Recent from talks

Nothing was collected or created yet.

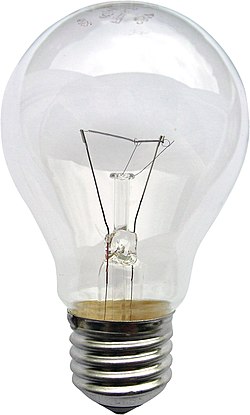

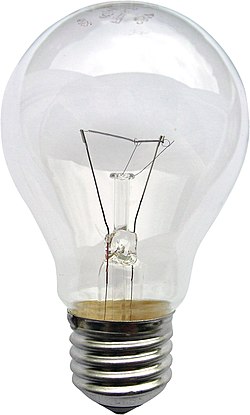

Edison screw

View on Wikipedia

Edison screw (ES) is a standard lightbulb socket for electric light bulbs. It was developed by Thomas Edison (1847–1931), patented in 1881,[1] and was licensed in 1909 under General Electric's Mazda trademark. The bulbs have right-hand threaded metal bases (caps) which screw into matching threaded sockets (lamp holders). For bulbs powered by AC current, the thread is generally connected to neutral and the contact on the bottom tip of the base is connected to the "live" phase.

In North America and continental Europe, Edison screws displaced other socket types for general lighting. In the early days of electrification, Edison screws were the only standard connector, and appliances other than light bulbs were connected to AC power via lamp sockets. Today Edison screw sockets comply with international standards.

Their types are designated as "Exx", such as "E26", where "xx" indicates the diameter of the socket in millimeters.

History

[edit]In the United States, early manufacturers of incandescent lamps used several different and incompatible bases in the 1880s and 1890s. In designing his screw,[1] Edison copied the lid of a kerosene can in his workshop, even sawing it off to make a prototype in 1880.[2] Another company, the Thomson-Houston Electric Company, used a threaded stud at the bottom of the socket and a flat contact ring.[3]: fig.8 The Sawyer-Man or Westinghouse base used a spring clip acting on grooves in the bulb base and a contact stud at the bottom of the lamp.[3]: fig.7 Most smaller competitors had to produce lamps for all three types,[2] and some used their own designs as well.[4] Other lamp bases include the bayonet mount and wedge base.

All three major designs were patented. Edison himself filed his applications in 1881[1] and 1890.[3] In response to Edison's patent, Reginald Fessenden invented the bi-pin connector for the 1893 World's Fair.

After some design tweaks Edison settled upon a screw 1 inch in diameter with 7 threads per inch of length, which much later became E26. Screw shells produced as early as 1888 had a lighter taper[5] than the modern ones.[6]

In 1892, Edison General Electric Company merged with Thomson-Houston to found General Electric, which gradually adopted the Edison screw and made it prevalent.[2] By about 1908, the Edison base was most common in the U.S. with the others falling out of use.[7]

Proposals to introduce one or several international standards for Edison screws began in 1918, when France suggested to the International Electrotechnical Commission (IEC) to take up the issue of sockets and holders.[8] All IEC attempts to reach consensus by 1925 failed, but lamp makers continued the work in an independent committee and developed two standards—one for Europe, another for Americas—which were endorsed by the IEC in 1930 and 1931 respectively.[9] It was in this period when E-designations of screws first originated in Germany (where seven DIN VDE standards were enacted in 1924—1925[10]) and then adopted by IEC.[11]

Types

[edit]

Specifications for all lamp mount types are defined in the following American National Standards Institute (ANSI)[12] and International Electrotechnical Commission (IEC) publications:

- Lamp Caps – ANSI C81.61 and IEC 60061-1

- Lamp Holders – ANSI C81.62 and IEC 60061-2

- Gauges (to ensure interchangeability) – ANSI C81.63 and IEC 60061-3

- Guidelines for Electrical Lamp Bases, Lampholders and Gauges – ANSI C81.64 and IEC 60061-4

Generally, the two standards are harmonized, although several types of screw mount are still defined in only one standard.

In the designation "Exx", "E" stands for "Edison" and "xx" indicates the diameter in millimeters as measured across the peaks of the thread on the base (male), e.g., E12 has a diameter of 12 mm. This is distinct from the glass envelope (bulb) diameter, which in the U.S. is given in eighths of an inch, e.g., A19, MR16, T12.[13] There are four commonly used thread size groups for mains supply lamps:

- Candelabra: E12 North America, E11 in Europe

- Intermediate: E17 North America, E14 (Small ES, SES) in Europe

- Medium or standard: E26 (MES) in North America, E27 (ES) in Europe

- Mogul: E39 North America, E40 (Goliath ES) in Europe.

The E26 and E27 are usually interchangeable, as are the E39 and E40, although less so; although there is only a 1 mm difference in thread outside diameter, there is a small difference in pitch; an E40 cap will often fit in an E39 holder but not the other way around. E11 and E12 are not interchangeable. Other semi-standard screw thread sizes are available for certain specific applications.[14]

The large E39 "Mogul" and E40 "Goliath" base are used on street lights, and high-wattage lamps (such as a 100 W / 200 W / 300 W 3-way) and many high-intensity discharge lamps. In areas following the U.S. National Electrical Code, general-use lamps over 300 W cannot use an E26 base and must instead use the E39 base. Medium Edison screw (MES) bulbs for 12 V are also produced for recreational vehicles. Large outdoor Christmas lights use Intermediate base, as do some desk lamps and many microwave ovens.[citation needed] Previously, emergency exit signs also tended to use the intermediate base,[citation needed] but U.S. and Canadian rules now require long-life and energy-efficient LED lamps, which can be purchased inside a conventional Edison base bulb as a retrofit. A medium screw base should not carry more than 25 amperes current; this may limit the practical rating of low voltage lamps.[15]

E29 "Admedium" bases are used for special applications; for example, UV spotlight lamps in magnetic crack detection machines.[citation needed]

In countries that use 220–240 volt AC domestic power, standard-size E27 and small E14 are the most common screw-mount sizes and are prevalent throughout continental Europe[a] and China.[16]

In 120 volt North America, 100 volt Japan and 110 volt Taiwan, the standard size for general-purpose lamps is E26.[17][18]

E12 is typically used for candelabra fixtures. E14 or E17 are also sometimes used, especially in small table lamps and novelty lighting, and occasionally the lights on newer ceiling fans. Christmas lights may use several base sizes: E17 for C9 bulbs, E12 for C7 bulbs, E10 for decades-old series-wired C6 bulb sets[19] in the U.S., and an entirely different wedge base for T1¾ mini-lights. For a short time early on, these mini lights were manufactured using E5 screw bases.

