Recent from talks

Nothing was collected or created yet.

Magnox

View on Wikipedia

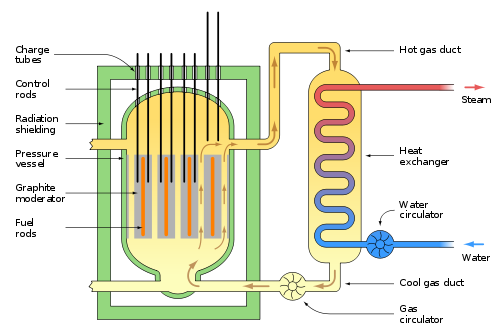

Magnox is a type of nuclear power / production reactor designed and produced in the United Kingdom. It was designed to run on natural uranium with graphite as the moderator and carbon dioxide gas as the heat exchange coolant. It belongs to the wider class of gas-cooled reactors. The name comes from the magnesium-aluminium alloy (called magnesium non-oxidising), used to clad the fuel rods inside the reactor. Like most other generation I nuclear reactors, the magnox was designed with the dual purpose of producing electrical power and plutonium-239 for the nascent nuclear weapons programme in Britain. The name refers specifically to the United Kingdom design but is sometimes used generically to refer to any similar reactor.

As with other plutonium-producing reactors, conserving neutrons is a key element of the design. In magnox, the neutrons are moderated in large blocks of graphite. The efficiency of graphite as a moderator allows the magnox to run using natural uranium fuel, in contrast with the more common commercial light-water reactor which requires slightly enriched uranium. Graphite oxidises readily in air, so the core is cooled with CO2, which is then pumped into a heat exchanger to generate steam to drive conventional steam turbine equipment for power production. The core is open on one end, so fuel elements can be added or removed while the reactor is still running.

The dual-use capability of the magnox design led to the UK building up a large stockpile of fuel-grade (reactor-grade) plutonium, with the aid of the B205 reprocessing facility. The low-to-interim burnup feature of the reactor design would become responsible for changes to US regulatory classifications after the US–UK reactor-grade plutonium detonation test of the 1960s. Despite improvements to the design in later decades as electricity generation became the primary operational aim, magnox reactors were never capable of competing with the higher efficiency and higher fuel burnup of pressurised water reactors.

In total, only a few dozen reactors of this type were constructed, most of them in the UK from the 1950s to the 1970s, with very few exported to other countries. The first magnox reactor to come online was Calder Hall (at the Sellafield site) in 1956, frequently regarded as the world's first commercial nuclear power station,[1] while the last in Britain to shut down was Reactor 1 in Wylfa (on Anglesey) in 2015. As of 2016[update], North Korea remains the only operator to continue using magnox style reactors, at the Yongbyon Nuclear Scientific Research Center. The magnox design was superseded by the advanced gas-cooled reactor, which is similarly cooled but includes changes to improve its economic performance.

General description

[edit]

Windscale

[edit]The UK's first full-scale nuclear reactor was the Windscale Pile in Sellafield. The pile was designed for the production of plutonium-239 which was bred in multi-week reactions taking place in natural uranium fuel. Under normal conditions, natural uranium does not absorb enough of its own emitted "fast" neutrons to maintain a chain reaction. To improve the fuel's sensitivity to neutrons, a neutron moderator is used, in this case highly purified graphite.[2][3]

The reactors consisted of a huge cube of this material (the "pile") made up of many smaller blocks and drilled through horizontally to make a large number of fuel channels. Uranium fuel was placed in aluminium canisters and pushed into the channels in the front, pushing previous fuel canisters through the channel and out the back of the reactor where they fell into a pool of water. The system was designed to work at low temperatures and power levels and was air-cooled with the help of large fans.[2][3]

Graphite is flammable and presents a serious safety risk. This was demonstrated[dubious – discuss] on 10 October 1957 when Unit 1 of the now two-unit site caught fire. The reactor burned for three days, and massive contamination was only avoided due to the addition of filtering systems that had previously been derided as unnecessary "follies".[4]

Magnox

[edit]

As the UK nuclear establishment began to turn its attention to nuclear power, the need for more plutonium for weapons development remained acute. This led to an effort to adapt the basic Windscale design to a power-producing version that would also produce plutonium. In order to be economically useful the plant would have to run at much higher power levels, and in order to efficiently convert that power to electricity, it would have to run at higher temperatures.

At these power levels, the fire risk is amplified and air cooling is no longer appropriate. In the case of the magnox design, this led to the use of carbon dioxide (CO2) as the coolant. There is no facility in the reactor to adjust the gas flow through the individual channels whilst at power, but gas flow was adjusted by using flow gags attached to the support strut which located into the diagrid. These gags were used to increase flow in the centre of the core and to reduce it at the periphery. Principal control over the reaction rate was provided by a number (48 at Chapelcross and Calder Hall) of boron-steel control rods which could be raised and lowered as required in vertical channels.

At higher temperatures, aluminium is no longer structurally sound, which led to the development of the magnox alloy fuel cladding. Unfortunately, magnox is increasingly reactive with increasing temperature, and the use of this material limited the operational gas temperatures to 360 °C (680 °F), much lower than desirable for efficient steam generation. This limit also meant that the reactors had to be very large in order to generate any given power level, which was further amplified by the use of gas for cooling, as the low thermal capacity of the fluid required very high flow rates.

The magnox fuel elements consisted of refined uranium enclosed in a loose-fitting magnox shell and then pressurised with helium. The outside of the shell was typically finned in order to improve heat exchange with the CO2. Magnox alloy is reactive with water, which means it cannot be left in a cooling pond after extraction from the reactor for extended periods. In contrast to the Windscale layout, the magnox design used vertical fuel channels. This required the fuel shells to lock together end-to-end, or to sit one on top the other to allow them to be pulled out of the channels from the top.

Like the Windscale designs, the later magnox reactors allowed access to the fuel channels and could be refuelled while operating. This was a key criterion for the design because its use of natural uranium leads to low burnup ratios and the requirement for frequent refuelling. For power use, the fuel canisters were left in the reactor as long as possible, while for plutonium production they were removed earlier. The complicated refuelling equipment proved to be less reliable than the reactor systems, and perhaps not advantageous overall.[6]

The entire reactor assembly was placed in a large pressure vessel. Due to the size of the pile, only the reactor core itself was placed within the steel pressure assembly, which was then surrounded by a concrete confinement building (or biological shield). As there was no water in the core, and thus no possibility of a steam explosion, the building was able to tightly wrap the pressure vessel, which helped reduce construction costs. In order to keep the size of the confinement building down, the early magnox designs placed the heat exchanger for the CO2 gas outside the dome, connected through piping. Although there were strengths with this approach in that maintenance and access was generally more straightforward, the major weakness was the radiation 'shine' emitted particularly from the unshielded top duct.

The magnox design was an evolution and never truly finalised, and later units differ considerably from earlier ones. As neutron fluxes increased in order to improve power densities problems with neutron embrittlement were encountered, particularly at low temperatures. Later units at Oldbury and Wylfa replaced the steel pressure vessels with prestressed concrete versions which also contained the heat exchangers and steam plant. Working pressure varies from 6.9 to 19.35 bar for the steel vessels, and 24.8 and 27 bar for the two concrete designs.[7]

No British construction company at the time was large enough to build all the power stations, so various competing consortiums were involved, adding to the differences between the stations; for example, nearly every power station used a different design of magnox fuel element.[8] Most of the magnox builds suffered time overruns and cost escalation.[9]

For the initial start up of the reactor neutron sources were located within the core to provide sufficient neutrons to initiate the nuclear reaction. Other aspects of the design included the use of flux shaping or flattening bars or controls rods to even out (to some extent) the neutron flux density across the core. If not used, the flux in the centre would be very high relative to the outer areas leading to excessive central temperatures and lower power output limited by the temperature of the central areas. Each fuel channel would have several elements stacked one upon another to form a stringer. This required the presence of a latching mechanism to allow the stack to be withdrawn and handled. This caused some problems as the Nimonic springs used contained cobalt, which became irradiated giving high gamma level when removed from the reactor. Additionally, thermocouples were attached to some elements and needed to be removed on fuel discharge from the reactor.

