experimental approach to optimise sheet stamping technologies: part II — aluminium alloys rubber-forming", Materials & Design, 22 (4): 299–315, doi:10.1016/S0261-3069(00)00088-1

- Morovvati, M.R.; Mollaei-Dariani, B.; Asadian-Ardakani, M.H. (2010), "A theoretical, numerical, and experimental investigation of plastic wrinkling of circular two-layer sheet metal in the deep drawing", Journal of Materials Processing Technology, 210 (13): 1738–1747, doi:10.1016/j.jmatprotec.2010.06.004

- Todd, Robert; Allen, Dell K.; Alting, Leo (1994), Manufacturing Processes Reference Guide, New York: Industrial Press Inc., ISBN 978-0-8311-3049-7

- Totten, George E.; Funatani, Kiyoshi; Xie, Lin (2004), Handbook of Metallurgical Process Design, CRC Press, ISBN 978-0-8247-4106-8

- Wick, Charles; Veilleux, R. (1984), Tool and manufacturing engineers handbook: Forming, vol. 2, SME, ISBN 978-0-87263-135-9

Deep drawing

View on GrokipediaIntroduction

Definition and Basic Principles

Deep drawing is a bulk deformation process in sheet metal forming where a flat sheet metal blank is radially drawn into a forming die by a mechanically or hydraulically loaded punch, creating hollow axisymmetric or non-axisymmetric shapes such as cups, boxes, or cylindrical components.[5] The process is classified as "deep" when the height or depth of the formed part exceeds the punch diameter, enabling the production of parts with significant depth relative to their width.[5] This method maintains the original thickness of the sheet with minimal thinning, distinguishing it from processes that rely on extensive stretching.[6] The basic principles of deep drawing revolve around controlled material flow under combined stresses. As the punch advances, the central portion of the blank forms the bottom of the part, while the surrounding flange experiences radial tensile stresses that draw the material inward toward the die cavity and tangential compressive (hoop) stresses that compress the edges.[5] A blank holder applies uniform pressure to the flange periphery to restrain excessive outward flow, preventing defects like wrinkling by facilitating even deformation and reducing friction against the die.[5] This setup ensures the material flows progressively from the flange to the sidewall and bottom radii, with the punch-die clearance typically set at 107-115% of the sheet thickness to balance these forces.[6] Unlike shallow drawing or stamping, which forms parts with limited depth through simple bending or stretching over a die, deep drawing achieves high depth-to-diameter ratios, often up to 2:1 or more via the limiting drawing ratio (LDR), allowing for taller, seamless structures in a single or multi-stage operation.[5] It is particularly cost-effective for producing high-volume axisymmetric parts, such as beverage cans or automotive panels, compared to subtractive machining, which generates waste and higher per-unit costs for similar geometries.[7] Essential to successful deep drawing is the sheet metal's formability, governed by properties like ductility, anisotropy (r-value >1.5 for favorable drawability), and strain-hardening exponent, which determine the material's ability to undergo large deformations without failure.[5]Historical Development

Manual sheet metal forming techniques, such as repetitive hammering and annealing to shape copper, gold, and silver into hollow objects, date back to ancient civilizations like those in Mesopotamia and Egypt around 3000 BCE, laying the groundwork for advanced metal manipulation.[8] However, deep drawing as a mechanized process emerged during the Industrial Revolution in the mid-19th century in Europe and America, with early presses developed for items like cookware and ammunition shells.[9] By the mid-19th century, innovations such as Henry Marchand's deep drawing press in 1866 in Philadelphia enabled the formation of larger hollow shells from sheet metal blanks, marking a shift from handcrafting to machine-based production.[10] Hydraulic presses, developed earlier in the late 18th century but adapted for metal forming by the 1850s, further facilitated scalable manufacturing of components like basins and ammunition shells. In the 20th century, post-World War II advancements introduced automation through transfer presses, allowing multi-stage deep drawing for higher-volume production of automotive and appliance parts.[11] The 1957 formation of the International Deep Drawing Research Group (IDDRG) standardized testing and research, promoting global improvements in the process.[10] By the 1960s, hydraulic deep drawing techniques expanded capabilities for complex geometries, such as irregular shapes in aerospace components, by combining fluid pressure with traditional punching.[12] The 1990s brought computer-aided design (CAD) integration for die optimization, enabling simulations to predict material flow and reduce trial-and-error in tooling, which streamlined design for intricate parts.[13] This evolution from manual forming to automated mass production transformed manufacturing, enabling efficient production of everyday items like cookware and cans while significantly lowering costs through minimized waste and labor.[14]Process Fundamentals

