Recent from talks

Nothing was collected or created yet.

B Reactor

View on Wikipedia

B Reactor | |

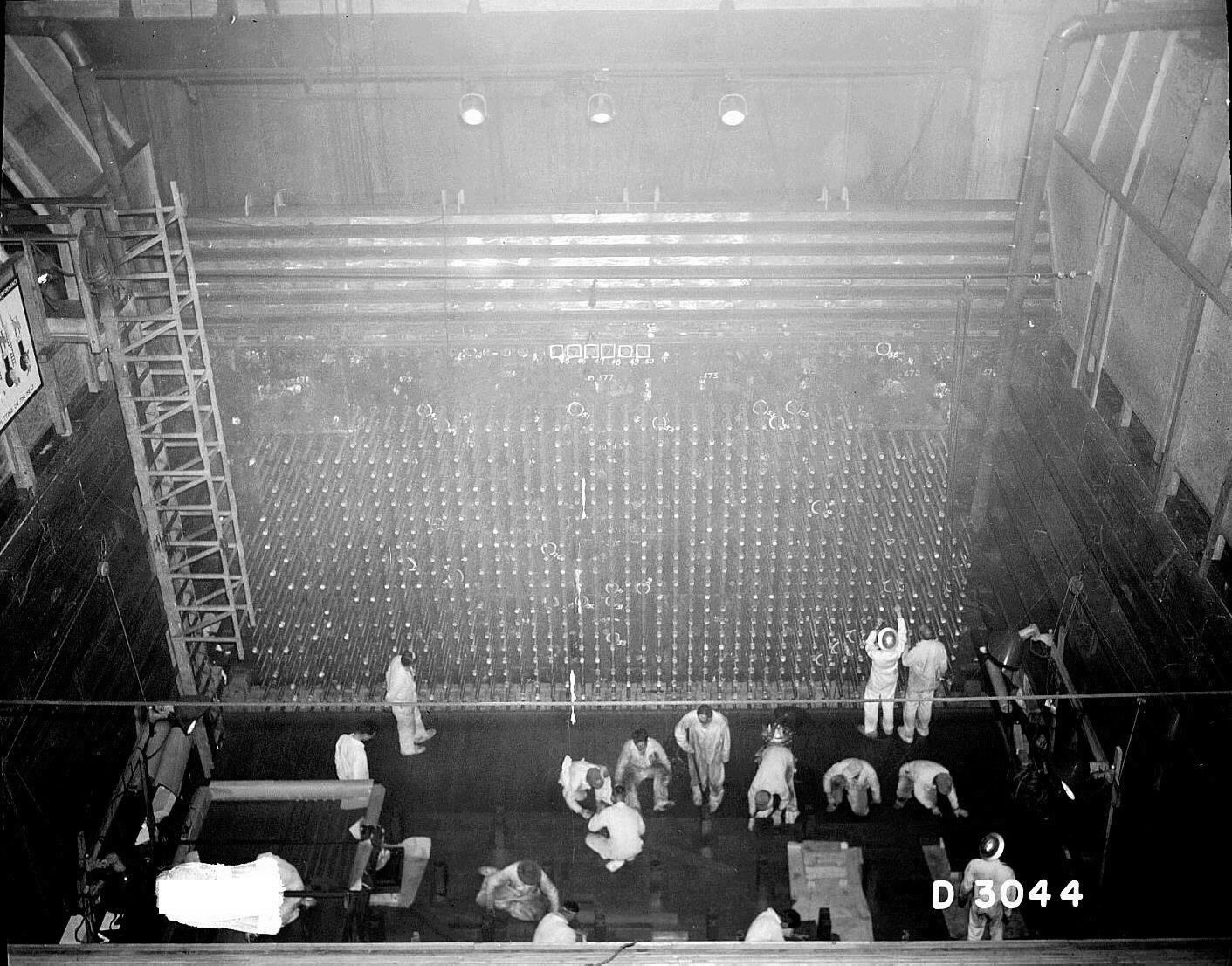

The face of B Reactor during construction. | |

| Location | About 5.3 miles (8.5 km) northeast of junction of State Route 24 and State Route 240 on the Hanford Site |