AGR

[edit]The dual-use nature of the magnox design leads to design compromises that limit its economic performance. As the magnox design was being rolled out, work was already underway on the advanced gas-cooled reactor (AGR) with the explicit intention of making the system more economical. Primary among the changes was the decision to run the reactor at much higher temperatures, about 650 °C (1,200 °F), which would greatly improve the efficiency when running the power-extracting steam turbines. This was too hot for the magnox alloy, and the AGR originally intended to use a new beryllium-based cladding, but this proved too brittle. This was replaced by a stainless steel cladding, but this absorbed enough neutrons to affect criticality, and in turn required the design to operate on slightly enriched uranium rather than the magnox's natural uranium, driving up fuel costs. Ultimately the economics of the system proved little better than Magnox. Former Treasury Economic Advisor, David Henderson, described the AGR programme as one of the two most costly British government-sponsored project errors, alongside Concorde.[10]

Technical information

[edit]Source:[11]

| Specification | Calder Hall | Wylfa | Oldbury |

|---|---|---|---|

| Thermal output (gross), MW | 182 | 1875 | 835 |

| Electrical output (gross), MW | 46 | 590 | 280 |

| Efficiency, % | 23 | 33 | 34 |

| Number of fuel channels | 1696 | 6150 | 3320 |

| Active core diameter | 9.45 m | 17.4 m | 12.8 m |

| Active core height | 6.4 m | 9.2 m | 8.5 m |

| Mean gas pressure | 7 bar | 26.2 bar | 25.6 bar |

| Mean inlet gas temperature °C | 140 | 247 | 245 |

| Mean outlet gas temperature °C | 336 | 414 | 410 |

| Total gas flow | 891 kg/s | 10254 kg/s | 4627 kg/s |

| Material | Natural uranium metal | Natural uranium metal | Natural uranium metal |

| Mass of uranium in tonnes | 120 | 595 | 293 |

| Pressure vessel internal diameter | 11.28 m | 29.3 m | 23.5 m |

| Pressure vessel internal height | 21.3 m | — | 18.3 m |

| Gas circulators | 4 | 4 | 4 |

| Steam generators | 4 | 1 | 4 |

| Number of generators | 2 | 2 | 1 |

Economics

[edit]

The first magnox reactors at Calder Hall[12] were designed principally to produce plutonium for nuclear weapons.[13] The production of plutonium from uranium by irradiation in a pile generates large quantities of heat which must be disposed of, and so generating steam from this heat, which could be used in a turbine to generate electricity, or as process heat in the nearby Windscale works, was seen as a kind of free by-product of an essential process.

The Calder Hall reactors had low efficiency by today's standards, only 18.8%.[14]

The British government decided in 1957 that electricity generation by nuclear power would be promoted, and that there would be a building programme to achieve 5,000 to 6,000 MWe capacity by 1965, a quarter of UK's generating needs.[13] Although Sir John Cockcroft had advised the government that electricity generated by nuclear power would be more expensive than that from coal, the government decided that nuclear power stations as alternatives to coal-fired power stations would be useful to reduce the bargaining power of the coal miners' unions,[9] and so decided to go ahead. In 1960 a government white paper scaled back the building programme to 3,000 MWe,[13] acknowledging that coal generation was 25% cheaper.[9] A government statement to the House of Commons in 1963 stated that nuclear generation was more than twice as expensive as coal.[9] The plutonium credit which assigned a value to the plutonium produced was used to improve the economic case,[15] although the operators of the power stations were never paid this credit.

Once removed from the reactor, the used fuel elements are stored in cooling ponds (with the exception of Wylfa which has dry stores in a carbon dioxide atmosphere) where the decay heat is transferred to the pond water, and then removed by the pond water circulation, cooling and filtration system. The fact that fuel elements can only be stored for a limited period in water before the magnox cladding deteriorates, and must therefore inevitably be reprocessed, added to the costs of the magnox programme.[16]

Later reviews criticised the continuing development project by project instead of standardisation on the most economical design, and for persisting with the development of a reactor which achieved only two export orders.[17]

A retrospective evaluation of costs, using a typical 5% discount rate on capital, estimated magnox electricity costs were nearly 50% higher than coal power stations would have provided.[18]

Safety

[edit]This section needs additional citations for verification. (October 2010) |

The magnox reactors were considered at the time to have a considerable degree of inherent safety because of their simple design, low power density, and gas coolant. Because of this they were not provided with secondary containment features. A safety design principle at the time was that of the "maximum credible accident", and the assumption was made that if the plant were designed to withstand that, then all other lesser but similar events would be encompassed. Loss of coolant accidents (at least those considered in the design) would not cause large-scale fuel failure as the Magnox cladding would retain the bulk of the radioactive material, assuming the reactor was rapidly shutdown (a SCRAM), because the decay heat could be removed by natural circulation of air. As the coolant is already a gas, explosive pressure buildup from boiling is not a risk, as happened in the catastrophic steam explosion at the Chernobyl accident. Failure of the reactor shutdown system to rapidly shut down the reactor, or failure of natural circulation, was not considered in the design. In 1967 Chapelcross experienced a fuel melt due to restricted gas flow in an individual channel and, although this was dealt with by the station crew without major incident, this event had not been designed or planned for, and the radioactivity released was greater than anticipated during the station design.

Despite the belief in their inherently safe design, it was decided that the magnox stations would not be built in heavily populated areas. The positioning constraint decided upon was that any 10-degree sector would have a population less than 500 within 1.5 miles (2.4 km), 10,000 within 5 miles (8.0 km) and 100,000 within 10 miles (16 km). In addition population around the site in all directions would be less than six times the 10-degree limits. Planning permission constraints would be used to prevent any large growth of population within five miles.[19]

In the older steel pressure vessel design, boilers and gas ducting are outside the concrete biological shield. Consequently, this design emits a significant amount of direct gamma and neutron radiation, termed direct shine, from the reactors.[20] For example, the most exposed members of the public living near Dungeness magnox reactor in 2002 received 0.56 mSv, over half the International Commission on Radiological Protection recommended maximum radiation dose limit for the public, from direct shine alone.[21] The doses from the Oldbury and Wylfa reactors, which have concrete pressure vessels which encapsulate the complete gas circuit, are much lower.

Reactors built

[edit]

In all, 11 power stations totalling 26 units were built in the United Kingdom where the design originated. In addition, one was exported to Tōkai in Japan[22] and another to Latina in Italy.[19] North Korea also developed their own magnox reactors, based on the UK design which was made public at an Atoms for Peace conference.

The first magnox power station, Calder Hall, was the world's first nuclear power station to generate electrical power on an industrial scale[12] (a power station in Obninsk, Russia started supplying the grid in very small non-commercial quantities on 1 December 1954). The first connection to the grid was on 27 August 1956, and the plant was officially opened by Queen Elizabeth II on 17 October 1956.[23] When the station closed on 31 March 2003, the first reactor had been in use for nearly 47 years.[24]

The first two stations (Calder Hall and Chapelcross) were originally owned by the UKAEA and primarily used in their early life to produce weapons-grade plutonium, with two fuel loads per year.[25] From 1964 they were mainly used on commercial fuel cycles and in April 1995 the UK Government announced that all production of plutonium for weapons purposes had ceased.[26]

The later and larger units were owned by the CEGB and operated on commercial fuel cycles.[27] However Hinkley Point A and two other stations were modified so that weapons-grade plutonium could be extracted for military purposes should the need arise.[28][29]

Derating to reduce corrosion

[edit]In early operation it was found that there was significant oxidation of mild steel components by the high temperature carbon dioxide coolant, requiring a reduction in operating temperature and power output.[30] For example, the Latina reactor was derated in 1969 by 24%, from 210 MWe to 160 MWe, by the reduction of operating temperature from 390 to 360 °C (734 to 680 °F).[31]

Last operating magnox reactor

[edit]The Nuclear Decommissioning Authority (NDA) announced on 30 December 2015 that Wylfa Unit 1 – the world's last operating Magnox reactor – was closed. The unit had generated electricity for five years longer than originally planned. Two units at Wylfa were both scheduled to shut down at the end of 2012, but the NDA decided to shut down Unit 2 in April 2012 so that Unit 1 could continue operating in order to fully utilise existing stocks of fuel, which was no longer being manufactured.[32]

The small 5 MWe experimental reactor, based on the magnox design, at Yongbyon in North Korea, continues to operate as of 2016[update].

Magnox definitions

[edit]Magnox alloy

[edit]Magnox is also the name of an alloy—mainly of magnesium with small amounts of aluminium and other metals—used in cladding unenriched uranium metal fuel with a non-oxidising covering to contain fission products. Magnox is short for magnesium non-oxidising. This material has the advantage of a low neutron capture cross-section, but has two major disadvantages:

- It limits the maximum temperature, and hence the thermal efficiency, of the plant.

