Recent from talks

Nothing was collected or created yet.

Hydronics

View on WikipediaThis article needs additional citations for verification. (July 2022) |

Hydronics (from Ancient Greek hydro- 'water') is the use of liquid water or gaseous water (steam) or a water solution (usually glycol with water) as a heat-transfer medium in heating and cooling systems.[1][2] The name differentiates such systems from oil and refrigerant systems.

Historically, in large-scale commercial buildings such as high-rise and campus facilities, a hydronic system may include both a chilled and a heated water loop, to provide for both heating and air conditioning. Chillers and cooling towers are used either separately or together as means to provide water cooling, while boilers heat water. A recent innovation is the chiller boiler system, which provides an efficient form of HVAC for homes and smaller commercial spaces.

District heating

[edit]Many larger cities have a district heating system that provides, through underground piping, publicly available high temperature hot water and chilled water. A building in the service district may be connected to these on payment of a service fee.

Types of hydronic system

[edit]Basic types

[edit]Hydronic systems can include the following kinds of distributions:[1]

- Chilled water systems

- Hot water systems

- Steam systems

- Steam condensate systems

- Ground source heat pump systems

Classification

[edit]Hydronic systems are further classified in five ways:

- Flow generation (forced flow or gravity flow)

- Temperature (low, medium, and high)

- Pressurization (low, medium, and high)

- Piping arrangement

- Pumping arrangement

Piping arrangements

[edit]Hydronic systems may be divided into several general piping arrangement categories:

- Single or one-pipe

- Two pipe steam (direct return or reverse return)

- Three pipe

- Four pipe

- Series loop

Single-pipe steam

[edit]

In the oldest modern hydronic heating technology, a single-pipe steam system delivers steam to the radiators where the steam gives up its heat and is condensed back to water. The radiators and steam supply pipes are pitched so that gravity eventually takes this condensate back down through the steam supply piping to the boiler where it can once again be turned into steam and returned to the radiators.

Despite its name, a radiator does not primarily heat a room by radiation. If positioned correctly a radiator will create an air convection current in the room, which will provide the main heat transfer mechanism. It is generally agreed that for the best results a steam radiator should be no more than one to two inches (2.5 to 5cm) from a wall.

Single-pipe systems are limited in both their ability to deliver high volumes of steam (that is, heat)[citation needed] and the ability to control the flow of steam to individual radiators[citation needed] (because closing off the steam supply traps condensate in the radiators). Because of these limitations, single-pipe systems are no longer preferred.

These systems depend on the proper operation of thermostatic air-venting valves located on radiators throughout the heated area. When the system is not in use, these valves are open to the atmosphere, and radiators and pipes contain air. When a heating cycle begins, the boiler produces steam, which expands and displaces the air in the system. The air exits the system through the air-venting valves on the radiators and on the steam pipes themselves. The thermostatic valves close when they become hot; in the most common kind, the vapor pressure of a small amount of alcohol in the valve exerts the force to actuate the valve and prevent steam from leaving the radiator. When the valve cools, air enters the system to replace the condensing steam.

Some more modern valves can be adjusted to allow for more rapid or slower venting. In general, valves nearest to the boiler should vent the slowest, and valves furthest from the boiler should vent the fastest.[citation needed] Ideally, steam should reach each valve and close each and every valve at the same time, so that the system can work at maximal efficiency; this condition is known as a "balanced" system.[citation needed]

Two-pipe steam systems

[edit]In two-pipe steam systems, there is a return path for the condensate and it may involve pumps as well as gravity-induced flow. The flow of steam to individual radiators can be modulated using manual or automatic valves.

Two-pipe direct return system

[edit]The return piping, as the name suggests, takes the most direct path back to the boiler.

Advantages

[edit]Lower cost of return piping in most (but not all) applications, and the supply and return piping are separated.

Disadvantages

[edit]This system can be difficult to balance due to the supply line being a different length than the return; the further the heat transfer device is from the boiler, the more pronounced the pressure difference. Because of this, it is always recommended to: minimize the distribution piping pressure drops; use a pump with a flat head characteristic[when defined as?], include balancing and flow-measuring devices at each terminal or branch circuit; and use control valves with a high head loss[when defined as?] at the terminals.

Two-pipe reverse return system

[edit]The two-pipe reverse return configuration which is sometimes called 'the three-pipe system' is different from the two-pipe system in the way that water returns to the boiler. In a two-pipe system, once the water has left the first radiator, it returns to the boiler to be reheated, and so with the second and third etc. With the two-pipe reverse return, the return pipe travels to the last radiator in the system before returning to the boiler to be reheated.

Advantages

[edit]The advantage with the two-pipe reverse return system is that the pipe run to each radiator is about the same, this ensures that the frictional resistance to the flow of water in each radiator is the same. This allows easy balancing of the system.

Disadvantages

[edit]The installer or repair person cannot trust that every system is self-balancing without properly testing it.

Water loops

[edit]Modern systems almost always use heated water rather than steam. This opens the system to the possibility of also using chilled water to provide air conditioning.

In homes, the water loop may be as simple as a single pipe that "loops" the flow through every radiator in a zone. In such a system, flow to the individual radiators cannot be modulated as all of the water is flowing through every radiator in the zone. Slightly more complicated systems use a "main" pipe that flows uninterrupted around the zone; the individual radiators tap off a small portion of the flow in the main pipe. In these systems, individual radiators can be modulated. Alternatively, a number of loops with several radiators can be installed, the flow in each loop or zone controlled by a zone valve connected to a thermostat.

In most water systems, the water is circulated by means of one or more circulator pumps. This is in marked contrast to steam systems where the inherent pressure of the steam is sufficient to distribute the steam to remote points in the system. A system may be broken up into individual heating zones using either multiple circulator pumps or a single pump and electrically operated zone valves.