A tiny E5 or E5.5 size is only used for extra-low voltages, such as in interior illumination for model buildings, and model vehicles such as model trains. These are often called "pea bulbs" if they are globe-shaped, but they commonly look like sub-miniature Christmas bulbs, or large "grain-of-wheat" bulbs. E10 bulbs are common on battery-powered flashlights, as are bayonet mounts (although those are usually held in with a circular flange located where the base meets the glass envelope of the bulb). The E11 base is sometimes used for 50/75/100 Watt halogen lamps in North America, where it is called the "mini-can", and tighter threads are used to keep them out of E12 base nightlights and other places where they could start a fire.[citation needed]

There are also adapters between screw sizes, and for adapting to or from bayonet caps. A socket extender makes the bulb stick out further, such as to accommodate a compact fluorescent lamp that is too large to fit in a recessed lighting fixture.

Most Edison screws have right-hand threads (bulb is turned clockwise to tighten), but left-hand threaded screws are sometimes used, usually for a non-standard voltage or wattage bulb. This prevents the use of an incorrect bulb, which could cause damage.[20] Public locations such as railway trains and the New York City Subway have used light bulbs with left-hand threads to discourage theft of the bulbs for use in regular light fixtures.[21][22]

Fittings

[edit]

| Designation | Base major diameter (thread external) |

Pitch mm[23] |

Name | Applications | IEC 60061-1 standard sheet |

|---|---|---|---|---|---|

| E5 (E5.5)[24] | 5.5 mm (0.217 in) | 1 | Lilliput Edison Screw (LES) | Indicator lights, decorative lights | 7004-25-3[25] |

| E10 | 10 mm (0.394 in) | 1.81 | Miniature Edison Screw (MES), C6 | Flashlights, bicycle lights | 7004-22 |

| E11 | 11 mm (0.433 in) | — | Mini-Candelabra Edison Screw (mini-can) | 120 V halogen mini-candelabra | 7004-6-1 |

| E12 | 12 mm (0.472 in) | 2.6 | Candelabra Edison Screw (CES), C7 | 120 V candelabra/night lamp | 7004-28 |

| E14 | 14 mm (0.551 in) | 2.82 | Small Edison Screw (SES) | 230 V candelabra/chandelier, night lamps, some pendant lights | 7004-23 |

| E16 | 16 mm (0.630 in) | 2.5 | |||

| E17 | 17 mm (0.669 in) | — | Intermediate Edison Screw (IES), C9 | 120 V appliance, decorative lights | 7004-26 |

| E18 | 18 mm (0.709 in) | 3.0 | |||

| E26 | 26 mm (1.024 in) | — | Medium Edison Screw (ES) | Standard 120 V lamps | 7004-21A-2 |

| E27 | 27 mm (1.063 in) | 3.62 | Edison Screw (ES) | Standard 230 V lamps | 7004-21 |

| E33 | 33 mm (1.299 in) | 4.23 | |||

| E39 | 39 mm (1.535 in) | — | Mogul Edison Screw | 120 V 250+ W industrial | 7004-24A-1 |

| E40 | 40 mm (1.575 in) | 6.35 | Goliath Edison Screw (GES) | 230 V 250+ W industrial | 7004-24 |

Three-way lamps have a d suffix to indicate double contacts, usually E26d or E27d, or rarely E39d. The second contact is used for the lower-wattage filament of the two inside the lamp. This extra contact is a ring located around the main contact. Unlike bayonet sockets, three-way and regular lamps are interchangeable, although the low filament or low setting does not work if mismatched.

The small Edison screw has nine threads per inch, or a pitch of 1⁄9 in or 2.8222 mm per thread.

The medium Edison screw has seven threads per inch, or a pitch of 1⁄7 in or 3.6286 mm per thread. In the U.S., the Energy Independence and Security Act of 2007 requirement for greater energy efficiency only applies to the medium Edison screw, all other being considered "specialty" lamps.[26]

Diazed fuses DII uses the same E27 thread as standard 230 V lamps, but have a longer body and cannot be screwed into a lamp holder (socket). A lamp base is too short to contact the bottom terminal of a fuse holder. However it is possible (but not useful) to screw a DII fuse holder without a fuse in an E27 lamp holder.

Other uses

[edit]

The Edison screw socket was used as an outlet (such as for toasters) when mains electricity was still mainly used for lighting, and before wall outlets became common.

In North America, fuses were used in buildings wired before 1960. These Edison base fuses would screw into a fuse socket similar to Edison-base incandescent lamps.

Some adapters for wall outlets use an Edison screw, allowing a light socket to become an ungrounded electrical outlet (such as to install Christmas lights temporarily via a porch light), or to make a pull-chain switch with two outlets, or to split it for two lamps. Another adapter can make a wall outlet into a lamp holder (lamp socket).

Various other accessories have been made, including a smoke detector that recharges over a few hours and lasts for a few days or weeks thereafter, and still allows the attached lamp to operate normally. There have also been electronics that stick onto the end of the screw base and allow the attached lamp to flash, for example, to attract the attention of arriving guests or emergency vehicles; others function as a dimmer or timer, or dim gradually in a child's bedroom in the evening.

Some vacuum tubes, such as certain rectifiers, use an Edison screw base.

See also

[edit]Notes

[edit]- ^ The BC or bayonet mount fitting is the most common light bulb fitting in the UK and many British Commonwealth countries, and is found in older installations[citation needed] in some other countries, including France and Greece.

References

[edit]- ^ a b c U.S. patent 0,251,554 (applied 1881, awarded 1881) Two examples of screw system appear, including the kerosene-can lid, but their overall formations are incompatible with today's Edison sockets. No explicit claims for the screw system. Beware patents.google.com's preview mode lacks several pages, must download full PDF.

- ^ a b c Oatman-Stanford, Hunter. "Let There Be Light Bulbs: How Incandescents Became the Icons of Innovation". Collectors Weekly. Retrieved 7 September 2020.

- ^ a b c U.S. patent 0,438,310 (applied 1890, awarded 1890) A lamp base that is compatible with 3 competing socket systems (Edison, Westinghouse, Thomson-Houston). This patent is not about Edison system itself. It rather is an enhancement to the already existing Edison system. Beware patents.google.com's preview mode lacks several pages, must download full PDF.

- ^ Jenkins, John. "Early Incandescent lamps". SPARK Museum of Electrical Invention. Retrieved 7 September 2020.

- ^ "American Standard for Threads for Lamp Sockets and Bases". ASA Bulletin. 3 (2). American Standards Association.: 83 1932. Retrieved 7 September 2020.