- It reacts with water, preventing long-term storage of spent fuel under water.

Magnox fuel incorporated cooling fins to provide maximum heat transfer despite low operating temperatures, making it expensive to produce. While the use of uranium metal rather than oxide made reprocessing more straightforward and therefore cheaper, the need to reprocess fuel a short time after removal from the reactor meant that the fission product hazard was severe. Expensive remote handling facilities were required to address this danger.

Magnox plants

[edit]The term magnox may also loosely refer to:

- Three North Korean reactors, all based on the declassified blueprints of the Calder Hall magnox reactors:

- A small 5 MWe experimental reactor at Yongbyon, operated from 1986 to 1994, and restarted in 2003. Plutonium from this reactor's spent fuel has been used in the North Korea nuclear weapons program.

- A 50 MWe reactor, also at Yongbyon, whose construction commenced in 1985 but was never finished in accord with the 1994 US-North Korea Agreed Framework.

- A 200 MWe reactor at Taechon, construction of which also halted in 1994.

- Nine UNGG power reactors built in France, all now shut down. These were carbon dioxide-cooled, graphite reactors with natural uranium metal fuel, very similar in design and purpose to the British magnox reactors except that the fuel cladding was magnesium-zirconium alloy and that the bars were disposed horizontally (instead of vertically for magnox).

Decommissioning

[edit]

The Nuclear Decommissioning Authority (NDA) is responsible for the decommissioning of the UK magnox power plants, at an estimated cost of £12.6 billion. There has been debate about whether a 25 or 100-year decommissioning strategy should be adopted. After 80 years short-lifetime radioactive material in the defuelled core would have decayed to the point that human access to the reactor structure would be possible, easing dismantling work. A shorter decommissioning strategy would require a robotic core dismantling technique.[33] The current approximately 100-year decommissioning plan is called Safestore. A 130-year Deferred Safestore Strategy was also considered, with an estimated cost saving of £1.4 billion, but not selected.[34]

In addition the Sellafield site which, amongst other activities, reprocessed spent magnox fuel, has an estimated decommissioning cost of £31.5 billion. Magnox fuel was produced at Springfields near Preston; estimated decommissioning cost is £371 million. The total cost of decommissioning magnox activities is likely to exceed £20 billion, averaging about £2 billion per productive reactor site.

Calder Hall was opened in 1956 as the world's first commercial nuclear power station, and is a significant part of the UK's industrial heritage. The NDA is considering whether to preserve Calder Hall reactor 1 as a museum site.

All the UK's magnox reactor sites (apart from Calder Hall) are operated by Magnox Ltd, a subsidiary of the NDA.

Reactor Sites Management Company (RSMC), a NDA Site Licence Company (SLC), originally held the contract to manage Magnox Ltd on behalf of the NDA. In 2007, RSMC was acquired by American nuclear fuel cycle service provider EnergySolutions from British Nuclear Fuels.[35]

On 1 October 2008, Magnox Electric Ltd separated into two nuclear licensed companies, Magnox North Ltd and Magnox South Ltd.[36]

Magnox North sites

Magnox South sites

In January 2011 Magnox North Ltd and Magnox South Ltd recombined as Magnox Ltd.[37] Following procurement and management issues with the contract, Magnox Ltd will become a subsidiary of the NDA in September 2019.[38][39]

List of Magnox reactors in the UK

[edit]| Name | Location | Location (GeoHack) | Number of units | Production per unit | Total production | First grid connection | Shut down |

|---|---|---|---|---|---|---|---|

| Calder Hall | near Whitehaven, Cumbria | NY025042 | 4 | 50 MWe | 200 MWe | 1956 | 2003 |

| Chapelcross | near Annan, Dumfries and Galloway | NY216697 | 4 | 60 MWe | 240 MWe | 1959 | 2004 |

| Berkeley | Gloucestershire | ST659994 | 2 | 138 MWe | 276 MWe | 1962 | 1989 |

| Bradwell | near Southminster, Essex | TM001087 | 2 | 121 MWe | 242 MWe | 1962 | 2002 |

| Hunterston "A" | between West Kilbride and Fairlie North Ayrshire | NS183513 | 2 | 180 MWe | 360 MWe | 1964 | 1990 |

| Hinkley Point "A" | near Bridgwater, Somerset | TR330623 | 2 | 235 MWe | 470 MWe | 1965 | 1999 |

| Trawsfynydd | Gwynedd | SH690381 | 2 | 195 MWe | 390 MWe | 1965 | 1991 |

| Dungeness "A" | Kent | TR074170 | 2 | 219 MWe | 438 MWe | 1966 | 2006 |

| Sizewell "A" | near Leiston, Suffolk | TM472634 | 2 | 210 MWe | 420 MWe | 1966 | 2006 |

| Oldbury | near Thornbury, South Gloucestershire | ST606945 | 2 | 217 MWe | 434 MWe | 1968 | 2012 |

| Wylfa | Anglesey | SH350937 | 2 | 490 MWe | 980 MWe | 1971 | 2015 |

Magnox reactors exported from the UK

[edit]| Name | Location | Number of units | Production per unit | Total production | First grid connection | Shut down |

|---|---|---|---|---|---|---|

| Latina | Italy | 1 | 160 MWe | 160 MWe | 1963 | 1987 following Italian referendum on nuclear power |

| Tokai Mura | Japan | 1 | 166 MWe | 166 MWe | 1966 | 1998 |

See also

[edit]- Nuclear power in the United Kingdom

- UNGG, the similar class of reactors built in France

- Edge of Darkness, 1985 British television drama about the nuclear industry, which went by the working title "Magnox".

References

[edit]- ^ Humphrys, John (2011). A Day That Shook the World : First Nuclear Power Station 1956. British Pathe. Retrieved 2 January 2023.

- ^ a b "First look at damaged Windscale pile". World Nuclear News. 21 August 2008.

- ^ a b "Windscale Pile problems". 27 June 2000. Archived from the original on 19 June 2018. Retrieved 24 August 2017.

- ^ Leatherdale, Duncan (4 November 2014). "Windscale Piles: Cockcroft's Follies avoided nuclear disaster". BBC News.

- ^ "Osborne hails UK nuclear deal with China as 'new dawn'". FT. 17 October 2013. Archived from the original on 10 December 2022. Retrieved 25 October 2014.

the country that built the first civil nuclear power station

- ^ Robert Hawley (2006). Nuclear Power in the UK – Past, Present & Future. World Nuclear Association Annual Symosium. Archived from the original on 14 December 2008.

- ^ Nuclear Installations Inspectorate (September 2000). Report by HM Nuclear Installations Inspectorate on the results of Magnox Long Term Safety Reviews (LTSRs) and Periodic Safety Reviews (PSRs) (PDF) (Report). Health and Safety Executive. p. 27 (Table 3). Archived from the original (PDF) on 26 May 2006. Retrieved 21 March 2010.

- ^ The Magnox Story (PDF) (Report). Springfields Fuels Limited. July 2008. Archived from the original (PDF) on 13 June 2011.

- ^ a b c d Walls, John (2011). "Nuclear Power Generation – Past Present and Future". In Roy M. Harrison; Ronald E. Hester (eds.). Nuclear Power and the Environment. Royal Society of Chemistry. pp. 8–9. ISBN 9781849731942. Retrieved 8 March 2019.

- ^ David Henderson (21 June 2013). "The more things change..." Nuclear Engineering International. Archived from the original on 25 June 2013. Retrieved 2 July 2013.

- ^ "Description of the Magnox Type of Gas Cooled Reactor (MAGNOX)" (PDF). www.iaea.org.

- ^ a b "Calder Hall Power Station" (PDF). The Engineer. 5 October 1956. Archived from the original (PDF) on 29 October 2013. Retrieved 25 October 2013.

- ^ a b c Ten Years of Nuclear Power (PDF) (Report). UKAEA. 1966. Archived from the original (PDF) on 29 October 2013. Retrieved 25 October 2013.

- ^ Steven B Krivit; Jay H Lehr; Thomas B Kingery, eds. (2011). Nuclear Energy Encyclopedia: Science, Technology, and Applications. Wiley. p. 28. ISBN 978-1-118-04347-9.

- ^ "Atomic Energy (Civil Use)". Parliamentary Debates (Hansard). 1 November 1955. Hc Deb 1 November 1955 Vol 545 Cc843-4. Retrieved 23 October 2013.