Improved efficiency and operating costs

[edit]There have been considerable improvements in the efficiency and therefore the operating costs of a hydronic heating system with the introduction of insulating products.

Radiator Panel system pipes are covered with a fire rated, flexible and lightweight elastomeric rubber material designed for thermal insulation. Slab Heating efficiency is improved with the installation of a thermal barrier made of foam. There are now many product offerings on the market with different energy ratings and installation methods.

Balancing

[edit]Most hydronic systems require balancing. This involves measuring and setting the flow to achieve an optimal distribution of energy in the system. In a balanced system every radiator gets just enough hot water to allow it to heat up fully.

Boiler water treatment

[edit]Residential systems may use ordinary tap water, but sophisticated commercial systems often add various chemicals to the system water. For example, these added chemicals may:

- Inhibit corrosion

- Prevent freezing of the water in the system

- Increase the boiling point of the water in the system

- Inhibit the growth of mold and bacteria

- Allow improved leak detection (for example, dyes that fluoresce under ultraviolet light)

Air elimination

[edit]All hydronic systems must have a means to eliminate air from the system. A properly designed, air-free system should continue to function normally for many years.

Air causes irritating system noises, and interrupts proper heat transfer to and from the circulating fluids. In addition, unless reduced below an acceptable level, the oxygen dissolved in water causes corrosion. This corrosion can cause rust and scale to build up on the piping. Over time these particles can become loose and travel around the pipes, reducing or even blocking the flow as well as damaging pump seals and other components.

Water-loop system

[edit]Water-loop systems can also experience air problems. Air found within hydronic water-loop systems may be classified into three forms:

Free air

[edit]Various devices such as manual and automatic air vents are used to address free air which floats up to the high points throughout the system. Automatic air vents contain a valve that is operated by a float. When air is present, the float drops, allowing the valve to open and bleed air out. When water reaches (fills) the valve, the float lifts, blocking the water from escaping. Small (domestic) versions of these valves in older systems are sometimes fitted with a Schrader-type air valve fitting, and any trapped, now-compressed air can be bled from the valve by manually depressing the valve stem until water rather than air begins to emerge.

Entrained air

[edit]Entrained air is air bubbles that travel around in the piping at the same velocity as the water. Air "scoops" are one example of products which attempt to remove this type of air.

Dissolved air

[edit]Dissolved air is also present in the system water and the amount is determined principally by the temperature and pressure (see Henry's law) of the incoming water. On average, tap water contains between 8-10% dissolved air by volume.

Removal of dissolved, free and entrained air can only be achieved with a high-efficiency air elimination device that includes a coalescing medium that continually scrubs the air out of the system. Tangential or centrifugal style air separator devices are limited to removal of free and entrained air only.

Accommodating thermal expansion

[edit]Water expands as it heats and contracts as it cools. A water-loop hydronic system must have one or more expansion tanks in the system to accommodate this varying volume of the working fluid. These tanks often use a rubber diaphragm pressurised with compressed air. The expansion tank accommodates the expanded water by further air compression and helps maintain a roughly constant pressure in the system across the expected change in fluid volume. Simple cisterns open to atmospheric pressure are also used.

Water also expands drastically as it vaporizes, or flashes, into steam. Sparge pipes can help accommodate flashing that may occur as high pressure condensate enters a lower pressure region.[3]

Automatic fill mechanisms

[edit]Hydronic systems are usually connected to a water supply (such as the public water supply). An automatic valve regulates the amount of water in the system and also prevents backflow of system water (and any water treatment chemicals) into the water supply.

Safety mechanisms

[edit]Excessive heat or pressure may cause the system to fail. At least one combination over-temperature and over-pressure relief valve is always fitted to the system to allow the steam or water to vent to the atmosphere in case of the failure of some mechanism (such as the boiler temperature control) rather than allowing the catastrophic bursting of the piping, radiators, or boiler. The relief valve usually has a manual operating handle to allow testing and the flushing of contaminants (such as grit) that may cause the valve to leak under otherwise-normal operating conditions.

Rapid condensation of steam can also lead to water hammer, which during rapid volume change from gas to liquid leads to a powerful vacuum force. This can damage and destroy fittings, valves and equipment. Proper design and the addition of vacuum breakers reduce or eliminate the risk of these problems.[4]

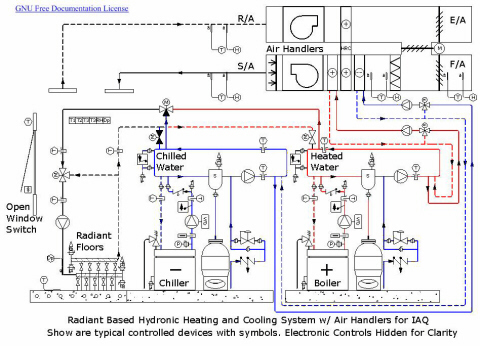

Typical schematic with control devices shown

[edit]See also

[edit]References

[edit]- ^ a b "2021 Uniform Mechanical Code". epubs.iapmo.org (Code book). IAPMO. 2021. pp. ix, 16. Retrieved 2022-07-22.

- ^ Siegenthaler, John (2012). Modern Hydronic Heating (Third ed.). Cengage Learning. p. 3.

- ^ Hall, Norm (2017-05-15). "Medium and High Pressure Steam Vented Flash Tank Trim". RL Deppmann. Retrieved 2022-07-22.

- ^ Harms, Bill (2006-09-01). "Plant Engineering | Water hammer in steam systems: cause and effect". Plant Engineering. Retrieved 2022-07-22.