- ^ Historical American standards:

- ASME 1474(1915), ASA C44-1931: "10". American national rolled threads for screw shells of electric sockets and lamp bases. Screw-thread standards for federal services. National Bureau of Standards Handbook. Vol. H28(1942) (1942 ed.). National Bureau of Standards. 1942. pp. 140–142. Retrieved 8 September 2020.

- ASA C81.1-1951: "15". American standard rolled threads for screw shells of electric lamp holders and screw shells of unassembled lamp bases. Screw-thread standards for federal services. National Bureau of Standards Handbook. Vol. H28(1957) PART III (1957 ed.). National Bureau of Standards. 1960 [1957]. pp. 34–36. Retrieved 8 September 2020.

- ^ "20". Interior wiring. I.C.S. Reference Library. Vol. 4B. New York: Scranton International Textbook Company. 1908 [1905]. p. S43 p41 (web 215/632). Retrieved 8 September 2020.

- ^ "(p256)". The Engineer (UK magazine). No. 127. Morgan-Grampian. 14 March 1919. p. 256. Retrieved 8 September 2020. (snippet)

- ^ Yates, JoAnne; Murphy, Craig N. (30 March 2021). Engineering Rules: Global Standard Setting since 1880. JHU Press. p. 108. ISBN 978-1-4214-4003-3. Retrieved 7 September 2020.

- ^ Dettmar, Georg (13 March 2013). Wegweiser für die vorschriftsgemäße Ausführung von Starkstromanlagen: Im Einverständnis mit dem Verbande Deutscher Elektrotechniker (in German). Springer-Verlag. p. 130. ISBN 978-3-642-47446-0. Retrieved 7 September 2020.

- ^ "(drawings of screw threads)". IEC Report of Plenary Meetings. International Electrotechnical Commission. 1935. p. 160. Retrieved 8 September 2020.

Medium screw cap E 27

- ^ ANSI C81 series:

- "Specifications for Bases (Caps) for Electric Lamps" (pdf). National Electrical Manufacturers Association (NEMA). 3 July 2019. ANSI C81.61 American National Standard. Retrieved 8 September 2020.

- "Electric Lampholders" (pdf). National Electrical Manufacturers Association (NEMA). 3 July 2019. ANSI C81.62 American National Standard. Retrieved 8 September 2020.

- "Gauges for Electric Lamp Bases and Lampholders" (pdf). National Electrical Manufacturers Association (NEMA). 6 September 2019. ANSI C81.63 American National Standard. Retrieved 8 September 2020.

- "Guidelines and General Information for Electrical Lamp Bases, Lampholders and Gauges" (pdf). National Electrical Manufacturers Association (NEMA). 19 June 2020. ANSI C81.64 American National Standard. Retrieved 8 September 2020.

- ^ "Lamp Size Reference". lightopedia.com. Retrieved 23 April 2017.

- ^ "Light Bulb Shape and Size Chart". Bulbs.com. Reference charts. Retrieved 5 February 2018.

- ^ Incandescent Lamps (manual). General Electric. 1976. p. 12. publication no. TP 110.

- ^

"灯泡螺口规格、灯泡的选购技巧". 搜房网家居装修 (in Chinese). Retrieved 28 February 2017.

最长[常] [sic]的使用的螺口灯泡规格是:E14和E27

- ^ "FAQ". LED waves (ledwaves.com). Retrieved 5 February 2018.

The E26 is the standard 120 Volt American base.

- ^ "E26: – 般電球、ボール電球の多くがこのサイズ。". support pages. Sharp Japan. Archived from the original on 10 February 2015. Retrieved 30 January 2015.

- ^ "C6 bulb sets". lamp evolution. Archived from the original on 20 October 2006.

- ^ Eisenbraun, Blair (24 March 2011). "Left handed incandescent light bulbs?". eLightBulbs (lightbulbs.com) (blog). Retrieved 27 July 2016.

- ^ McManus, Chris (2004). Right Hand, Left Hand: The origins of asymmetry in brains, bodies, atoms, and cultures. Harvard University Press. p. 46. ISBN 978-067401613-2. Retrieved 25 January 2015.

- ^ Schneier, B. (2003). Beyond Fear: Thinking sensibly about security in an uncertain world. Springer Science+Business Media. p. 221. ISBN 978-038702620-6. Retrieved 25 January 2015.

- ^ Edison thread

- ^ "E5.5" designation does not exist in IEC 60061 database. Examples of usage:

- "(advertisement) Pisello E5.5 Fused 3V 1.5W CL". Bailey - The lamp company. Archived from the original on 19 March 2021. Retrieved 19 March 2021.

- "(advertisement) Midget Screw Base (E5)". BulbTown. Archived from the original on 25 August 2017. Retrieved 19 March 2021.

- ^ "IEC 60061 International Standard – Lamp caps and holders" (PDF) (in French and English) (3.51 ed.). Geneva: IEC. December 2014. Archived from the original (PDF) on 16 April 2013. Retrieved 22 March 2015.(subscription required)

- ^ Formisano, Bob. "2007 Energy Bill – Are They Phasing Out or Making Incandescent Bulbs Illegal? Incandescent Exemptions: Where You Can Still Use Existing Bulbs". About.com. Archived from the original on 27 April 2009. Retrieved 22 March 2015.

External links

[edit] Media related to Edison screw at Wikimedia Commons

Media related to Edison screw at Wikimedia Commons- Edison screw thread (in English)

Edison screw

View on GrokipediaHistory

Invention and Patenting

The Edison screw base, a threaded socket system for securing incandescent lamps, was developed by Thomas Edison and his assistants at the Menlo Park laboratory in New Jersey during 1880.[1] Early experimental bulbs from late 1879 relied on insecure wooden sockets with spring contacts and thumb screws, which often led to bulbs falling out or poor electrical connections.[1] Inspired by the threaded lid of a kerosene can, Edison's team prototyped a screw-in base that year, featuring a roughly 1-inch diameter with coarse threads for easy installation and reliable contact between the bulb's center pin and side threading.[1][7] This design addressed practical needs for user-replaceable lamps in a commercial electric lighting system, prioritizing mechanical simplicity and electrical continuity over prior plug-in or keyless alternatives.[1] Edison filed for patent protection on the screw base as part of an integrated lamp-and-socket assembly. U.S. Patent No. 251,554, titled "Electric Lamp," was granted to Edison on December 27, 1881, describing a bulb with a threaded metal base that screws into a matching socket, establishing both electrical contact and mechanical fixation through rotation.[8] The patent emphasized the base's insulating material (such as porcelain or composition) surrounding conductive threads and a central contact, enabling safe, vibration-resistant operation in fixed installations.[8] An earlier related filing, U.S. Patent No. 248,424 for "Fitting and Fixture for Electric Lamps" (issued October 18, 1881), detailed compatible socket fixtures but deferred to the screw mechanism's core innovation in No. 251,554.[9] These patents built on Edison's foundational U.S. Patent No. 223,898 (January 27, 1880) for the incandescent lamp itself, which initially used non-screw bases, by incorporating the screw for practical deployment.[10][8] The screw base's adoption stemmed from its causal advantages in reliability and manufacturability, facilitating Edison's vision of a distributed electric power network with interchangeable components.[1] Licensing and production began soon after patenting, with initial use in Edison's Pearl Street Station system in 1882, though widespread standardization occurred later amid competition from bayonet and other fittings.[7]Early Commercialization

