Recent from talks

Nothing was collected or created yet.

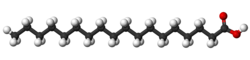

Stearic acid

View on Wikipedia | |

| |

| Names | |

|---|---|

| Preferred IUPAC name

Octadecanoic acid | |

Other names

| |

| Identifiers | |

3D model (JSmol)

|

|

| 608585 | |

| ChEBI | |

| ChEMBL | |

| ChemSpider | |

| DrugBank | |

| ECHA InfoCard | 100.000.285 |

| EC Number |

|

| 11738 | |

| KEGG | |

PubChem CID

|

|

| RTECS number |

|

| UNII | |

CompTox Dashboard (EPA)

|

|

| |

| |

| Properties | |

| C18H36O2 | |

| Molar mass | 284.484 g·mol−1 |

| Appearance | White solid |

| Odor | Pungent, oily |

| Density | 0.9408 g/cm3 (20 °C)[2] 0.847 g/cm3 (70 °C) |

| Melting point | 69.3 °C (156.7 °F; 342.4 K)[2] |

| Boiling point | 361 °C (682 °F; 634 K) decomposes 232 °C (450 °F; 505 K) at 15 mmHg[2] |

| 0.0018 g/100 g (0 °C) 0.0029 g/100 g (20 °C) 0.0034 g/100 g (30 °C) 0.0042 g/100 g (45 °C) 0.0050 g/100 g (60 °C)[3] | |

| Solubility | Soluble in [4] |

| Solubility in dichloromethane | 3.58 g/100 g (25 °C) 8.85 g/100 g (30 °C) 18.3 g/100 g (35 °C)[4] |

| Solubility in hexane | 0.5 g/100 g (20 °C) 4.3 g/100 g (30 °C) 19 g/100 g (40 °C) 79.2 g/100 g (50 °C) 303 g/100 g (60 °C)[4] |

| Solubility in ethanol | 1.09 g/100 mL (10 °C) 2.25 g/100 g (20 °C) 5.42 g/100 g (30 °C) 22.7 g/100 g (40 °C) 105 g/100 g (50 °C) 400 g/100 g (60 °C)[3] |

| Solubility in acetone | 4.73 g/100 g[5] |

| Solubility in chloroform | 15.54 g/100 g[5] |

| Solubility in toluene | 13.61 g/100 g[5] |

| Vapor pressure | 0.01 kPa (158 °C)[2] 0.46 kPa (200 °C) 16.9 kPa (300 °C)[6] |

| −220.8·10−6 cm3/mol | |

| Thermal conductivity | 0.173 W/m·K (70 °C) 0.166 W/m·K (100 °C)[7] |

Refractive index (nD)

|

1.4299 (80 °C)[2] |

| Structure | |

| B-form = Monoclinic[8] | |

| B-form = P21/a[8] | |

| B-form = Cs 2h[8] | |

a = 5.591 Å, b = 7.404 Å, c = 49.38 Å (B-form)[8] α = 90°, β = 117.37°, γ = 90°

| |

| Thermochemistry | |

Heat capacity (C)

|

501.5 J/mol·K[2][6] |

Std molar

entropy (S⦵298) |

435.6 J/mol·K[2] |

Std enthalpy of

formation (ΔfH⦵298) |

−947.7 kJ/mol[2] |

Std enthalpy of

combustion (ΔcH⦵298) |

−11342.4 kJ/mol[9] |

| Hazards | |

| NFPA 704 (fire diamond) | |

| Flash point | 205 °C (401 °F; 478 K) |

| Lethal dose or concentration (LD, LC): | |

LD50 (median dose)

|

4640 mg/kg (rats, oral)[10] 21.5 mg/kg (rats, intravenous)[4] |

Except where otherwise noted, data are given for materials in their standard state (at 25 °C [77 °F], 100 kPa).