Hydronics

View on GrokipediaFundamentals

Definition and History

Hydronics is the engineering discipline and technology involving the use of liquid water, steam, or water-based solutions (such as glycol mixtures) as heat-transfer media in closed-loop systems for heating, cooling, and industrial processes. These systems circulate the fluid through piping networks to convey thermal energy from a source, such as a boiler or chiller, to emitters like radiators or underfloor panels, providing precise temperature control and even distribution. Unlike forced-air systems that rely on ducted convection or direct electric resistance heating, hydronic approaches leverage the high specific heat capacity of water for efficient, quiet operation with minimal air movement.[9][10][11] The origins of hydronic systems trace back to 19th-century developments in steam and hot-water heating, evolving from earlier European experiments with central heating. In the United States, steam heating gained prominence in the mid-1800s, with Joseph Nason and Robert Briggs receiving a patent in 1863 for an improved steam radiator design, while Robert Briggs began installing hot-water systems around 1840 using gravity circulation. By the 1860s, hot-water boilers were mass-produced, and the 1880s marked a key milestone with U.S. and British patents for advanced radiators, including Walter Jones's 1881 design for a ventilating hot-water radiator that enhanced air circulation. These early gravity-fed systems relied on natural convection, with vertical piping and expansion tanks to manage thermal expansion, laying the groundwork for modern hydronics.[12][13] In the 20th century, hydronic technology advanced through the adoption of pressurized systems and mechanical circulation, enabling more compact and versatile installations. High-pressure hot-water systems, inspired by Angier March Perkins's 1831 patent, became feasible with stronger materials and boilers, transitioning from open gravity designs to closed, pressurized loops by the early 1900s. The introduction of electrically powered circulators in the 1930s allowed for smaller-diameter piping and flexible layouts, while glycol-water mixtures for freeze protection emerged in the mid-20th century, adapting automotive antifreeze formulations to safeguard outdoor and exposed hydronic applications. Meanwhile, district heating systems rose in Europe from the 1920s, with Sweden's first installation in Västerås in 1920 and Denmark's expansion in the 1930s, often using hot water for efficient urban-scale distribution.[12][11][14][15] Post-1950s innovations were driven by energy efficiency demands, particularly following the 1970s oil crises, which prompted a shift toward low-temperature hot-water systems operating at 120–140°F (49–60°C) to pair with condensing boilers and heat pumps. This evolution reduced energy consumption by minimizing heat loss and enabling integration with renewable sources, while components like wet-rotor circulators (introduced by Taco in 1958) standardized reliable flow control. By the late 20th century, these advancements solidified hydronics as a cornerstone of sustainable building thermal management.[11][16]Heat Transfer Principles

In hydronic systems, heat transfer primarily occurs through convection, where thermal energy is carried by the movement of fluids such as water or steam. Forced convection dominates in these systems, driven by pumps or circulators that propel the fluid through pipes and heat exchangers, enhancing heat dissipation to surrounding air or surfaces via the fluid's bulk motion.[17] Natural convection, induced by buoyancy forces from density differences due to temperature gradients, plays a secondary role, such as in passive heat emission from uncirculated fluid pockets, but is less efficient and typically yields lower heat transfer rates.[18] Conduction supplements convection by transferring heat through the solid walls of pipes and fittings, governed by the material's thermal conductivity and the temperature differential across the wall thickness. This mechanism is crucial for minimizing heat loss in insulated piping, where materials like copper exhibit high conductivity (approximately 400 W/m·K), facilitating rapid heat flow to the fluid or from it.[18] In steam-based hydronic systems, phase change adds a distinct mechanism: as steam condenses on heat-emitting surfaces, it releases latent heat at a constant temperature, enabling compact and efficient energy delivery without significant sensible temperature drop.[19] The rate of sensible heat transfer in fluid streams, applicable to water-based systems, is described by the equation where is the heat transfer rate (in kW), is the mass flow rate (kg/s), is the specific heat capacity, and is the temperature difference (K). For steam systems, the latent heat of condensation contributes substantially, with kJ/kg at 100°C and atmospheric pressure, representing the energy released per unit mass during phase change from vapor to liquid.[20] Heat conduction across pipe walls is quantified using the overall heat transfer coefficient (W/m²·K), which accounts for combined resistances in the equation , where is the surface area; typical values for insulated hydronic pipes range from 0.5 to 5 W/m²·K depending on insulation thickness and material.[18] Water, the primary fluid in hydronic systems, has a specific heat capacity of 4.18 kJ/kg·K near room temperature, allowing it to absorb and transport significant thermal energy with modest temperature changes; its thermal conductivity (about 0.6 W/m·K) and viscosity (around 0.001 Pa·s at 20°C) influence flow regimes and convective efficiency, with higher viscosity promoting laminar flow and reduced heat transfer.[21] Steam, by contrast, offers higher energy density due to its latent heat component—up to 40 times that of sensible heat in water at similar temperatures—but introduces corrosion risks from dissolved oxygen in condensate and potential acidic formation, accelerating oxidation in steel components compared to the more stable, oxygen-managed water loops.[19][22] Effective fluid circulation in closed loops requires accounting for pressure dynamics, where Bernoulli's principle describes energy conservation along a streamline: , with pressure drops arising from friction and elevation changes that pumps must overcome to maintain flow. In hydronic piping, this principle underpins calculations for head loss, ensuring balanced distribution without excessive energy use.[23]System Types