|---|---|

| Nearest city | Richland, Washington |

| Coordinates | 46°37′49″N 119°38′50″W / 46.63028°N 119.64722°W |

| Area | 9.5 acres (3.8 ha) |

| Built | 7 June 1943[1] to September 1944[2] |

| Architect | E.I. DuPont de Nemours & Company |

| NRHP reference No. | 92000245 |

| Significant dates | |

| Added to NRHP | 3 April 1992 |

| Designated NHL | 19 August 2008[3] |

The B Reactor at the Hanford Site, near Richland, Washington, was the first large-scale nuclear reactor ever built, at 250 MW. It achieved criticality on September 26, 1944. The project was a key part of the Manhattan Project, the United States nuclear weapons development program during World War II. Its purpose was to convert part of its natural uranium fuel into plutonium-239 by neutron activation, for use in nuclear weapons. Pure plutonium was then chemically separated in the site's T Plant, as an alternative to the Project's uranium enrichment plants. The B reactor was graphite moderated and water-cooled, via a contaminating open cycle with the Columbia River.

It was preceded by Clinton Laboratory's X-10 Graphite Reactor, a pilot plant for reactor production and chemical separation of plutonium, which by mid-1944 had reached a capacity of 4 MW. The B reactor thus represented a massive leap of two orders of magnitude in reactor design. Primarily constructed by DuPont, the operation was assisted by scientists including Enrico Fermi, John Archibald Wheeler, and Chien-Shiung Wu. Two identical reactors, the D Reactor and F Reactor, were launched in December 1944 and February 1945. The plutonium from the site was used in the Trinity test, the Fat Man bomb detonated above Nagasaki, the demon core, and thousands of US warheads during the Cold War. By the early 1960s, the reactors had been upgraded to capacities of 2000 MW. It is historically significant as the world's first large-scale reactor, the first to use water cooling, the first to experience xenon poisoning, the first employed for thermonuclear weapon tritium production, and the seventh critical assembly in total.

The reactor was permanently shut down in February 1968. It has been designated a U.S. National Historic Landmark since 19 August 2008[3][4] and in July 2011 the National Park Service recommended that the B Reactor be included in the Manhattan Project National Historical Park commemorating the Manhattan Project.[5] Visitors can take a tour of the reactor by advance reservation.[6]

Design and construction

[edit]The reactor was designed and built by E. I. du Pont de Nemours and Company based on experimental designs tested by Enrico Fermi at the University of Chicago, and tests from the X-10 Graphite Reactor at Oak Ridge National Laboratory. It was designed to operate at 250 megawatts (thermal).

The purpose of the reactor was to breed plutonium from natural uranium metal. Enriching fissionable 235U from 238U, the dominant natural isotope, was extremely complex; plutonium's distinct chemistry made separation trivial by comparison. For example, the Y12 uranium enrichment plant in Tennessee required 14,700 tons of silver loaned by the Treasury Department for the windings in its calutrons, employed 22,000 people and consumed more electrical power than most states. Reactor B on the other hand needed only a few dozen employees and far fewer exotic materials required in much smaller quantities. The most important special material needed were the 1,200 tons of purified graphite for neutron moderation, and only enough electricity to run the cooling pumps.[7][8]

The reactor has a footprint of 46 by 38 ft (14 by 12 m) (about 1,750 sq ft (163 m2) and is 41 ft (12 m) tall, giving a volume of 71,500 cu ft (2,020 m3). The reactor core itself consists of a 36 ft-tall (11 m) graphite box measuring 28 by 36 ft (8.5 by 11.0 m) occupying a volume of 36,288 cu ft (1,027.6 m3) and weighing 1,200 short tons (1,100 t). It is penetrated horizontally through its entire length by 2,004 aluminum tubes containing fuel and vertically by channels housing the control rods.[4]

