Recent from talks

Nothing was collected or created yet.

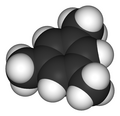

Mesitylene

View on Wikipedia

| |||

| Names | |||

|---|---|---|---|

| Preferred IUPAC name

1,3,5-Trimethylbenzene[1] | |||

| Other names

Mesitylene[1]

sym-Trimethylbenzene | |||

| Identifiers | |||

3D model (JSmol)

|

|||

| ChEBI | |||

| ChemSpider | |||

| ECHA InfoCard | 100.003.278 | ||

| EC Number |

| ||

| KEGG | |||

PubChem CID

|

|||

| UNII | |||

| UN number | 2325 | ||

CompTox Dashboard (EPA)

|

|||

| |||

| |||

| Properties | |||

| C9H12 | |||

| Molar mass | 120.19 g/mol | ||

| Appearance | Colorless liquid[2] | ||

| Odor | Distinctive, aromatic[2] | ||

| Density | 0.8637 g/cm3 at 20 °C | ||

| Melting point | −44.8 °C (−48.6 °F; 228.3 K) | ||

| Boiling point | 164.7 °C (328.5 °F; 437.8 K) | ||

| 0.002% (20°C)[2] | |||

| Vapor pressure | 2 mmHg (20°C)[2] | ||

| −92.32·10−6 cm3/mol | |||

| Structure | |||

| 0.047 D[3] | |||

| Hazards | |||

| Flash point | 50 °C; 122 °F; 323 K[2] | ||

| NIOSH (US health exposure limits): | |||

PEL (Permissible)

|

none[2] | ||

REL (Recommended)

|

TWA 25 ppm (125 mg/m3)[2] | ||

IDLH (Immediate danger)

|

N.D.[2] | ||

| Safety data sheet (SDS) | [1] | ||

Except where otherwise noted, data are given for materials in their standard state (at 25 °C [77 °F], 100 kPa).

| |||

Mesitylene or 1,3,5-trimethylbenzene is a derivative of benzene with three methyl substituents positioned symmetrically around the ring. The other two isomeric trimethylbenzenes are 1,2,4-trimethylbenzene (pseudocumene) and 1,2,3-trimethylbenzene (hemimellitene). All three compounds have the formula C6H3(CH3)3, which is commonly abbreviated C6H3Me3. Mesitylene is a colorless liquid with sweet aromatic odor. It is a component of coal tar, which is its traditional source. It is a precursor to diverse fine chemicals. The mesityl group (Mes) is a substituent with the formula C6H2Me3 and is found in various other compounds.[4]

Preparation

[edit]Mesitylene is prepared by transalkylation of xylene over solid acid catalyst:[4]

- 2 C6H4(CH3)2 ⇌ C6H3(CH3)3 + C6H5CH3

- C6H4(CH3)2 + CH3OH → C6H3(CH3)3 + H2O

Although impractical, it could be prepared by trimerization of propyne, also requiring an acid catalyst, which yields a mixture of 1,3,5- and 1,2,4-trimethylbenzenes.

Trimerization of acetone via aldol condensation, which is catalyzed and dehydrated by sulfuric acid is another method of synthesizing mesitylene.[5]

Reactions

[edit]Oxidation of mesitylene with nitric acid yields trimesic acid, C6H3(COOH)3. Using manganese dioxide, a milder oxidising agent, 3,5-dimethylbenzaldehyde is formed. Mesitylene is oxidised by trifluoroperacetic acid to produce mesitol (2,4,6-trimethylphenol).[6] Bromination occurs readily, giving mesityl bromide:[7]

- (CH3)3C6H3 + Br2 → (CH3)3C6H2Br + HBr

Mesitylene is a ligand in organometallic chemistry, one example being the organomolybdenum complex [(η6-C6H3Me3)Mo(CO)3][8] which can be prepared from molybdenum hexacarbonyl.

Applications

[edit]Mesitylene is mainly used as a precursor to 2,4,6-trimethylaniline, a precursor to colorants. This derivative is prepared by selective mononitration of mesitylene, avoiding oxidation of the methyl groups.[9]

Niche uses

[edit]

Mesitylene is used in the laboratory as a specialty solvent. In the electronics industry, mesitylene has been used as a developer for photopatternable silicones due to its solvent properties.