Steam-Based Systems

Steam-based hydronic systems utilize steam as the primary medium for heat transfer, leveraging the phase change from water to vapor to efficiently distribute thermal energy through piping to radiators or other terminals. These systems operate by generating steam in a boiler at low pressures, typically ranging from 1 to 15 psi, which allows the vapor to travel via gravity or minimal pressure differentials to heat emitters before condensing back into water for return. Unlike liquid-based hydronics, steam systems rely on the latent heat of vaporization, enabling smaller pipe sizes but introducing complexities related to phase change dynamics.[24][25] Single-pipe steam systems represent one of the earliest and simplest configurations, where a single pipe serves dual purposes: distributing steam to radiators and returning condensate to the boiler. In this gravity-fed design, steam enters the radiator from the top, displacing air through vents, while condensed water drains back through the same pipe at the bottom due to natural slope and pressure differences. Typical operating pressures are around 2 psig to ensure even distribution without excessive force, and the system requires precise piping pitch—often 1 inch per 10 feet—to facilitate condensate flow without water hammer. These systems offer advantages in simplicity and cost-effectiveness, making them particularly suitable for retrofitting or maintaining older buildings constructed before widespread modernization.[24] Two-pipe steam systems enhance control and efficiency by employing separate supply lines for steam delivery and return lines for condensate drainage, allowing for more balanced heat distribution across multiple zones. Steam travels through the supply pipe to the radiator inlet, condenses to release heat, and the resulting water exits via a dedicated return pipe equipped with steam traps to block vapor escape while permitting liquid flow. A key distinction in these systems is between dry steam, which is superheated or saturated without moisture droplets for optimal transfer, and wet steam, which carries water and can lead to uneven heating or noise; dry steam is achieved through proper boiler tuning and oversized headers. This setup supports advanced controls like thermostatic radiator valves, enabling precise temperature regulation that is less feasible in single-pipe arrangements.[25] Operational challenges in steam-based systems stem from the corrosive nature of condensate and inherent heat dissipation. Oxygen dissolved in returning condensate, often introduced through air absorption during system cycles, reacts with iron in pipes and boilers to form rust, accelerating corrosion that can compromise system integrity if not mitigated by chemical treatments or deaerators. Steam traps are essential for efficient operation, as they automatically discharge condensate while retaining steam, but they require regular maintenance to prevent failures that cause flooding or energy waste. Efficiency losses are notable from radiation in uninsulated pipes, where heat transfer to surroundings can account for 15-20% of total energy input in poorly maintained setups; proper insulation reduces these losses by approximately 90%, preserving more thermal energy for end-use.[26][27][28][29][30] Steam systems were prevalent in residential and commercial buildings prior to the 1940s, becoming a dominant heating method in the late 19th and early 20th centuries due to advancements in boiler design and the availability of coal as fuel. Their adoption peaked in the Northeast United States, where they provided reliable central heating for middle-income homes until the post-World War II shift toward forced-air and hot-water systems. In modern applications, steam-based hydronics are largely limited to high-rise buildings (typically six stories or more) and industrial settings, where their ability to handle vertical distribution without pumps remains advantageous, though strict safety codes—such as those from the ASME Boiler and Pressure Vessel Code—mandate robust pressure relief, corrosion monitoring, and zoning to address risks like explosions or leaks.[31][25][32][33]Water-Based Systems

Water-based hydronic systems utilize liquid water as the heat transfer medium, circulating it through closed loops to provide heating or cooling in buildings. These systems are designed for efficient energy distribution, operating at lower pressures than steam alternatives and allowing precise temperature control via pumps and valves. Unlike steam systems, which rely on phase change for heat transfer, water-based setups maintain water in liquid form, enabling quieter operation and reduced risk of leaks from high-pressure components. Hot water systems in hydronics typically employ closed-loop circulation, where water is heated to supply temperatures ranging from 140°F to 180°F (60°C to 82°C) before distribution to emitters such as radiators or underfloor coils. This temperature range ensures effective heat transfer while minimizing energy loss and material stress in the piping. To manage thermal expansion as water volume increases with heating—up to 4% from 60°F to 180°F—expansion tanks are integrated into the system, absorbing excess volume and maintaining stable pressure, typically pre-charged to 12-15 psi to match the system's cold fill pressure.[34][35] Chilled water systems adapt the same principles for cooling applications, supplying water at 40°F to 55°F (4°C to 13°C) from chillers to air handlers or fan coils, with return temperatures often 10°F to 16°F higher to optimize chiller efficiency. These systems integrate directly with centrifugal or absorption chillers, where the cold water absorbs heat from building spaces, enabling large-scale cooling in commercial and institutional settings without the need for direct refrigerant distribution.[36][37] Hot water (HWS) and chilled water (CWS) systems are widely used hydronic HVAC systems in commercial and large buildings. Advantages:- Superior heat transfer capability, as water carries approximately 3500 times more heat per unit volume than air, enabling smaller pipes and reduced space requirements compared to ducted air systems.

- High efficiency in large-scale applications due to centralized plant control and opportunities for heat recovery.

- Excellent zoning and individual room temperature control, particularly in four-pipe configurations that allow simultaneous heating and cooling.

- Quiet operation, with no large fans or ducts in occupied spaces.

- Effective humidity control and even temperature distribution.

- High initial costs from extensive piping, pumps, valves, insulation, and central equipment.

- Potential risks including water leaks, corrosion, scaling, air entrapment, and freezing (particularly in chilled water lines).

- Complex installation, ongoing maintenance, and control requirements, along with higher pump energy consumption.

- Slower response times compared to direct expansion (DX) systems.

- Larger overall infrastructure footprint for equipment and piping.

