Recent from talks

Nothing was collected or created yet.

Electrical resistance and conductance

View on Wikipedia

| Electromagnetism |

|---|

|

| Electric resistance | |

|---|---|

Common symbols | R |

| SI unit | ohm (Ω) |

| In SI base units | kg⋅m2⋅s−3⋅A−2 |

| Dimension | |

| Electric conductance | |

|---|---|

Common symbols | G |

| SI unit | siemens (S) |

| In SI base units | kg−1⋅m−2⋅s3⋅A2 |

Derivations from other quantities | |

| Dimension | |

The electrical resistance of an object is a measure of its opposition to the flow of electric current. Its reciprocal quantity is electrical conductance, measuring the ease with which an electric current passes. Electrical resistance shares some conceptual parallels with mechanical friction. The SI unit of electrical resistance is the ohm (Ω), while electrical conductance is measured in siemens (S) (formerly called the 'mho' and then represented by ℧).

The resistance of an object depends in large part on the material it is made of. Objects made of electrical insulators like rubber tend to have very high resistance and low conductance, while objects made of electrical conductors like metals tend to have very low resistance and high conductance. This relationship is quantified by resistivity or conductivity. The nature of a material is not the only factor in resistance and conductance, however; it also depends on the size and shape of an object because these properties are extensive rather than intensive. For example, a wire's resistance is higher if it is long and thin, and lower if it is short and thick. All objects resist electrical current, except for superconductors, which have a resistance of zero.

The resistance R of an object is defined as the ratio of voltage V across it to current I through it, while the conductance G is the reciprocal:

For a wide variety of materials and conditions, V and I are directly proportional to each other, and therefore R and G are constants (although they will depend on the size and shape of the object, the material it is made of, and other factors like temperature or strain). This proportionality is called Ohm's law, and materials that satisfy it are called ohmic materials.

In other cases, such as a transformer, diode, incandescent light bulb or battery, V and I are not directly proportional. The ratio V/I is sometimes still useful, and is referred to as a chordal resistance or static resistance,[1][2] since it corresponds to the inverse slope of a chord between the origin and an I–V curve. In other situations, the derivative may be most useful; this is called the differential resistance.

Introduction

[edit]

In the hydraulic analogy, current flowing through a wire (or resistor) is like water flowing through a pipe, and the voltage drop across the wire is like the pressure drop that pushes water through the pipe. Conductance is proportional to how much flow occurs for a given pressure, and resistance is proportional to how much pressure is required to achieve a given flow.

The voltage drop (i.e., difference between voltages on one side of the resistor and the other), not the voltage itself, provides the driving force pushing current through a resistor. In hydraulics, it is similar: the pressure difference between two sides of a pipe, not the pressure itself, determines the flow through it. For example, there may be a large water pressure above the pipe, which tries to push water down through the pipe. But there may be an equally large water pressure below the pipe, which tries to push water back up through the pipe. If these pressures are equal, no water flows. (In the image at right, the water pressure below the pipe is zero.)

The resistance and conductance of a wire, resistor, or other element is mostly determined by two properties:

- geometry (shape), and

- material

Geometry is important because it is more difficult to push water through a long, narrow pipe than a wide, short pipe. In the same way, a long, thin copper wire has higher resistance (lower conductance) than a short, thick copper wire.

Materials are important as well. A pipe filled with hair restricts the flow of water more than a clean pipe of the same shape and size. Similarly, electrons can flow freely and easily through a copper wire, but cannot flow as easily through a steel wire of the same shape and size, and they essentially cannot flow at all through an insulator like rubber, regardless of its shape. The difference between copper, steel, and rubber is related to their microscopic structure and electron configuration, and is quantified by a property called resistivity.

In addition to geometry and material, there are various other factors that influence resistance and conductance, such as temperature; see below.

Conductors and resistors

[edit]

Substances in which electricity can flow are called conductors. A piece of conducting material of a particular resistance meant for use in a circuit is called a resistor. Conductors are made of high-conductivity materials such as metals, in particular copper and aluminium. Resistors, on the other hand, are made of a wide variety of materials depending on factors such as the desired resistance, amount of energy that it needs to dissipate, precision, and costs.

Ohm's law

[edit]

For many materials, the current I through the material is proportional to the voltage V applied across it: over a wide range of voltages and currents. Therefore, the resistance and conductance of objects or electronic components made of these materials is constant. This relationship is called Ohm's law, and materials which obey it are called ohmic materials. Examples of ohmic components are wires and resistors. The current–voltage graph of an ohmic device consists of a straight line through the origin with positive slope.

Other components and materials used in electronics do not obey Ohm's law; the current is not proportional to the voltage, so the resistance varies with the voltage and current through them. These are called nonlinear or non-ohmic. Examples include diodes and fluorescent lamps.

Relation to resistivity and conductivity

[edit]

The resistance of a given object depends primarily on two factors: what material it is made of, and its shape. For a given material, the resistance is inversely proportional to the cross-sectional area; for example, a thick copper wire has lower resistance than an otherwise-identical thin copper wire. Also, for a given material, the resistance is proportional to the length; for example, a long copper wire has higher resistance than an otherwise-identical short copper wire. The resistance R and conductance G of a conductor of uniform cross section, therefore, can be computed as

where is the length of the conductor, measured in metres (m), A is the cross-sectional area of the conductor measured in square metres (m2), σ (sigma) is the electrical conductivity measured in siemens per meter (S·m−1), and ρ (rho) is the electrical resistivity (also called specific electrical resistance) of the material, measured in ohm-metres (Ω·m). The resistivity and conductivity are proportionality constants, and therefore depend only on the material the wire is made of, not the geometry of the wire. Resistivity and conductivity are reciprocals: . Resistivity is a measure of the material's ability to oppose electric current.

