Recent from talks

Nothing was collected or created yet.

GM Family II engine

View on Wikipedia

| Family II engine | |

|---|---|

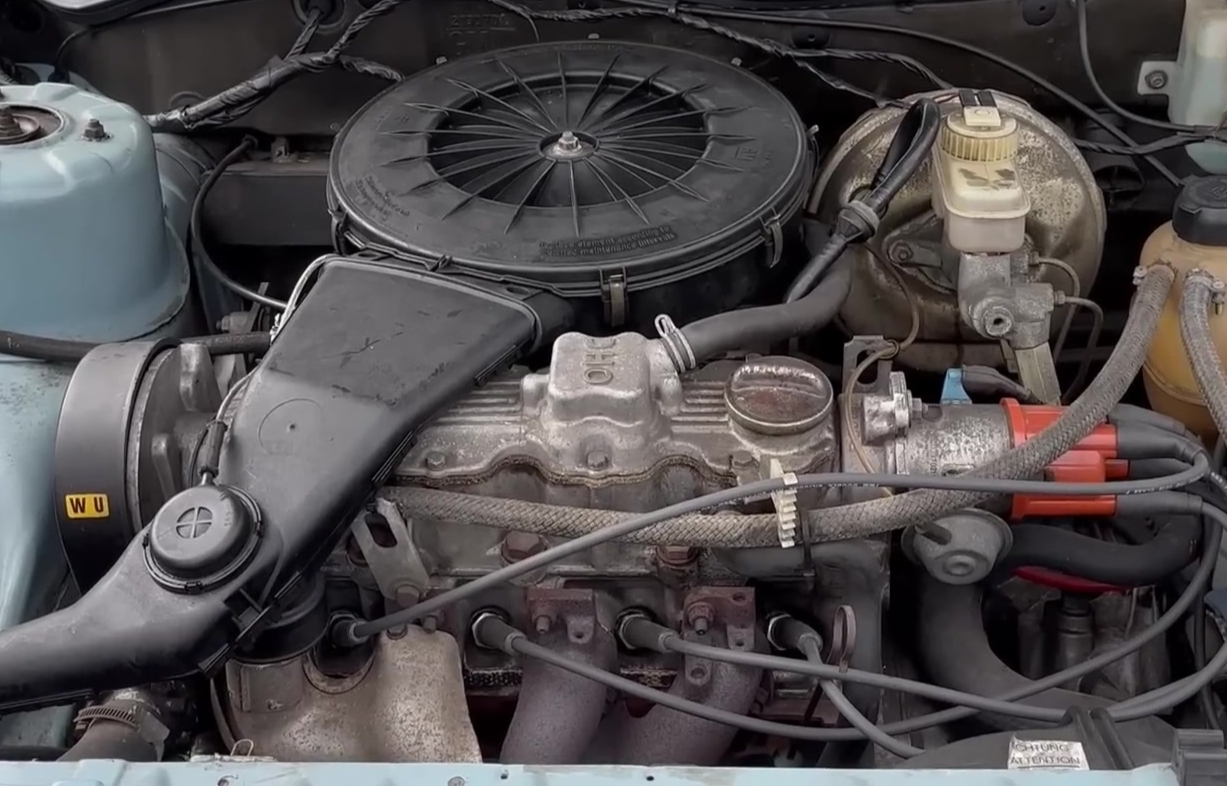

An early GM Family II engine (16S) fitted to a 1982 Opel Ascona C (Vauxhall Cavalier Mk2) | |

| Overview | |

| Manufacturer | |

| Also called |

|

| Production | |

| Layout | |

| Configuration | |

| Cylinder block material | Cast iron |

| Cylinder head material | Aluminium |

| Valvetrain |

|

| Combustion | |

| Oil system | Wet sump |

| Cooling system | Water-cooled |

| Chronology | |

| Predecessor | |

| Successor |

|

The Family II is a straight-4 piston engine that was originally developed by Opel in the 1970s, debuting in 1981. Available in a wide range of cubic capacities ranging from 1598 to 2405 cc, it simultaneously replaced the Opel CIH and Vauxhall Slant-4 engines, and was GM Europe's core mid-sized powerplant design for much of the 1980s, and provided the basis for the later Ecotec series of engines in the 1990s.

The Family II shares its basic design and architecture with the smaller Family I engine (which covered capacities from 1.0 to 1.6 litres) – and for this reason the Family I and Family II engines are also known informally as the "small block" and "big block", respectively – although the 1.6 L capacity was available in either type depending on its fuelling system.

The engine also spawned two diesel variants, the 1.6 L and 1.7 L.

The engine features a cast iron block, an aluminium head, and a timing belt driven valvetrain. The timing belt also drives the water pump. It was first used in the Opel Kadett D, Ascona C, and their corresponding Vauxhall sister models, the Astra and Cavalier II. Many General Motors subsidiaries, including Daewoo, GM do Brasil, GM Powertrain, and Holden have used this design.

Family II engines for the European and Australasian markets were manufactured by Holden at its Fisherman's Bend plant in Melbourne until 2009, whilst the Americas were supplied from the São José dos Campos plant in the São Paulo region of Brazil.

By 1986, the Family II unit had almost completely replaced the CIH engine as Opel/Vauxhall's core 4-cylinder engine – the CIH continuing only in 2.4L 4-cylinder format, and in all 6-cylinder applications in the Omega and Senator models until 1994.

The development track of these engines split in 1987, with the introduction of the 20XE; which featured a 16-valve DOHC head, with Holden production of the SOHC versions ending in 2009. Although SOHC versions stayed in production in Brazil, most DOHC engines were replaced by the all-aluminium GM Ecotec engine family.

In 2004, a 2.0 L MultiPower engine was made available for the taxi market which could use gasoline, alcohol, and natural gas.