- ^ Radioactive Waste Management Advisory Committee (November 2000). RWMAC's Advice to Ministers on the Radioactive Waste Implications of Reprocessing, Annex 4: Dry storage and disposal of Magnox spent fuel (Report). Department for Environment, Food and Rural Affairs. Archived from the original on 19 August 2006.

- ^ S H Wearne, R H Bird (February 2010). UK Experience of Consortia Engineering for Nuclear Power Stations (Report). School of Mechanical, Aerospace & Civil Engineering, University of Manchester. Archived from the original on 24 October 2009. Retrieved 19 September 2010.

- ^ Richard Green (July 1995). "The Cost of Nuclear Power Compared with Alternatives to the Magnox Programme". Oxford Economic Papers. 47 (3). Oxford University Press: 513–24. doi:10.1093/oxfordjournals.oep.a042185. Retrieved 25 October 2013.

- ^ a b M.C. Grimston; W.J. Nuttall (October 2013). The Siting of UK Nuclear Power Installations (PDF) (Report). University of Cambridge. CWPE 1344 & EPRG 1321. Retrieved 16 September 2018.

- ^ Fairlie, Ian (July 1993). "Magnox gamma shine" (PDF). Safe Energy. 95. Retrieved 18 June 2018.

- ^ Director, Environment Health Safety and Quality. "Discharges and Monitoring of the Environment in the UK – Annual Report 2002" (PDF). BNFL. pp. 7–8, 87–88, 119–121. Archived from the original (PDF) on 16 November 2004.

- ^ Tsutomu Nakajima, Kazukiyo Okano and Atsushi Murakami (1965). "Manufacture of Pressure Vessel for Nuclear Power Reactor" (PDF). Fuji Electric Review. 11 (1). Fuji Electric Co. Retrieved 17 April 2014.

- ^ "Calder Hall Celebrates 40 Years of Operation" (Press release). BNFL. Archived from the original on 22 February 2004. Retrieved 22 February 2004.

- ^ Brown, Paul (21 March 2003). "First nuclear power plant to close". The Guardian. London. Retrieved 12 May 2010.

- ^ Hayes, Peter (16 November 1993). Should the United States Supply Light Water Reactors to Pyongyang? (Report). Nautilus Institute. Archived from the original on 7 March 2006. Retrieved 21 August 2006.

- ^ "Plutonium and Aldermaston – an historical account" (PDF). UK Ministry of Defence. 4 September 2001. Archived from the original (PDF) on 13 December 2006. Retrieved 15 March 2007.

- ^ S H Wearne, R H Bird (December 2016). UK Experience of Consortia Engineering for Nuclear Power Stations (PDF) (Report). Dalton Nuclear Institute, University of Manchester. Archived from the original (PDF) on 26 March 2017. Retrieved 25 March 2017.

- ^ David Lowry (13 November 2014). "The world's first 'Nuclear Proliferation Treaty'". Ecologist. Retrieved 2 December 2014.

- ^ Reginald Maudling (24 June 1958). "Atomic Power Stations (Plutonium Production)". Parliamentary Debates (Hansard). HC Deb 24 June 1958 vol 590 cc246-8. Retrieved 2 December 2014.

the Central Electricity Generating Board has agreed to a small modification in the design of Hinkley Point and of the next two stations in its programme so as to enable plutonium suitable for military purposes to be extracted should the need arise.

- ^ Lobner, Peter (21 May 2016). "Farewell Magnox: 1956 - 2015". The Lyncean Group of San Diego. Retrieved 1 June 2021.

- ^ Volterra, E. (1989). "Operating experience with the Latina Magnox reactor". IAEA: 120–132. IWGGCR-19. Retrieved 1 June 2021.

- ^ "World's last operating Magnox reactor closes". World Nuclear News. 31 December 2015. Retrieved 4 January 2016.

- ^ "Minutes of the Joint Meeting Held at Oldbury" (PDF). Berkeley Nuclear Licensed Site and Oldbury on Severn Power Station Site Stakeholder Groups. 1 November 2006. p. 7. Archived from the original (PDF) on 14 October 2012. Retrieved 14 November 2007.

- ^ Lindberg, John (24 November 2021). "To wait, or not to wait: the question of Safestore". Nuclear Engineering International. Archived from the original on 6 December 2021. Retrieved 6 December 2021.

- ^ "EnergySolutions". Archived from the original on 21 October 2011. Retrieved 29 October 2011.

- ^ "Archived copy". Archived from the original on 4 October 2018. Retrieved 5 June 2008.

{{cite web}}: CS1 maint: archived copy as title (link) - ^ "Magnox Limited". Magnox. Archived from the original on 2 April 2012.

- ^ "NDA to take over management of Magnox sites". World Nuclear News. 3 July 2018. Retrieved 9 July 2018.

- ^ "The Nuclear Decommissioning Authority's Magnox contract". Public Accounts Committee. UK Parliament. 27 February 2018. Retrieved 9 July 2018.

External links

[edit]- EnergySolutions

- Nuclear Sites Stakeholder Information – Overview of each Magnox power station, provided by British Nuclear Group

- Magnox Safety Reviews Archived 26 May 2006 at the Wayback Machine, September 2000, HSE Nuclear Installations Inspectorate

- Magnox Electric plc's strategy for decommissioning its nuclear licensed sites Archived 14 May 2013 at the Wayback Machine, February 2002, HSE Nuclear Installations Inspectorate

- The decommissioning of commercial magnox gas cooled reactor power stations in the United Kingdom, G. Holt, Magnox Electric, IAEA meeting paper, 8–10 September 1997

- Operating experience with the Latina Magnox reactor, 21–23 September 1988, Ente Nazionale per l'Energia Electrica

- Review of ageing processes and their influence on Safety and Performance at Wylfa Nuclear Power Station, John Large, 14 March 2001 – includes detailed diagrams

- Magnox Fuel Element Design – Atomic Energy Insights

- Sellafield Magnox cooling ponds cleanup job commences – Nuclear Engineering International

- A ponderous hazard – Nuclear Engineering International

- British Nuclear Group image asset library Archived 2 April 2006 at the Wayback Machine – A large collection of interior and exterior photographs of all the Magnox power stations in the UK.

- S. E. Jensen and E. Nonbol (Riso National Laboratory) (November 1998). Description of the Magnox Type of Gas Cooled Reactor (MAGNOX) (PDF) (Report). IAEA. ISBN 87-7893-050-2. NKS/RAK-2(97)TR-C5. Retrieved 17 April 2014.

Magnox

View on GrokipediaMagnox reactors are a class of graphite-moderated, carbon dioxide-cooled nuclear reactors that utilize natural uranium metal fuel elements clad in a magnesium-based alloy called Magnox.[1][2] Developed in the United Kingdom during the 1950s, they formed the basis of the world's first commercial-scale nuclear power program, with the prototype Calder Hall reactors achieving grid connection in August 1956 and official opening by Queen Elizabeth II in October of that year.[1] A total of 26 such reactors were built across 10 sites, initially designed for dual civilian and military roles—generating electricity while producing plutonium-239 at low burn-up rates suitable for weapons applications, with early operations limited to about 0.4 GWd/t to yield weapons-grade material.[1][3] These Generation I reactors featured thermal efficiencies ranging from 22% in early designs to 28% in later variants, operated beyond their nominal 20-year design life for over 40 years in many cases, and demonstrated the technical viability of gas-cooled systems using unenriched fuel, paving the way for subsequent advanced gas-cooled reactors despite challenges like limited fuel burn-up (400-600 MWd/t) and cladding temperature constraints around 415°C.[1][2]