This formula is not exact, as it assumes the current density is totally uniform in the conductor, which is not always true in practical situations. However, this formula still provides a good approximation for long thin conductors such as wires.

Another situation for which this formula is not exact is with alternating current (AC), because the skin effect inhibits current flow near the center of the conductor. For this reason, the geometrical cross-section is different from the effective cross-section in which current actually flows, so resistance is higher than expected. Similarly, if two conductors near each other carry AC current, their resistances increase due to the proximity effect. At commercial power frequency, these effects are significant for large conductors carrying large currents, such as busbars in an electrical substation,[3] or large power cables carrying more than a few hundred amperes.

The resistivity of different materials varies by an enormous amount: For example, the conductivity of teflon is about 1030 times lower than the conductivity of copper. Loosely speaking, this is because metals have large numbers of "delocalized" electrons that are not stuck in any one place, so they are free to move across large distances. In an insulator, such as Teflon, each electron is tightly bound to a single molecule so a great force is required to pull it away. Semiconductors lie between these two extremes. More details can be found in the article: Electrical resistivity and conductivity. For the case of electrolyte solutions, see the article: Conductivity (electrolytic).

Resistivity varies with temperature. In semiconductors, resistivity also changes when exposed to light. See below.

Measurement

[edit]

An instrument for measuring resistance is called an ohmmeter. Simple ohmmeters cannot measure low resistances accurately because the resistance of their measuring leads causes a voltage drop that interferes with the measurement, so more accurate devices use four-terminal sensing.

Typical values

[edit]| Component | Resistance (Ω) |

|---|---|

| 1 meter of copper wire with 1 mm diameter | 0.02[a] |

| 1 km overhead power line (typical) | 0.03[5] |

| AA battery (typical internal resistance) | 0.1[b] |

| Incandescent light bulb filament (typical) | 200–1000[c] |

| Human body | 1000–100,000[d] |

Static and differential resistance

[edit]Many electrical elements, such as diodes and batteries do not satisfy Ohm's law. These are called non-ohmic or non-linear, and their current–voltage curves are not straight lines through the origin.

Resistance and conductance can still be defined for non-ohmic elements. However, unlike ohmic resistance, non-linear resistance is not constant but varies with the voltage or current through the device; i.e., its operating point. There are two types of resistance:[1][2]

- Static resistance

This corresponds to the usual definition of resistance; the voltage divided by the current

It is the slope of the line (chord) from the origin through the point on the curve. Static resistance determines the power dissipation in an electrical component. Points on the current–voltage curve located in the 2nd or 4th quadrants, for which the slope of the chordal line is negative, have negative static resistance. Passive devices, which have no source of energy, cannot have negative static resistance. However active devices such as transistors or op-amps can synthesize negative static resistance with feedback, and it is used in some circuits such as gyrators.- Differential resistance

It is the derivative of the voltage with respect to the current; the slope of the current–voltage curve at a point

If the current–voltage curve is non-monotonic (with peaks and troughs), the curve has a negative slope in some regions—so in these regions the device has negative differential resistance. Devices with negative differential resistance can amplify a signal applied to them, and are used to make amplifiers and oscillators. These include tunnel diodes, Gunn diodes, IMPATT diodes, magnetron tubes, and unijunction transistors.

AC circuits

[edit]Impedance and admittance

[edit]

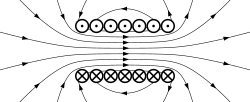

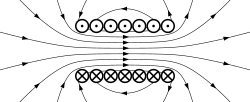

When an alternating current flows through a circuit, the relation between current and voltage across a circuit element is characterized not only by the ratio of their magnitudes, but also the difference in their phases. For example, in an ideal resistor, the moment when the voltage reaches its maximum, the current also reaches its maximum (current and voltage are oscillating in phase). But for a capacitor or inductor, the maximum current flow occurs as the voltage passes through zero and vice versa (current and voltage are oscillating 90° out of phase, see image below). Complex numbers are used to keep track of both the phase and magnitude of current and voltage:

where:

- t is time;

- u(t) and i(t) are the voltage and current as a function of time, respectively;

- U0 and I0 indicate the amplitude of the voltage and current, respectively;

- is the angular frequency of the AC current;

- is the displacement angle;

- U and I are the complex-valued voltage and current, respectively;

- Z and Y are the complex impedance and admittance, respectively;

- indicates the real part of a complex number; and

- is the imaginary unit.

The impedance and admittance may be expressed as complex numbers that can be broken into real and imaginary parts:

where R is resistance, G is conductance, X is reactance, and B is susceptance. These lead to the complex number identities which are true in all cases, whereas is only true in the special cases of either DC or reactance-free current.