Hybrid and Advanced Systems

Hybrid and advanced hydronic systems integrate multiple fluid types or innovative technologies to enhance efficiency and adaptability beyond traditional single-fluid setups. These systems often combine steam and water circuits, where steam provides high-temperature heat for industrial processes while water handles lower-temperature distribution for space heating, allowing precise control in mixed-use facilities.[42] Ground-source heat pump (GSHP) hydronics represent a key advancement, employing closed-loop configurations that circulate a heat transfer fluid—typically water or a glycol solution—through underground pipes for geothermal exchange, achieving coefficient of performance (COP) values typically ranging from 3 to 4 for heating applications.[43] This setup leverages stable ground temperatures to improve overall system efficiency compared to air-source alternatives. Dual-fluid systems further exemplify hybrid designs, particularly in industrial environments, where steam generates intense heat for manufacturing needs and hydronic water loops distribute moderated warmth to building zones, reducing energy losses during transfer.[42] Emerging concepts like low-temperature hydronics operate with supply water below 140°F (60°C), which lowers pumping power requirements and boosts heat pump efficiency by minimizing viscous losses and enabling higher COPs—up to 44% improvement when reducing temperatures from 140°F to 120°F.[44] Variable flow systems complement this by dynamically adjusting circulation rates based on demand, often reducing overall energy consumption by 20-30% through optimized pump operation and reduced pressure differentials.[45] As of 2024, air-to-water heat pumps have seen significant market expansion, integrating with hydronic loops for low-carbon heating and cooling applications.[46] Adoption of these advanced hydronics has surged in green buildings since 2010, driven by standards emphasizing energy efficiency and sustainability, with integrations like phase-change materials (PCMs) for thermal storage enhancing performance.[47] PCMs, embedded in hydronic components such as pipes or storage tanks, absorb and release latent heat during phase transitions, stabilizing temperatures and extending heat availability without significant volume changes, thereby improving system responsiveness in variable-load scenarios.[48] These innovations build on foundational water-based hydronics by incorporating geothermal or material-based enhancements for greater resilience and lower operational costs.Piping Configurations

Single-Pipe Arrangements

Single-pipe arrangements represent the most basic configuration in steam-based hydronic heating systems, where a single pipe serves both to deliver steam from the boiler to the heating elements and to return the resulting condensate to the boiler. This shared-line approach relies on gravity for condensate drainage and is designed to minimize material costs and installation complexity, making it suitable primarily for low-pressure steam applications. In the design, steam enters the system from the top of the boiler, traveling through mains pitched toward the boiler at rates such as 1/2 inch per 10 feet for parallel flow or 1 inch per 10 feet for counterflow arrangements, while condensate collects and drains from the bottom of the pipes and radiators. Configurations include upfeed systems, where steam rises through vertical risers to upper-level radiators and condensate flows downward against the incoming steam, and downfeed systems, where both steam and condensate descend together in overhead mains before entering radiators. To prevent water hammer and ensure proper operation, the lowest point of the steam main must be at least 28 inches above the boiler's water line, and steam traps or vents are installed at radiator ends to facilitate air escape and condensate discharge.[24][49] These systems find primary application in small residential steam heating setups, where simplicity and low initial cost outweigh the need for precise control. Pipe sizing is determined based on the equivalent direct radiation (EDR) load, a measure of heating capacity, with examples including 2-inch mains handling up to 386 square feet of EDR and 3-inch mains up to 1,163 square feet; runouts to individual radiators are typically one size larger for lengths exceeding 8 feet to accommodate flow without excessive pressure loss. Velocity limits for saturated steam in these pipes are generally maintained between 4,000 and 10,000 feet per minute to balance efficient distribution with minimal erosion and noise, though residential low-pressure systems often operate at the lower end to reduce pressure drops. Historically, single-pipe steam systems became prevalent in U.S. homes constructed from the 1920s to the 1950s, particularly in urban multifamily buildings, as they aligned with the era's widespread adoption of centralized steam heating before the rise of forced-hot-water alternatives.[24][50][51] Despite their advantages in cost and ease of installation, single-pipe arrangements are prone to operational issues, including uneven heating across radiators due to cumulative pressure drops in the shared line, which delay steam arrival to distant or higher units and can result in short-cycling if the boiler is oversized. The counterflow of steam and condensate also risks water logging in mains if pitching or venting is inadequate, exacerbating noise and inefficiency. These systems are inherently unsuitable for hot-water hydronics without the addition of circulation pumps, as they depend on steam's natural pressure and gravity for flow rather than forced circulation. Retrofitting older installations presents significant challenges, such as frequent steam trap failures that lead to condensate backup, water hammer, and reduced system lifespan, often requiring comprehensive replacement of vents, traps, and sometimes mains to achieve modern efficiency standards.[24][49]Two-Pipe Arrangements

Two-pipe arrangements in hydronic systems utilize separate supply and return piping lines to deliver heated or cooled water to terminal units, such as radiators or fan coil units, and return it to the heat source. This configuration allows for independent control of flow direction and enables precise zoning, where different areas of a building can receive conditioned water at consistent temperatures without the temperature degradation common in series-connected setups. By maintaining distinct paths for supply and return, two-pipe systems facilitate better overall system balance and efficiency in distributing thermal energy.[52] Within two-pipe systems, the direct return configuration arranges supply and return pipes in parallel, where the supply water travels sequentially to each terminal unit, and the return follows the shortest path back from the nearest unit to the boiler or chiller. This results in shorter piping lengths for zones closer to the heat source, making it a common choice in older installations due to its simplicity and reduced material requirements. However, the unequal pipe lengths between zones can lead to flow imbalances, with nearer units receiving higher flow rates and farther ones experiencing restrictions, often necessitating balancing valves for adjustment.[53][54] In contrast, the reverse return design equalizes the total pipe length for each circuit by routing the return line in the opposite direction of the supply, ensuring that the path length from supply to return is approximately the same for all terminal units. This self-balancing feature promotes uniform flow distribution without extensive manual adjustments, ideal for systems requiring consistent performance across multiple zones. While more effective for achieving hydraulic balance, reverse return systems incur higher installation costs due to the additional piping length and complexity involved.[53][52][54] Overall, direct return systems offer lower upfront costs but are prone to operational imbalances that may increase maintenance needs, whereas reverse return provides superior uniformity at the expense of greater piping expenses. Two-pipe systems, in general, enhance energy efficiency over single-pipe configurations, particularly by reducing electrical energy consumption for pumps through improved flow dynamics.[53][55]Loop and Return Systems

