Recent from talks

Nothing was collected or created yet.

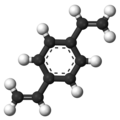

Divinylbenzene

View on Wikipedia | |||

| |||

| Names | |||

|---|---|---|---|

| Other names

Diethylene benzene, DVB, Vinylstyrene

| |||

| Identifiers | |||

3D model (JSmol)

|

|||

| ChemSpider | |||

| ECHA InfoCard | 100.013.932 | ||

| EC Number |

| ||

PubChem CID

|

|||

| RTECS number |

| ||

| UNII |

| ||

| UN number | 3532 3534 | ||

CompTox Dashboard (EPA)

|

|||

| |||

| |||

| Properties | |||

| C10H10 | |||

| Molar mass | 130.190 g·mol−1 | ||

| Appearance | pale, straw-colored liquid[1] | ||

| Density | 0.914 g/mL | ||

| Melting point | −66.9 to −52 °C (−88.4 to −61.6 °F; 206.2 to 221.2 K) | ||

| Boiling point | 195 °C (383 °F; 468 K) | ||

| 0.005% (20°C)[1] | |||

| Solubility in other solvents | Soluble in ethanol and ether | ||

| Vapor pressure | 0.7 mmHg (20°C)[1] | ||

| Hazards | |||

| Flash point | 76 °C (169 °F; 349 K) | ||

| Explosive limits | 1.1%-6.2%[1] | ||

| NIOSH (US health exposure limits): | |||

PEL (Permissible)

|

none[1] | ||

REL (Recommended)

|

TWA 10 ppm (50 mg/m3)[1] | ||

IDLH (Immediate danger)

|

N.D.[1] | ||

Except where otherwise noted, data are given for materials in their standard state (at 25 °C [77 °F], 100 kPa).

| |||

Divinylbenzene (DVB) is an organic compound with the chemical formula C6H4(CH=CH2)2 and structure H2C=CH−C6H4−HC=CH2 (a benzene ring with two vinyl groups as substituents). It is related to styrene (vinylbenzene, C6H5−CH=CH2) by the addition of a second vinyl group.[2] It is a colorless liquid manufactured by the thermal dehydrogenation of isomeric diethylbenzenes. Under synthesis conditions, o-divinylbenzene converts to naphthalene and thus is not a component of the usual mixtures of DVB.[3]

Production and use

[edit]It is produced by dehydrogenation of diethylbenzene:

- C6H4(C2H5)2 → C6H4(C2H3)2 + 2 H2

Divinylbenzene is usually encountered as a 2:1 mixture of m- and p-divinylbenzene, containing also the corresponding isomers of ethylvinylbenzene.

Styrene and divinylbenzene react to form the copolymer styrene-divinylbenzene, S-DVB or Sty-DVB. The resulting cross-linked polymer is mainly used for the production of ion exchange resin and Merrifield resins for peptide synthesis.[3]

Nomenclature

[edit]- Ortho: variously known as 1,2-diethenylbenzene, 1,2-divinylbenzene, o-vinylstyrene, o-divinylbenzene

- Meta: known as 1,3-diethenylbenzene, 1,3-divinylbenzene, m-vinylstyrene, m-divinylbenzene

- Para: known as 1,4-diethenylbenzene, 1,4-divinylbenzene, p-vinylstyrene, p-divinylbenzene.

These compounds are systematically called diethenylbenzene, although this nomenclature is rarely encountered.

References

[edit]- ^ a b c d e f g NIOSH Pocket Guide to Chemical Hazards. "#0248". National Institute for Occupational Safety and Health (NIOSH).

- ^ CRC Handbook of Chemistry and Physics 65Th Ed.

- ^ a b Denis H. James William M. Castor, "Styrene" in Ullmann's Encyclopedia of Industrial Chemistry, Wiley-VCH, Weinheim, 2005. doi:10.1002/14356007.a25_329.pub2.

.png/250px-Divinylbenzene_(structural_diagram).png)

.png)