The core is surrounded by a thermal shield of cast iron 8 to 10 in (20 to 25 cm) thick weighing 1,000 short tons (910 t). Masonite and steel plates enclose the thermal shield on its top and sides, forming a biological shield for radiation protection. The bottom of the thermal shield was supported by a 23 ft-thick (7.0 m) concrete pad topped by cast-iron blocks. Based on the success of the first atomic pile, graphite was selected to moderate the nuclear reaction. This reaction was fueled by 200 short tons (180 t) of metallic uranium slugs approximately 25 mm (1 in) diameter, 70 mm (3 in) long (about as large as of a roll of quarters[4]), sealed in aluminum cans, and loaded into the aluminum tubes.[4]

The reactor was water-cooled. Its coolant was pumped from the Hanford Reach of the Columbia River, through the aluminum tubes and around the uranium slugs at a rate of 75,000 US gal (280,000 L) per minute. The water was discharged into settling basins. Water was held in the basins to permit the decay of short-lived radioactive waste, the settling out of particulate matter gathered from the reactor, and for the water to cool to within 11 °F of the river's temperature. It was then discharged back into the Columbia River.[9]

Operation

[edit]The B Reactor had its first nuclear chain reaction in September 1944, the D Reactor in December 1944 and the F Reactor in February 1945. The initial operation was halted by a problem identified as neutron absorption by the fission product Xe-135, first identified in a research paper of Chien-Shiung Wu that was shared with Fermi.[10] It was overcome by increasing the amount of uranium charged. The reactor produced plutonium-239 by irradiating uranium-238 with neutrons generated by the nuclear reaction. It was one of three reactors – along with the D and F reactors – built about six miles (10 km) apart on the south bank of the Columbia River. Each reactor had its own auxiliary facilities that included a river pump house, large storage and settling basins, a filtration plant, large motor-driven pumps for delivering water to the face of the pile, and facilities for emergency cooling in case of a power failure.[4]

Emergency shutdown of the reactor, referred to as a SCRAM, was attained either by rapidly fully inserting the vertical safety rods or, as a backup method, by the injection of borated water into the reactor. In January 1952, the borated water system was replaced by a "Ball-3X" system that injected nickel-plated high-boron steel balls into the channels occupied by the vertical safety rods.[4]

The plutonium for the nuclear bomb used in the Trinity test in New Mexico and the Fat Man bomb dropped on Nagasaki, Japan was created in the B reactor. The B Reactor ran for two decades, and was joined by additional reactors constructed later. It was permanently shut down in February 1968.[4][11]

Current status

[edit]

The United States Department of Energy has administered the site since 1977[12][13] and offers public tours on set dates during the spring, summer, and fall of the year, as well as special tours for visiting officials.[6][14]

As of 2014[update] six of the nine production reactors at Hanford were considered to be in "interim safe storage" status, and two more were to receive similar treatment. The exception was the B Reactor, which was given special status for its historical significance.[15]

In a process called cocooning or entombment, the reactor buildings are demolished up to the 4 ft-thick (1.2 m) concrete shield around the reactor core. Any openings are sealed and a new roof is built.[16] Most auxiliary buildings at the first three reactors have been demolished, as well. The C reactor was put into operation in 1952 and was shut down in 1969.[17] It was cocooned as of 1998.[18] The D reactor operated from 1944 to June 1967, and was cocooned in 2004. The DR Reactor went online in October 1950,[19] and was shut down in 1964. It was cocooned in 2002.[20] The F reactor was shut down in June 1965 and cocooned in 2003.[21] The H Reactor became operational as of October 1949 and was shut down as of April 1965. It was cocooned as of 2005.[22] Cocooning of the N-Reactor, which operated from 1963 to 1987, was completed as of 14 June 2012.[23] The decommissioned reactors are inspected every five years by the Department of Energy.[18]