SOHC

[edit]| SOHC | |

|---|---|

Family II engine (20SEH) fitted to a Vauxhall Cavalier Mk3 (Opel Vectra A) | |

| Overview | |

| Manufacturer | General Motors |

| Also called | 8-valve |

| Production | 1981–2009 |

| Layout | |

| Displacement |

|

| Cylinder bore |

|

| Piston stroke |

|

| Valvetrain | Single overhead cam |

| Compression ratio |

|

| Combustion | |

| Fuel system | |

| Fuel type | |

These engines formed the basis of the modern Family II lineup, starting with the 16SH (1600S) version in the Opel Kadett D/Ascona C (Vauxhall Astra Mk1/Cavalier Mk2) in 1981. Configuration was limited to a single over head cam, and two valves per cylinder in a cross flow layout (8 valves total). Superficially these engines look similar to the "small block" Family I engine; the key difference to aid identification is the position of the oil filter – on the Family I it is on the front face of the cylinder block, pointing towards front of the car, on the Family II it is adjacent to the crankshaft pulley pointing downward. The Family II also has a more sophisticated crankcase breathing circuit, with an additional pipe that runs from the crankcase to the camshaft box, with a further pipe running from a small plenum chamber on the rocker cover.

The 1.8-liter versions appeared first in carburetted form (18N) in 1982 and later also in injected (18LE) and further forms. The 2-liter 20NE was introduced in 1986 for the Opel Omega A (Vauxhall Carlton Mk2) and Ascona C3 (Vauxhall Cavalier Mk2c) and served as the base from which the updated 20SEH, and ultimately the 20XE/C20XE "Red Top". The final versions of this engine, labelled Ecotec, evolved from this engine as well.

Early Family II engines had a reputation for rapid camshaft and follower wear (a trait shared with the smaller Family I engine), the problem afflicted Kadett D/Astra I and Ascona C/Cavalier II vehicles fitted with the engine. Improved metallurgy of both the cam lobes and followers, combined with a change to the lubrication specification eventually solved the issue.

Another known issue on the Family II was for the water pump to become jammed into its mounting due to corrosion if the engine was run with no antifreeze; the pump is mounted into an eccentric shaped aperture so it can also function as the timing belt tensioner. If the pump cannot turn then the belt cannot be tensioned. Later versions of the engine were equipped with a separate jockey pulley to combat the issue.

1.6

[edit]The 1.6-liter iteration (1,598 cc or 97.5 cu in) has an 80.0 mm (3.15 in) bore and a 79.5 mm (3.13 in) stroke. Opel began production of the 1.6-liter engine in 1980.[4] A diesel fueled version also became available. The diesel produced 54 PS (40 kW) at 4600 rpm and 70.8 lb⋅ft (96.0 N⋅m) of torque at 2400 rpm. It also had a 23:1 compression ratio and a Bosch injection pump.[5] The diesel featured valves that rotate, increasing durability.[6]

| Engine | Power | Torque | Compression Ratio | Fuel Delivery | Engine Management | Applications |

|---|---|---|---|---|---|---|

| 16LF | 72 hp (53 kW ) at 5200 rpm with Ethanol

73 hp (54 kW) at 5400 rpm with Gasoline |

12.6 kgfm (124 Nm) at 2600 rpm with ethanol

12.3 kgfm (121 Nm) at 3000 rpm with Gasoline |

12:1 with Ethanol

8:1 with Gasoline |

Carburetor single barrel Weber 190 or brosol h 35 alfa1

Ethanol/Gasoline |

| |

| 16SH | 66 kW (90 PS; 89 hp) at 5800 rpm | 126 N⋅m (93 lb⋅ft) at 3800–4200 rpm | GM Varajett II | Opel Kadett D Opel Ascona C Opel Kadett E | ||

| 16D/16DA | 40 kW (54 PS; 54 hp) at 4600 rpm | 96 N⋅m (71 lb⋅ft) at 2400 rpm | Bosch VE |

|

1.7

[edit]The 1.7-liter iteration (1,700 cc or 103.7 cu in) has an 82.5 mm (3.25 in) bore and a 79.5 mm (3.13 in) stroke.

The engine uses diesel fuel, and uses indirect injection.

| Engine | Power | Torque | Compression Ratio | Fuel Delivery | Engine Management | Applications |

|---|---|---|---|---|---|---|

| 17D | 42 kW (57 PS; 56 hp) | 105 N⋅m (77 lb⋅ft) at 2400 rpm | 23:1 | Bosch injection pump | Mechanical Indirect |

|

| 17DR | 44 kW (60 PS; 59 hp) | 105 N⋅m (77 lb⋅ft) at 2650 rpm | 23:1 | Lucas injection pump | Mechanical Indirect |

|

| X17DTL | 50 kW (68 PS; 67 hp) | 132 N⋅m (97 lb⋅ft) at 2400 rpm | 22:1 | Various | Mechanical Indirect | 1994–2000 Opel Astra |

1.8

[edit]The 1.8-liter iteration (1,796 cc or 109.6 cu in) has an 84.8 mm (3.34 in) bore and a 79.5 mm (3.13 in) stroke. It was first available in the facelifted Opel Manta B in May 1982, and quickly made its way into a number of other Opel and GM cars. It was originally available as the 18N and the 18S, for low and high octane petrol respectively. The C18NV was first installed in the Opel Rekord E2 from May 1985 and was one of the first catalysed mass market automobiles sold in Germany (and Europe). The Family II engines in a longitudinal installation (for rear-wheel drive) have one major design difference from their transverse mounted counterparts – the distributor is driven by a small drivebelt from the camshaft timing sprocket rather than directly off the transmission end of the camshaft, which on the Manta B and Rekord E2 (both older vehicles that had originally been designed around the CIH engine) would have meant the distributor fouling the firewall or being impossible to service.