The complex angle is the phase difference between the voltage and current passing through a component with impedance Z. For capacitors and inductors, this angle is exactly -90° or +90°, respectively, and X and B are nonzero. Ideal resistors have an angle of 0°, since X is zero (and hence B also), and Z and Y reduce to R and G respectively. In general, AC systems are designed to keep the phase angle close to 0° as much as possible, since it reduces the reactive power, which does no useful work at a load. In a simple case with an inductive load (causing the phase to increase), a capacitor may be added for compensation at one frequency, since the capacitor's phase shift is negative, bringing the total impedance phase closer to 0° again.

Y is the reciprocal of Z () for all circuits, just as for DC circuits containing only resistors, or AC circuits for which either the reactance or susceptance happens to be zero (X or B = 0, respectively) (if one is zero, then for realistic systems both must be zero).

Frequency dependence

[edit]A key feature of AC circuits is that the resistance and conductance can be frequency-dependent, a phenomenon known as the universal dielectric response.[8] One reason, mentioned above is the skin effect (and the related proximity effect). Another reason is that the resistivity itself may depend on frequency (see Drude model, deep-level traps, resonant frequency, Kramers–Kronig relations, etc.)

Energy dissipation and Joule heating

[edit]

Resistors (and other elements with resistance) oppose the flow of electric current; therefore, electrical energy is required to push current through the resistance. This electrical energy is dissipated, heating the resistor in the process. This is called Joule heating (after James Prescott Joule), also called ohmic heating or resistive heating.

The dissipation of electrical energy is often undesired, particularly in the case of transmission losses in power lines. High voltage transmission helps reduce the losses by reducing the current for a given power.

On the other hand, Joule heating is sometimes useful, for example in electric stoves and other electric heaters (also called resistive heaters). As another example, incandescent lamps rely on Joule heating: the filament is heated to such a high temperature that it glows "white hot" with thermal radiation (also called incandescence).

The formula for Joule heating is: where P is the power (energy per unit time) converted from electrical energy to thermal energy, R is the resistance, and I is the current through the resistor.

Dependence on other conditions

[edit]Temperature dependence

[edit]Near room temperature, the resistivity of metals typically increases as temperature is increased, while the resistivity of semiconductors typically decreases as temperature is increased. The resistivity of insulators and electrolytes may increase or decrease depending on the system. For the detailed behavior and explanation, see Electrical resistivity and conductivity.

As a consequence, the resistance of wires, resistors, and other components often change with temperature. This effect may be undesired, causing an electronic circuit to malfunction at extreme temperatures. In some cases, however, the effect is put to good use. When temperature-dependent resistance of a component is used purposefully, the component is called a resistance thermometer or thermistor. (A resistance thermometer is made of metal, usually platinum, while a thermistor is made of ceramic or polymer.)

Resistance thermometers and thermistors are generally used in two ways. First, they can be used as thermometers: by measuring the resistance, the temperature of the environment can be inferred. Second, they can be used in conjunction with Joule heating (also called self-heating): if a large current is running through the resistor, the resistor's temperature rises and therefore its resistance changes. Therefore, these components can be used in a circuit-protection role similar to fuses, or for feedback in circuits, or for many other purposes. In general, self-heating can turn a resistor into a nonlinear and hysteretic circuit element. For more details see Thermistor#Self-heating effects.

If the temperature T does not vary too much, a linear approximation is typically used: where is called the temperature coefficient of resistance, is a fixed reference temperature (usually room temperature), and is the resistance at temperature . The parameter is an empirical parameter fitted from measurement data. Because the linear approximation is only an approximation, is different for different reference temperatures. For this reason it is usual to specify the temperature that was measured at with a suffix, such as , and the relationship only holds in a range of temperatures around the reference.[9]

The temperature coefficient is typically +3×10−3 K−1 to +6×10−3 K−1 for metals near room temperature. It is usually negative for semiconductors and insulators, with highly variable magnitude.[e]

Strain dependence

[edit]Just as the resistance of a conductor depends upon temperature, the resistance of a conductor depends upon strain.[10] By placing a conductor under tension (a form of stress that leads to strain in the form of stretching of the conductor), the length of the section of conductor under tension increases and its cross-sectional area decreases. Both these effects contribute to increasing the resistance of the strained section of conductor. Under compression (strain in the opposite direction), the resistance of the strained section of conductor decreases. See the discussion on strain gauges for details about devices constructed to take advantage of this effect.

Light illumination dependence

[edit]Some resistors, particularly those made from semiconductors, exhibit photoconductivity, meaning that their resistance changes when light is shining on them. Therefore, they are called photoresistors (or light dependent resistors). These are a common type of light detector.

Superconductivity

[edit]Superconductors are materials that have exactly zero resistance and infinite conductance, because they can have V = 0 and I ≠ 0. This also means there is no joule heating, or in other words no dissipation of electrical energy. Therefore, if superconductive wire is made into a closed loop, current flows around the loop forever. Superconductors require cooling to temperatures near 4 K with liquid helium for most metallic superconductors like niobium–tin alloys, or cooling to temperatures near 77 K with liquid nitrogen for the expensive, brittle and delicate ceramic high temperature superconductors. Nevertheless, there are many technological applications of superconductivity, including superconducting magnets.

See also

[edit]- Conductance quantum

- Von Klitzing constant (its reciprocal)

- Electrical measurements

- Contact resistance

- Electrical resistivity and conductivity for more information about the physical mechanisms for conduction in materials.