The three aromatic hydrogen atoms of mesitylene are in identical chemical shift environments. Therefore, they only give a single peak near 6.8 ppm in the 1H NMR spectrum; the same is also true for the nine methyl protons, which give a singlet near 2.3 ppm. For this reason, mesitylene is sometimes used as an internal standard in NMR samples that contain aromatic protons.[10]

Uvitic acid is obtained by oxidizing mesitylene or by condensing pyruvic acid with baryta water.[11]

The Gattermann reaction can be simplified by replacing the HCN/AlCl3 combination with zinc cyanide (Zn(CN)2).[12] Although it is highly toxic, Zn(CN)2 is a solid, making it safer to work with than gaseous hydrogen cyanide (HCN).[13] The Zn(CN)2 reacts with the HCl to form the key HCN reactant and ZnCl2 that serves as the Lewis-acid catalyst in-situ. An example of the Zn(CN)2 method is the synthesis of mesitaldehyde from mesitylene.[14]

History

[edit]Mesitylene was first prepared in 1837 by Robert Kane, an Irish chemist, by heating acetone with concentrated sulfuric acid.[15] He named his new substance "mesitylene" because the German chemist Carl Reichenbach had named acetone "mesit" (from the Greek μεσίτης, the mediator),[16] and Kane believed that his reaction had dehydrated mesit, converting it to an alkene, "mesitylene".[17] However, Kane's determination of the chemical composition ("empirical formula") of mesitylene was incorrect. The correct empirical formula was provided by August W. von Hofmann in 1849.[18] In 1866 Adolf von Baeyer gave a correct mesitylene's empirical formula; however, with a wrong structure of tetracyclo[3.1.1.11,3.13,5]nonane.[19] A conclusive proof that mesitylene was trimethylbenzene was provided by Albert Ladenburg in 1874; however, assuming wrong benzene structure of prismane.[20]

- Historical mesitylene structures

-

Mesitylene by Adolf von Baeyer (tetracyclo[3.1.1.11,3.13,5]nonane)

-

Mesitylene by Albert Ladenburg (1,2,6-trimethylprismane)

Mesityl group

[edit]The group (CH3)3C6H2- is called mesityl (organic group symbol: Mes). Mesityl derivatives, e.g. tetramesityldiiron, are typically prepared from the Grignard reagent (CH3)3C6H2MgBr.[21] Due to its large steric demand, the mesityl group is used as a large blocking group in asymmetric catalysis (to enhance diastereo- or enantioselectivity) and organometallic chemistry (to stabilize low oxidation state or low coordination number metal centers). Larger analogues with even greater steric demand, for example 2,6-diisopropylphenyl (Dipp) and the analogously named Tripp ((iPr)3C6H2, Is) and supermesityl ((tBu)3C6H2, Mes*) groups, may be even more effective toward achieving these goals.

Safety and the environment

[edit]Mesitylene is also a major urban volatile organic compound (VOC) which results from combustion. It plays a significant role in aerosol and tropospheric ozone formation as well as other reactions in atmospheric chemistry.[citation needed]

References

[edit]- ^ a b Nomenclature of Organic Chemistry : IUPAC Recommendations and Preferred Names 2013 (Blue Book). Cambridge: The Royal Society of Chemistry. 2014. p. 139. doi:10.1039/9781849733069-FP001. ISBN 978-0-85404-182-4.

- ^ a b c d e f g h NIOSH Pocket Guide to Chemical Hazards. "#0639". National Institute for Occupational Safety and Health (NIOSH).

- ^ Zhao, Jun; Zhang, Renyi (2004). "Proton transfer reaction rate constants between hydronium ion (H3O+) and volatile organic compounds". Atmospheric Environment. 38 (14): 2177–2185. Bibcode:2004AtmEn..38.2177Z. doi:10.1016/j.atmosenv.2004.01.019.