History and Development

Origins in Post-War Britain

Following World War II, the United Kingdom initiated an independent nuclear weapons program to establish a plutonium production capability for national deterrence, constructing the Windscale Piles—air-cooled graphite reactors—in 1947 at the Windscale site in Cumbria.[4][5] These facilities began producing weapons-grade plutonium by 1950, marking the onset of Britain's reactor technology development amid geopolitical pressures from the emerging Cold War and the U.S. atomic monopoly under the 1946 McMahon Act.[1] The dual imperative of military plutonium supply and civil electricity generation drove early designs, as post-war reconstruction strained domestic coal supplies—exacerbated by mining inefficiencies and strikes—prompting a strategic pivot toward nuclear energy for long-term independence from fossil fuel vulnerabilities tied to imperial trade routes in decline.[6] In 1952, the UK government approved the civil nuclear power program, selecting the Calder Hall site adjacent to Windscale for the world's first dual-purpose power station, explicitly designed to generate electricity while breeding plutonium for defense needs.[1] Construction commenced in 1953 under the Ministry of Supply, with the first reactor achieving criticality in 1956 and connecting to the national grid on August 27 of that year, followed by official opening by Queen Elizabeth II on October 17.[1] This initiative reflected first-principles reasoning for energy security: leveraging existing military R&D to address civilian power shortages without immediate reliance on imported enrichment technology, as the UK prioritized accessible natural uranium and graphite to minimize foreign dependencies.[7] The Magnox program's origins underscored causal realism in policy—military imperatives subsidized civil advancements, enabling rapid deployment despite the era's technological constraints, as evidenced by Calder Hall's 180 MW capacity serving both grids.[1] Initial reactor concepts evolved directly from Windscale's graphite-moderated piles, favoring natural uranium to exploit the UK's domestic ore resources and avoid the complexities of isotopic separation, a capability then dominated by the U.S.[1] This approach not only facilitated plutonium extraction for deterrence but also positioned nuclear fission as a hedge against recurrent fuel crises, aligning with Britain's post-imperial need for autonomous energy production.[6]Prototype Reactors and Initial Designs

The Windscale Piles, operational from 1950 to 1951, served as early air-cooled graphite-moderated reactors primarily designed for plutonium production to support the UK's nuclear weapons program.[1] These prototypes demonstrated the feasibility of graphite moderation with natural uranium fuel but revealed significant safety risks, including potential graphite oxidation and ignition under air cooling, as evidenced by empirical observations of moderator heating and subscale airflow tests conducted during design phases. These findings prompted a shift to carbon dioxide (CO2) gas cooling in subsequent designs, as CO2's lower reactivity with graphite reduced fire hazards compared to air, a decision validated through controlled oxidation experiments and thermal modeling that prioritized causal safety mechanisms over initial air-cooling simplicity.[8] Calder Hall, commissioned on October 17, 1956, marked the first operational Magnox-type reactor, featuring a graphite-moderated core with natural uranium fuel clad in Magnox alloy and CO2 cooling at pressures up to 200 psi.[9] Each of its four reactor units generated 180 MW thermal power, yielding an initial electrical output of 35 MWe per unit, later uprated to 46 MWe through empirical derating reversals and efficiency tweaks based on early operational data showing stable heat transfer and low corrosion rates.[10] This prototype confirmed the viability of dual-purpose operation for electricity generation and plutonium breeding, with design iterations incorporating Windscale-derived graphite stack segmentation and CO2 circulation loops tested in subscale rigs to ensure uniform cooling and minimize Wigner energy buildup risks.[1] Initial Magnox designs evolved iteratively from these prototypes, emphasizing empirical validation over theoretical projections; for instance, fuel element spacing and gas duct geometries were refined via hot-loop simulations at facilities like the UK Atomic Energy Authority's labs, addressing airflow instabilities observed in Windscale analogs.[11] By 1957, Chapelcross followed as a near-identical prototype site with four units mirroring Calder Hall's configuration, further proving the design's scalability through shared empirical data on fuel canning integrity and moderator purity control.[9] These early reactors established core parameters—such as 3-4% burnup limits and 250-300°C outlet temperatures—that balanced neutron economy with material durability, grounded in post-irradiation examinations revealing minimal cladding-uranium interactions under CO2 environments.[2]Expansion of the Magnox Program

The expansion of the Magnox program was formalized by the UK government's 1955 White Paper, "A Programme of Nuclear Power," which established the world's first purely commercial nuclear power initiative with an initial target of 1,400–1,800 MWe installed capacity by 1965 to address rising electricity demand and lessen dependence on coal amid post-war shortages and import vulnerabilities.[1][7] This policy emphasized domestic energy production using British-designed reactors, aiming to create an export industry while securing affordable baseload power without the balance-of-payments strain from fossil fuel imports.[7] In response to the 1956 Suez Crisis, which highlighted oil import risks, a 1957 White Paper revised the target upward to 5,000–6,000 MWe, accelerating orders for multiple stations and extending the program timeline into the late 1960s.[1] Construction commenced on commercial units following prototypes like Calder Hall, with key starts including Chapelcross's four reactors in 1959 and Hunterston A's two units in 1964, culminating in 26 Magnox reactors built across 11 sites by 1971.[1][7] The program's scale ultimately delivered approximately 4,200 MWe of capacity, falling short of the ambitious revised goals due to design iterations and cost overruns but fulfilling the core objective of rapid deployment.[1] By providing reliable, indigenous electricity generation, the Magnox expansion directly displaced coal-fired output, averting substantial investments in conventional capacity—estimated at £1,200 million over the decade—and bolstering energy security against foreign supply disruptions.[1][7] This shift supported the UK's diversification from fossil fuels, contributing to economic stability during a period of industrial growth and geopolitical uncertainty.[7]Technical Design and Features

Reactor Core and Moderation

The Magnox reactor core comprises a stacked array of graphite bricks forming a cylindrical moderator structure, typically 6 to 10 meters in height and 9 to 14 meters in diameter, with vertical channels machined through the graphite to accommodate fuel elements and control rods.[2][12] This geometry supports a low power density of less than 1 kW per liter, enabling operation with natural uranium fuel by providing sufficient volume for neutron moderation without excessive flux gradients.[13] Graphite functions as the neutron moderator by slowing fast fission neutrons to thermal energies through elastic scattering with carbon-12 nuclei, which have a low mass ratio to neutrons (approximately 1:1), achieving moderation in roughly 100 collisions per neutron while exhibiting a minimal thermal neutron absorption cross-section of 3.5 millibarns.[14] This high moderating ratio—defined as the ratio of scattering to absorption cross-sections, exceeding 200 for graphite—ensures efficient chain reaction sustenance in unenriched uranium, where fast fission is insufficient, with empirical data from Magnox operations confirming neutron economy sufficient for criticality at low enrichments.[15] The moderator's low absorption preserves neutrons for fuel interactions, as verified by core loading experiments at prototypes like Calder Hall, where initial supercritical masses around 130 tons of uranium achieved sustained reactions.[16] Control of reactivity occurs via 60 to 90 absorbing rods per reactor, inserted into dedicated graphite channels from above, constructed from materials such as boron steel or cadmium alloys to capture neutrons and adjust the multiplication factor.[17] These rods, often termed "black rods" for their strong absorption, enable fine-tuned power regulation, with operational records showing effective shutdown capabilities through full insertion.[2] Thermal power generation in the core varies by design, from approximately 180 MWth in early units like Calder Hall to 500 MWth or more in later stations such as Oldbury, derived from fission heat release at average neutron fluxes of 10^13 to 10^14 neutrons per square centimeter per second, as measured during commissioning tests.[18][12] This output reflects the moderated neutron spectrum's efficiency in inducing fissions in natural uranium's U-235 isotope (0.7% abundance), with heat uniformly distributed across the graphite lattice to minimize hotspots.[2]Fuel Elements and Magnox Alloy

The fuel elements in Magnox reactors consist of cylindrical metallic uranium slugs, typically around 1 meter in length and 2.8-3.4 cm in diameter, encased in a thin canning made from Magnox alloy to prevent reaction with the coolant and moderator while minimizing neutron absorption..pdf) This design accommodates natural uranium metal with approximately 0.72% U-235 content, eliminating the need for isotopic enrichment and enabling direct use of domestically sourced ore in post-war Britain.[19] Magnox alloy, primarily magnesium with 0.7-0.8% aluminum and trace amounts of beryllium (around 50 ppm), was selected for its low thermal neutron capture cross-section (about 0.063 barns for Mg), compatibility with metallic uranium up to 500°C, and intended resistance to oxidation in dry carbon dioxide environments.[20][21] However, the alloy's sensitivity to oxidation accelerates above 400°C in the presence of moisture or CO2 impurities, imposing strict limits on cladding temperatures to avoid degradation and potential fuel failure.[22] This trade-off facilitated the use of unenriched fuel but constrained operating parameters, contributing to lower thermal efficiency compared to enriched-fuel designs. The fuel cycle relies on online refueling, allowing individual elements to be replaced without shutting down the reactor, with an average residence time in the core of about 3 years to balance burn-up and reactivity control.[23] Empirical observations of Magnox cladding corrosion, particularly from trace water vapor or operational impurities, necessitated conservative burn-up limits of 3-5 GWd/t to maintain cladding integrity and prevent anisotropic swelling of the uranium metal that could breach the can.[24] These limits, derived from early operational data, prioritized safety over maximizing fuel utilization, reflecting the design's emphasis on reliability with natural uranium.Cooling System and Containment