The K East and K West reactors were built in the 1950s and went into use in 1955. They were shut down in 1970 and 1971, but reused temporarily for storage later.[24] Preliminary plans for interim stabilizing of the K-East and K-West reactors were underway as of 30 January 2018.[16]

The B Reactor was added to the National Register of Historic Places (#92000245) on 3 April 1992. A Record of Decision (ROD) was issued in 1999, and an EPA Action Memorandum in 2001 authorized hazards mitigation in the reactor with the intention of allowing public tours of the reactor.[25] It was named a National Historic Landmark on 19 August 2008.[3][4]

In December 2014, passage of the 2015 National Defense Authorization Act (NDAA) made the B reactor part of the Manhattan Project National Historical Park, which also includes historic sites at Oak Ridge, Tennessee and Los Alamos, New Mexico.[26][27] The park was formally established by a Memorandum of Agreement on November 10, 2015, which was signed by the National Park Service and the Department of Energy. Museum development at Hanford may include the B Reactor, Bruggemann's Warehouse, Hanford High School, Pump House, and White Bluffs Bank.[28]

Timeline of major events

[edit]| Year | Date | Event |

|---|---|---|

| 1943 | October | U.S. Army Corps of Engineers breaks ground to build B Reactor[29] |

| 1944 | 13 September | First uranium fuel slug loaded into B Reactor[29] |

| 1944 | 26 September | Initial reactor criticality achieved[29] |

| 1945 | 3 February | B Reactor plutonium delivered to Los Alamos[29] |

| 1945 | 16 July | B Reactor plutonium used in world's first nuclear explosion. (Trinity Test Site, New Mexico) [29] |

| 1945 | 9 August | B Reactor plutonium used in Fat Man bomb dropped on Nagasaki, Japan[29] |

| 1946 | March | B Reactor operations suspended[29] |

| 1948 | June | B Reactor operation resumed[29] |

| 1949 | March | B Reactor begins production of tritium for use in hydrogen bombs[29] |

| 1954 | 1 March | First use of B Reactor tritium in a test detonation of a hydrogen bomb at Bikini Atoll[citation needed] |

| 1968 | January 29 | Atomic Energy Commission directs shutdown of B Reactor[29] |

| 1976 | B Reactor declared National Historic Mechanical Engineering Landmark by American Society of Mechanical Engineers[29] | |

| 1994 | B Reactor declared National Historic Civil Engineering Landmark by American Society of Civil Engineers[29] | |

| 2008 | B Reactor declared National Historic Landmark by U.S. Department of Interior and National Park Service[29] | |

| 2009 | U.S. Department of Energy announces public tours[30] | |

| 2011 | July | National Park Service recommends B Reactor be included in a national historic park commemorating the Manhattan Project.[5] |

| 2014 | December | 2015 National Defense Authorization Act (NDAA) includes B reactor in Manhattan Project National Historical Park[26] |

| 2015 | 10 November | Manhattan Project National Historical Park formally established by Memorandum of Agreement[28] |

See also

[edit]References

[edit]- ^ Shannon Dininny (26 August 2008). "World's first nuclear reactor now a landmark". Associated Press. Archived from the original on 16 September 2008. Retrieved 26 August 2008.

Construction began on June 7, 1943...

- ^ "Department of Energy – B Reactor". United States Department of Energy. 20 April 2007. Archived from the original on 16 September 2008. Retrieved 26 August 2008.

Completed in September 1944...

- ^ a b c "Weekly List Actions" (PDF). National Park Service. 29 August 2008. Archived from the original on 31 October 2008. Retrieved 30 August 2008.