Following the development of a practical incandescent lamp in 1879, Thomas Edison patented the screw base design in 1881, enabling secure, interchangeable connections between bulbs and sockets without the loosening issues of prior plug-in terminals.[1] This innovation, inspired by the threaded lid of a kerosene can, was integral to the Edison Electric Light Company's production strategy, with initial manufacturing occurring at the Harrison Lamp Works in New Jersey starting in 1881.[11] Early screw bases featured a brass shell, an insulated ring contact, and plaster-of-Paris attachment to the bulb glass, allowing for relatively straightforward assembly in volumes supporting commercial power installations.[11] Commercial rollout accelerated with the first full-scale Edison central station at Pearl Street in New York City in September 1882, which deployed thousands of screw-base lamps in a grid system serving 59 customers and approximately 400 paying users initially.[12] The design's simplicity facilitated mass production and user-friendly replacement, contributing to the system's reliability over gas lighting alternatives, though early filaments limited bulb life to around 600 hours. By 1890, the Edison screw base had achieved dominance, capturing about 70 percent of the U.S. market share amid competition from varied base types.[3] Adoption extended to marine and industrial applications, such as the 1880 installation on the steamship S.S. Columbia, marking one of the earliest commercial uses of Edison's lighting systems incorporating evolving base designs.[12] Despite initial manufacturing challenges like filament variability, the screw base's mechanical advantages—right-hand threading for tight seals and central contact for current—drove its integration into standardized sockets, laying groundwork for broader electrification.[7] The 1892 merger forming General Electric further propelled commercialization, as the company refined and licensed the technology.[7]Standardization Processes

The Edison screw base attained de facto standardization in the United States primarily through market dominance rather than initial formal regulatory processes, driven by Thomas Edison's patent (U.S. Patent 438,920, granted January 27, 1891, though developed earlier) and the rapid commercialization of compatible incandescent lamps and sockets.[6] By 1890, the screw-type base had captured approximately 70 percent of the U.S. market share for bulb connectors, supplanting earlier variants like bayonet or side-prong designs due to its mechanical simplicity, ease of manufacturing, and reliable electrical contact via the threaded center electrode.[3] This adoption accelerated after the 1892 merger forming General Electric Company, which prioritized the Edison base in production, further entrenching it as the preferred interface for household and commercial lighting by the early 1900s.[7] Industry consensus in the U.S. reinforced this without a single mandating body initially; lamp manufacturers, recognizing the base's practicality and installed base effects, aligned on its dimensions—such as the E26 medium screw with a 26 mm nominal diameter and 14 threads per inch pitch—through voluntary coordination via trade groups like the National Electric Lamp Association (predecessor influences to modern standards bodies).[11] By the 1910s, competing designs had largely faded, solidifying the Edison screw as the functional standard for 120 V systems, later codified in American National Standards Institute (ANSI) specifications like C78 series for lamp-base interchangeability, which reference the base's thread form and tolerances to ensure compatibility across manufacturers.[13] Internationally, formal standardization efforts commenced in 1918 when France proposed unifying cap types to the International Electrotechnical Commission (IEC), aiming to resolve regional variations (e.g., differing thread pitches or diameters in Europe) for global trade and safety.[7] The IEC designated the Edison screw as "E" followed by diameter in millimeters (e.g., E26/E27), with dimensional standards outlined in IEC 7004-21A-2, specifying precise thread geometry, contact resistance limits, and insulation requirements to prevent arcing or loose fits.[14] Lampholder performance, including mechanical endurance (e.g., 100 insertion cycles without failure) and electrical ratings up to 660 V, is governed by IEC 60238, first published in earlier editions and revised periodically to incorporate empirical testing data from global interoperability trials.[15] These processes emphasized empirical validation over theoretical ideals, prioritizing bases that minimized manufacturing variability and field failures observed in early 20th-century deployments. Regional adaptations, such as the slightly coarser E27 thread for 220-240 V markets, emerged from these deliberations to balance universality with voltage-specific safety margins.[5]Technical Design

Thread and Dimensional Standards

The Edison screw employs a right-hand, single-start, coarse cylindrical thread standardized across sizes for secure mechanical and electrical connection in lampholders.[16] The thread pitch measures 3.629 mm, equivalent to approximately 7 threads per inch, ensuring compatibility between caps and sockets while minimizing cross-threading risks.[17] This pitch derives from early designs and is codified in international standards such as IEC 60061-1 for lamp caps, which specifies dimensional tolerances, gauging, and interchangeability requirements.[18] Dimensional standards designate the base as "E" followed by the nominal major thread diameter in millimeters (e.g., E27 for 27 mm), with actual dimensions incorporating tolerances for manufacturing variations.[19] IEC 60238 governs lampholder specifications for common sizes E14, E27, and E40, referencing IEC 60061 series for precise cap dimensions, including effective screw thread length, center contact protrusion, and shell thickness to prevent arcing or loose fits.[20] In North America, E26 aligns closely with ANSI equivalents but adheres to IEC tolerances for global compatibility, featuring a major diameter range of 26.05–26.41 mm and minimum effective thread length of 19.56 mm.[5] E27 variants extend the minimum length to 22 mm for higher-voltage applications up to 250 V. Additionally, E27 features a taller insulator height of at least 5 mm compared to 3.25 mm for E26, enhancing base contact insulation to prevent arcing and shorts at higher voltages, as specified in IEC 60061-1.[5][18]| Size | Nominal Diameter (mm) | Major Diameter Tolerance (mm) | Typical Applications |

|---|---|---|---|

| E14 | 14 | 13.85–14.15 (peak) | Candelabra, low-power lamps ≤250 V, ≤2 A[20] |

| E26 | 26 | 26.05–26.41 (peak); 24.72 (trough) | Medium base, 120 V household ≤4 A[5] [17] |

| E27 | 27 | 26.05–26.45 (peak); 24.76 (trough) | Medium base, 240 V international ≤4 A[5] [17] |

| E40 | 40 | ~40 (detailed in IEC 60061) | Goliath base, high-power ≤500 V, ≤16 A[20] |