| |

Stearic acid (/ˈstɪərɪk/ STEER-ik, /stiˈærɪk/ stee-ARR-ik) is a saturated fatty acid with an 18-carbon chain.[9] The IUPAC name is octadecanoic acid.[9] It is a soft waxy solid with the formula CH3(CH2)16COOH.[9] The triglyceride derived from three molecules of stearic acid is called stearin.[9] Stearic acid is a prevalent fatty acid in nature, found in many animal and vegetable fats, but is usually higher in animal fat than vegetable fat. It has a melting point of 69.4 °C (156.9 °F) °C and a pKa of 4.50.[11]

Its name comes from the Greek word στέαρ "stéar", which means tallow. The salts and esters of stearic acid are called stearates.[9] As its glycerol ester, stearic acid is one of the most common saturated fatty acids found in nature and in the food supply, following palmitic acid.[12][13] Dietary sources of stearic acid include meat, poultry, fish, eggs, dairy products, and foods prepared with fats; beef tallow, lard, butterfat, cocoa butter, and shea butter are rich fat sources of stearic acid.[9][12]

Production

[edit]In terms of its biosynthesis, stearic acid is produced from palmitoyl-CoA, with malonyl-CoA a two-carbon building block (after decarboxylation).

Stearic acid is obtained from fats and oils by the saponification of the triglycerides using hot water (about 100 °C). The resulting mixture is then distilled.[14] Commercial stearic acid is often a mixture of stearic and palmitic acids, although purified stearic acid is available. Commercially, oleic acid, as found in palm and soy, can be hydrogenated to give stearic acid.

Uses and occurrence

[edit]In general, the applications of stearic acid exploit its bifunctional character, with a polar head group that can be attached to metal cations and a nonpolar chain that confers solubility in organic solvents.[9] The combination leads to uses as a surfactant and softening agent. Stearic acid undergoes the typical reactions of saturated carboxylic acids, a notable one being reduction to stearyl alcohol, and esterification with a range of alcohols.[9] This is used in a large range of manufactures, from simple to complex electronic devices.[9]

Food

[edit]Of the saturated fatty acids consumed in the United States, stearic acid consumption is second (26% of total saturated fatty acid intake) to palmitic acid (56% of total saturated fatty acid intake).[12] Stearic acid is more abundant in animal fat (up to 33% in beef liver[15]: 739 ) than in vegetable fat (typically less than 5%).[12] The important exceptions are the foods cocoa butter (34%) and shea butter, where the stearic acid content (as a triglyceride) is 28–45%.[9][15] Examples of the use of stearic acid in food manufacturing include baked goods, frozen dairy products, gelatins, puddings, hard candy, and nonalcoholic beverages.[9]

Stearic acid (E number E570) is found in some foods.[9][16]

Soaps and cosmetics

[edit]Stearic acid is mainly used in the production of detergents, soaps, and cosmetics such as shampoos and shaving cream products.[9] Stearate soap, such as sodium stearate, could be made from stearic acid but instead are usually produced by saponification of stearic acid-containing triglycerides. Esters of stearic acid with ethylene glycol (glycol stearate and glycol distearate) are used to produce a pearly effect in shampoos, soaps, and other cosmetic products.[9]

Lubricants, softening and release agents

[edit]In view of the soft texture of the sodium salt, which is the main component of soap, other salts are also useful for their lubricating properties. Lithium stearate is an important component of grease. The stearate salts of zinc, calcium, cadmium, and lead are used as heat stabilizers for PVC. Stearic acid is used along with castor oil for preparing softeners in textile sizing. They are heated and mixed with caustic potash or caustic soda. Related salts are also commonly used as release agents, e.g. in the production of automobile tires. As an example, it can be used to make castings from a plaster piece mold or waste mold, and to make a mold from a shellacked clay original. In this use, powdered stearic acid is mixed in water and the suspension is brushed onto the surface to be parted after casting. This reacts with the calcium in the plaster to form a thin layer of calcium stearate, which functions as a release agent.[17]

Steric acid can be converted to zinc stearate, which is used as a lubricant for playing cards (fanning powder) to ensure a smooth motion when fanning. Stearic acid is a common lubricant during injection molding and pressing of ceramic powders.[18]