In 1983, the 1.8 L engine was added to certain North American market J-cars; the engines were imported from Brazil.[7] The LA5 (RPO code) is a turbocharged version that was optional in the North American market from 1984.

| Engine[8] | Power | Torque | Compression Ratio | Fuel Delivery | Engine Management | Applications |

|---|---|---|---|---|---|---|

| 18E

S18E |

85 kW (115 PS) at 5800 rpm | 151 N⋅m (111 lb⋅ft) at 4800 rpm | 9.5:1 | Multipoint fuel injection | (Bosch LE-Jetronic) |

|

| 18LE | 79 kW (106 hp) at 5,600 rpm (catalyst) | 151 N⋅m (111 lb⋅ft) at 3,600 rpm | 8.8:1 | Multipoint fuel injection |

| |

| 18N | 62 kW (84 PS) at 5400 rpm | 135 N⋅m (100 lb⋅ft) at 3000 rpm | 8.2:1 | Pierburg 2E3 |

| |

| E18NV | 62 kW (84 PS) at 5400 rpm | 143 N⋅m (105 lb⋅ft) at 2600 rpm | 9.2:1 | Pierburg 2EE |

| |

| C18NE | 74 kW (100 PS) at 5800 rpm | 140 N⋅m (100 lb⋅ft) at 3000 rpm | 8.9:1 | Multipoint fuel injection | (Bosch LU-Jetronic) | 1985.05–1986.08 Opel Ascona C

Opel Kadett E |

| C18NZ | 66 kW (90 PS; 89 hp) at 5400 rpm | 145 N⋅m (107 lb⋅ft) at 3000 rpm | 9.2:1 | Monopoint fuel injection | (Multec) |

|

| LH8 | 63 kW (84 hp) at 5200 rpm | 138 Nm (102 lb-ft) at 2800 rpm | 9:1 | Throttle-body fuel injection |

| |

| LA5 | 112 kW (150 hp) at 5600 rpm | 204 NM (150 lb-ft) at 2800 rpm | 8:1 | Multi-port fuel injection

turbocharged |

|

2.0

[edit]The single overhead camshaft 1,998 cc (121.9 cu in) inline four cylinder engines feature a square 86 mm (3.4 in) bore and stroke. They also feature fuel injection, an aluminium crossflow cylinder head with a belt-driven overhead camshaft, electronic ignition, a six-bolt flywheel, and a 6,400 rpm redline. Originally, developed by Opel, these engines have been used in Brazilian market vehicles, Korean market vehicles and North American market vehicles; with the first versions appearing in 1981,[1] although did not start appearing in European Opel/Vauxhall models until 1986 – firstly in the Omega A and then in the facelift Ascona C3 for the 1987 model year.

The North American versions were used primarily in the J-body compact cars from 1983 through 1994 although the turbocharged version did make a brief appearance in the N-body Pontiac Grand Am. The SOHC version also appeared in the Opel Kadett E-based, Daewoo produced, Pontiac LeMans for the US market. In the Brazilian market these engines are still built under the FlexPower name. Differences between the engines are usually emissions related. However, the 20SEH version was more powerful version produced for Opel's sportier models such as the Ascona GT and Kadett GSi, (their corresponding Vauxhall sisters being the Cavalier SRi 130 and the Astra GTE); it featured a more aggressive camshaft, and high compression pistons.

The LT3 (RPO code) or C20GET is a turbocharged version produced in Brazil for the North American market.[7] It featured brilliant red powder coating on the camshaft cover, intake manifold and boost pipe. The engine was equipped with a water-cooled Garrett T-25 turbocharger; however it did not use an intercooler. Maximum boost at WOT was 9 psi (62 kPa).[9]

| Engine | Power | Torque | Compression Ratio | Fuel Delivery | Engine Management | Applications |

|---|---|---|---|---|---|---|

| 20LE |

| |||||

| 20NE | 115 PS (85 kW) at 5200 rpm | 175 N⋅m (129 lb⋅ft) at 2600 rpm | 9.2:1 | Multipoint fuel injection | Motronic ML 4.1 |

|

| 20SE | 122 PS (90 kW) at 5400 rpm | 175 N⋅m (129 lb⋅ft) at 2600 rpm | 10.0:1 | Multipoint fuel injection | Motronic ML 4.1 | |

| 20SEH | 127–130 PS (93–96 kW) at 5600 rpm | 180 N⋅m (130 lb⋅ft) at 4600 rpm | 10.0:1 | Multipoint fuel injection |

|

|

| C20NE | 115 PS (85 kW) at 5200 rpm | 170 N⋅m (130 lb⋅ft) at 2600 rpm | 9.2:1 | Multipoint fuel injection |

|

|

| X20SE | 115 PS (85 kW) at 5200 rpm | 178 N⋅m (131 lb⋅ft) at 2800 rpm | 10.0:1 | Multipoint fuel injection | Motronic M1.5.4 | Opel Omega |

| LT2 | 96 hp (72 kW) | 160 N⋅m (118 lb⋅ft) | Throttle body fuel injection |

| ||

| LE4 | 110 hp (82 kW) at 5200 rpm | 167 N⋅m (123 lb⋅ft) at 3600 rpm | Multi-Port Fuel Injection | 1992–1994 Pontiac Sunbird | ||

| LT3[9] | 165 hp (123 kW) at 5600 rpm | 175 lb⋅ft (237 N⋅m) at 4000 rpm | 8.0:1 | Multi-Port Fuel Injection |

|

2.2

[edit]The 2.2 L or 2,198 cc (134.1 cu in) version has an 86mm (3.38 in) bore and a 94.6mm (3.7 in) stroke. It is codenamed C22NE and 22LE.