The cooling system in Magnox reactors uses carbon dioxide (CO₂) gas as the primary coolant to extract heat from the uranium fuel elements embedded in the graphite moderator. CO₂ flows downward through the core channels, entering at temperatures of approximately 250°C and exiting at up to 400°C after absorbing fission heat via forced convection.[25] The heated gas is then directed to external once-through boilers, where it transfers thermal energy to pressurized water, generating steam for turbine-driven electricity production.[2] Circulation is maintained by multiple axial-flow gas circulators per reactor, typically organized into independent circuits to enhance reliability and allow for maintenance without full shutdown. Operating pressures range from 6.9 to 17 bar (100-250 psi), selected to optimize heat transfer coefficients while limiting corrosion and stress on the Magnox alloy cladding and steel components.[26] This low-pressure gas loop minimizes pumping power requirements compared to liquid coolants, contributing to the design's simplicity.[27] Containment relies on a steel pressure vessel housing the reactor core, graphite stack, and CO₂ inventory, serving as the primary barrier to prevent coolant escape and fission product release. Early stations like Calder Hall featured cylindrical steel vessels surrounded by thick concrete biological shields for radiation attenuation, but without a dedicated full-containment envelope designed for severe accident pressures.[28] Later Magnox designs, such as at Oldbury, incorporated spherical steel vessels up to 20 meters in diameter and weighing around 5,000 metric tons, engineered for pressure retention and thermal gradients.[29] Pre-stressed concrete biological shields in some units provided additional structural support and partial secondary containment, though empirical monitoring across the fleet recorded near-zero leak rates from vessel integrity during decades of operation.[30] This approach prioritized inherent safety through low coolant pressure and robust material selection over active post-accident confinement systems.[31]Differences from Successor Designs

The Magnox reactors utilized natural uranium metal fuel clad in a magnesium-aluminum alloy, enabling operation without uranium enrichment facilities and thus facilitating British nuclear independence from U.S. technology restrictions in the post-war era.[32] This contrasted with successor Advanced Gas-cooled Reactors (AGRs), which required slightly enriched uranium dioxide (typically 2-3% U-235) to achieve higher fuel burn-up and neutron utilization, and Pressurized Water Reactors (PWRs), which demand 3-5% enrichment for their light-water moderated cores.[32] The natural uranium approach in Magnox supported dual civilian-military roles but limited burn-up to approximately 3,000-7,000 MWd/t due to fuel swelling and cladding constraints, compared to 18,000-25,000 MWd/t in AGRs and 40,000-60,000 MWd/t in PWRs.[33] Thermal efficiency in Magnox designs ranged from 23% in early prototypes like Calder Hall to 33% in later stations, restricted by the Magnox alloy's low tolerance for temperatures above 400°C, which caused corrosion in CO2 coolant and limited steam conditions to avoid reactivity with water.[34] AGRs improved this to about 41% by adopting stainless steel cladding and silicon carbide sleeves on fuel pins, allowing gas outlet temperatures up to 650°C for more efficient steam cycles while retaining graphite moderation and CO2 cooling.[32] PWRs, by contrast, achieved around 33% efficiency through higher-pressure water systems (15-16 MPa) but introduced complexities like corrosion-resistant zircaloy cladding and secondary steam generators absent in gas-cooled Magnox.[32] Core design in Magnox featured simpler, finned fuel elements for enhanced heat transfer in low-pressure CO2 flow (about 0.7 MPa), prioritizing plutonium breeding over power density. Successor AGRs evolved this with clustered oxide fuel pins in graphite strings for on-load refueling and higher power densities, mitigating Magnox's off-load refueling downtime. PWRs diverged fundamentally with compact, water-filled lattices enabling higher power densities (around 100 kW/liter vs. Magnox's 0.5-1 kW/liter) but requiring robust pressure vessels to contain high-pressure coolant, unlike the steel or pre-stressed concrete containment of Magnox.[35] These advancements in successors enhanced economic viability and fuel utilization while addressing Magnox's foundational trade-offs for early deployment.[36]Operational History

Commissioning and Early Operations

The first Magnox reactor at Calder Hall achieved criticality in May 1956, with the station connecting to the UK national grid on 27 August 1956 and officially opened by Queen Elizabeth II on 17 October 1956.[1][13] Initially designed for dual military and civil purposes, Calder Hall's four reactors prioritized plutonium production for the UK's nuclear weapons program, generating weapons-grade plutonium alongside limited electricity output of approximately 60 MWe per reactor.[37] Subsequent Magnox stations followed rapidly, with Berkeley and Bradwell entering operation in 1962, marking the expansion of the fleet.[38] By 1965, multiple stations were online, contributing to nuclear power's growing share of UK electricity generation, though exact percentages varied with ramp-up phases; the program demonstrated early reliability with load factors often exceeding expectations for graphite-moderated gas-cooled designs.[1] As military plutonium demands stabilized post-Suez Crisis and into the 1960s, operations shifted emphasis toward sustained civil electricity production, optimizing fuel cycles for higher power output while maintaining natural uranium fueling.[7] Early empirical data showed Magnox reactors achieving stable operations, with initial stations like Calder Hall ramping to full power within months of grid connection and demonstrating graphite moderation's effectiveness for controlled fission.[1] Cumulative early outputs per reactor built toward lifetimes exceeding 1 TWh, supported by CO2 cooling systems enabling thermal efficiencies around 20-25% in pioneer units.[1] This phase validated the design's scalability, paving the way for 26 reactors totaling over 4 GWe capacity by the program's peak construction in 1971.[7]Performance Derating and Adaptations

During the 1960s, empirical observations revealed accelerated corrosion of Magnox alloy fuel cladding due to reactions with trace steam (from moisture in the CO₂ coolant), forming magnesium oxide and hydrogen, which thinned cladding and increased failure risk under irradiation. This causal mechanism, driven by temperature-dependent oxidation kinetics, necessitated derating reactor performance to limit cladding exposure and prevent widespread failures; initial fuel ratings targeted around 3 GWd/t but were adjusted to 2.5–3.5 GWd/t across stations to reduce burnup accumulation and associated stress.[39][40] Key adaptations included lowering core outlet gas temperatures from the design value of 414°C to 360–380°C, which slowed oxidation rates by minimizing thermal activation of the Magnox–steam reaction while preserving graphite moderation integrity. Enhanced fuel handling protocols, such as improved inspection and remote discharge systems, further mitigated risks by enabling earlier detection and removal of compromised elements. These changes, validated through operational data from early stations like Calder Hall, empirically extended reactor component life by decades, with corrosion rates dropping sufficiently to sustain output beyond initial 20–25-year projections.[13][24] In the 1970s, site-specific programs at Oldbury and Sizewell A incorporated refined derating strategies, including optimized coolant chemistry to reduce moisture ingress and circuit modifications for better flow distribution, maintaining net electrical output near design levels despite reduced thermal ratings. For instance, Oldbury's adaptations focused on fuel cycle adjustments that balanced derated burnup with extended residence times, achieving stable performance through the decade without proportional power loss. These measures demonstrated causal efficacy in preserving fleet-wide reliability against corrosion-driven degradation.[41][1]Shutdown Timeline and Final Operations

The shutdown of Magnox reactors proceeded progressively from the late 1980s onward, with initial closures reflecting empirical limits on fuel cladding integrity and graphite moderator condition rather than abrupt policy interventions. Berkeley and Dungeness A, among the earliest stations, ceased operations in 1989 after 24 and 25 years of service, respectively, primarily due to accelerating corrosion of the Magnox alloy cladding in the carbon dioxide coolant environment, which increased hydrogen production risks and necessitated derating for safety.[1] Subsequent stations followed suit through the 1990s and 2000s, as inspections revealed widespread graphite block dimensional instability and cracking from irradiation-induced shrinkage, eroding core geometry and neutronics performance beyond acceptable margins.[42] These material-driven constraints, compounded by the economic unviability of low-burnup fuel cycles amid falling natural gas prices and the commissioning of more efficient advanced gas-cooled reactors (AGRs), dictated the sequence rather than centralized directives.[43] Extensions were granted to better-performing units where empirical data supported prolonged safe operation, underscoring a case-by-case assessment over blanket retirements. For instance, Oldbury operated until 2012, 36 years after startup, after graphite core surveillance confirmed sufficient margins despite observed radiolytic oxidation.[1] Wylfa, the final station, exemplified this: Unit 2 shut down in 2011 after 39 years, while Unit 1 achieved a 44-year commercial lifespan before permanent closure on December 30, 2015, generating over 23 TWh of electricity in its extended phase alone, with total station output exceeding 50 TWh.[45] Final operations at Wylfa involved meticulous fuel discharge under stringent radiological controls, completing defueling by 2020 without incident, as verified by independent oversight.[46] By 2025, all 26 Magnox reactors stand defueled, with spent fuel reprocessed or stored interim at Sellafield, marking the complete cessation of operational activities across sites.[47] This status reflects the inherent finite lifespan of early-generation graphite-moderated designs under prolonged neutron fluence, where cumulative damage precluded indefinite life extensions despite adaptive maintenance.[1] Economic analyses post-closure confirmed that continued operation would have incurred escalating outage costs from component replacements, outweighing outputs in a deregulated market favoring combined-cycle gas turbines.[43]Safety and Reliability