Mechanics and Stresses

In deep drawing, the deformation process divides the blank into three primary zones: the flange, the die radius, and the wall. The flange region experiences compressive radial flow as material is drawn inward, primarily through shear deformation without significant thickness change, facilitating the overall inward material movement toward the die. The die radius zone involves bending and subsequent unbending of the sheet as it transitions from the flat flange to the vertical wall, where localized strains occur due to curvature changes. The wall zone undergoes tensile stretching, leading to potential thinning as the material elongates circumferentially to accommodate the formed shape.[5][15][16] Stress distributions in these zones are critical to process success. In the flange, radial tensile stress (σ_r) develops and increases toward the die radius as the punch advances, pulling material inward, while tangential compressive stress (σ_θ) acts circumferentially, promoting thickening and risking wrinkling if not controlled. At the die radius, combined bending stresses superimpose on the radial tension, exacerbating local strains. In the wall, circumferential strain induces thinning under dominant radial tensile stresses transmitted from the punch, with σ_r peaking near the die radius due to the force balance across the cup height. These stresses follow equilibrium conditions derived from plasticity theory, where the radial stress at a point in the flange can be approximated as σ_r = σ_f ln(R_0 / r), with σ_f as the flow stress, R_0 the initial blank radius, and r the current radius (compressive signs adjusted for convention).[5][16][17] Strain paths in deep drawing ideally align with the von Mises yield criterion, which governs plastic flow under multiaxial loading by equating effective stress to the uniaxial flow stress, ensuring balanced deformation without excessive localization. In the flange, strains are primarily under radial tension and circumferential compression, following a path close to plane strain. The wall experiences uniaxial-like tensile strain paths, promoting uniform thinning until necking onset. However, material anisotropy influences these paths; earing defects arise from planar anisotropy, where a high normal anisotropy parameter (r-value > 1) enhances drawability by resisting thinning, while deviations in directional r-values (e.g., Δr ≠ 0) cause uneven flow and ear formation at 0° and 90° orientations.[17][18][19] The ideal drawing force, neglecting friction and bending effects, represents the minimum punch load required for deformation and is given by: where is the punch diameter, the initial sheet thickness, the average flow stress, and the initial blank diameter; this simplified model assumes radial flow equilibrium in the flange and constant stress transmission through the wall. Actual forces include additional components from friction and bending at the die radius, but this equation establishes the baseline for process design.[15] Finite element analysis (FEA) provides essential simulation capabilities for predicting strain distributions in deep drawing, modeling the nonlinear material behavior, contact interactions, and geometric nonlinearities across zones. Using software like DEFORM or ANSYS, FEA discretizes the blank into elements to compute stress-strain fields, revealing thinning patterns, potential failure sites, and force evolutions; for instance, simulations incorporate plasticity models (e.g., von Mises) and friction coefficients to optimize parameters without physical trials. These models confirm uniform strain in ideal cases but highlight anisotropy effects on earing, aiding in process refinement for complex geometries.[20][21]Key Parameters and Limiting Drawing Ratio