Electrical and Mechanical Specifications

The electrical and mechanical specifications for Edison screw lampholders and bases are primarily defined by IEC 60238, which covers E14, E27, and E40 sizes designed for lamp and semi-luminaire connections, with analogous provisions in ANSI C81 standards for variants like E26.[21] [18] These standards specify thread dimensions, voltage and current limits, torque resistance, insulation properties, and mechanical durability to ensure safe interchangeability and performance. All Edison screw threads employ a right-hand coarse pitch of approximately 3.63 mm (equivalent to 7 threads per inch), facilitating secure mechanical engagement across sizes.[17] Voltage ratings vary by region and size: E26 bases, common in North America, are rated for 120 V AC, while E27 bases, prevalent in Europe and elsewhere, support up to 250 V AC, with IEC 60238 permitting 250 V for E14 and switched E27 lampholders. The taller insulator height in E27 (minimum 5 mm versus 3.25 mm in E26) provides enhanced safety by improving insulation against arcing and short circuits at higher voltages, as per IEC 60061-1.[5][18][20] Current capacities are limited to prevent overheating; E27 caps handle lamps up to 4 A (roughly 1000 W at 250 V), E40 up to 16 A (or 32 A at reduced voltage), and smaller sizes like E14 accordingly lower.[22] [23] Mechanical torque specifications include insertion and removal tests: 1 Nm for E14 and 2 Nm for E27 using standardized test caps, ensuring the screw shell and outer components withstand repeated cycling without deformation or loosening.[24] Electrical performance requires low contact resistance, typically below 0.5 Ω between the center terminal and shell, to minimize voltage drop and heat generation.[25] Dielectric strength testing mandates no breakdown at specified voltages, such as 750 V or higher per product implementations aligned with IEC, while insulation resistance exceeds measurable thresholds under dry and humid conditions to prevent leakage currents.[25] [26] Mechanical strength evaluations involve impact tests on the shell and dome, torque application to verify thread integrity, and endurance cycling, confirming robustness against vibration and handling stresses in typical installations.[24]| Size | Diameter (mm) | Typical Voltage (V AC) | Max Current (A) | Insertion Torque (Nm) |

|---|---|---|---|---|

| E14 | 14 | 250 | <4 | 1 |

| E26/E27 | 26/27 | 120/250 | 4 | 2 |

| E40 | 40 | 250 | 16 (32 at low V) | Varies |

Materials and Manufacturing

The Edison screw base affixed to light bulbs consists primarily of aluminum for the exterior shell in contemporary manufacturing, providing corrosion resistance and lightweight construction, while the interior is insulated with glass frit or cementitious compounds to prevent electrical shorts and enhance mechanical strength.[27] Historically, from the late 19th century onward, bases employed brass for the threaded shell due to its malleability and conductivity, with insulation via plaster of Paris initially, transitioning to porcelain for improved thermal stability.[27] Manufacturing of the bulb base begins with stamping or drawing sheet metal into a cylindrical form, followed by thread-rolling to create the coarse right-hand screw profile standardized at 7 threads per inch for medium sizes like E26/E27.[27] The formed shell is then cemented onto the bulb's stem assembly, where lead-in wires are spot-welded to the base's eyelet and shell for circuit completion, with automated sealing ensuring vacuum integrity during bulb exhaustion.[27] Corresponding sockets, which receive the Edison screw, utilize heat-resistant ceramics such as unglazed porcelain for high-wattage applications up to 660 watts, owing to its superior thermal endurance and electrical insulation properties.[28] Phenolic resins, commonly known as Bakelite, serve as a durable, moldable alternative in vintage and industrial sockets, valued for flame retardancy and dimensional stability under heat.[29] [30] Modern variants incorporate thermoset plastics like polycarbonate or nylon, engineered for UL-listed fire resistance and compatibility with lower-heat LED bulbs.[31] Socket fabrication typically involves injection molding or compression molding for plastic and phenolic bodies, with porcelain variants produced via slip casting or dry pressing followed by high-temperature firing to achieve density and strength.[32] Brass or nickel-plated steel forms the internal screw shell and spring-loaded center contact, assembled via crimping or soldering to insulated wire leads, ensuring reliable torque resistance up to 0.5 Nm during bulb insertion.[33]Types and Variants

Miniature and Candelabra Sizes

Miniature Edison screw bases, such as the E10, feature a 10 mm diameter thread and are rated for low voltages up to 30 V, making them suitable for compact, low-power applications.[19] These bases, standardized under IEC 60061-1 sheet 7004-22, employ a finer thread pitch compared to larger variants to ensure secure fit in small sockets.[19] Common uses include flashlights, appliance indicator lights, and miniature decorative lamps.[34] [35] The E11 mini-candelabra base, with an 11 mm diameter, supports 120 V or 240 V operation and is designed for halogen bulbs in landscape, track, and recessed lighting fixtures.[36] Its specifications align with IEC 60061-1 for dimensional consistency, facilitating interchangeability in specialized installations.[19] Candelabra sizes, primarily the E12 with a 12 mm diameter, are rated for 120 V and feature a thread pitch optimized for decorative and low-wattage bulbs.[4] Standardized per IEC 60061-1 sheet 7004-28, E12 bases are prevalent in chandeliers, sconces, ceiling fans, and holiday lighting due to their aesthetic compatibility with small bulb envelopes.[37] [4] These bases provide reliable electrical contact through a central contact and threaded shell, similar to larger Edison screws but scaled for finer fixtures.[34]Medium and Goliath Sizes