- Johnson–Nyquist noise

- Quantum Hall effect, a standard for high-accuracy resistance measurements.

- Resistor

- RKM code

- Series and parallel circuits

- Sheet resistance

- SI electromagnetism units

- Thermal resistance

- Voltage divider

- Voltage drop

Footnotes

[edit]- ^ The resistivity of copper is about 1.7×10−8 Ω⋅m.[4]

- ^ For a fresh Energizer E91 AA alkaline battery, the internal resistance varies from 0.9 Ω at −40 °C, to 0.1 Ω at +40 °C.[6]

- ^ A 60 W light bulb (in the USA, with 120 V mains electricity) draws RMS current 60 W/120 V = 500 mA, so its resistance is 120 V/500 mA = 240 Ω. The resistance of a 60 W light bulb in Europe (230 V mains) is 900 Ω. The resistance of a filament is temperature-dependent; these values are for when the filament is already heated up and the light is already glowing.

- ^ 100 kΩ for dry skin contact, 1 kΩ for wet or broken skin contact. High voltage breaks down the skin, lowering resistance to 500 Ω. Other factors and conditions are relevant as well. For more details, see the electric shock article, and NIOSH 98-131.[7]

- ^ See Electrical resistivity and conductivity for a table. The temperature coefficient of resistivity is similar but not identical to the temperature coefficient of resistance. The small difference is due to thermal expansion changing the dimensions of the resistor.

References

[edit]- ^ a b Brown, Forbes T. (2006). Engineering System Dynamics: A Unified Graph-Centered Approach (2nd ed.). Boca Raton, Florida: CRC Press. p. 43. ISBN 978-0-8493-9648-9.

- ^ a b Kaiser, Kenneth L. (2004). Electromagnetic Compatibility Handbook. Boca Raton, Florida: CRC Press. pp. 13–52. ISBN 978-0-8493-2087-3.

- ^ Fink & Beaty (1923). "Standard Handbook for Electrical Engineers". Nature. 111 (2788) (11th ed.): 17–19. Bibcode:1923Natur.111..458R. doi:10.1038/111458a0. hdl:2027/mdp.39015065357108. S2CID 26358546.

- ^ Cutnell, John D.; Johnson, Kenneth W. (1992). Physics (2nd ed.). New York: Wiley. p. 559. ISBN 978-0-471-52919-4.

- ^ McDonald, John D. (2016). Electric Power Substations Engineering (2nd ed.). Boca Raton, Florida: CRC Press. pp. 363ff. ISBN 978-1-4200-0731-2.

- ^ Battery internal resistance (PDF) (Report). Energizer Corp. Archived from the original (PDF) on 11 January 2012. Retrieved 13 December 2011.

- ^ "Worker Deaths by Electrocution" (PDF). National Institute for Occupational Safety and Health. Publication No. 98-131. Retrieved 2 November 2014.

- ^ Zhai, Chongpu; Gan, Yixiang; Hanaor, Dorian; Proust, Gwénaëlle (2018). "Stress-dependent electrical transport and its universal scaling in granular materials". Extreme Mechanics Letters. 22: 83–88. arXiv:1712.05938. Bibcode:2018ExML...22...83Z. doi:10.1016/j.eml.2018.05.005. S2CID 51912472.

- ^ Ward, M.R. (1971). Electrical Engineering Science. McGraw-Hill. pp. 36–40.

- ^ Meyer, Sebastian; et al. (2022), "Characterization of the deformation state of magnesium by electrical resistance", Volume 215, Scripta Materialia, vol. 215, p. 114712, doi:10.1016/j.scriptamat.2022.114712, S2CID 247959452

External links

[edit]- "Resistance calculator". Vehicular Electronics Laboratory. Clemson University. Archived from the original on 11 July 2010.

- "Electron conductance models using maximal entropy random walks". wolfram.com. Wolfram Demonstrantions Project.

Electrical resistance and conductance

View on GrokipediaBasic Concepts

Overview

Electrical resistance is the opposition to the flow of electric current through a material, arising from interactions between charge carriers and the atomic structure of the conductor.[6] This opposition causes energy dissipation as heat, limiting the current for a given voltage. The SI unit of electrical resistance is the ohm (Ω), defined such that 1 Ω equals 1 volt per ampere (V/A).[7] Electrical conductance is the reciprocal of resistance, quantifying a material's ability to allow electric current to pass through it.[8] Denoted by the relation , where is conductance and is resistance, it measures the ease of current flow. The SI unit of conductance is the siemens (S), defined as the reciprocal of the ohm and equivalent to 1 ampere per volt (A/V).[2] The concept of electrical resistance was formalized by German physicist Georg Simon Ohm in his 1827 publication Die galvanische Kette, mathematisch bearbeitet, which established resistance as a fundamental property influencing current in circuits.[9] Ohm's work laid the groundwork for understanding these quantities, later connected through Ohm's law relating voltage, current, and resistance. To conceptualize these ideas, resistance can be likened to friction in fluid flow, where it hinders current like frictional drag impedes the movement of water through a pipe, while conductance represents the relative ease of that flow.[10] The ohm (Ω) employs SI prefixes for scaling, such as kilo- (k, denoting ) for kΩ or milli- (m, denoting ) for mΩ, to express a wide range of values in practical applications.[11] Similarly, the siemens (S) uses prefixes like milli- (mS, S) or micro- (μS, S) to denote smaller conductances, ensuring precise representation across scales.[11]Conductors and Resistors