Deep drawing success depends on several critical parameters that control material flow, prevent defects like wrinkling or tearing, and ensure formability. The blank diameter (D) represents the initial size of the circular sheet metal workpiece, which determines the volume of material available for forming the final cup shape. The punch diameter (d) defines the inner diameter of the drawn cup and directly influences the extent of radial reduction during the process. Clearance between the punch and die, typically 5-10% of the sheet thickness (t), allows for smooth material flow while minimizing friction and avoiding shearing; values outside this range can lead to excessive thinning or galling.[22] The blank holder force (BHF), often set at 30-40% of the anticipated drawing force, clamps the blank periphery to restrict uncontrolled radial flow and suppress wrinkling in the flange region, though excessive BHF can increase friction and promote fracture. Punch speed, commonly ranging from 0.1 to 1 m/s in production operations, affects strain rates and heat generation; slower speeds (e.g., below 0.3 m/s) reduce defects in sensitive materials but lower throughput, while higher speeds enhance efficiency for ductile metals. The reduction ratio, defined as , quantifies the percentage diameter decrease in a single stage and typically falls between 40% and 50% for optimal formability without failure, with higher values risking instability.[23][24][6] The limiting drawing ratio (LDR), denoted as , serves as a primary formability metric, representing the maximum blank-to-punch diameter ratio achievable in a single draw before necking or fracture occurs at the cup wall. A common theoretical approximation for the maximum LDR under ideal frictionless conditions is , where is the strain-hardening exponent derived from tensile testing; this formula accounts for material work-hardening behavior.[25] Typical LDR values range from 1.8 to 2.2 for low-carbon steels, reflecting their balanced ductility, while high-strength alloys exhibit lower ratios (e.g., 1.5-1.8) due to reduced formability and higher sensitivity to thinning.[26] For required reductions exceeding an LDR of 2.2, multi-stage drawing is employed, involving intermediate redraw operations or annealing to restore ductility and prevent cumulative strain hardening. In multi-stage processes, each subsequent draw achieves progressively smaller reductions (e.g., 20-30% in the second stage), with annealing between stages mitigating work hardening for deeper parts. Drawing efficiency, calculated as , measures process performance relative to theoretical limits, often achieving 70-90% in optimized setups by minimizing redundant deformation.[6][27] Formability in deep drawing is evaluated using the Swift cup test, a standardized method where progressively larger blank diameters are drawn into cylindrical cups until failure occurs, thereby determining the LDR by identifying the largest successful blank size relative to the punch diameter. This test simulates production conditions and highlights material limits under biaxial stretching and radial compression, with failure typically manifesting as circumferential cracks at the cup base.[28][29]Materials and Tooling

Workpiece Materials and Properties

Deep drawing primarily utilizes sheet metals with good formability, including low-carbon steels such as DD13, aluminum alloys like 3003, stainless steels such as 304, brass, copper, and titanium, typically in thicknesses ranging from 0.5 to 6 mm.[6][30] Low-carbon steels are favored for their balanced strength and ductility in applications requiring moderate deformation, while aluminum alloys offer lightweight alternatives with adequate drawability. Stainless steels like 304 provide corrosion resistance but demand careful process control due to their higher strength.[31][32] Brass and copper are selected for their excellent malleability in decorative or conductive components.[33] Titanium is used in high-performance applications like aerospace components for its high strength-to-weight ratio and corrosion resistance, though it requires specialized tooling due to its lower formability at room temperature.[7] Essential properties for workpiece materials in deep drawing include high ductility with elongation exceeding 30%, low yield strength in the range of 200-400 MPa, a normal anisotropy ratio (r) greater than 1.0 to reduce earing defects, and a strain hardening exponent (n) above 0.15.[31][16] These attributes ensure the sheet can undergo significant plastic deformation without fracturing, as measured in tensile tests. For instance, low-carbon steels like DD13 exhibit formability indices with n values of 0.2-0.25, enabling reliable cup formation.[34] Aluminum alloy 3003 supports limiting drawing ratios (LDR) around 2.0, reflecting its favorable strain distribution during forming.[35] Material characteristics significantly influence process outcomes; softer materials like aluminum reduce required drawing forces compared to steels, easing equipment demands and improving efficiency.[36] High-strength steels, including advanced high-strength steels (AHSS), facilitate lightweighting in structural parts but necessitate elevated blank holder forces (BHF) to prevent wrinkling, higher than for conventional steels.[37] Warm drawing at temperatures of 200-400°C enhances formability by approximately 20% in materials like aluminum and AHSS, by lowering flow stress and increasing ductility without altering microstructure significantly.[38] Selection of workpiece materials is guided by achievable LDR, required surface finish, and application demands, with recent post-2020 trends emphasizing AHSS in automotive components for improved crash performance and fuel efficiency while maintaining formability through optimized alloying.[39][40] For high surface quality needs, materials with low r-variation, such as stabilized low-carbon steels, are preferred to minimize directional inconsistencies.[16]Die and Punch Materials