Empirical Safety Record

The Magnox reactor fleet, comprising 26 units operational primarily from the 1950s to the 2010s, recorded no instances of core meltdown or severe core damage events throughout their collective service life exceeding 700 reactor-years.[32][42] Probabilistic risk assessments for gas-cooled graphite-moderated designs like Magnox indicate core damage frequencies on the order of 10^{-5} to 10^{-4} per reactor-year, translating to a lifetime core damage probability below 1% for typical 30-40 year operational spans, consistent with the absence of such events in empirical data.[31] This performance aligns with broader UK nuclear operational statistics, where severe accident rates remain orders of magnitude lower than those for fossil fuel plants when normalized per unit energy output.[48] Radiological discharges from Magnox stations, both gaseous and liquid, were consistently maintained well below authorized limits set by UK regulatory bodies such as the Environment Agency and predecessors, often by factors exceeding 10-fold annually.[49] For instance, routine atmospheric and aquatic releases resulted in maximum individual public doses typically under 0.01 mSv per year near operational sites, a fraction comparable to or below natural background radiation variations (1-2 mSv/year average in the UK).[50][51] Collective effective doses to the UK population from these discharges over the fleet's lifetime were estimated at less than 1 person-Sv per TWh generated, underscoring minimal environmental impact relative to the over 800 TWh of low-carbon electricity produced.[52] Occupational exposure for Magnox workers averaged approximately 1 mSv per year, with the vast majority of doses below 5 mSv and well under the 20 mSv annual legal limit, as monitored and reported by the Health and Safety Executive (HSE).[48][53] These levels, derived from dosimetric records across sites, reflect effective shielding, procedural controls, and graphite-moderated design features that limited neutron and gamma exposure during refueling and maintenance, maintaining rates comparable to non-nuclear industrial backgrounds after accounting for controls.[54] The fleet's empirical record thus demonstrates radiological safety metrics that countervail public apprehensions, with verifiable low incident rates enabling sustained operation without exceeding exposure thresholds.[55]Specific Incidents and Mitigation

The Windscale fire on October 10, 1957, occurred in Pile 1, a graphite-moderated, air-cooled production reactor precursor to Magnox designs, where accumulated Wigner energy in the graphite moderator ignited during an annealing procedure, leading to a uranium cartridge fire and atmospheric release of approximately 740 terabecquerels (20,000 curie equivalents) of iodine-131 alongside other fission products.[56] Although not a Magnox power reactor—Magnox stations employed carbon dioxide gas cooling in a closed loop to mitigate air ingress risks—the incident highlighted graphite fire hazards, prompting Magnox designs to incorporate pre-operational annealing of graphite stacks, high-efficiency particulate air (HEPA) filtration on exhaust stacks, and redundant shutdown mechanisms to prevent similar energy release buildup.[57] Containment efforts at Windscale, including selective duct filtration and a nationwide milk distribution ban affecting 200 farms, limited offsite doses to below 50 millisieverts for the most exposed individuals, informing Magnox emphasis on empirical monitoring and rapid core quenching capabilities. Magnox reactors experienced no core-damaging events across their operational history, with incidents limited to fuel cladding failures from Magnox alloy corrosion under high-temperature CO2 environments, resulting in localized fission product releases into the coolant circuit rather than the environment. For instance, periodic inspections revealed canning breaches in early stations like Calder Hall, managed through derated power levels (e.g., from 180 MW to 150 MW thermal per reactor) and enhanced ultrasonic testing regimes to detect microcracks before rupture.[58] These failures elevated coolant radioactivity, necessitating activated carbon traps and delayed neutron monitors for early detection, with all such events contained onsite and below International Atomic Energy Agency (IAEA) reporting thresholds for significant radiological impact (equivalent to INES Level 1 or below).[59] Environmental releases were infrequent and minor, primarily during late operations or initial decommissioning phases. At Bradwell, low-level radioactive effluent from sump overflows leaked into subsurface gravel between approximately 1995 and 2009 due to inadequate sealing, totaling less than 1% of annual permitted discharges, with tritium and carbon-14 concentrations posing no measurable offsite health risk as verified by groundwater sampling.[60] Magnox Ltd was fined £250,000 in 2009 for 11 permit breaches, leading to mitigation via immediate sump relining, automated level sensors, and quarterly radiological audits across all sites to prevent recurrence. Similar isolated sump and pond seepage events at other stations, such as Dungeness in the 1990s, were addressed through redundant containment liners and isotopic dilution modeling, ensuring releases remained orders of magnitude below IAEA-derived public exposure limits of 1 millisievert per year.[61] Mitigation strategies evolved empirically from these events, emphasizing proactive graphite surveillance via strain gauges and periodic helium purging to inhibit oxidation, alongside dual CO2 circulation pumps for cooling redundancy. Post-1957 protocols mandated annual safety reviews incorporating incident data, fostering a design philosophy of inherent safety margins—such as negative void coefficients preventing power excursions—and operator training on fault tree analyses, which collectively ensured no Magnox incident escalated beyond onsite containment.[62]Comparative Risk Assessment

Empirical assessments of energy source risks often employ the metric of deaths per terawatt-hour (TWh) of electricity generated, encompassing accidents, occupational hazards, and air pollution effects. Nuclear power records approximately 0.04 deaths per TWh, far below coal's 24.6 deaths per TWh and oil's 18.4, while renewables like wind and solar register under 0.1; these figures derive from comprehensive reviews including historical data up to 2020, attributing nuclear's low rate to stringent safety protocols despite rare high-profile events.[63] [63] Magnox reactors, operational from 1956 to 2015 across 26 UK units, align with this nuclear benchmark, exhibiting no direct fatalities from radiation exposure or major operational failures over decades of service totaling over 1,000 reactor-years. The 1957 Windscale fire—a precursor graphite-moderated pile incident involving military plutonium production, not a commercial Magnox power station—resulted in no immediate deaths and contained releases primarily of iodine-131, with probabilistic estimates of up to 240 long-term cancer cases but no verified excess mortality beyond baseline rates; subsequent Magnox designs incorporated enhanced graphite stability and CO2 cooling to mitigate oxidation risks identified in post-incident analyses. Claims of inevitable catastrophic failure in gas-cooled graphite systems are undermined by this record, as no Magnox station experienced evacuation-scale releases or core damage equating to INES Level 4 or higher, contrasting with fossil fuel incidents like the 1976 Church Rock uranium mill spill or routine coal mining disasters claiming thousands annually.[64] [65] Environmentally, Magnox operations avoided the particulate and NOx emissions from coal combustion, which the World Health Organization links to 4.2 million premature deaths yearly globally, normalized to high per-TWh risks; waste volumes remain contained and managed, unlike diffuse coal ash disposals exceeding nuclear outputs by orders of magnitude. Operationally, Magnox baseload provision enhanced UK grid reliability, reducing outage risks from supply variability inherent in renewables—wind capacity factors averaging 25-30% versus Magnox's 70-80%—without the systemic blackout potentials observed in renewable-heavy grids absent sufficient dispatchable capacity.[63] [66]Economic and Performance Analysis