Conductors are materials that exhibit low electrical resistance, facilitating the easy flow of electric current due to the abundance of free electrons. Metals such as copper and silver are prime examples of good conductors, with copper widely used in electrical wiring for its favorable combination of low resistance and availability.[12][13] Silver, while offering even lower resistance, is less common in practical applications due to its higher cost.[14] These materials form the basis of conductive elements like wires, which serve as pathways for current in circuits and power distribution systems.[15] Resistors, in contrast, are passive electronic components intentionally designed to introduce a specific amount of resistance into a circuit, primarily to limit current flow, divide voltages, or protect other components from excessive power. They are categorized into fixed resistors, which maintain a constant resistance value, and variable resistors, such as potentiometers and rheostats, which allow adjustable resistance for applications like volume controls or tuning circuits.[16] Fixed resistors are often constructed using carbon film, where a thin layer of carbon is deposited on a ceramic substrate, or wirewound designs that wrap a resistive alloy wire around an insulating core for higher power handling.[17][18] Potentiometers typically employ a sliding or rotating contact on a resistive element to vary resistance, enabling precise control in analog devices.[19] Insulators are materials characterized by high electrical resistance, which effectively blocks the flow of current and prevents unintended electrical paths. Common examples include rubber, glass, and plastics like polyvinyl chloride (PVC), which are employed to coat conductive wires and components.[20][21] These materials play a critical role in electrical systems by insulating conductors, thereby avoiding short circuits that could lead to equipment damage or hazards.[22] Semiconductors occupy an intermediate position in terms of resistance, with properties between those of conductors and insulators, allowing controlled conductivity that can be modulated by factors such as temperature, doping, or applied electric fields. Silicon is the most prevalent semiconductor material, forming the foundation of integrated circuits and transistors due to its tunable electrical behavior.[23] Unlike pure conductors, which maintain low resistance regardless of conditions, or insulators, which resist current flow consistently, semiconductors enable the design of devices like diodes and transistors by exploiting this variability.[24][25] In practice, no conductor achieves the ideal state of zero resistance; real-world conductors possess finite resistance, resulting in energy losses primarily through heat generation via Joule heating. This deviation from ideality necessitates considerations in circuit design, such as minimizing wire lengths or selecting materials with the lowest possible resistance to reduce these losses.Ohm's Law

Ohm's law describes the fundamental linear relationship between voltage, current, and resistance in electrical circuits. It states that the direct current (I) through a conductor between two points is directly proportional to the voltage (V) across the two points, with the proportionality constant being the resistance (R) of the conductor. This relationship is mathematically expressed as where V is the potential difference in volts (V), I is the electric current in amperes (A), and R is the resistance in ohms (Ω).[26] The law was formulated by German physicist Georg Simon Ohm based on extensive experimental measurements of voltage and current in metallic conductors, culminating in his 1827 publication Die galvanische Kette, mathematisch bearbeitet, where he derived the proportionality from empirical data showing consistent ratios of voltage to current. Graphically, Ohm's law manifests as a straight line when voltage is plotted against current, with the line passing through the origin and the slope corresponding to the resistance R. This linear V-I characteristic confirms the direct proportionality for materials obeying the law.[27] In terms of conductance, the reciprocal of resistance, the law can be rewritten as where G is the conductance in siemens (S), defined as . This form emphasizes the ease with which current flows for a given voltage in low-resistance materials.[28] The law applies specifically to ohmic materials—such as most metals and resistors—under conditions of constant temperature and steady-state direct current, where resistance remains independent of the applied voltage or current.[29] It assumes a linear response, holding true for DC circuits where the current is uniform and the material's properties do not vary with operating conditions. However, Ohm's law breaks down for non-ohmic devices, such as diodes or filament lamps, where the V-I relationship is nonlinear due to factors like temperature dependence or asymmetric charge carrier behavior.[30] In practical applications, Ohm's law forms the basis for analyzing simple resistor circuits, enabling calculations such as determining the current through a resistor given the voltage and resistance values, as in . This underpins fundamental circuit design and troubleshooting in electronics.[31]Material Properties