In deep drawing, the selection of materials for punches, dies, and blank holders prioritizes high wear resistance, hardness, and durability to withstand repetitive high-pressure contact with deformable sheet metals, ensuring consistent part quality over production runs. Standard materials include tool steels such as D2 and A2, which are air-hardening alloys offering excellent abrasion resistance due to their high chromium and carbon content, typically heat-treated to a hardness of 58-62 HRC for optimal performance in moderate to high-volume applications.[41][42] For low-volume or prototype production, simpler carbon steels like T10 are employed, providing cost-effective hardness around 60 HRC but with lower wear resistance compared to alloyed variants.[43] For high-production environments demanding extended tool life, cemented carbides such as tungsten carbide-cobalt (WC-Co) composites are preferred, exhibiting superior hardness of 89-93 HRA due to their dense microstructure of hard carbides in a tough binder phase.[41][44] Advanced powder metallurgy (PM) tool steels, exemplified by CPM-10V, further enhance performance in corrosive or abrasive conditions through fine-grained vanadium carbides that boost wear resistance while maintaining toughness, often outperforming traditional D2 in demanding forming scenarios.[45] To mitigate friction and extend service life, surface coatings like titanium nitride (TiN) or diamond-like carbon (DLC) are applied via physical vapor deposition, reducing coefficient of friction by up to 50% and minimizing adhesive wear during sheet metal flow.[46] Design considerations for these tools emphasize geometry to facilitate material flow and prevent defects, with die radii typically set at 8-12 times the square root of sheet thickness (√t) to avoid cracking, and punch nose radii at 10-15% of the punch diameter (d) to distribute stress evenly.[47] Tolerances are maintained at ±0.05 mm to ensure dimensional accuracy, while modular die designs incorporating interchangeable components offer flexibility for varying part sizes and quick adjustments in production lines.[47] These material and design choices must align with workpiece properties, such as ductility, to optimize deformation without galling. Maintenance practices focus on surface integrity, where polishing tools to a roughness of Ra < 0.2 μm significantly reduces galling by promoting smooth metal-tool interfaces and uniform lubrication distribution.[48] Post-2020 advancements include additive manufacturing techniques, such as fused deposition modeling with reinforced polymers like PLA or PETG, enabling rapid production of complex die geometries with lattice structures that reduce material volume by up to 24% while sustaining forming forces over hundreds of cycles in testing applications.[49][50]Operational Aspects

Lubrication and Cooling Methods

In deep drawing, lubrication plays a critical role in minimizing friction at the tool-workpiece interface, thereby facilitating material flow and reducing wear. Lubricants are categorized into several types based on their composition and application suitability. Dry film lubricants, such as those formed by phosphate conversion coatings combined with soap, offer low coefficients of friction typically ranging from 0.05 to 0.1, making them effective for conventional sheet metal forming where a thin, adherent layer is needed without liquid residue.[51] Wet lubricants, including emulsions and straight oils, provide both boundary lubrication and cooling, with emulsions being water-based mixtures that are economical for large-scale operations. Solid lubricants like graphite and molybdenum disulfide (MoS₂) are used in high-load scenarios due to their layered structure, which shears easily to maintain low friction under dry or semi-dry conditions. For high-speed deep drawing, plastic films—such as polyethylene or polyvinyl chloride coatings applied to the blank—enable rapid processing by forming a temporary barrier that minimizes galling and supports higher drawing ratios.[52][51] Lubricants are applied through methods like spraying for even coverage on complex shapes, dipping for full immersion of blanks, and roller coating for precise control in continuous lines. Application quantities are generally controlled at 1-5 g/m² to balance lubrication efficacy with post-process cleaning requirements, avoiding buildup that could affect subsequent operations. Selection depends on workpiece material; wax-based dry films are commonly used for steel to provide adhesion resistance, while vanishing oils—formulations that evaporate quickly—are preferred for aluminum alloys to prevent staining and ensure clean surfaces.[51][53] Cooling complements lubrication by dissipating frictional heat in the deformation zone, with air jets or water mist systems employed on presses to maintain tool and workpiece temperatures. In high-speed production lines, effective cooling is essential to keep temperatures below 100°C, preventing thermal softening that could lead to uneven material flow or reduced formability.[54] Proper lubrication reduces drawing forces by 20-40% compared to dry conditions, allowing for deeper draws and lower energy consumption while also improving surface integrity. Enhanced lubrication can achieve surface roughness values (Ra) below 0.4 μm, contributing to superior aesthetic and functional quality in formed parts. Post-2020, environmental regulations have driven a shift toward bio-lubricants, such as vegetable oil-based formulations (e.g., cottonseed or jatropha), which offer comparable friction reduction to mineral oils with greater biodegradability and lower toxicity.[55][56][56] Lubricant effectiveness, particularly the coefficient of friction (μ), is assessed using draw bead simulators that replicate the bending and restraining forces in the die's bead region, providing reliable measurements under controlled conditions to guide process optimization.[57]Power Requirements and Force Calculations