Niche uses

[edit]Being inexpensive, nontoxic, and fairly inert, stearic acid finds many niche applications.[9][14] Varied examples of stearic acid use in manufacturing include soaps and greases, household soap products, synthetic rubber, cosmetic and pharmaceutical creams and lotions, candles, phonograph records, lubricants, shoe and metal polishes, food packaging, and rubber compounds.[9]

Stearic acid is used as a negative plate additive in the manufacture of lead-acid batteries.[citation needed] It is added at the rate of 0.6 g per kg of the oxide while preparing the paste. It is believed to enhance the hydrophobicity of the negative plate, particularly during dry-charging process. It also reduces the extension of oxidation of the freshly formed lead (negative active material) when the plates are kept for drying in the open atmosphere after the process of tank formation. As a consequence, the charging time of a dry uncharged battery during initial filling and charging (IFC) is comparatively lower, as compared to a battery assembled with plates which do not contain stearic acid additive. Fatty acids are classic components of candle-making. Stearic acid is used along with simple sugar or corn syrup as a hardener in candies.[9]

Metabolism

[edit]An isotope labeling study in humans[19] concluded that the fraction of dietary stearic acid that oxidatively desaturates to oleic acid is 2.4 times higher than the fraction of palmitic acid analogously converted to palmitoleic acid. Also, stearic acid is less likely to be incorporated into cholesterol esters. In epidemiologic and clinical studies, stearic acid was found to be associated with lowered LDL cholesterol in comparison with other saturated fatty acids.[12]

Examples

[edit]- Salts

- Potassium stearate

- Calcium stearate

- Cobaltous stearate

- Lithium stearate

- Magnesium stearate

- Mercuric stearate

- Sodium stearate

- Zinc stearate

- Esters

References

[edit]- ^ Susan Budavari, ed. (1989). Merck Index (11th ed.). Rahway, New Jersey: Merck & Co., Inc. p. 8761. ISBN 978-0-911910-28-5.

- ^ a b c d e f g h Lide, David R., ed. (2009). CRC Handbook of Chemistry and Physics (90th ed.). Boca Raton, Florida: CRC Press. ISBN 978-1-4200-9084-0.

- ^ a b Theneshkumar, S.; Gnanaprakash, D.; N., Nagendra Gandhi (2010). "Supporting Information Solubility and Mass Transfer Coefficient Enhancement of Stearic Acid through Hydrotropy". Journal of Chemical & Engineering Data. 55 (9): 2980–2984. doi:10.1021/je901041n.

- ^ a b c d "stearic acid". Chemister.ru. 2007-03-19. Retrieved 2017-06-30.

- ^ a b c Seidell, Atherton; Linke, William F. (1919). Solubilities of Inorganic and Organic Compounds (2nd ed.). D. Van Nostrand Company. p. 677.

- ^ a b Octadecanoic acid in Linstrom, Peter J.; Mallard, William G. (eds.); NIST Chemistry WebBook, NIST Standard Reference Database Number 69, National Institute of Standards and Technology, Gaithersburg (MD) (retrieved 2014-06-15)

- ^ Vargaftik, Natan B.; et al. (1993). Handbook of Thermal Conductivity of Liquids and Gases (illustrated ed.). CRC Press. p. 318. ISBN 978-0-8493-9345-7.

- ^ a b c d von Sydow, E. (1955). "On the structure of the crystal form B of stearic acid". Acta Crystallographica. 8 (9): 557–560. Bibcode:1955AcCry...8..557V. doi:10.1107/S0365110X55001746.

- ^ a b c d e f g h i j k l m n o p q r "Stearic acid". PubChem, US National Library of Medicine. 29 April 2023. Retrieved 5 May 2023.

- ^ Science Lab.com. "Stearic acid MSDS" (PDF). Retrieved 2020-09-30.

- ^ Loften, J.R.; Linn, J.G.; Drackley, J.K.; Jenkins, T.C.; Soderholm, C.G.; Kertz, A.F. (August 2014). "Invited review: Palmitic and stearic acid metabolism in lactating dairy cows". Journal of Dairy Science. 97 (8): 4661–4674. doi:10.3168/jds.2014-7919. ISSN 0022-0302. PMID 24913651.