Medium Edison screw bases, known as E26 in North American standards and E27 internationally, have a thread diameter of 26 mm for E26 and 27 mm for E27.[14] [38] E26 bases are designed for 120 V systems with a minimum screw thread length of 19.56 mm, while E27 bases suit 220-240 V applications with a 22 mm thread length. Additionally, E27 bases incorporate a taller insulator height of 5 mm minimum compared to 3.25 mm for E26, enhancing separation between the live contact and neutral screw base to mitigate risks of short circuits and electric arcs at higher voltages.[38] [5] These bases are mechanically interchangeable due to minimal differences in thread outside diameter, enabling physical compatibility across regions despite voltage distinctions.[5] They serve general lighting needs in residential table lamps, ceiling fixtures, outdoor spotlights, and floodlights, accommodating bulb shapes like A19, G25, and BR30.[4] [17] Goliath Edison screw bases, designated E39 and E40, feature larger thread diameters of 39 mm and 40 mm, respectively, for high-power installations.[36] E39 bases align with 120 V ratings for industrial use over 250 W, whereas E40 bases support 220-240 V systems in commercial settings.[39] [36] Like medium sizes, E39 and E40 are often interchangeable mechanically but require matching socket voltage ratings to prevent hazards.[4] These bases accommodate high-intensity discharge (HID) lamps, tubular or elliptical designs, and high-wattage LEDs in applications such as street lights, metal halide fixtures, and large industrial luminaires.[40] [17]| Base Type | Diameter (mm) | Typical Voltage (V) | Primary Applications |

|---|---|---|---|

| E26 | 26 | 120 | Household and general lighting fixtures[4] |

| E27 | 27 | 220-240 | International residential and commercial lamps[4] |

| E39 | 39 | 120 | Industrial high-wattage setups[36] |

| E40 | 40 | 220-240 | HID and street lighting systems[40] |

Regional and Specialized Adaptations

The Edison screw base exhibits primary regional adaptations through the E26 and E27 variants, which differ subtly in dimensions to align with prevailing electrical standards. The E26 base, with a 26 mm diameter, is standardized for 120 V systems in North America, including the United States and Canada, as well as Japan and Taiwan.[17][4] In contrast, the E27 base, featuring a 27 mm diameter, predominates in regions with 220–240 V grids, such as Europe, the United Kingdom, Australia, and much of Asia.[17][41] This 1 mm disparity in thread diameter, combined with E27's slightly longer screw length for enhanced alignment, prevents seamless interchangeability and ensures compatibility with voltage-specific bulb designs and fixtures.[5][38] These adaptations reflect historical divergences in electrical infrastructure: North American systems, rooted in early 20th-century 110–120 V adoption, favor E26 for household and general lighting, while higher-voltage European standards post-World War II solidified E27 usage.[42] Although the bases share the same Edison screw threading principle and are often visually indistinguishable at a glance, using an E26 bulb in an E27 socket or vice versa risks poor electrical contact, overheating, or failure due to mismatched thread pitch, voltage tolerances, and differences in base contact insulation that compromise safety against arcs and shorts at higher voltages.[4][43][5] Adapters exist but are not recommended for permanent installations, as they compromise safety and efficiency.[5] Specialized adaptations of the Edison screw extend to high-wattage industrial applications, such as the EX39 variant for mogul-sized bases (derived from E39). The EX39 incorporates an extended screw tip—approximately 1–2 mm longer than standard E39—for improved centering and contact stability in sockets handling 250–1000 W lamps, commonly used in arenas, warehouses, and floodlighting.[44] This modification reduces arcing and vibration-induced loosening in demanding environments, while maintaining backward compatibility with E39 sockets.[44] In marine and rough-service contexts, reinforced Edison screw variants feature thicker brass plating or anti-corrosion coatings to withstand humidity and mechanical stress, though these are less standardized and often custom-specified by manufacturers for sectors like shipping or mining.[45]Applications and Integration

Primary Use in Lighting Fixtures

The Edison screw base, developed by Thomas Edison in the 1880s, functions primarily as the mechanical and electrical interface in lighting fixtures for attaching incandescent, fluorescent, and LED bulbs to deliver illumination.[46] This threaded design allows bulbs to be inserted by rotation, establishing contact between the bulb's base threads and the socket's helical interior, while a central pin completes the circuit for power transmission up to rated voltages like 120V for E26 or 220-240V for E27 variants.[4] Its adoption accelerated after the 1892 merger forming General Electric, which standardized the screw mechanism across lamp production, supplanting earlier friction-fit or thumbscrew holders that proved unreliable.[7] In household and commercial settings, Edison screw sockets predominate in table lamps, ceiling pendants, wall sconces, and recessed fixtures, where the base's self-aligning threads ensure secure seating against vibration and thermal expansion without requiring tools for routine maintenance.[2] Medium bases (E26/E27, approximately 26-27 mm diameter) handle general lighting loads from 40W to 100W equivalents, supporting applications in indoor ambient lighting, task illumination, and outdoor fixtures like floodlights when weatherproofed.[4] [47] The mechanism's inherent torque resistance minimizes loosening over time, though periodic retightening may be needed in high-use environments.[48] Regional standards reflect voltage differences—E26 optimized for North American 120V systems and E27 for European 230V grids—but their near-identical thread pitches (7.28 mm per turn) enable mechanical interchangeability, albeit with voltage mismatch risks if cross-applied.[5] [38] This versatility has sustained its role as the default for retrofit-compatible fixtures, accommodating transitions from incandescent to energy-efficient LEDs without socket alterations.[48]Compatibility with Bulb Technologies

The Edison screw base, standardized in sizes such as E26 and E27, supports compatibility with incandescent, halogen, compact fluorescent lamp (CFL), and light-emitting diode (LED) technologies through mechanical threading that ensures secure electrical contact in matching lampholders.[49] These bases adhere to International Electrotechnical Commission (IEC) standards, including IEC 60238 for E27 lampholders, which specify dimensions for interchangeability with lamps designed for direct screw-in installation.[21] Originally engineered for carbon and later tungsten-filament incandescent bulbs, the base's design accommodates filament-based lighting where electrical current passes through the screw thread to heat the filament to luminosity.[50] Halogen bulbs, utilizing a tungsten-halogen regenerative cycle within a quartz envelope to achieve higher efficacy and color temperature than standard incandescents, frequently employ E26 or E27 bases for household applications, maintaining compatibility with existing fixtures rated for medium-base sockets.[49] Self-ballasted CFLs, which integrate miniaturized fluorescent tubes with electronic ballasts, were developed with Edison screw bases to enable retrofit replacement of incandescents starting in the late 1970s, offering substantial energy savings—typically 75% less power for equivalent light output—while fitting standard E26/E27 sockets without ballast alterations.[51] LED bulbs, employing semiconductor diodes for electroluminescence, dominate modern replacements with E26/E27 bases incorporating driver circuits to convert mains voltage, achieving up to 80% energy efficiency over incandescents and lifespans exceeding 25,000 hours.[49] Specialized variants, such as three-way incandescent bulbs with dual filaments for stepped brightness levels (e.g., 50W/100W/150W), utilize standard E26 bases in compatible sockets featuring multiple contacts, as defined by dimensional gauges in IEC 60061-3 to verify safe interchangeability.[52] However, compatibility excludes technologies like linear fluorescent tubes or high-intensity discharge (HID) lamps, which typically require pin or mogul bases, necessitating adapters for Edison sockets and potentially compromising electrical safety or performance.[34] E26 and E27 bases exhibit mechanical similarity—26 mm and 27 mm diameters, respectively—but differ in voltage ratings (120V for E26, 220-250V for E27), permitting physical insertion across systems while advising against electrical mismatch to prevent overheating or failure.[5] This broad adaptability has sustained the Edison screw's prevalence in general lighting, facilitating transitions from inefficient incandescents to efficient alternatives amid global efficiency regulations.[53]Socket Design and Installation Practices