In hydronic systems, loop and return configurations encompass specialized setups beyond basic two-pipe arrangements, often used in water-based systems to achieve balanced circulation in complex or zoned applications. These include series loop systems, primary-secondary piping, and hybrid direct-reverse combinations, particularly suited for radiant heating or multi-zone control.[52][56] Series loop systems, also known as water-based single-pipe equivalents, connect terminal units like baseboards or radiators in a continuous loop where supply water flows sequentially through each unit before returning to the source. This configuration simplifies piping but results in varying temperatures across units, with downstream ones receiving cooler water, limiting its use to smaller residential applications. Advantages include low material costs and ease of installation, though it requires careful sizing to minimize temperature drops, typically limited to systems under 100 feet total length.[57][58] Primary-secondary loop systems decouple the primary boiler/chiller loop from secondary distribution loops using closely spaced tees or hydraulic separators, allowing independent flow rates and temperatures for different zones or subsystems. This design prevents interactions between circuits, enabling variable speed pumping and integration with multiple heat sources/sinks, common in commercial buildings for efficiency. The secondary loops operate with their own pumps, ensuring balanced flow without affecting the primary circuit's stability.[38] A direct-reverse combination, a variant for larger systems, uses a reverse return header for mains with direct return risers to branches, achieving near-equal circuit lengths (within ±10% flow variation if riser drops ≤50% of terminal drops). This hybrid promotes self-balancing while minimizing piping compared to full reverse return, ideal for radiant panel systems with serpentine or grid coils. Serpentine loops suit small areas with simple tubing paths, while grid configurations handle larger panels for even distribution.[52] For sizing these systems, engineers use fluid dynamics principles, such as the volumetric flow rate , where is pipe cross-sectional area and is velocity. Pressure drop is calculated via the Darcy-Weisbach equation: with as friction factor, length, diameter, density, and velocity, to ensure equitable flow and minimal losses across loops.[52]Key Components

Boilers and Heat Sources

In hydronic heating systems, boilers serve as the primary heat generation equipment, transferring thermal energy from a fuel source to water or a water-glycol mixture for distribution throughout the building. These systems typically operate at temperatures between 140°F and 180°F for hot water applications, enabling efficient heat transfer via convection and radiation. Boilers are engineered for reliability in residential, commercial, and industrial settings, with design considerations focusing on pressure ratings, heat output, and integration with system controls to maintain consistent performance. Boiler designs are broadly categorized into fire-tube and water-tube types, each suited to different scales and operational demands. In fire-tube boilers, hot combustion gases pass through tubes submerged in a surrounding water vessel, heating the water indirectly; this configuration is common in lower-pressure applications, such as residential and light commercial hydronic systems, due to its simpler construction and lower cost. Conversely, water-tube boilers circulate water through tubes exposed to hot gases on the exterior, allowing for higher steam pressures and faster response times, which makes them preferable for larger industrial hydronic installations where space constraints or high-capacity needs arise. Both types can be fueled by natural gas, propane, heating oil, or electricity, with gas-fired models dominating residential use for their balance of availability and efficiency, oil-fired options providing robust performance in areas without gas infrastructure, and electric variants offering clean operation without combustion byproducts. Heat sources in hydronic boilers fall into traditional combustion-based systems, which burn fossil fuels like natural gas or oil to generate heat via a flame within a combustion chamber, and electric immersion heaters, where resistive elements directly heat the water without flue gases or venting requirements. Combustion boilers are favored for their high output and cost-effectiveness in larger systems, while electric immersion boilers excel in smaller, modular setups or regions with renewable electricity grids, though they may incur higher operating costs depending on local energy prices. Sizing a boiler involves precise load calculations to match the unit's output to the building's heating demands, typically estimated at 30 to 60 BTU per square foot for residential hydronic applications, adjusted for factors like insulation, climate zone, and desired indoor temperature; for instance, a 2,000-square-foot home in a moderate climate might require a boiler rated at 80,000 to 100,000 BTU/hr. Routine maintenance is essential for boiler longevity and efficiency, particularly blowdown procedures that involve draining small amounts of water to remove accumulated sediment and dissolved solids, preventing scale buildup and corrosion within the heat exchanger. This process, performed weekly or as needed based on water quality, helps sustain optimal heat transfer and reduces the risk of operational failures. Efficiency is measured by the Annual Fuel Utilization Efficiency (AFUE) rating, with non-condensing boilers typically achieving 80-85% and condensing models exceeding 90%, often reaching 92-95% or higher under optimal conditions. Condensing boilers, introduced commercially in the United States during the 1990s, enhance efficiency by recovering latent heat from flue gas condensation, where water vapor in the exhaust is cooled below its dew point to extract additional energy, enabling overall thermal efficiencies of 95-98% when paired with low-return-temperature systems. Proper water treatment, such as pH balancing and inhibitor dosing, complements these maintenance practices to minimize scaling and extend equipment life.Pumps and Circulation

In hydronic systems, pumps are essential for circulating water or other heat-transfer fluids through closed loops to distribute heating or cooling efficiently. The primary function of these pumps is to overcome system resistance and maintain the required flow rates, ensuring balanced heat transfer across boilers, heat exchangers, and terminal units. Centrifugal pumps are the most common type used in hydronic applications due to their ability to handle large volumes of low-viscosity fluids like water at moderate pressures.[59] Positive displacement pumps, such as gear or piston types, are employed in scenarios involving high-viscosity fluids, including glycol-water mixtures used for freeze protection in hydronic loops, where they provide consistent flow regardless of pressure variations.[60] To enable modulation in response to varying system demands, many modern hydronic pumps incorporate variable-speed drives (VSDs), which adjust motor speed to optimize energy use and prevent over-pumping.[61] Circulation in hydronic systems often employs a primary-secondary pumping configuration to decouple the boiler or chiller loop from the distribution loop, enhancing control and efficiency. Primary pumps operate at constant speed to maintain minimum flow through the heat source, typically sized at around 2-3 GPM per 18,000-24,000 BTU/hr capacity depending on temperature differential.[59] Secondary pumps, often variable-speed, handle zone-specific distribution, allowing flow adjustments based on load without affecting the primary circuit.[59] Head calculations are critical for pump selection, comprising static head from elevation differences and friction head from pipe and fitting losses, with total dynamic head (TDH) representing the combined resistance the pump must overcome. Static head remains constant regardless of flow rate, while friction head increases with the square of the flow velocity.[59] Pump performance is matched to system requirements using the pump curve, where head is a function of flow rate , denoted as , ensuring operation near the best efficiency point. The TDH is calculated as: where velocity head is typically minor in hydronic designs.[59] Modern hydronic pumps frequently use electronically commutated motors (ECMs) instead of traditional permanent split capacitor (PSC) motors, achieving energy reductions of 50-70% through higher efficiency across variable speeds—ECMs maintain about 80% efficiency at all speeds, compared to PSC motors' 40-60% depending on speed.[62] Typical flow rates in hydronic cooling applications range from 1.2 to 3 GPM per ton of cooling capacity, varying with the temperature differential across the system (e.g., 10-20°F rise). Piping configurations influence these calculations by affecting friction losses, but pump selection prioritizes overall loop dynamics.[59]Valves and Controls