- ^ a b c d e Hunter, J. E.; Zhang, J.; Kris-Etherton, P. M. (2009). "Cardiovascular disease risk of dietary stearic acid compared with trans, other saturated, and unsaturated fatty acids: A systematic review". American Journal of Clinical Nutrition. 91 (1): 46–63. doi:10.3945/ajcn.2009.27661. PMID 19939984.

- ^ Gunstone, F. D., John L. Harwood, and Albert J. Dijkstra "The Lipid Handbook with Cd-Rom. 3rd ed. Boca Raton: CRC Press, 2007. ISBN 0849396883 | ISBN 978-0849396885

- ^ a b Anneken, David J.; Both, Sabine; Christoph, Ralf; Fieg, Georg; Steinberner, Udo; Westfechtel, Alfred (2006). "Fatty Acids". Ullmann's Encyclopedia of Industrial Chemistry. Weinheim: Wiley-VCH. doi:10.1002/14356007.a10_245.pub2. ISBN 3527306730.

- ^ a b Beare-Rogers, J.; Dieffenbacher, A.; Holm, J.V. (2001). "Lexicon of lipid nutrition (IUPAC Technical Report)". Pure and Applied Chemistry. 73 (4): 685–744. doi:10.1351/pac200173040685. S2CID 84492006.

- ^ Aguilar, Fernando; Crebelli, Riccardo; Di Domenico, Alessandro; et al. (2017). "Re-evaluation of fatty acids (E 570) as a food additive". EFSA Journal. 15 (5): 4785. doi:10.2903/j.efsa.2017.4785. PMC 7009963. PMID 32625490.

- ^ Angelo Nora; Alfred Szczepanek; Gunther Koenen (2005). "Metallic Soaps". Ullmann's Encyclopedia of Industrial Chemistry. Weinheim: Wiley-VCH. doi:10.1002/14356007.a16_361. ISBN 978-3-527-30673-2.

- ^ Tsenga, Wenjea J.; Mo Liua, Dean; Hsub, Chung-King (1999). "Influence of stearic acid on suspension structure and green microstructure of injection-molded zirconia ceramics". Ceramics International. 25 (2): 191–195. doi:10.1016/S0272-8842(98)00024-8.

- ^ Emken, Edward A. (1994). "Metabolism of dietary stearic acid relative to other fatty acids in human subjects". American Journal of Clinical Nutrition. 60 (6): 1023S – 1028S. doi:10.1093/ajcn/60.6.1023S. PMID 7977144.

External links

[edit]Stearic acid

View on GrokipediaProperties

Physical properties

Stearic acid has the molecular formula and a molar mass of 284.48 g/mol.[10] It appears as a white, waxy solid at room temperature.[11] The compound exhibits a melting point range of 69.3–69.7 °C and a boiling point of 361 °C at 100 mmHg.[12] Its density is 0.94 g/cm³ in the solid state and 0.839 g/cm³ in the liquid state at 75 °C.[10] Stearic acid is insoluble in water, with a solubility of 0.0003 g/100 mL at 20 °C, but it is soluble in organic solvents such as ethanol, ether, and chloroform.[10] The refractive index is 1.4299 at 80 °C, and the flash point is 196 °C.[10] Key thermal properties include a heat of combustion of -11,298 kJ/mol (approximately -39.7 kJ/g) and a specific heat capacity of the solid phase around 2.1 J/g·K at room temperature.[13]| Property | Value |

|---|---|

| Molecular formula | |

| Molar mass | 284.48 g/mol |

| Appearance | White waxy solid |

| Melting point | 69.3–69.7 °C |

| Boiling point | 361 °C (at 100 mmHg) |

| Density (solid) | 0.94 g/cm³ |

| Density (liquid, 75 °C) | 0.839 g/cm³ |

| Solubility in water (20 °C) | 0.0003 g/100 mL |

| Refractive index (80 °C) | 1.4299 |

| Flash point | 196 °C |

| Heat of combustion | -11,298 kJ/mol (-39.7 kJ/g) |

| Specific heat capacity (solid) | ~2.1 J/g·K |