Edison screw sockets, or lampholders, consist of a female threaded brass or nickel-plated metal shell that matches the bulb's screw base diameter, such as 26 mm for E26 or 27 mm for E27 variants, with a standardized thread pitch of 7.7 threads per inch (approximately 3.3 mm per thread).[17] The socket includes a spring-loaded center contact, typically a phosphor bronze tab, for electrical connection to the bulb's base tip, housed within an insulating body made of heat-resistant materials like porcelain, phenolic resin, or ceramic to prevent short circuits and withstand operational temperatures up to 250°C in high-wattage applications.[54] These designs comply with international standards such as IEC 60238 for E14, E27, and E40 lampholders, which specify dimensions, electrical ratings, and mechanical interchangeability to ensure safe bulb insertion and retention.[55] Wiring practices for Edison screw sockets prioritize safety by connecting the neutral conductor to the threaded shell terminal—often marked silver—and the live or hot conductor to the center contact terminal—typically brass—ensuring that during bulb removal, the energized connection disengages first, minimizing shock risk.[46] Terminals accommodate wires of 12 to 18 AWG gauge via screw clamps or push-fit mechanisms, with maximum ratings of 250 V and 660 W for medium bases under standard conditions.[33] Installation requires de-energizing the circuit, stripping wire insulation to 1/2 inch, securing connections without exposed conductors, and verifying polarity to avoid reversed hot-neutral configurations that could energize the shell prematurely.[56] Mounting involves threading the socket onto a compatible nipple or rod—often 1/8 IPS (iron pipe size)—and securing with a setscrew or locknut to the fixture base, allowing for pendant, recessed, or surface installations while maintaining electrical isolation through the insulating skirt.[57] For three-way sockets, an additional tap contact enables stepped switching for multi-filament bulbs, integrated via internal wiring to the switch mechanism.[58] Post-installation, sockets must be tested for continuity and insulation resistance per local codes, such as UL listing for North American E26 types rated at 120 V, contrasting with IEC-compliant E27 for 220-240 V systems, though mechanical compatibility permits cross-use with voltage-matched bulbs.[5]Safety and Performance

Inherent Advantages of the Screw Mechanism

The screw mechanism in Edison bases provides a key safety benefit through its electrical configuration, where the threaded shell connects to the neutral conductor and the center contact to the live conductor. This arrangement minimizes shock risk during bulb insertion or removal, as users primarily contact the neutral shell rather than the live center, assuming proper wiring polarity.[59][60] In contrast to bayonet mounts, which expose contacts on both sides and may require handling near live elements, the Edison screw's design enhances user safety in residential and general applications.[48] Mechanically, the threaded interface ensures a secure, self-aligning connection that resists loosening from vibration or thermal expansion, common in lighting fixtures subject to movement or heat cycles. The multiple thread engagements create a robust mechanical lock and large surface area for electrical contact, reducing resistance, arcing, and intermittent power loss that could lead to flickering or premature failure.[61][48] This reliability supports consistent performance across incandescent, LED, and other bulb types, contributing to longer socket and bulb lifespans by maintaining stable current flow.[62] The mechanism's simplicity also aids installation, requiring only a rotational motion without precise pin alignment, which lowers the force needed and reduces wear on components over repeated cycles. This inherent ease promotes compliance with safe handling practices, as evidenced by its adoption as a global standard since the 1880s for general service lamps.[46][63]Common Failure Modes and Hazards

Loose connections in Edison screw sockets, often resulting from vibration-induced loosening or thread wear, can cause intermittent electrical contact, leading to flickering lights and premature bulb failure.[64][65] Arcing may occur at the contact points due to these poor connections or deteriorated components, generating heat that damages the socket shell or bulb base over time.[64] Overheating represents a primary failure mode, typically from installing bulbs exceeding the socket's rated wattage—such as using a 100W incandescent in a fixture designed for 60W—or from inadequate ventilation trapping heat.[64][65] This can manifest as socket discoloration, buzzing sounds, or smoke, signaling potential meltdown of insulation materials.[64] Corrosion or dust accumulation in the threads exacerbates fitting issues, including stuck bulbs that require forceful removal, risking glass breakage and exposure to live contacts if power remains on.[65] Key hazards include fire risks from sustained arcing or overheating, which can ignite nearby combustibles like dust or wiring insulation; such incidents have been documented in fixtures with loose screw-in bases.[64][66] Electric shock is another concern, particularly during bulb insertion or removal in live sockets, where the exposed center terminal carries line voltage, or when attempting to free corroded bulbs without de-energizing the circuit.[65] Mismatched bases, such as an E26 bulb in an E27 socket, heighten arcing potential due to slight dimensional variances and voltage incompatibilities (120V vs. 230V systems), amplifying fire and short-circuit dangers.[67]Regulatory Standards and Improvements

The primary international standard governing Edison screw lampholders is IEC 60238, which specifies dimensional, mechanical, and electrical requirements for E14, E27, and E40 thread sizes, including insulation resistance, dielectric strength, and contact conductivity to mitigate risks of electric shock, arcing, and fire.[15] This standard, updated in 2020, mandates tests for thread engagement torque (typically 0.4–0.6 Nm for E27) and creepage distances exceeding 3 mm for 250 V applications, ensuring reliable bulb retention and thermal endurance up to 150°C.[55] In the United States, ANSI C81.62 outlines specifications for electric lamp holders, including Edison screw types, harmonizing with IEC 60061-2 for interchangeability while addressing national voltage variations (e.g., 120 V ratings). Safety certification under UL 496 for Edison-base lampholders requires evaluation of enclosure integrity, marking durability, and protection against short circuits, with provisions for higher-temperature plastics like polycarbonate to replace early porcelain designs prone to cracking. These standards collectively enforce minimum pull-out forces (e.g., 50 N for E27) to prevent loosening from vibration, a common failure mode in early 20th-century installations.[50] Regulatory improvements have focused on enhancing durability and compatibility with modern loads, such as LED retrofits, through revisions incorporating finite element analysis for stress distribution and corrosion-resistant nickel-plated contacts specified in IEC 60238 amendments since 2011.[55] National codes, like the NEC Article 410 in the US (2023 edition), mandate grounded metal lampholders for wet locations and limit exposed live parts, reducing shock hazards compared to pre-1950s unregulated sockets. In Europe, EN IEC 60238:2018 aligns with RoHS directives, prohibiting hazardous materials like lead in solders, thereby improving environmental safety without compromising electrical performance.[50] Gauges per ANSI C81.63 and IEC 60061-3 ensure global manufacturing precision, minimizing rejection rates below 1% in compliant production.[68]Extensions and Alternatives

