Recent from talks

Nothing was collected or created yet.

Insulator (electricity)

View on Wikipedia| Electromagnetism |

|---|

|

An electrical insulator is a material in which electric current does not flow freely. The atoms of the insulator have tightly bound electrons which cannot readily move. Other materials—semiconductors and conductors—conduct electric current more easily. The property that distinguishes an insulator is its resistivity; insulators have higher resistivity than semiconductors or conductors. The most common examples are non-metals.

A perfect insulator does not exist because even the materials used as insulators contain small numbers of mobile charges (charge carriers) which can carry current. In addition, all insulators become electrically conductive when a sufficiently large voltage is applied that the electric field tears electrons away from the atoms. This is known as electrical breakdown, and the voltage at which it occurs is called the breakdown voltage of an insulator. Some materials such as glass, paper and PTFE, which have high resistivity, are very good electrical insulators. A much larger class of materials, even though they may have lower bulk resistivity, are still good enough to prevent significant current from flowing at normally used voltages, and thus are employed as insulation for electrical wiring and cables. Examples include rubber-like polymers and most plastics which can be thermoset or thermoplastic in nature.

Insulators are used in electrical equipment to support and separate electrical conductors without allowing current through themselves. An insulating material used in bulk to wrap electrical cables or other equipment is called insulation. The term insulator is also used more specifically to refer to insulating supports used to attach electric power distribution or transmission lines to utility poles and transmission towers. They support the weight of the suspended wires without allowing the current to flow through the tower to ground.

Physics of conduction in solids

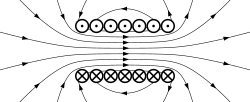

[edit]Electrical insulation is the absence of electrical conduction. Electronic band theory (a branch of physics) explains that electric charge flows when quantum states of matter are available into which electrons can be excited. This allows electrons to gain energy and thereby move through a conductor, such as a metal, if an electric potential difference is applied to the material. If no such states are available, the material is an insulator.

Most insulators have a large band gap. This occurs because the "valence" band containing the highest energy electrons is full, and a large energy gap separates this band from the next band above it. There is always some voltage (called the breakdown voltage) that gives electrons enough energy to be excited into this band. Once this voltage is exceeded, electrical breakdown occurs, and the material ceases being an insulator, passing charge. This is usually accompanied by physical or chemical changes that permanently degrade the material and its insulating properties.

When the electric field applied across an insulating substance exceeds in any location the threshold breakdown field for that substance, the insulator suddenly becomes a conductor, causing a large increase in current, an electric arc through the substance. Electrical breakdown occurs when the electric field in the material is strong enough to accelerate free charge carriers (electrons and ions, which are always present at low concentrations) to a high enough velocity to knock electrons from atoms when they strike them, ionizing the atoms. These freed electrons and ions are in turn accelerated and strike other atoms, creating more charge carriers, in a chain reaction. Rapidly the insulator becomes filled with mobile charge carriers, and its resistance drops to a low level. In a solid, the breakdown voltage is proportional to the band gap energy. When corona discharge occurs, the air in a region around a high-voltage conductor can break down and ionise without a catastrophic increase in current. However, if the region of air breakdown extends to another conductor at a different voltage it creates a conductive path between them, and a large current flows through the air, creating an electric arc. Even a vacuum can suffer a sort of breakdown, but in this case the breakdown or vacuum arc involves charges ejected from the surface of metal electrodes rather than produced by the vacuum itself.

In addition, all insulators become conductors at very high temperatures as the thermal energy of the valence electrons is sufficient to put them in the conduction band.[1][2]

In certain capacitors, shorts between electrodes formed due to dielectric breakdown can disappear when the applied electric field is reduced.[3][4][5][relevant?]

Uses

[edit]A flexible coating of an insulator is often applied to electric wire and cable; this assembly is called insulated wire. Wires sometimes don't use an insulating coating, just air, when a solid (e.g. plastic) coating may be impractical. Wires that touch each other produce cross connections, short circuits, and fire hazards. In coaxial cable the center conductor must be supported precisely in the middle of the hollow shield to prevent electro-magnetic wave reflections. Wires that expose high voltages can cause human shock and electrocution hazards.