It was mainly used in the Brazilian market, in the Opel Omega A (Chevrolet Omega in Brazil) with 116 hp and the Opel Vectra B (Chevrolet Vectra in Brazil) with 123 hp. This engine replaced the 2.0 8v C20NE (116 hp) version that was considered weak when fitted to cars like Omega and Vectra, by the Brazilian market, however 2.2L Omega A's for the European market continued to use the older CIH engine, rather than the Family II.

Applications:

- Isuzu Faster

- FS Lublin, modified C22NED engine

2.4

[edit]The 2,405 cc (146.8 cu in) version has an 87.5 mm (3.44 in) bore and a 100 mm (3.9 in) stroke.

- C24SE – 2.4 L SOHC – Isuzu Rodeo (C24SE built by Holden)

- X24XF— 2.4 L MPFI SOHC 8V FlexPower

DOHC

[edit]| DOHC | |

|---|---|

C20LET "Red Top" engine fitted to an Opel Kadett E GSi (Vauxhall Astra Mk2 GTE) | |

| Overview | |

| Manufacturer | General Motors |

| Also called | "Red Top"/ XE TWIN-TEC Ecotec |

| Production | 1987–2014 |

| Layout | |

| Displacement |

|

| Cylinder bore |

|

| Piston stroke |

|

| Valvetrain | Double overhead cam |

| Combustion | |

| Fuel system | Multi-port fuel injection |

| Fuel type | Gasoline |

The first naturally aspirated DOHC 16-valve version of the 2.0 L— 1,998 cc (121.9 cu in)—cast-iron-block engine was introduced in 1988 – derived from the SOHC 2.0L (20SEH) engines (appearing first in the Opel Kadett E GSi/Vauxhall Astra Mk2 GTE, and later the Opel Vectra A/Vauxhall Cavalier Mk3 GSi 2000) – coming in either non-catalysed (20XE) or catalysed (C20XE) versions. The engine is commonly nicknamed the Red Top (or just "XE") because of the appearance of the red L-shaped spark plug cover (black colours were available too; the rocker cover was available in silver only).[11]

1994 saw the introduction of the Ecotec series – which again consisted of a DOHC 16-valve cylinder head (this time co-developed with Lotus) mounted atop a development of the Family II block. The 2-liter versions therefore became the X20XEV, now producing 136 hp (101 kW) and taking on the GM Ecotec name. In its final, 1999 iteration, it became the X20XER. unlike the original 20XE/C20XE these were intended more for mainstream application (as opposed to racing and high-performance applications) in response to tightening emissions standards, and to reflect the overall family car market moving towards multivalve technology as was being increasingly found in competing vehicles.

Again, these engines have no commonality with the later GM Ecotec engine introduced in 1999, and first used in the Opel Vectra B, which are to a completely different design to the Family II.

Coscast

[edit]This lineup features the same block as the SOHC engines with an 86 mm (3.4 in) bore and stroke and a Cosworth-developed timing belt-driven double overhead camshaft (DOHC) 16 valve cylinder head (Cosworth Project KB). The cylinder heads were cast and assembled by either Cosworth or, as demand increased, Kolbenschmidt. In general, the heads from this lineup are supposed to flow appreciablу better than their Lotus successors.

The 20XE came into production in 1987. The engine was designed by Cosworth, UK. The engine was originally intended for race application, hence Cosworth's involvement.[12] At the time of its launch, this engine was something of a milestone unit in Europe and was widely used in motorsport in many specialist race versions.

The engine had a low optimum specific fuel consumption of 232 g/kWh which is equivalent to a maximum efficiency of 37%; a better efficiency than some of the diesel engines that were available at the time of its release. The valves are set at 46° and are accompanied by pistons with shallow valve pockets – thereby eliminating the need for a shorter connecting rod hence, allowing a suitable compression ratio to be achieved. Long spark plugs are used and positioned concentric to the cylinder. Power output was rated at 157 bhp. The later engine were suffixed C20XELN to indicate "Low Noise" revisions (smaller cylinder head port, cast pistons, and different crank bearing size) in line with EU regulations

In 1988 the C20XE was introduced, and was fitted with a catalyst and oxygen sensor in the exhaust. This was due to new emission standards, which forced manufacturers to equip their cars with a catalytic converter and a lambda or oxygen sensor – this requirement permitted the fitment of the Bosch Motronic 2.5 engine management system. Engine power output dropped to 150 PS (110 kW). Vauxhall complied with the new emission controls in 1988, although the legislation wasn't law until 1991. Vehicles fitted with the C20XE engine produced before 1991 can have their catalytic converter legally removed, and the vehicle will still comply with MOT regulations.

The C20LET engine was introduced in 1992, and was fitted to the Opel/Vauxhall Vectra Turbo/Cavalier Turbo, Calibra Turbo, and the South African made Opel Astra 200t S. It is similar to the C20XE, apart from the primary addition of a KKK-16 turbocharger,[13] forged Mahle pistons, Bosch Motronic M2.7 electronic engine control unit,[13] and black plastic plenum/'top hat' shroud with a "turbo" script. It produces a DIN rated output of 150 kW (201 hp), and generates 280 newton-metres (207 lbf⋅ft) of torque.[13] Boost pressure is 0.6 bars (8.7 psi) continuous with a 0.8 bars (12 psi) overboost.

Some versions of the engine implemented switchable Traction Control (commonly included in the early Astra GSi models). The inlet had a secondary throttle valve sandwiched underneath the primary throttle body. This is closed by a motor/arm assembly when the traction control ECU senses loss of grip/spin at the wheels. The engine was also equipped with a different throttle position sensor (six pin, as opposed to three), and a different coolant temperature sensor (which was black, as opposed to the normal light blue colour).

The engines that appeared in the early 1990s also swapped the cast metal spark plug cover for a cheaper (and less regarded) plastic version. Those used round tooth cambelts while the later used square (with a plastic pre-tensioner). There are also subtle differences between the crankshaft, and visible difference in the pattern of the SFi airbox.