In hydronic systems, valves and controls are essential for regulating fluid flow, pressure, and temperature to ensure efficient heat distribution and system stability. Balancing valves, such as globe and needle types, are used to adjust flow rates across circuits, maintaining proportional heat output through equal percentage characteristics. These manual devices allow precise throttling, particularly at low flow rates, to achieve design conditions during commissioning. Control valves, including thermostatic radiator valves (TRVs) and zone valves, modulate flow in response to demand, while check valves prevent backflow by closing against reverse pressure differentials. Thermostatic radiator valves operate automatically without electricity, using a sensor to expand or contract a wax or liquid element that adjusts the valve opening based on room temperature, typically maintaining accuracy within ±2°F. Zone control valves, often 2-way configurations, are placed on the supply side of circuits to isolate zones and prevent heat migration when off. Check valves, such as spring-loaded types, are installed downstream of pumps with sufficient straight piping to ensure unidirectional flow and protect against reverse circulation. In contrast, manual controls rely on fixed adjustments, whereas automatic systems integrate sensors and actuators for dynamic response. Proportional-Integral-Derivative (PID) controllers provide precise modulation by calculating an error value between setpoint and actual conditions, adjusting valve position via algorithms to minimize oscillations and stabilize supply temperatures. In a typical two-pipe loop schematic, balancing valves are positioned at branch inlets from the supply header, zone control valves follow on individual circuits, and check valves sit immediately after circulators; temperature sensors are integrated near mixing points or emitters to feed data back to the PID controller for real-time adjustments. Electronic actuators, widely adopted since the early 2000s, receive 0-10V signals from building management systems to enable demand-based operation of control valves, reducing energy consumption by 15-25% through optimized flow and elimination of overpumping.Operational Considerations

Balancing and Distribution

Balancing in hydronic systems involves adjusting flow rates through valves to achieve proportional distribution of heated or chilled water across all zones, ensuring uniform temperatures and optimal performance. The proportional balancing method, a widely adopted technique, begins at the hydraulically remotest circuit and sequentially adjusts balancing valves using flow meters to match design flow rates, minimizing differential pressures and pump energy use. This approach relies on measuring and setting flows in a cascading manner, where each branch is proportioned relative to the total system flow, often achieving within 10% of design conditions across circuits. For instance, in chilled water applications with a typical 10°F temperature differential, valves are adjusted to deliver approximately 2 gallons per minute (GPM) per 10,000 BTU/hr of load to maintain efficient heat transfer without over- or under-supplying zones.[63][64][65] Distribution strategies in hydronics emphasize zoning to isolate sections of the system for independent control, preventing uneven heating or cooling due to varying loads. Manifolds serve as central hubs that branch flows to multiple zones, equipped with individual shutoff and balancing valves for precise allocation; in multi-zone setups, these allow actuators to open or close paths based on thermostat demands, supporting variable flow without significant pressure fluctuations. Pressure-independent control valves (PICVs) enhance this by automatically modulating flow to a set rate regardless of system pressure changes, integrating a differential pressure regulator with a control valve to stabilize delivery at 1-5 GPM per zone depending on load. This combination is particularly effective in large buildings, where zoning manifolds reduce overall piping complexity while PICVs ensure consistent performance during partial load operations. Effective heat distribution also requires unobstructed convective airflow around baseboard convectors; obstructing the front impedes airflow, traps heat within the unit, reduces overall efficiency, potentially leads to inadequate room heating, and restricts access for maintenance such as cleaning.[56][66][67][68][69] Tools for balancing include non-invasive ultrasonic flow meters, which clamp onto pipes to measure velocity and volume without disrupting operations, providing accuracy within ±1-2% for flows as low as 0.1 GPM in diameters up to 48 inches. These meters use transit-time principles to calculate flow by analyzing ultrasound propagation differences in moving water, ideal for verifying adjustments in existing systems. Software simulations aid pre-installation planning by modeling hydraulic networks, predicting pressure drops and flow distributions based on pipe layouts and valve settings; tools like the Belimo Hydronic Simulator visualize multi-story system behaviors, allowing virtual tweaks to optimize before physical setup. Such digital approaches reduce on-site trial-and-error by up to 50%.[70][71][72] Poor balancing leads to significant efficiency losses, with unbalanced systems experiencing up to 30% higher energy consumption due to excessive pump work and uneven zone temperatures that trigger compensatory heating or cooling. Standards such as ASHRAE 90.1 mandate proportional balancing for hydronic systems to minimize throttling losses, requiring construction documents to specify balancing procedures, pump impeller trimming or speed adjustments to design flows, and a certified balance report for systems serving areas over 5,000 square feet. Compliance ensures systems operate within 110% of design pump power, promoting energy conservation in commercial applications.[73][74]Air Elimination and Water Treatment