- ^ a b Karl Griesbaum, Arno Behr, Dieter Biedenkapp, Heinz-Werner Voges, Dorothea Garbe, Christian Paetz, Gerd Collin, Dieter Mayer, Hartmut Höke “Hydrocarbons” in Ullmann's Encyclopedia of Industrial Chemistry 2002 Wiley-VCH, Weinheim. doi:10.1002/14356007.a13_227.

- ^ Cumming, W. M. (1937). Systematic organic chemistry (3E). New York, USA: D. Van Nostrand Company. p. 57.

- ^ Chambers, Richard D. (2004). "Functional Compounds Containing Oxygen, Sulphur or Nitrogen and their Derivatives". Fluorine in Organic Chemistry. CRC Press. pp. 242–243. ISBN 9780849317903.

- ^ Lee Irvin Smith (1931). "Bromomesitylene". Org. Synth. 11: 24. doi:10.15227/orgsyn.011.0024.

- ^ Girolami, G. S.; Rauchfuss, T. B. and Angelici, R. J., Synthesis and Technique in Inorganic Chemistry, University Science Books: Mill Valley, CA, 1999. ISBN 0-93570248-2.

- ^ Gerald Booth (2007). "Nitro Compounds, Aromatic". Ullmann's Encyclopedia of Industrial Chemistry. Weinheim: Wiley-VCH. doi:10.1002/14356007.a17_411. ISBN 978-3527306732.

- ^ "Mesitylene (1,3,5-Trimethyl Benzene)".

- ^ "Definition of uvitic acid". merriam-webster.com. Retrieved 31 October 2016.

- ^ Adams R.; Levine, I. (1923). "Simplification of the Gattermann Synthesis of Hydroxy Aldehydes". J. Am. Chem. Soc. 45 (10): 2373–77. doi:10.1021/ja01663a020.

- ^ Adams, Roger (1957). Organic Reactions, Volume 9. New York: John Wiley & Sons, Inc. pp. 38 & 53–54. doi:10.1002/0471264180.or009.02. ISBN 9780471007265.

{{cite book}}: ISBN / Date incompatibility (help) - ^ Fuson, R. C.; Horning, E. C.; Rowland, S. P.; Ward, M. L. (1955). "Mesitaldehyde". Organic Syntheses. doi:10.15227/orgsyn.023.0057; Collected Volumes, vol. 3, p. 549.

- ^ Robert Kane (1839) "On a series of combinations derived from pyroacetic spirit [acetone]" Transactions of the Royal Irish Academy, vol. 18, pages 99–125.

- ^ Reichenbach's research is excerpted in: C. Reichenbach (1834) "Ueber Mesit (Essiggeist) und Holzgeist" (On mesit (spirit of vinegar) and wood spirits), Annalen der Pharmacie, vol. 10, no. 3, pages 298–314.

- ^ For an explanation of the original of the name "mesitylene", see also: Henry E. Roscoe, A Treatise on Chemistry (New York, New York: D. Appleton and Co., 1889), vol. III, page 102, footnote 2.

- ^ A.W. Hofmann (1849) "On the composition of mesitilole [mesitylene], and some of its derivatives", The Quarterly Journal of the Chemical Society of London, vol. 2, pages 104–115. (Note: The empirical formula of mesitylene as stated in Hofmann's paper (C18H12 ) is incorrect; however, this happened because Hofmann used 6 as the atomic weight of carbon, instead of the correct atomic weight of 12. Once the correct atomic weight is used in Hofmann's calculations, his results give the correct empirical formula of C9H12.)

- ^ Adolf von Baeyer (1866) "Ueber die Condensationsproducte des Acetons" (On condensation products of acetone), Annalen der Chemie und Pharmacie, vol. 140, pages 297–306.

- ^ Albert Ladenburg (1874) "Ueber das Mesitylen" (On mesitylene), Berichte der deutschen chemischen Gesellschaft, vol. 7, pages 1133–1137. doi:10.1002/cber.18740070261

- ^ Lee Irvin Smith (1931). "Isoodurene". Org. Synth. 11: 66. doi:10.15227/orgsyn.011.0066.