- ^ a b c d e f g h Michele S. Gerber; Brian Casserly; Frederick L. Brown (February 2007). National Historic Landmark Nomination: B Reactor / 105-B; The 105-B Building in the 100-B/C Area at Hanford (PDF) (Report). National Park Service. Archived from the original (PDF) on 26 October 2012.

- ^ a b Cary, Annette (13 July 2011). "HANFORD: Park service recommends B Reactor for national park". Tri-City Herald. Archived from the original on 4 February 2013. Retrieved 17 July 2011.

- ^ a b "The B Reactor National Historic Landmark". Manhattan Project: B Reactor. Retrieved 12 November 2015.

- ^ The New World 1939, Page 71, Richard G. Hewlett, 1972

- ^ "B Reactor". U.S. Department of Energy.

- ^ United States Department of Energy. "Hanford Site Virtual Tours: 100-B Area". Hanford Site website. Richland, Washington. Archived from the original on 17 September 2008. Retrieved 23 October 2009.

- ^ Dicke, William (18 February 1997). "Chien-Shiung Wu, 84, Top Experimental Physicist".

- ^ Boyle, Rebecca (2017). "Greetings from Isotopia". Distillations. 3 (3): 26–35. Retrieved 19 June 2018.

- ^ Long, Tony (4 August 1977). "All U.S. Energy Placed Under Single Roof". Wired.com. Retrieved 19 June 2018.

- ^ "S. 826 — 95th Congress: Department of Energy Organization Act". www.GovTrack.us. 1977. Retrieved 19 June 2018.

- ^ "Hanford Site Tours". Hanford.gov. Retrieved 19 June 2018.

- ^ National Research Council (2014). Best Practices for Risk-Informed Decision Making Regarding Contaminated Sites: Summary of a Workshop Series. Washington, DC: The National Academies Press. ISBN 978-0-309-30305-7. Retrieved 19 June 2018.

- ^ a b Office of Environmental Management (30 January 2018). "Hanford Workers Enter Reactor to Prepare for Cocooning". Energy.gov. Retrieved 19 June 2018.

- ^ "C Reactor". Hanford.gov. Retrieved 19 June 2018.

- ^ a b Cary, Annette (4 July 2015). "Looking inside Hanford's cocooned reactors". Tri-City Herald. Retrieved 19 June 2018.

- ^ "D and DR Reactors". Hanford.gov. Retrieved 19 June 2018.

- ^ "ISS Reactors". Hanford.gov. Retrieved 19 June 2018.

- ^ Cary, Annette (22 October 2014). "Hanford's F Reactor passes 5-year inspection". Tri-City Herald. Retrieved 19 June 2018.

- ^ "H Reactor". Hanford.gov. Retrieved 19 June 2018.

- ^ Office of Environmental Management (14 June 2012). "N Reactor Placed In Interim Safe Storage: Largest Hanford Reactor Cocooning Project Now Complete". Energy.gov. Retrieved 19 June 2018.

- ^ Gerber, Michele Stenehjem (2007). On the home front : the cold war legacy of the Hanford nuclear site (3rd ed.). Lincoln: University of Nebraska Press. p. 227. ISBN 978-0803259959. Retrieved 19 June 2018.

- ^ Potter, Robert F. "Preserving the Hanford B-Reactor: A Monument to the Dawn of the Nuclear Age". APS Physics. Retrieved 19 June 2018.

- ^ a b "Congress Passes Manhattan Project National Historical Park Act". Atomic Heritage Foundation. 12 December 2014. Retrieved 20 June 2018.

- ^ "B Reactor Museum Association Richland, Washington, USA". B Reactor. Retrieved 20 June 2018.

- ^ a b "Foundation Document Manhattan Project National Historical Park Tennessee, New Mexico, Washington" (PDF). NATIONAL PARK SERVICE • U.S. DEPARTMENT OF THE INTERIOR. January 2017. p. 33. Retrieved 20 June 2018.