In its last version before production ended, the C20XE came with a new engine management system which included a distributorless ignition system, namely Bosch Motronic 2.8. The last version was called C20LN (Low Noise) and has a stronger engine block.

Porosity issues

[edit]In 1991, the Coscast cylinder head was replaced with the GM cylinder head which was manufactured by Kolben-Schmidt.[14][15] One of the most prominently recognized qualities of the Coscast head is its inherent lack of porosity; this was achieved by pumping the liquid metal into the mold rather than pouring it, hence, minimizing the presence of tiny air bubbles that usually form during the standard casting process. The Coscast head can be identified by a Coscast logo which is stamped under the 3rd exhaust port and a ridge on the head under the distributor.

The GM head was a poured casting, and featured a slightly different oil/water gallery design. These design changes required that a pair of Welch plugs be pressed in at either end of the head. In situations where a complete C20XE is still fitted to a vehicle, the presence of Welch plugs (or lack of) has proven to be the sole means of differentiating between GM and Coscast heads. A reinforced version of the GM head became available in the later years of the C20XE; however, these reinforcements meant that it had smaller inlet/exhaust channels than the other two.[16]

Since an engine's oil circulates at much higher pressures than its coolant, oil in a porous head has a tendency to gradually seep into the coolant galleries. A typical symptom of a porous head is usually a 'mayonnaise'-like substance forming somewhere inside the cooling system (usually, this can be found residing on the coolant reservoir cap). However, depending on the degree of porosity, symptoms of a porous head have a tendency to vary. Many C20XE operators have described the symptom as a curry-like residue or in more severe cases, a thick brown sludge which may overcome the entire cooling system. In such instances, engine oil will readily react with the sulfur in rubber components, hence quickly degrading coolant pipes and hoses to the point of failure. During the porous head debacle, GM faced bankruptcy – therefore dealers failed to recall affected models. Due in part, to the engine's immense prominence and demand, many businesses now specialize in the repair of porous GM C20XE/LET heads – by either sleeving the affected gallery or by injecting a polymer based substance into the porous region. Reportedly, a small number of total GM C20XE cylinder heads ever exhibited significant symptoms of porosity.[17]

Motorsport

[edit]The C20XE has seen extensive use in motorsport. Typical uses for the engine have ranged from hillclimb events, to open wheel racing categories. Despite its age, it remains the powerplant of choice for many Formula 3 teams and has most recently found acclaim in the Australian F3 scene where Tim Macrow, the 2007 Australian F3 champion, drove an Opel-Spiess powered car to claim victory. Tuned by Spiess, an F3 grade C20XE is easily capable of producing 250 bhp (190 kW) in its naturally aspirated form. Many aftermarket tuners have further developed the C20XE for racing purposes. The C20XE was used by the Chevrolet WTCC (World Touring Car Championship) team and the Lada WTCC team. The engine was also an option in Westfield kitcars. The engine is a favourite for both N/A and turbo motoring enthusiasts for its robust design, materials and construction

| Engine | Power | Torque | Compression Ratio | Fuel Delivery | Engine Management | Applications |

|---|---|---|---|---|---|---|

| 20XE | 115 kW (156 PS) | 203 N⋅m (150 lb⋅ft) | 10.5:1 | Sequential multi-port fuel injection | Bosch Motronic 2.5 (no catalytic converter) | Opel Kadett Opel Vectra |

| C20XE | 110 kW (150 PS) at 6000 rpm | 196 N⋅m (145 lb⋅ft) at 4600 rpm | 10.5:1 | Sequential multi-port fuel injection |

|

|

| C20LET | 150 kW (204 PS) at 5600 rpm | 280 N⋅m (207 lb⋅ft) at 2400 rpm | 9.0:1 | Sequential multi-port fuel injection | Bosch Motronic 2.7 |

|

Ecotec branded models (in association with Lotus)

[edit]1.8

[edit]The X18XE was branded as Ecotec. All these engines feature an 81.6 mm (3.21 in) bore and an 86.0 mm (3.39 in) stroke.

2.0

[edit]The X20XEV is the first Family II engine branded as Ecotec, a mass-market successor to the C20XE with a Lotus-developed cylinder head. The new cylinder head had a smaller valve angle compared to the older C20XE, to give more torque in the lower revs. It is a 1,998 cc (121.9 cu in) naturally aspirated engine with 16 valves and belt driven double overhead camshafts (DOHC). 86 mm (3.4 in) bore and stroke in cast-iron OHC-derived cylinder block and aluminium cylinder head. The X20XEV was equipped with exhaust gas recirculation (EGR) to reduce nitrogen dioxide emissions and air injection reactor (AIR) to speed up the warming up of the catalytic converter and to reduce unburnt hydrocarbons and carbon monoxide. The engine is rated at 100 kW (136 PS; 134 bhp).[18] A higher output version called the X20XER produced 118 kW (158 hp) at 6500 rpm and 188 N⋅m (139 lb⋅ft) at 4300 rpm.

The Z20LET is a turbocharged version of the X20XEV for the Opel Astra G and features an 8.8:1 compression, 200 PS (147 kW; 197 hp) and 195 lb⋅ft (264 N⋅m) of torque. From 2005, the Z20LET engine was revised for the Astra H and Zafira B, to three different model designations, Z20LEL, Z20LER and Z20LEH. The differing designations denote the engine power output, 170 PS (125 kW; 168 hp), 200 PS (147 kW; 197 hp) and 240 PS (177 kW; 237 hp). Further revisions to the original design include under-piston oil cooling, a revised turbocharger unit and the deletion of the contra-rotating balancer shafts in the 240 hp (179 kW) Z20LEH engine (as used in the Astra VXR), to reduce mechanical losses. The Z20LEH also features high quality Mahle forged pistons, which are much stronger than the cast pistons fitted to the Z20LET, Z20LEL and Z20LER.