The drawing force in deep drawing operations is a critical parameter that determines the required press capacity and is calculated using established analytical models accounting for material deformation, geometry, and frictional effects. A widely used formula for the ideal maximum drawing force is given by where is the punch diameter, is the sheet thickness, is the initial blank diameter, and is the mean flow stress of the material. This expression derives from the work of deformation in the flange under ideal conditions. Practical calculations include additional terms for friction over the die radius and punch face, as well as bending effects at the die entry, which can add 10-20% to the total force depending on radii and lubrication. The mean flow stress is approximated as , where is the yield strength and is the ultimate tensile strength, providing a reasonable estimate for strain-hardening materials under plane strain conditions typical in deep drawing. An efficiency factor of 0.7-0.9 is often applied to account for process inefficiencies, such as non-uniform deformation and heat generation, yielding conservative estimates validated against experimental data.[58][58] The blank holder force (BHF) prevents wrinkling in the flange by controlling material inflow and is typically set as , where ranges from 0.1 to 0.2 based on material ductility and draw ratio, ensuring sufficient restraint without excessive thinning at the cup wall. More precisely, an approximation is , reflecting the frictional resistance needed over the blank holder contact area, with the total press force then incorporating a safety margin of 1.5 times the sum of drawing and blank holder forces to accommodate dynamic loads and tool deflections. These calculations assume a drawing ratio up to the limiting value of about 2.0 for single-stage operations, beyond which multi-stage drawing is required. Lubrication reduces (typically 0.05-0.15 with good oils), lowering both forces by 10-30%.[58][58] Power requirements are determined from the force and punch velocity, using , where is the punch speed (often 10-50 mm/s for conventional presses) and is the mechanical efficiency, approximately 0.8 for most hydraulic or mechanical systems accounting for losses in transmission and friction. For multi-stage deep drawing, the total power is the sum across stations, with energy per part ranging from 1-10 kJ depending on part size and material; for example, a single-stage cup with 100 mm diameter requires about 5-8 kJ based on integrated force-displacement curves. Press selection involves hydraulic types for forces up to 5000 kN, suitable for high-volume production due to their smooth force delivery, while mechanical presses dominate for speeds over 100 strokes/min. Post-2020 advancements in servo-electric presses enable precise force control (within 1% variation) and variable speeds, ideal for complex geometries requiring adaptive blank holding, though limited to forces below 3000 kN.[58] Material-specific forces vary with strength and thickness; the following table provides representative values for a 50% reduction (drawing ratio of 2.0) in single-stage deep drawing of a 100 mm diameter cup, assuming mm, , and efficiency factor of 0.8, based on empirical models including adjustments for friction and bending (~15%), validated against experimental data:| Material | Yield Strength (MPa) | Ultimate Strength (MPa) | Mean Flow Stress (MPa) | Drawing Force (kN) | Blank Holder Force (kN) | Total Press Force (kN, incl. 1.5x margin) |

|---|---|---|---|---|---|---|

| Mild Steel (e.g., DC04) | 140 | 270 | 205 | 150-170 | 15-25 | 260-290 |

| Stainless Steel (e.g., AISI 304) | 215 | 515 | 365 | 250-280 | 25-45 | 430-480 |

| Aluminum Alloy (e.g., AA5182) | 160 | 310 | 235 | 120-140 | 12-20 | 210-240 |