Resistivity

Electrical resistivity, often denoted by the symbol , is an intrinsic property of a material that measures its inherent opposition to the flow of electric current, independent of the specimen's dimensions. It is defined as the electrical resistance of a uniform prismatic specimen of the material multiplied by its cross-sectional area and divided by its length , expressed by the formula . The SI unit of resistivity is the ohm-meter (), reflecting the adjustment for geometric factors to isolate the material's characteristic resistance per unit length and area.[32][33][34] At the microscopic level, resistivity arises primarily from the scattering of conduction electrons by obstacles within the material, such as lattice vibrations (phonons), impurities, and defects. The classical Drude model describes this process by treating electrons as a gas of free particles that undergo frequent collisions, with resistivity inversely proportional to the electron density, charge, and mean free path—the average distance an electron travels between scattering events. This mean free path, typically on the order of tens to hundreds of nanometers in metals at room temperature, limits the electrons' drift velocity under an applied electric field, leading to finite conductivity.[35][36] The value of resistivity varies significantly with temperature due to changes in scattering rates. In metals, increased temperature intensifies lattice vibrations, shortening the mean free path and thus raising resistivity, which is characterized by a positive temperature coefficient (typically around to per kelvin). Conversely, in semiconductors, higher temperatures provide thermal energy to excite additional charge carriers from the valence band to the conduction band, outweighing scattering effects and resulting in a decrease in resistivity with a negative temperature coefficient.[37][38] Representative examples illustrate the range of resistivity values across material classes. For copper, a prototypical conductor, at 20°C, enabling efficient current flow in wiring applications. In contrast, insulators such as glass exhibit extremely high resistivities, often exceeding at room temperature, which prevents significant current leakage and supports their use in electrical isolation.[39][40] To accurately measure resistivity, especially in thin films where contact resistance can dominate, the four-point probe method is commonly employed. This technique uses four collinear probes in contact with the sample: a known current is injected through the outer pair, while the voltage drop is measured across the inner pair, eliminating the effects of probe-sample contact resistance and yielding the sheet resistance from which bulk resistivity is calculated if the film thickness is known.[41][42]Conductivity

Electrical conductivity, denoted by the symbol σ, quantifies a material's ability to conduct electric current and is defined as the reciprocal of electrical resistivity ρ, such that σ = 1/ρ.[32] The SI unit of conductivity is the siemens per meter (S/m), which reflects the material's intrinsic ease of charge carrier flow under an applied electric field.[32] From a microscopic perspective, the Drude model provides a classical explanation for conductivity in metals, treating conduction electrons as a gas of free particles subject to collisions. In this model, the conductivity is given by σ = n e² τ / m, where n is the density of charge carriers (typically electrons), e is the elementary charge, τ is the average relaxation time between collisions, and m is the effective mass of the electron.[43] This formula highlights how conductivity depends on the number of available carriers, their charge, mobility (influenced by τ and m), and scattering processes that limit mean free path. Electrical conductivity arises through different mechanisms depending on the material. In metals, it is primarily electronic, driven by the drift of free electrons in response to an electric field, enabling high values at room temperature.[44] In electrolytes, ionic conductivity predominates, where charged ions migrate through the medium, often in solutions or molten salts.[44] Semiconductors exhibit both electronic and ionic contributions, with conductivity tunable via external factors; for instance, silicon's intrinsic conductivity is low (~10^{-4} S/m), but it can incorporate both free electrons and holes as carriers.[44] Among metals, silver exhibits one of the highest electrical conductivities, approximately 6.3 × 10^7 S/m at 20°C, owing to its high electron density and low scattering rates in pure form.[45] It is important to distinguish electrical conductivity from thermal conductivity, as the former pertains specifically to the transport of electric charge by carriers, whereas the latter involves the transfer of thermal energy, often by the same carriers in metals but through different physical processes like phonon interactions in insulators.[46] Several factors influence conductivity in materials. In semiconductors, doping—intentional introduction of impurities—increases conductivity by orders of magnitude; for example, adding phosphorus to silicon provides extra electrons, raising n-type conductivity from intrinsic levels to ~10^2–10^4 S/m.[47] In metals, higher purity enhances conductivity by reducing impurity scattering, which shortens τ; even trace impurities can decrease silver's conductivity by 10–20% compared to its ideal value.[48]Relation to Geometry

The resistance of a conductor is intrinsically linked to its material properties and geometric configuration, particularly for prismatic shapes with uniform cross-section. For a cylindrical conductor of length and cross-sectional area , the resistance is expressed as where is the material's resistivity. This relation derives from Ohm's law applied to the conductor, where the voltage drop corresponds to the electric field integrated along the length, assuming uniform current density and .[49]/University_Physics_II_-Thermodynamics_Electricity_and_Magnetism(OpenStax)/09%3A_Current_and_Resistance/9.04%3A_Resistivity_and_Resistance) The reciprocal quantity, electrical conductance , follows as where is the conductivity. This form highlights how conductance increases with larger cross-sectional area, providing more pathways for current, and decreases with greater length./06%3A_Steady_Current_and_Conductivity/6.05%3A_Conductance)[50] In practical terms, these formulas illustrate key geometric effects: a longer conductor exhibits higher resistance because the current must traverse a greater distance, while a thicker conductor (larger ) has lower resistance due to reduced opposition from parallel current paths. For instance, doubling the length of a wire doubles its resistance, assuming constant material and cross-section, whereas doubling the diameter quadruples the area and thus halves the resistance. For non-uniform geometries, such as tapered resistors where the cross-section varies along the length, the total resistance requires integrating the differential form , where is the local area, rather than using the simple lumped formula.[49][50] Unit consistency in the resistance formula ensures dimensional homogeneity: with in ohm-meters (), in meters (), and in square meters (), the result is in ohms (). This standardization facilitates calculations across scales, from microscopic wires to macroscopic components./University_Physics_II_-Thermodynamics_Electricity_and_Magnetism(OpenStax)/09%3A_Current_and_Resistance/9.04%3A_Resistivity_and_Resistance)[50] These geometric dependencies underpin resistor design, where engineers select materials with known and tailor and —often via winding wire around a core or depositing thin films—to achieve precise resistance values for circuit applications.[33][51]Measurement and Values