The 2.0-litre X20SED D-TEC 16 Valve DOHC MPFi was built by Holden and used in the Daewoo Nubira.

The L34 also known as the U20SED is a 2.0 L (1,998 cc (121.9 cu in)) engine that was built until 2009 by Holden in Australia, dubbed D-TEC by GMDAT (the new Daewoo after the buyout from GM) or E-TEC II by Chevrolet (GM). It has an 86.0 mm (3.39 in) bore and stroke. Power is rated at 120 PS (88 kW; 118 hp) in South America and Europe, 126 hp (94 kW; 128 PS) in Canada, and 132 hp (98 kW; 134 PS) in the United States; all are at 5400 rpm and torque is rated at 126 lb⋅ft (171 N⋅m). The engine has been used on the Daewoo Lacetti and its various rebadged models, such as the Chevrolet Optra, Suzuki Reno, and Suzuki Forenza.

This engine was discontinued in 2010 and new generation open deck engines replaced starts with a prefix of the letter A e.g. A20NHT A20NHH A20NFT….

| Engine | Power | Torque | Compression Ratio | Fuel Delivery | Engine Management | Applications |

|---|---|---|---|---|---|---|

| X20XEV | 136 PS; 134 hp (100 kW) | 185 Nm at 4000 rpm | 10.8:1 | Siemens Simtec 56.1/56.5/70 |

| |

| X20XER | 160 PS (118 kW; 158 hp) | 188 N⋅m (139 lb⋅ft) at 4300 rpm | 10.8:1 | Siemens Simtec 70 |

| |

| Z20LET | 200 PS (147 kW; 197 hp) | 267 N⋅m (197 lb⋅ft) | 8.8:1 | Sequential multi-port fuel injection | Bosch Motronic ME1.5.5 |

|

| Z20LEL | 170 PS (125 kW; 168 hp) | 262 N⋅m (193 lb⋅ft) | 8.8:1 | Sequential multi-port fuel injection | Bosch Motronic ME7.6 |

|

| Z20LER | 200 PS (147 kW; 197 hp) | 262 N⋅m (193 lb⋅ft) | 8.8:1 | Sequential multi-port fuel injection | Bosch Motronic ME7.6 |

|

| Z20LEH | 240 PS (177 kW; 237 hp) | 320 N⋅m (236 lb⋅ft) | 8.8:1 | Sequential multi-port fuel injection | Bosch Motronic ME7.6 |

|

| X20SED | Multi-port fuel injection |

| ||||

| U20SED (L34) | 119–132 hp (89–98 kW) at 5400 rpm | 126 lb⋅ft (171 N⋅m) |

|

2.2

[edit]The 2.2 L engine was a derivative of the GM Family II engine introduced in 1995 built by Holden in Australia that saw usage first in Australian and European versions of Isuzu-derived trucks and SUVs, and was later used in the Isuzu Rodeo and Daewoo Leganza. The X22XE was also used in the Opel/Vauxhall Sintra (1996–1999). The 2.2-liter shares many details together all listed below:

- Bore: 86.0 mm

- Stroke: 94.6 mm

- Volume: 2198 cc

X22XE

- Power: 100 kW (136 hp) at 5,200 rpm, 104 kW (141 hp) at 5400 rpm (Sintra)

- Torque: 202 N⋅m (149 lb⋅ft) at 2,600 rpm

- Compression ratio: 10.5:1

- Engine management: Bosch Motronic M 1.5.4

- Octane requirement: 91/95/98, with knock control

- Control: timing belt

- Exhaust system: AGR, regulated catalytic

- Properties: balance shafts

Y22XE (used on Omega, 1999–2003)

- Power: 107 kW (145 hp) at 5,400 rpm

- Torque: 205 N⋅m (151 lb⋅ft) at 4,000 rpm

- Compression ratio: 10.5:1

- Engine management: Siemens Simtec 71

- Octane requirement: 91/95/98, with knock control

- Control: timing belt

- Exhaust system: AGR, regulated catalytic

- Properties: balance shafts, electronic throttle, cruise control

Z22XE (used on Omega, 1999–2003)

- Specifications as Y22XE, but meets Euro IV emissions regulations.

Further applications:

- Isuzu Faster

- Isuzu MU/Isuzu Amigo (1995–2004)

- Opel/Vauxhall Frontera (1998–2004)

- Honda Passport (1998–2002)

- Opel Omega

- Opel Blazer (Indonesian market)

2.4

[edit]- X24SFD—2.4 L (2405 cc) SFI DOHC 16V – Chevrolet Astra, Chevrolet Vectra

- 150 hp at 5200 rpm

- 228 Nm at 4000 rpm

- Z24XE—2.4 L (2405 cc) DOHC – Chevrolet Captiva, Opel Antara (2006–2010), this engine was built by Holden until 2009. The 2006 Chevrolet Vectra also received a 2.4 L 16V FlexPower engine.

- 100–103 kW (136–140 hp) at 5200 rpm

- 220 N⋅m (160 lb⋅ft) at 2200 rpm

See also

[edit]References

[edit]- ^ a b "Werk Kaiserslautern. Zahlen und Fakten". Retrieved 29 December 2014.

- ^ "Holden stops Family II engine Production". Zer Customs. Retrieved 23 May 2014.

- ^ "GM do Brasil Milestones: 1980 – 1989". Retrieved 29 December 2014.

- ^ "Werk Kaiserslautern. Zahlen und Fakten" [Kaiserslauten plant: Data and facts] (in German). Opel AG. Retrieved 23 May 2014.

- ^ "Astra-Cavalier Product Guide". Archived from the original on 26 July 2014. Retrieved 18 July 2014.