- ^ a b c d e f g h i j k l m Ms, Gerber (May 2009), Manhattan Project B Reactor: World's first full-scale nuclear reactor, vol. HNF-41115, Rev. 0, US Department of Energy, OSTI 952590

- ^ Manhattan Project B Reactor Tour Information, 14 February 2011, archived from the original on 21 July 2011, retrieved 17 July 2011

Further reading

[edit]- Washington Closure Hanford- "Project News Volume 1, Issue 04" (PDF). Archived from the original (PDF) on 29 November 2010. Retrieved 28 September 2010.

- "Hanford Site – Timeline 1943–1990" (PDF). 1997. Archived from the original (PDF) on 25 February 2009.

- History of the 100-B area (PDF) (Report). US DoE. WHC-EP-0273.

External links

[edit]- Historic American Engineering Record (HAER) No. WA-164, "B Reactor, Richland, Benton County, WA", 32 photos, 148 data pages, 4 photo caption pages

- "Ranger in Your Pocket" online tours Atomic Heritage Foundation

- Hanford 25th Anniversary Celebration Video of the 25th anniversary celebration of the construction of B Reactor

- B Reactor Museum Association A collection of Hanford-related documents from a group working to preserve the B-100 Reactor at Hanford.

- Hanford Site Tours – Department of Energy, includes B Reactor

B Reactor

View on GrokipediaHistorical Context

Role in the Manhattan Project

The B Reactor served as the cornerstone of plutonium production within the Manhattan Project, the United States' classified program to develop atomic weapons during World War II. Established at the Hanford Site in Washington state, it was engineered to irradiate uranium fuel in a sustained nuclear chain reaction, yielding plutonium-239 as a fissile material alternative to scarce uranium-235. This approach addressed the project's urgent need for bomb-grade material, leveraging graphite-moderated reactor technology scaled from Enrico Fermi's experimental Chicago Pile-1 to industrial levels capable of processing thousands of tons of uranium annually.[2][7] Construction of the B Reactor, the first of three planned plutonium facilities at Hanford's 100 Area, began in October 1943 under the direction of the U.S. Army Corps of Engineers and E.I. du Pont de Nemours & Company, which managed operations to maintain secrecy and efficiency. The reactor's design incorporated a 36-foot aluminum process tube lattice housing 2,004 uranium slugs cooled by the Columbia River, enabling power outputs up to 250 megawatts thermal. It achieved initial criticality on September 26, 1944, just 13 months after groundbreaking, validating the feasibility of continuous, high-volume plutonium breeding essential for weaponizing the element.[3][8][9] In its early operations, the B Reactor supplied the plutonium core for the Trinity test detonation on July 16, 1945—the world's first nuclear explosion—and for the Fat Man implosion-type bomb dropped on Nagasaki, Japan, on August 9, 1945, contributing directly to the war's end. By February 1945, it had reached full production power, yielding approximately 250 grams of plutonium daily and demonstrating the Manhattan Project's capacity to transition from laboratory-scale experiments to wartime industrial output under extreme secrecy constraints.[1][4][10]Hanford Site Selection and Establishment