Most insulated wire and cable products have maximum ratings for voltage and conductor temperature. The product may not have an ampacity (current-carrying capacity) rating, since this is dependent on the surrounding environment (e.g. ambient temperature).

In electronic systems, printed circuit boards are made from epoxy plastic and fibreglass. The nonconductive boards support layers of copper foil conductors. In electronic devices, the tiny and delicate active components are embedded within nonconductive epoxy or phenolic plastics, or within baked glass or ceramic coatings.

In microelectronic components such as transistors and ICs, the silicon material is normally a conductor because of doping, but it can easily be selectively transformed into a good insulator by the application of heat and oxygen. Oxidised silicon is quartz, i.e. silicon dioxide, the primary component of glass.

In high voltage systems containing transformers and capacitors, liquid insulator oil is the typical method used for preventing arcs. The oil replaces air in spaces that must support significant voltage without electrical breakdown. Other high voltage system insulation materials include ceramic or glass wire holders, gas, vacuum, and simply placing wires far enough apart to use air as insulation.

Insulation in electrical apparatus

[edit]

The most important insulation material is air. A variety of solid, liquid, and gaseous insulators are also used in electrical apparatus. In smaller transformers, generators, and electric motors, insulation on the wire coils consists of up to four thin layers of polymer varnish film. Film-insulated magnet wire permits a manufacturer to obtain the maximum number of turns within the available space. Windings that use thicker conductors are often wrapped with supplemental fiberglass insulating tape. Windings may also be impregnated with insulating varnishes to prevent electrical corona and reduce magnetically induced wire vibration. Large power transformer windings are still mostly insulated with paper, wood, varnish, and mineral oil; although these materials have been used for more than 100 years, they still provide a good balance of economy and adequate performance. Busbars and circuit breakers in switchgear may be insulated with glass-reinforced plastic insulation, treated to have low flame spread and to prevent tracking of current across the material.

In older apparatus made up to the early 1970s, boards made of compressed asbestos may be found; while this is an adequate insulator at power frequencies, handling or repairs to asbestos material can release dangerous fibers into the air and must be carried out cautiously. Wire insulated with felted asbestos was used in high-temperature and rugged applications from the 1920s. Wire of this type was sold by General Electric under the trade name "Deltabeston."[6]

Live-front switchboards up to the early part of the 20th century were made of slate or marble. Some high voltage equipment is designed to operate within a high pressure insulating gas such as sulfur hexafluoride. Insulation materials that perform well at power and low frequencies may be unsatisfactory at radio frequency, due to heating from excessive dielectric dissipation.

Electrical wires may be insulated with polyethylene, crosslinked polyethylene (either through electron beam processing or chemical crosslinking), PVC, Kapton, rubber-like polymers, oil impregnated paper, Teflon, silicone, or modified ethylene tetrafluoroethylene (ETFE). Larger power cables may use compressed inorganic powder, depending on the application.

Flexible insulating materials such as PVC (polyvinyl chloride) are used to insulate the circuit and prevent human contact with a 'live' wire – one having voltage of 600 volts or less. Alternative materials are likely to become increasingly used due to EU safety and environmental legislation making PVC less economic.

In electrical apparatus such as motors, generators, and transformers, various insulation systems are used, classified by their maximum recommended working temperature to achieve acceptable operating life. Materials range from upgraded types of paper to inorganic compounds.

Class I and Class II insulation

[edit]All portable or hand-held electrical devices are insulated to protect their user from harmful shock.

Class I insulation requires that the metal body and other exposed metal parts of the device be connected to earth via a grounding wire that is earthed at the main service panel—but only needs basic insulation on the conductors. This equipment needs an extra pin on the power plug for the grounding connection.

Class II insulation means that the device is double insulated. This is used on some appliances such as electric shavers, hair dryers and portable power tools. Double insulation requires that the devices have both basic and supplementary insulation, each of which is sufficient to prevent electric shock. All internal electrically energized components are totally enclosed within an insulated body that prevents any contact with "live" parts. In the EU, double insulated appliances all are marked with a symbol of two squares, one inside the other.[7]

It has been suggested that this article be split out into articles titled electrical insulation and electrical insulator. (Discuss) (June 2021) |

Telegraph and power transmission insulators

[edit]

Conductors for overhead high-voltage electric power transmission are bare, and are insulated by the surrounding air. Conductors for lower voltages in distribution may have some insulation but are often bare as well. Insulating supports are required at the points where they are supported by utility poles or transmission towers. Insulators are also required where wire enters buildings or electrical devices, such as transformers or circuit breakers, for insulation from the case. Often these are bushings, which are hollow insulators with the conductor inside them.