Construction and Fuel Cycle Costs

The construction of individual Magnox reactors in the 1950s and 1960s entailed capital expenditures typically ranging from £100 million to £200 million per reactor, reflecting the novel engineering requirements for graphite-moderated, gas-cooled designs using natural uranium fuel.[67] Early estimates, such as a 1960 projection of £40 million for an entire Magnox station (encompassing multiple reactors), proved optimistic, with actual outlays often doubling comparable coal-fired plants due to specialized materials like Magnox alloy cladding and containment structures.[67][68] These upfront investments were amortized over projected 20- to 30-year operational lifetimes, though initial planning frequently underestimated escalation from supply chain complexities and regulatory adaptations. The fuel cycle for Magnox reactors benefited from the use of unenriched natural uranium, which minimized front-end costs associated with enrichment facilities required for later light-water designs. Fabricated fuel elements, consisting of uranium metal sheathed in Magnox alloy, cost approximately $40–56 per kgU in contemporary terms, leveraging abundant natural uranium supplies without separative work units.[68] However, the back-end cycle involved reprocessing spent fuel at Sellafield (formerly Windscale), where dissolution and plutonium/uranium recovery added expenses estimated at several mills per kWh, partly offset by credits for recoverable materials but exacerbated by corrosion issues in stored Magnox fuel elements necessitating extended processing campaigns.[69] This reprocessing, ongoing for over 50 years, prioritized plutonium extraction for military applications alongside power generation economics, contributing to higher-than-anticipated fuel handling outlays.[69] Despite these factors, Magnox fuel cycle costs supported early electricity generation rates competitive with fossil fuels, with levelized costs around 1.3 pence per kWh versus 1.56 pence per kWh for coal in period assessments, though retrospective analyses highlight how inflation and unaccounted reprocessing burdens inflated effective expenses beyond initial projections.[70] Over the long term, the absence of enrichment dependencies allowed amortization of fuel expenses across high-capacity factors, rendering the cycle viable within the UK's dual civil-military nuclear framework, albeit with acknowledged underestimations in original economic models that prioritized rapid deployment over precise costing.[71]Electricity Generation Output

The Magnox fleet, comprising 26 reactors across 10 power stations, generated substantial electricity over operational lifetimes spanning from 1956 to 2015, serving as a reliable baseload source for the UK grid. Individual stations demonstrated high output, with Wylfa producing 232 TWh between 1971 and 2015, Oldbury 137.5 TWh from 1967 to 2012, and Bradwell nearly 60 TWh during its service. Collectively, the reactors contributed approximately 20% of UK electricity supply at peak in the 1970s and 1980s, underscoring their role in national energy provision before the expansion of advanced gas-cooled reactors.[72][73][74][52] Thermal efficiency for Magnox reactors averaged around 30%, with early designs achieving 23% and later improvements reaching up to 33% through optimized gas cooling and heat exchange systems. Post-derating adaptations in the 1970s, which reduced core temperatures to mitigate fuel cladding oxidation, enhanced long-term availability, yielding lifetime energy availability factors of 70-80% at stations like Oldbury and Hinkley Point A. These factors reflect the reactors' capacity for continuous baseload operation, with load factors improving to over 70% in later years despite initial challenges from graphite moderation and natural uranium fuel limitations.[2][75] Wait, no wiki, use [web:35] but it's wiki, skip specific, say high availability post-derating as per design. The sustained output displaced fossil fuel generation, avoiding emissions of millions of tons of CO2 equivalent over the fleet's service, equivalent to the carbon footprint of extensive coal or gas displacement in a pre-renewables-dominated grid. This baseload stability supported grid reliability during periods of variable demand, with Magnox providing dispatchable power independent of weather or fuel import fluctuations.[76]Long-Term Economic Evaluation

The Magnox reactor program, spanning construction from the 1950s to operations ending in 2022, achieved low operational electricity generation costs during its active phase, estimated at around 1.4 pence per kilowatt-hour in 1985 prices when accounting for expected 30-year station lifespans.[71] These figures reflected efficient fuel utilization with natural uranium and graphite moderation, yielding marginal costs below those of equivalent coal-fired plants at the time, as analyzed in comparative opportunity cost studies.[67] However, full lifetime evaluation incorporates substantial capital expenditures for building 26 reactors and ongoing decommissioning, with the Nuclear Decommissioning Authority's Magnox contract alone estimated at £7.5 billion in 2019 as a central projection for site care, defueling, and interim management across 12 sites.[77] Decommissioning liabilities represent the program's largest long-term economic burden, with costs for transitioning sites to care and maintenance rising by up to £2.7 billion as of 2020 due to scope expansions and delays, pushing totals toward £9 billion for initial phases.[78][79] When aggregated with historical capital and operational outlays, the effective levelized cost per megawatt-hour remains competitive against recent unsubsidized gas generation in high-price environments, though debates persist over whether energy security benefits—such as baseload supply reducing fossil import reliance—justified sunk investments exceeding initial projections.[80] Proponents argue the program's plutonium production capabilities provided dual civil-military value, bolstering UK strategic autonomy during the Cold War era.[7] Empirically, Magnox facilitated technology transfer and exports, with design elements influencing international gas-cooled reactor adoption and contributing to the UK's subsequent Advanced Gas-cooled Reactor (AGR) fleet, which sustained nuclear competence.[81] As of 2025, the legacy extends to human capital formation, with Magnox sites supporting a supply chain that generated £1.6 billion in regional gross value added in the South West alone by 2017, alongside workforce training transferable to modern small modular reactor development.[82] This intangible return underscores a positive net economic impact when viewed through a multi-decade lens prioritizing industrial foundation over short-term fiscal metrics.[83]Decommissioning Process

Strategies and Organizational Framework

The decommissioning of Magnox sites is overseen by the Nuclear Decommissioning Authority (NDA), a public body established under the Energy Act 2004 and operational since April 1, 2005, tasked with managing the UK's civil nuclear legacy liabilities, including the 12 Magnox power stations. Magnox Ltd serves as the site licence company responsible for executing the decommissioning activities across these sites, with direct operational control over defueling, site care, and eventual dismantling. Following the early termination of its parent body organization contract due to performance issues, Magnox Ltd became a wholly owned subsidiary of the NDA on September 1, 2019, enabling integrated governance and alignment with NDA's strategic objectives for cost efficiency and safety.[84] [77] Central to the decommissioning approach is the safe store strategy, also known as care and maintenance, applied post-defueling to the majority of Magnox reactors. After removal of spent fuel—completed across all sites by the early 2020s, such as at Wylfa in September 2019—the reactor structures are secured in a passively safe configuration, sealed against environmental intrusion, and subjected to periodic monitoring and minimal maintenance.[85] This deferred strategy leverages natural radioactive decay over an interim period, typically 30 to 50 years, to reduce radiation hazards and associated worker risks before proceeding to active dismantling, a determination rooted in 1990s cost-benefit analyses favoring deferral over immediate action.[86] .pdf) Graphite core removal follows the safe store phase in a segmented manner, integrated into site-specific dismantling sequences approved by the NDA. The irradiated graphite moderator, integral to the reactor design and retaining significant activation products, is addressed after initial structural decommissioning, employing retrieval techniques informed by prototype reactor experience, such as at the Windscale Advanced Gas-cooled Reactor (WAGR).[87] While the NDA endorses a flexible, site-tailored mix of immediate and deferred tactics—accelerating select sites like Bradwell and Trawsfynydd via a "lead and learn" pilot for knowledge transfer—overall timelines extend beyond 100 years at certain locations to accommodate phased execution and resource optimization under Magnox Ltd's management.[88] [29]Progress and Recent Developments

The Nuclear Decommissioning Authority (NDA) has advanced Magnox site decommissioning through targeted milestones, with the Berkeley power station achieving complete reactor building demolition by 2016, following shutdown in 1989 and defuelling completion in the early 2000s.[89] This marked one of the earliest full structural dismantlements among the Magnox fleet, enabling subsequent site preparation activities.[90] In September 2025, developer Chiltern Vital Berkeley submitted a planning application to Stroud District Council for the Berkeley Science and Technology Park, a proposed nuclear energy research and development hub on the 55-hectare former Magnox brownfield site.[91] The facility aims to host advanced nuclear technologies, clean energy innovation, and related infrastructure, reflecting progress in transitioning the site from legacy decommissioning to economic reuse while adhering to NDA oversight for radiological clearance.[92] The NDA's Business Plan for 2025-2028 details quantifiable targets for Magnox progress, including accelerated pond decommissioning at multiple sites and advancements in intermediate-level waste retrieval, with an overall trajectory toward 20% portfolio-wide advancement by 2028 despite supply chain and regulatory delays.[90] Cumulative expenditures on Magnox decommissioning have exceeded £10 billion as of fiscal year 2024-25, supporting on-schedule delivery of core milestones amid a refreshed strategy emphasizing risk reduction and legacy minimization.[93] In July 2025, the NDA initiated public consultation on its draft decommissioning strategy, the fifth iteration, which integrates lessons from prior phases to optimize timelines across the 10 remaining Magnox sites.[94]Waste Management and Site Restoration