- ^ Isakson, Börje, ed. (22 September 1982). "Kadett Diesel nu i Sverige" [Kadett Diesel now in Sweden]. Teknikens Värld (in Swedish). Vol. 34, no. 20. Stockholm, Sweden: Specialtidningsförlaget AB. p. 55.

- ^ a b Yoffie, David B. (May 1993). Beyond free trade : firms, governments, and global competition. Boston, Mass.: Harvard Business School Press. p. 221. ISBN 978-0875843445. Retrieved 30 July 2014.

- ^ "Motoroversigt. Opel Benzin- og Diesel-motorer ('57–'86)" (PDF). Retrieved 29 December 2014.

- ^ a b "DaRkMuCk's GM LT3 Engine Website". Lt3engine.i8.com. Archived from the original on 4 March 2016. Retrieved 4 June 2012.

- ^ "Modules – Liste". ODB-2 Website. 2005. Archived from the original on 13 February 2012. Retrieved 25 May 2008.

- ^ "C20XE conversion list". Robbie's Manta Site. Archived from the original on 8 October 2007. Retrieved 5 July 2007.

- ^ "Interview with Dr Fritz indra" (PDF). CalibraWiki.com. Retrieved 13 April 2008.

- ^ a b c "Vauxhall Cavalier Turbo information". The Cavalier Turbo Owner's Register. Archived from the original on 4 March 2016. Retrieved 3 November 2009.

- ^ "Benefits of Coscast head". Retrieved 15 November 2010.

- ^ "What engines are affected with porous heads". Archived from the original on 19 December 2017. Retrieved 15 November 2010.

- ^ "Detailed GM & Cosworth difference photos". Vauxsport. Archived from the original on 30 April 2012. Retrieved 13 April 2008.

- ^ "Porous GM Head Info". Scoobler. Archived from the original on 18 April 2008. Retrieved 22 April 2008.

- ^ Vauxhall, "Vauxhall Calibra DTM Special Edition Sales Brochure", 1995.

- ^ Autopedia online – www.autopedia.net.au

GM Family II engine

View on GrokipediaHistory and Development

Origins and Introduction

The development of the GM Family II engine was initiated by Opel in the late 1970s as a modern overhead-camshaft straight-four design intended to replace the aging cam-in-head (CIH) engines used in Opel models and the Vauxhall Slant-4 powerplants in British GM vehicles.[4][5] This new engine family addressed the automotive industry's pressing needs during that era, including enhanced fuel efficiency to counter the effects of the 1970s oil crises and stricter emissions regulations across Europe and North America that foreshadowed later unified Euro standards. Central to its conception was a modular architecture allowing for displacements ranging from 1.6 liters to 2.4 liters, enabling adaptability across various GM platforms while maintaining a common block and head design for cost-effective production and tuning.[6][7] The Family II engine debuted in 1981, shortly after the Frankfurt Motor Show, powering the Opel Kadett D and signifying GM's transition to transverse-mounted configurations in front-wheel-drive vehicles—a departure from the rear-drive layouts of prior Kadett generations. The initial variant, a 1.6-liter single overhead camshaft (SOHC) unit coded 16SH, delivered 90 horsepower and set the foundation for the engine family's widespread adoption.[7][8]Production Timeline and Locations

The GM Family II engine entered production in 1981, with initial manufacturing centered at the Opel facility in Rüsselsheim, Germany, to serve European markets.[9] That same year, General Motors-Holden opened a dedicated $300 million engine plant at Fishermans Bend in Melbourne, Australia, producing the cast-iron block engines primarily for local, Asian, and export applications.[10] Production of SOHC variants continued at Fishermans Bend until late 2009, by which point nearly five million units had been built there, including over four million for export.[11] Meanwhile, DOHC versions were produced at GM's São José dos Campos plant in Brazil, supporting South American models with region-specific modifications, until they were largely replaced by the Ecotec family in the early 2000s.[12] The manufacturing footprint evolved from its European origins to include Australian expansion for right-hand-drive and export efficiency, followed by Brazilian localization to address fuel flexibility needs, such as the 2004 introduction of the 2.0 L MultiPower variant at São José dos Campos, designed for compatibility with gasoline, ethanol, or natural gas.[12] Following its phase-out, the engine was succeeded by the all-aluminum Ecotec family.Design and Features

Core Architecture

The GM Family II engine employs an inline-four cylinder configuration, featuring a cast iron block for structural integrity and an aluminum cylinder head to reduce weight while maintaining thermal efficiency. This fundamental design allows for a compact layout suitable for transverse mounting in front-wheel-drive vehicles, such as the Opel Kadett and Chevrolet Cavalier models where the engine debuted in 1979.[13] Displacements across the Family II variants are achieved through variations in bore and stroke dimensions, enabling a range from 1.6 liters to 2.4 liters while sharing the same basic architecture. For instance, the 1.6-liter version measures 80 mm bore by 79.5 mm stroke, yielding 1,598 cc, as implemented in the 1979 Opel Kadett. At the upper end, the 2.4-liter displacement uses 87.5 mm bore by 100 mm stroke for 2,405 cc, applied in applications like the Isuzu Rodeo. These adjustments allow flexibility in power output and application without altering the core block design.[14][12] The cooling system is water-cooled, with a centrifugal pump driven by the timing belt to ensure reliable circulation of coolant through the block and head passages. This belt-driven setup integrates the water pump with the valvetrain timing components, simplifying maintenance and reducing accessory drive complexity in the transverse FWD orientation. The system includes a thermostat-controlled flow and radiator integration optimized for compact engine bays in passenger cars.[15] Compression ratios vary by variant and fuel type to optimize performance and efficiency, typically ranging from 8.0:1 to 10.5:1 for gasoline applications, as seen in the 9.2:1 ratio of the 1.6-liter SOHC unit. Diesel variants, such as the 1.6-liter 16D producing 54 hp, employ higher ratios around 23:1 to support compression ignition, though these remain within the shared block architecture. These ratios are tuned via piston crown design and head gasket thickness, influencing fuel economy and emissions compliance across global markets.[14][16]Valvetrain and Cylinder Head Variants