Non-Lighting and Industrial Uses

The Edison screw base finds application in heating elements designed to fit standard lamp sockets, enabling simple installation for spot heating without dedicated fixtures. Cartridge heaters with Edison screw bases, such as the Chromalox SCB series, provide 50 to 200 watts at 120 or 240 volts, featuring a brass sheath for durability and compatibility with porcelain sockets commonly used in lighting.[69] These devices generate convective and radiant heat for supplemental warming in enclosures, closets, or small spaces, leveraging the base's threaded design for secure electrical contact and mechanical retention under thermal expansion.[70] Infrared heating solutions also employ Edison screw configurations, including ceramic bulb elements and screw-in E-Mitters® from manufacturers like Tempco and Ceramicx, which operate at surface temperatures up to 530°C (986°F) for targeted drying, curing, or pain relief applications.[71][72] These non-illuminating emitters prioritize thermal output over visible light, with wattages ranging from 60 to 200 watts at 120 volts, and are suited for industrial processes like plastic forming or automotive paint baking due to their quick heat-up times and ease of replacement.[73] Beyond heating, Edison screw bases support ultraviolet (UV) emitters in pest control devices, where the primary function is insect attraction rather than general illumination. Bulbs like the Feit Electric 9-watt LED bug zapper with E26 base produce UV wavelengths alongside optional visible light modes, fitting standard sockets to enable retrofit in outdoor or indoor traps that electrocute attracted pests.[74] Similarly, fluorescent UV tubes or LEDs with medium screw bases are integrated into electronic fly traps for commercial and residential use, emphasizing non-visible spectrum output for efficacy in low-light environments.[75] In industrial contexts, the Edison screw's robustness facilitates its use in high-vibration or harsh environments, such as temporary power distribution adapters or modular sensor housings, though such adaptations remain niche compared to lighting dominance. The base's self-aligning thread and contact reliability under load support quick servicing in manufacturing lines, reducing downtime versus pin-based alternatives.[76]Adapters for Interoperability

Adapters for Edison screw bases enable the mechanical compatibility of bulbs with differing diameters in sockets designed for other sizes, promoting flexibility in lighting installations without requiring fixture modifications. These devices typically consist of a threaded male connector that screws into the existing socket and a female receiver for the target bulb base, ensuring secure electrical contact. Common configurations bridge the gap between smaller bases like E10 (9.3 mm diameter), E12 (11.5 mm), and E14 (13.5 mm) used in compact or decorative fixtures, and larger ones such as E26/E27 (26 mm) prevalent in general household lighting.[77] Step-up adapters, which insert into a smaller-diameter socket to accommodate a larger-base bulb, are frequently employed to utilize widely available E26/E27 bulbs in legacy E14 candelabra or appliance sockets, such as those in chandeliers or ovens. For instance, an E14-to-E27 adapter screws into an E14 socket and provides an E27 female thread, allowing standard medium-base LEDs to replace inefficient incandescents in undersized fixtures.[78] Conversely, step-down adapters fit into larger E26/E27 sockets to accept smaller E14 or E12 bulbs, useful when miniature lamps are needed for space-constrained applications like night lights or appliances. These adapters maintain interoperability across voltage regions, as E26 (North American 120 V standard) and E27 (IEC 220–240 V equivalent) share identical thread dimensions despite regional electrical differences.[79] Safety considerations for these adapters include ensuring they comply with standards like UL 1993 for self-ballasted lamp adapters, which mandates secure threading to prevent loosening and electrical shock from exposed contacts. Poorly constructed adapters risk arcing or disconnection under vibration, as evidenced by recalls for models with inadequately locked screws.[80][81] Users should select adapters rated for the socket's voltage and current (typically up to 250 V, 2–5 A for household use) and avoid overloading, as excessive heat from high-wattage bulbs can degrade insulation. While effective for temporary or retrofit solutions, permanent installations favor matching bases to minimize failure points, aligning with electrical codes emphasizing reliable connections.[82]Comparisons to Competing Base Types

The Edison screw base, standardized as types such as E26 (medium) and E27 (European medium), competes primarily with bayonet cap (BC or B22) fittings, prevalent in the UK and Commonwealth countries, and bi-pin bases like GU10 or G4/G9, common in low-voltage halogen and LED recessed lighting.[53][4] Bayonet bases feature two opposing pins that engage L-shaped slots in the socket for a quarter-turn lock, while bi-pin bases use straight pins inserted into spring-loaded contacts, often without rotation.[83][48] These alternatives arose to address perceived limitations in the screw mechanism, such as loosening from vibration, though Edison screw remains dominant globally due to its early patent in 1881 and widespread adoption in mains-voltage fixtures.[44]| Aspect | Edison Screw (e.g., E26/E27) | Bayonet Cap (e.g., B22) | Bi-Pin (e.g., GU10, G9) |

|---|---|---|---|

| Installation Method | Continuous rotation (typically 4-6 turns) into threaded socket | Push in pins, then quarter-turn to lock | Align and insert pins into contacts; some twist |

| Mechanical Security | Prone to loosening over time from vibration or thermal cycling, requiring periodic tightening | High; locking mechanism resists vibration-induced loosening | Excellent; spring tension holds firmly, minimal loosening risk |

| Insertion Speed | Slower due to full threading | Faster; quick push-and-lock | Fastest; direct insertion, no rotation needed |

| Safety Features | Central contact for polarity; shell grounded, but loose contact can cause arcing or filament-shell short | Dual contacts reduce live exposure during insertion; less arcing risk but potential pin shorting if misaligned | Low-voltage often used; secure contact but exposed pins pose shock risk in mains applications |

| Prevalence | Global standard for household mains (120-240V); over 90% of US fixtures | Common in UK/Australia (e.g., 240V domestic); declining with LED shift | Specialized for track, recessed, and low-voltage (12V/24V); growing in MR16/GU10 LEDs |

| Compatibility | Broad retrofit support; adapters available for others | Regional; adapters to screw common in transition markets | Fixture-specific; less universal, often non-retrofit |