Mesitylene

View on GrokipediaChemical Identity

Nomenclature

The preferred IUPAC name for mesitylene is 1,3,5-trimethylbenzene (CAS 108-67-8).[1] This compound is commonly referred to as mesitylene, a name coined by Irish chemist Robert Kane upon its first synthesis (prepared in 1837, published 1838) from acetone and sulfuric acid. The term derives from "mesityl," itself stemming from the early name "mesit" for acetone, which originates from the Greek mesitēs (μεσίτης), meaning "mediator," reflecting the compound's perceived intermediate role in chemical transformations and its symmetrical structure positioning it as a "middle" entity among aromatic hydrocarbons.[7][8] It is also known as sym-trimethylbenzene, emphasizing the symmetric placement of its three methyl groups. Other synonyms include the abbreviation 1,3,5-TMB. Mesitylene must be distinguished from the other trimethylbenzene isomers: 1,2,3-trimethylbenzene (hemimellitene) and 1,2,4-trimethylbenzene (pseudocumene).[1]Molecular Structure

Mesitylene has the chemical formula C₉H₁₂ and consists of a benzene ring with three methyl groups attached at the 1, 3, and 5 positions, creating a highly symmetric structure.[1] This arrangement imparts D_{3h} point group symmetry to the molecule, arising from its planar geometry, a principal C₃ rotation axis perpendicular to the ring, and horizontal mirror planes that include the molecular plane and bisect the ring.[9] Typical bond lengths in the structure include approximately 1.39 Å for the aromatic C-C bonds within the benzene ring and about 1.50 Å for the bonds connecting the ring carbons to the methyl groups, as determined from computational models.[1] The high symmetry results in a very small dipole moment of 0.10 D, rendering the molecule nearly nonpolar.[10] The positioning of the methyl groups introduces significant steric hindrance at the 2, 4, and 6 positions of the ring, where the ortho hydrogens relative to each methyl are effectively shielded, influencing reactivity patterns.[11]Physical and Thermodynamic Properties

Appearance and Basic Properties

Mesitylene appears as a colorless liquid at standard room temperature and pressure, exhibiting a distinctive sweet and aromatic odor that is characteristic of many alkylbenzenes. This physical form stems from its relatively low melting point, allowing it to remain liquid under ambient conditions. The compound's low polarity, arising from its highly symmetric molecular structure with three methyl groups symmetrically substituted on the benzene ring, contributes to its limited interaction with polar solvents like water while favoring miscibility with nonpolar organic media. Key physical properties of mesitylene are summarized in the following table:| Property | Value | Conditions | Source |

|---|---|---|---|

| Molecular weight | 120.19 g/mol | - | PubChem |

| Melting point | -44.8 °C | - | PubChem; O'Neil, M.J., ed. The Merck Index, 14th ed. (2006) |

| Boiling point | 164.7 °C | 1 atm (760 mmHg) | PubChem; O'Neil, M.J., ed. The Merck Index, 14th ed. (2006) |

| Density | 0.8637 g/cm³ | 20 °C | PubChem; O'Neil, M.J., ed. The Merck Index, 14th ed. (2006) |

| Vapor pressure | 2 mmHg | 20 °C | PubChem; NIOSH Pocket Guide to Chemical Hazards (2024) |

| Vapor density | 4.1 | vs. air = 1 | PubChem; NIOSH Pocket Guide to Chemical Hazards (2024) |

| Solubility in water | 0.002 g/100 mL | 20 °C | PubChem; O'Neil, M.J., ed. The Merck Index, 14th ed. (2006) |

| Solubility in organic solvents | Miscible | e.g., ethanol, ether | PubChem |

| Flash point | 50 °C | closed cup | PubChem; NIOSH Pocket Guide to Chemical Hazards (2024) |

![Mesitylene by Adolf von Baeyer (tetracyclo[3.1.1.11,3.13,5]nonane)](http://upload.wikimedia.org/wikipedia/commons/thumb/0/0e/Mesitylen_by_Adolf_von_Baeyer.png/330px-Mesitylen_by_Adolf_von_Baeyer.png)