In hydronic systems, air enters primarily through makeup water, system leaks, or during initial filling, manifesting in three forms: free air as pockets that accumulate at high points due to buoyancy, entrained air as microbubbles suspended in the water flow, and dissolved air as gases like oxygen and nitrogen integrated into the water molecules.[75] In radiators, trapped free air pockets commonly cause cold spots, uneven heating, or lack of heat in sections, typically resolved by manual bleeding of the radiators. Free air pockets disrupt circulation by blocking flow paths, while entrained and dissolved air promote corrosion by introducing oxygen that accelerates metal oxidation, particularly in steel and iron components. Effective air elimination is essential to maintain system efficiency and longevity, as unaddressed air can lead to cavitation in pumps, resulting in erosion and premature failure.[76] Air elimination methods target these forms through mechanical and chemical means. Automatic vents installed at high points release free air pockets via float mechanisms that open when air displaces water, allowing escape without manual intervention. Purge valves enable manual draining of accumulated air during startup or maintenance, often combined with high-velocity flow to sweep bubbles toward separators. For entrained microbubbles, air separators or microbubble eliminators use coalescing media or tangential flow to capture and vent up to 100% of free and entrained air, with advanced models removing 99.6% of dissolved gases through low-pressure degassing chambers.[75] These devices, typically placed near the boiler outlet where temperatures are highest and pressures lowest, prevent air recirculation and are standard in modern closed-loop designs to minimize noise, reduce energy losses from compressible air pockets, and extend component life.[76] Water treatment in hydronic systems focuses on maintaining fluid quality to prevent corrosion, scaling, and biological growth, which can degrade pipes, heat exchangers, and boilers. pH control is critical, with levels maintained between 8.5 and 10.5 for steel piping to form a protective oxide layer on metal surfaces while avoiding excessive alkalinity that promotes scaling; this range is achieved through buffering agents added during initial fill or via automated dosing systems. Corrosion inhibitors, such as nitrites, are dosed to concentrations of 800-1200 ppm to passivate steel and iron by creating a thin, adherent film that blocks oxygen access, with levels monitored via test kits to ensure efficacy against galvanic and pitting corrosion in mixed-metal systems. Additional treatment methods include chemical dosing for biocides to control microbial-induced corrosion and filtration to remove suspended solids that could abrade components or harbor bacteria. Side-stream filters with 10-50 micron ratings capture particulates during partial flow bypass, while automated chemical feed pumps maintain inhibitor and pH levels based on real-time sensors. Standards like ASTM D1384 evaluate inhibitor performance by immersing metal coupons in treated water at 88°C for 336 hours, measuring weight loss to ensure corrosion rates below 1 mg/cm²/week for solder, copper, brass, steel, and aluminum.[77] In closed-loop systems, periodic boiler blowdown—typically draining 5-10% of volume quarterly—removes concentrated solids and prevents sludge buildup that can otherwise lead to poor circulation and cold radiators, with rates adjusted based on conductivity monitoring to sustain total dissolved solids below 1000 ppm. These practices, when integrated, can extend system life by 20-30 years while optimizing heat transfer efficiency.Thermal Expansion and Safety

In hydronic systems, thermal expansion occurs as water heats up, increasing its volume by approximately 3-5% over typical operating temperature ranges, necessitating mechanisms to accommodate this change without compromising system integrity. Diaphragm-type expansion tanks are widely used to manage this expansion, featuring a flexible diaphragm that separates the system water from a pre-charged air cushion, typically set at 12 psi to match initial system pressure and prevent waterlogging.[78] These tanks absorb the expanded volume during heating and release it during cooling, maintaining stable pressure. The required tank volume can be calculated using the formula: where is the expansion factor (approximately , with F as the volumetric expansion coefficient of water), is the system water volume, is the pre-charge pressure (psia), is the initial fill pressure (psia), and is the maximum operating pressure (psia); this ensures the tank provides sufficient acceptance volume without over-pressurization.[79][80] Safety devices are essential to mitigate risks from unchecked expansion or operational anomalies. Pressure relief valves, set to a maximum of 30 psi in low-pressure hydronic systems, automatically discharge excess pressure to prevent vessel rupture, as required by the ASME Boiler and Pressure Vessel Code (BPVC) Section IV for heating boilers.[81][82] Low-water cutoffs interrupt boiler operation if water levels drop, avoiding dry-firing and potential overheating damage.[83] Expansion joints in piping accommodate linear thermal movements, reducing stress on connections in longer runs or where building settlement occurs.[84] Automatic fill systems maintain proper pressure by introducing makeup water as needed. Auto-fill valves, often combined with backflow preventers, regulate incoming pressure to 12-15 psi, ensuring consistent system fill while preventing contamination from reverse flow.[85] Failure to address thermal expansion properly accounts for a significant portion of hydronic system failures, including ruptures, underscoring the importance of these integrated safeguards.[86]Common Radiator Problems in Hot Water Systems

In hot water boiler (hydronic) systems employing radiators, several common problems can arise that result in uneven or no heat, reduced efficiency, or system damage. These issues are often mitigated through routine maintenance such as bleeding, flushing, or component replacement. The most common radiator problems include:- Trapped air in radiators, causing cold spots, uneven heating, or complete lack of heat in sections (often fixed by bleeding the radiators).[76]

- Sludge, sediment, or debris buildup, leading to poor circulation, reduced heat output, cold radiators, and potential boiler damage (addressed by system flushing and water treatment).[77]

- Leaks from radiator valves, bleed screws, pipe connections, or corrosion/pinholes in older radiators, resulting in water loss and potential air ingress.

- Faulty or stuck thermostatic radiator valves (TRVs) or manual valves, preventing proper water flow and causing uneven heating.

- Noisy operation (gurgling, banging, or knocking) due to air, water hammer, or circulation issues (often related to trapped air or flow problems).[76]