Measurement Techniques

Electrical resistance and conductance are typically measured using direct current (DC) or alternating current (AC) techniques, depending on the frequency range and precision required. In DC methods, the most straightforward approach is the voltmeter-ammeter setup, where a known current is passed through the sample via an ammeter, and the voltage drop across it is measured with a voltmeter; resistance is then calculated using Ohm's law as the ratio of voltage to current.[52] This method is widely used in introductory and general laboratory settings due to its simplicity and accessibility.[52] For higher precision in DC measurements, particularly for resistances in the ohm to kiloohm range, the Wheatstone bridge circuit balances two voltage dividers to null the current through a galvanometer, allowing the unknown resistance to be determined from known standard resistors without direct current measurement.[53] This technique, originally refined in the 19th century, minimizes errors from instrument internal resistances and is still employed in calibration labs.[54] In AC methods, suitable for components exhibiting frequency-dependent behavior, LCR meters apply a sinusoidal voltage or current at selectable frequencies (typically from a few hertz to megahertz) and measure the resulting impedance magnitude and phase, from which the effective resistance can be extracted.[55] These instruments use auto-balancing bridge principles or vector analysis to separate resistive components from capacitive or inductive effects.[56] For high-frequency applications up to several gigahertz, impedance analyzers provide broader frequency sweeps and higher resolution, employing RF signal generation and vector network analysis to characterize resistance as part of the overall impedance.[57] Such tools are essential for evaluating components like capacitors or inductors where skin effect or dielectric losses influence the resistive component.[57] To mitigate errors from lead and contact resistances, especially in low-resistance measurements (below 1 ohm), four-terminal sensing, also known as the Kelvin method, separates the current-carrying leads from the voltage-sensing leads, ensuring the voltmeter measures only the voltage across the sample itself.[58] This configuration uses high-impedance sensing to draw negligible current, providing accuracies down to microohms in precision setups.[59] It is commonly integrated into specialized instruments for applications like shunt resistor calibration or printed circuit board trace evaluation.[58] Common tools for resistance measurement include multimeters, which offer versatile two- or four-wire modes for general-purpose DC and low-frequency AC readings across a broad range (milliohms to megaohms) with moderate accuracy.[60] For very low resistances, micro-ohmmeters employ high-current sources and Kelvin connections to resolve values as small as microohms, often used in welding or connector testing.[61] Conversely, megohmmeters apply high voltages (up to 1000 V) to measure insulation resistances in the megohm to gigaohm range, detecting leakage paths in cables or dielectrics.[61] These devices typically feature automated ranging and digital displays for ease of use in field or lab environments.[60] Measurement accuracy can be compromised by several error sources, including contact resistance at probe-sample interfaces, which adds extraneous voltage drops and is particularly problematic in low-resistance setups unless mitigated by four-terminal methods.[62] Thermal electromotive forces (EMFs) generated at dissimilar metal junctions can introduce offset voltages in DC measurements, requiring reversal techniques or low-current operation to average them out.[63] In AC contexts, frequency limitations arise from parasitic capacitances or inductances in leads and instruments, distorting readings above the device's specified bandwidth.[56] Calibration against traceable standards, such as those maintained by the National Institute of Standards and Technology (NIST), is essential to quantify and correct these errors, ensuring uncertainties below 0.01% for precision work.[64] For small-signal applications, techniques akin to differential resistance measurement may be referenced briefly in AC setups to assess non-linear behaviors.[63]Typical Values

Electrical resistance and conductance vary widely across materials, components, and environmental conditions, providing essential reference points for engineering and scientific applications. For metals, which exhibit low resistivity and high conductivity, copper serves as a benchmark with a resistivity of 1.72 × 10^{-8} Ω·m at 20°C, making it ideal for electrical wiring due to its efficient current-carrying capacity.[38] Semiconductors like undoped silicon have higher resistivities, typically ranging from 10^3 to 10^5 Ω·m, reflecting their intermediate behavior between conductors and insulators and dependence on purity and temperature.[65] Insulators, such as Teflon (polytetrafluoroethylene, PTFE), demonstrate extremely high resistivity exceeding 10^{18} Ω·cm (or 10^{16} Ω·m), enabling their use in high-voltage insulation where minimal current leakage is critical.[66] Common components exhibit practical resistance ranges tailored to circuit needs. Fixed resistors, the most prevalent type, are available in standard values from 1 Ω to 10 MΩ, following E-series preferences to cover logarithmic decades with tolerances like 5% or 1%.[67] The human body presents variable resistance influenced by skin condition, measuring 1 kΩ to 100 kΩ for dry skin but dropping significantly to around 1 kΩ or less when wet due to reduced barrier impedance.[68] Conductance, the reciprocal of resistance, reaches exceptional levels in superconductors, approaching infinite conductivity (zero resistivity) below their critical temperature, as observed in materials like niobium-titanium alloys cooled to near absolute zero for applications in MRI machines and particle accelerators.[69] Environmental media also show diverse values; dry air has a resistivity of approximately 10^{16} Ω·m, acting as an effective insulator under normal conditions, while electrolytes like seawater exhibit low resistivity around 0.2 Ω·m owing to dissolved salts enhancing ionic conduction.[38][70] For practical wiring, resistance scales with geometry, particularly cross-sectional area in wire gauges. The table below lists typical DC resistance per meter for solid copper wires at 20°C across common American Wire Gauge (AWG) sizes, illustrating how thinner wires yield higher resistance.| AWG | Diameter (mm) | Resistance (Ω/m) |