The GM Family II engine employs overhead camshaft valvetrain designs in both single overhead camshaft (SOHC) and double overhead camshaft (DOHC) configurations, with corresponding cylinder head variants tailored for efficiency and performance. The SOHC setup utilizes an 8-valve aluminum cylinder head actuated by a single camshaft driven by a timing belt, prioritizing simplicity and fuel economy in base applications. It features hydraulic bucket tappets for reduced maintenance.[17][18] The SOHC valvetrain, introduced in 1979 with the Opel Kadett D, powered economy-oriented models such as the Opel Ascona C from 1981, where the timing belt also drives the water pump for integrated accessory operation.[17] In contrast, the DOHC configuration features a 16-valve aluminum cylinder head with dual camshafts, enabling higher rev limits and improved airflow for sportier variants.[19] The DOHC design debuted in 1987 under the 20XE engine code, initially with solid lifters before transitioning to hydraulic lifters in subsequent iterations for reduced maintenance and noise. All variants use aluminum cylinder heads for weight savings and heat dissipation, paired with a cast-iron block.[19] DOHC models are interference engines, where timing belt failure can result in severe piston-valve contact; thus, replacement is recommended every 60,000 miles to maintain reliability.[20][21] SOHC variants share the belt-driven timing system but operate as non-interference designs in most applications.[21]SOHC Models

1.6 L

The 1.6 L version of the GM Family II engine, with a displacement of 1,598 cc, features a bore of 80.0 mm and a stroke of 79.5 mm, making it the smallest petrol variant in the SOHC lineup designed for economy-focused applications. This engine, introduced in 1980, was primarily used in entry-level compact vehicles to provide reliable performance with modest fuel consumption.[22] Standard compression ratio stands at 9.2:1, supporting efficient operation on regular unleaded fuel.[23] Key variants include the carbureted 16SH code, which delivers 89 hp (66 kW) at 5,800 rpm and 93 lb-ft (126 Nm) of torque at 3,400 rpm, equipped with a GM Varajet II carburetor for straightforward fueling.[23] The 16LH and 16SV codes represent transitional and later iterations, with power outputs ranging from 75 to 82 hp at around 5,800 rpm and torque between 99 and 128 Nm, reflecting minor tuning differences for regional markets.[24] By 1987, the lineup evolved to include multi-point fuel injection in select versions, improving throttle response and emissions compliance while maintaining the core cast-iron block design shared with larger Family II engines.[1] A diesel variant, coded 16D and introduced in 1983, offers a displacement of 1,598 cc with indirect injection, producing 54 hp (40 kW) at 4,600 rpm and suitable for low-rev torque in fuel-efficient models. This version, with a higher compression ratio of around 23:1, emphasizes durability and economy over performance.[16]| Variant Code | Fuel System | Power | Torque | Notes |

|---|---|---|---|---|

| 16SH | Carbureted | 89 hp @ 5,800 rpm | 93 lb-ft @ 3,400 rpm | Standard petrol, 9.2:1 compression[23] |

| 16LH/16SV | Carbureted/Injection | 75-82 hp @ 5,800 rpm | 99-128 Nm | Economy-oriented, evolved to MPFI by late 1980s[24] |

| 16D | Diesel Injection | 54 hp @ 4,600 rpm | ~96 Nm @ 2,400 rpm | 1,598 cc, introduced 1983[25] |

1.7 L

The 1.7 L variant of the GM Family II engine is exclusively a diesel powerplant, featuring a displacement of 1,700 cc and engine codes 17D or 17DR, with indirect injection via a Bosch VE mechanical pump. It delivers power outputs ranging from 54 to 57 hp at 4,600 rpm and torque between 96 and 105 Nm at 2,400 rpm, emphasizing low-end usability for economy-oriented applications.[26] This configuration utilizes a cast-iron block and aluminum head, paired with the SOHC valvetrain for efficient operation in compact vehicles.[27] Introduced in 1984 for the Opel Kadett E and Ascona C models, the 1.7 L diesel was developed to prioritize fuel efficiency, achieving up to 50 mpg (US) on highway cycles in contemporary evaluations, making it suitable for European markets facing rising fuel costs.[27][28] The engine's bore measures 82 mm and stroke 79.5 mm, contributing to its design that supports the high compression ratio of 22:1, optimized for naturally aspirated indirect injection to balance emissions and performance.[12][26] No gasoline version of the 1.7 L displacement was produced within the Family II lineup, distinguishing it from smaller and larger petrol variants. In the 1990s, limited turbocharged diesel experiments based on this architecture, such as the X17DTL variant producing 67 hp and 132 Nm, were explored but saw minimal production adoption.[29]1.8 L

The 1.8 L single overhead camshaft (SOHC) variant of the GM Family II engine displaces 1,796 cc and features a bore of 84.8 mm and a stroke of 79.5 mm.[30] Introduced in 1982 for European markets, it was produced with engine codes such as 18E for multi-point fuel injection versions and 18SV for carbureted models.[31] Power output ranged from 84 hp in emissions-controlled variants to 110 hp in higher-tune configurations, with torque between 137 Nm and 158 Nm, making it suitable for mid-range compact and midsize vehicles.[32] By 1990, multi-point fuel injection became standard across applications, improving efficiency and drivability over earlier carbureted setups.[30]| Variant | Displacement | Bore × Stroke | Power Range | Torque Range | Fuel System | Key Features |

|---|---|---|---|---|---|---|

| SOHC (18E/18SV) | 1,796 cc | 84.8 mm × 79.5 mm | 84–110 hp | 137–158 Nm | Carburetor or multi-point injection | Introduced 1982; mid-range use |