The selection of the Hanford Site for plutonium production in the Manhattan Project began in spring 1942, driven by the need for a large-scale facility to irradiate uranium fuel in nuclear reactors and separate plutonium chemically.[11] Scientists at the Metallurgical Laboratory in Chicago, led by Arthur Compton, established key criteria including a minimum water supply of 25,000 U.S. gallons per minute for cooling, at least 100,000 kilowatts of electric power, and extensive isolation buffers such as a 4-mile safety radius around chemical separation plants and a 225-square-mile exclusion area to mitigate unknown radiation hazards.[11] These requirements assumed the construction of three to four helium-cooled reactors and two separation plants, prioritizing sites distant from population centers, railroads, and highways to ensure secrecy and safety.[11] By December 14, 1942, a meeting in Wilmington, Delaware, finalized these criteria, leading to Hanford's recommendation on December 31 after evaluating multiple locations.[11] Hanford, a remote desert valley along the Columbia River in southeastern Washington, was favored for its abundant cooling water from the river, reliable hydroelectric power from the nearby Grand Coulee and Bonneville Dams, stable basalt geology suitable for containment, and an uninhabited tract of approximately 500,000 acres with existing railroad access and regional labor availability.[11] [7] It outperformed alternatives like sites near Oak Ridge, Tennessee—deemed too proximate to urban areas for the risks of reactor operations—and other candidates in Indiana or Colorado that lacked comparable water and power resources or sufficient isolation.[11] [12] General Leslie Groves, head of the Manhattan Project, personally inspected the site and endorsed it on January 16, 1943, with final War Department approval on February 9, 1943.[7] [11] Site establishment proceeded rapidly in March 1943, with the U.S. government acquiring about 780 square miles of land for $5.1 million (in 1943 dollars), displacing fewer than 1,500 residents from the small farming communities of Hanford, White Bluffs, and Richland, who received compensation based on appraised property values excluding improvements like crops and equipment.[12] [13] The acquisition, managed by Colonel Franklin T. Matthias of the Army Corps of Engineers, involved 90-day eviction notices, though some residents pursued legal challenges settled out of court; the process also impacted Native American groups like the Wanapum tribe by restricting access to traditional Columbia River fishing grounds.[7] DuPont was contracted to design and construct the Hanford Engineer Works, emphasizing secrecy through compartmentalization and rapid wartime mobilization, which enabled groundbreaking for initial facilities like the B Reactor's water-cooling plant by August 1943.[11] [13] This establishment positioned Hanford as the primary site for full-scale plutonium production, complementing uranium enrichment at Oak Ridge.[12]Design and Engineering

Technical Specifications

The B Reactor was a graphite-moderated, light-water-cooled nuclear reactor designed for large-scale plutonium production as part of the Manhattan Project.[2][14] Its core consisted of a graphite stack measuring 36 feet by 36 feet by 28 feet, comprising approximately 2,200 tons of high-purity graphite arranged in about 75,000 machined blocks.[14][15] The reactor was designed for a thermal power output of 250 megawatts.[2][14] Horizontal process tubes numbering 2,004 pierced the graphite moderator, each 44 feet long with an outer diameter of 1.73 inches and inner diameter of 1.61 inches, fabricated from 2S aluminum alloy coated with 72S zinc.[14][15] These tubes accommodated stacks of 32 to 35 cylindrical uranium fuel slugs per tube, each slug 1.44 inches in diameter and 8.7 inches long, clad in aluminum with a 0.086-inch annular gap for coolant flow.[14] Cooling water from the Columbia River, demineralized and pumped at an initial rate of 30,000 gallons per minute (20 gallons per minute per tube at 200 psi inlet pressure and 18-19.5 feet per second velocity), passed through the tubes in a single pass before discharge.[2][14][15] Control and safety systems included 9 horizontal control rods and 29 vertical safety rods inserted through dedicated channels in the graphite stack.[14] Helium gas circulated through the graphite at 2,600 cubic feet per minute to facilitate heat transfer and remove impurities, with later modifications incorporating CO2 to manage graphite swelling from neutron exposure.[14] The reactor was enclosed in a 105-B building measuring 120 feet by 150 feet by 120 feet high, featuring a 10-inch cast iron thermal shield and additional biological shielding of masonite, steel, and concrete totaling around 10,000 tons.[14][15]| Parameter | Specification |

|---|---|

| Thermal Power (Design) | 250 MW |

| Graphite Mass | ~2,200 tons |

| Process Tubes | 2,004 (aluminum, 44 ft long) |

| Fuel Slugs per Tube | 32–35 (uranium, aluminum-clad) |

| Coolant Flow (Initial) | 30,000 gpm total (20 gpm/tube) |

| Control Rods | 9 horizontal, 29 vertical safety rods |