|---|---|---|

| 10 | 2.588 | 0.00334 |

| 12 | 2.053 | 0.00531 |

| 14 | 1.628 | 0.00843 |

| 18 | 1.024 | 0.02095 |

| 22 | 0.644 | 0.0842 |

Resistance Characteristics

Static Resistance

Static resistance, also known as chordal resistance, is defined as the ratio of the change in voltage to the change in current over a finite range along the current-voltage (I-V) characteristic curve, given byThis measure corresponds to the inverse slope of a straight line (chord) drawn from the origin to a point on the I-V curve.[72] For ohmic (linear) devices, where the I-V relationship follows Ohm's law, static resistance is constant and simply equals at any operating point.[73] In steady-state direct current (DC) circuits, static resistance quantifies the total opposition to current flow, identical to the conventional resistance value used in basic circuit analysis.[73] It applies directly to components like resistors, where the value remains fixed regardless of the applied voltage or current within rated limits. For non-linear devices, such as semiconductor diodes, static resistance is evaluated at a specific DC operating point as the ratio of the applied DC voltage to the resulting DC current, , providing an average slope over that range rather than an instantaneous value.[74] This approach is particularly useful for approximating device behavior in DC-biased circuits without requiring detailed curve analysis. Static resistance finds key applications in power calculations for electrical components and systems. The power dissipated as heat (Joule heating) in a device can be computed using or equivalently , helping engineers select appropriately rated parts to avoid overheating or failure. In non-linear contexts, it serves as an effective average resistance for overall circuit performance estimates, such as determining load currents or voltage drops in rectifier circuits. A practical example is the internal resistance of a battery, which manifests as a static voltage drop under load and is calculated as , where is the open-circuit voltage; this metric assesses battery health and efficiency during discharge.[75] Multimeters commonly employ static resistance measurements for component testing in DC mode, applying a small known current (typically 1 mA or less) across the device and computing resistance from the measured voltage drop via Ohm's law.[76] However, this method assumes steady-state conditions and can be inaccurate for components with time-varying signals or highly non-linear responses, where small-signal approximations like differential resistance offer a more precise local characterization.[73]

Differential Resistance

Differential resistance, also known as dynamic or small-signal resistance, quantifies the local responsiveness of a device to infinitesimal changes in voltage and current at a specific operating (bias) point on its current-voltage (I-V) characteristic curve. It is defined as the reciprocal of the derivative of current with respect to voltage, expressed mathematically asrepresenting the slope of the tangent line to the I-V curve at that point. This measure is crucial for non-linear devices where the overall resistance varies with bias, providing insight into incremental behavior rather than average performance.[77][78] The related concept of differential conductance, , directly gives the slope of the I-V curve and is the inverse of differential resistance. In applications involving non-ohmic components, such as semiconductor devices, differential resistance informs small-signal models used in circuit design. For instance, in transistor amplifiers, it determines key parameters like transconductance () and output resistance, influencing overall gain and stability. Similarly, in noise analysis for low-signal circuits, the equivalent thermal noise voltage across the device is , where is Boltzmann's constant, is temperature, and is bandwidth, highlighting its role in assessing signal-to-noise ratios.[79][80] For forward-biased p-n junction diodes, the differential resistance simplifies to , where (ideality factor, typically 1 for diffusion-dominated transport or 2 for recombination) accounts for non-idealities, mV at room temperature is the thermal voltage, and is the DC bias current. This expression arises from differentiating the Shockley ideal diode equation , where is the saturation current, and is widely used to predict diode performance in rectifiers and detectors.[78] To experimentally determine differential resistance, a small-amplitude AC signal (typically millivolts) is superimposed on a DC bias, and the AC voltage and current responses are measured to compute their ratio, effectively probing the derivative without significantly perturbing the operating point. Lock-in amplifiers are commonly employed for this purpose, as they demodulate the AC components at a known reference frequency, rejecting broadband noise and enabling precise extraction of the small-signal parameters even at cryogenic temperatures or low currents.[81][82] A prominent example of negative differential resistance occurs in tunnel diodes, where quantum mechanical band-to-band tunneling in heavily doped p-n junctions leads to a region in the I-V curve with , resulting in . This counterintuitive effect, first demonstrated in germanium junctions, enables negative resistance oscillators operating at microwave frequencies and low-noise amplifiers, with peak-to-valley current ratios exceeding 10 in optimized devices. Unlike static resistance, which provides a global average, differential resistance reveals this local instability critical for such high-speed applications.

![{\displaystyle {\begin{aligned}R&=\rho {\frac {\ell }{A}},\\[5pt]G&=\sigma {\frac {A}{\ell }}\,.\end{aligned}}}](https://wikimedia.org/api/rest_v1/media/math/render/svg/b24667605c2703efd09de736ebc63d30be931418)

![{\displaystyle R(T)=R_{0}[1+\alpha (T-T_{0})]}](https://wikimedia.org/api/rest_v1/media/math/render/svg/5b6622ab35566bd32d26736effa752dc8ace798d)