Recent from talks

Nothing was collected or created yet.

Vinasse

View on WikipediaVinasse is a byproduct of the sugar or ethanol industry.[1] Sugarcane or sugar beet is processed to produce crystalline sugar, pulp and molasses. The latter are further processed by fermentation to ethanol, ascorbic acid or other products. Juice sugarcane can also be processed directly by ethanol fermentation. After the removal of the desired product (alcohol, ascorbic acid, etc.) the remaining material is called vinasse. Vinasse is sold after a partial dehydration and usually has a viscosity comparable to molasses. Commercially offered vinasse comes either from sugar cane and is called cane-vinasse or from sugar beet and is called beet-vinasse. Vinasse produced from sugar cane is also called dunder.[2]

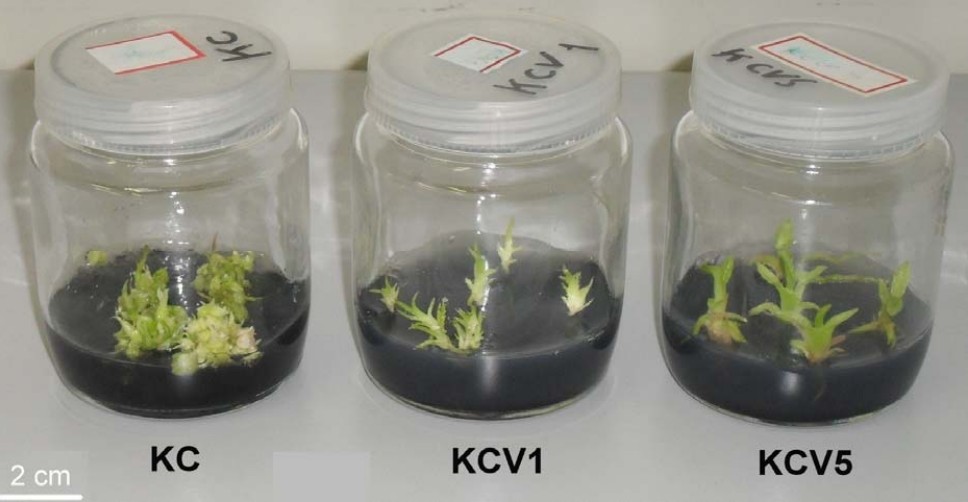

In the process of distillation of the alcohol and as a result of the heating in the distillation process, in the pulp of the beet reactions of condensation and predominantly molecular ruptures take place. This causes a high fulvic acid concentration in this byproduct. One use of vinasse is in thermophilic digesters. In Brazil, thermophilic digestion is a source of biogas using pure and hot vinasse as the source of production of methane. In the past, vinasse was a problem in production of ethanol, but vinasse is also a good fertilizer (at least for some time) and a source of methane that can be used to generate heat or electricity. Moreover, other uses of vinasse involving also the formulation of nutritive solutions for hydroponics,[3] formulation of culture media for plant tissue culture [4] and culture media for algal growth.[5][6]

See also

[edit]References

[edit]- ^ Hidalgo, K. (2009) Vinasse in feed: Good for animal and environment. Feed Tech, 13(5):18-20.

- ^ Muspratt, Sheridan; Horsford, Eben Norton (1860). Chemistry, Theoretical, Practical, and Analytical: As Applied and Relating to the Arts and Manufactures. W. Mackenzie. pp. 107. Retrieved 27 February 2012.

dunder.

- ^ Santos, J. D. et al (2013) Development of a vinasse nutritive solutions for hydroponics. Journal of Environmental Management 114: 8-12.

- ^ Silva, A. L. L. et al (2014) Development of a vinasse culture medium for plant tissue culture. Pakistan Journal of Botany 46 (6): 2195-2202.

- ^ Gollo, A. L. et al (2016) Developing a plant culture medium composed of vinasse originating from Haematococcus pluvialis culture. Pakistan Journal of Botany 48 (1): 295-303.

- ^ Colusse, Guilherme Augusto; Santos, André Oliveira; Rodrigues, Jenifer Mota; Barga, Marcelo Calide; Duarte, Maria Eugênia Rabello; de Carvalho, Júlio Cesar; Noseda, Miguel Daniel (2021-07-01). "Rice vinasse treatment by immobilized Synechococcus pevalekii and its effect on Dunaliella salina cultivation". Bioprocess and Biosystems Engineering. 44 (7): 1477–1490. doi:10.1007/s00449-021-02531-9. ISSN 1615-7605.

Further reading

[edit]- Tejada, M., Gonzalez, J.L., 2006. Effects of two beet vinasse forms on soil physical properties and soil loss. Catena 68, 41–50