Materials

[edit]Insulators used for high-voltage power transmission are made from glass, porcelain or composite polymer materials. Porcelain insulators are made from clay, quartz or alumina and feldspar, and are covered with a smooth glaze to shed water. Insulators made from porcelain rich in alumina are used where high mechanical strength is a criterion. Porcelain has a dielectric strength of about 4–10 kV/mm.[8] Glass has a higher dielectric strength, but it attracts condensation and the thick irregular shapes needed for insulators are difficult to cast without internal strains.[9] Some insulator manufacturers stopped making glass insulators in the late 1960s, switching to ceramic materials.

Some electric utilities use polymer composite materials for some types of insulators. These are typically composed of a central rod made of fibre reinforced plastic and an outer weathershed made of silicone rubber or ethylene propylene diene monomer rubber (EPDM). Composite insulators are less costly, lighter in weight, and have excellent hydrophobic properties. This combination makes them ideal for service in polluted areas.[10] However, these materials do not yet have the long-term proven service life of glass and porcelain.

-

Power lines supported by ceramic pin-type insulators in California, USA

-

10 kV ceramic insulator, showing sheds

Design

[edit]

The electrical breakdown of an insulator due to excessive voltage can occur in one of two ways:

- A puncture arc is a breakdown and conduction of the material of the insulator, causing an electric arc through the interior of the insulator. The heat resulting from the arc usually damages the insulator irreparably. Puncture voltage is the voltage across the insulator (when installed in its normal manner) that causes a puncture arc.

- A flashover arc is a breakdown and conduction of the air around or along the surface of the insulator, causing an arc along the outside of the insulator. Insulators are usually designed to withstand flashover without damage. Flashover voltage is the voltage that causes a flash-over arc.

Most high voltage insulators are designed with a lower flashover voltage than puncture voltage, so they flash over before they puncture, to avoid damage.

Dirt, pollution, salt, and particularly water on the surface of a high voltage insulator can create a conductive path across it, causing leakage currents and flashovers. The flashover voltage can be reduced by more than 50% when the insulator is wet. High voltage insulators for outdoor use are shaped to maximise the length of the leakage path along the surface from one end to the other, called the creepage length, to minimise these leakage currents.[11] To accomplish this the surface is moulded into a series of corrugations or concentric disc shapes. These usually include one or more sheds; downward facing cup-shaped surfaces that act as umbrellas to ensure that the part of the surface leakage path under the 'cup' stays dry in wet weather. Minimum creepage distances are 20–25 mm/kV, but must be increased in high pollution or airborne sea-salt areas.

Types

[edit]

Insulators are characterized in several common classes:

- Pin insulator - The pin-type insulator is mounted on a pin affixed on the cross-arm of the pole. The insulator has a groove near the top just below the crown. The conductor passes through this groove and is tied to the insulator with annealed wire of the same material as the conductor. Pin-type insulators are used for transmission and distribution of communication signals, and electric power at voltages up to 33 kV. Insulators made for operating voltages between 33 kV and 69 kV tend to be bulky and have become uneconomical.

- Post insulator - A type of insulator in the 1930s that is more compact than traditional pin-type insulators and which has rapidly replaced many pin-type insulators on lines up to 69 kV and in some configurations, can be made for operation at up to 115 kV.

- Suspension insulator - For voltages greater than 33 kV, it is a usual practice to use suspension type insulators, consisting of a number of glass or porcelain discs connected in series by metal links in the form of a string. The conductor is suspended at the bottom end of this string while the top end is secured to the cross-arm of the tower. The number of disc units used depends on the voltage.

- Strain insulator - A dead end or anchor pole or tower is used where a straight section of line ends, or angles off in another direction. These poles must withstand the lateral (horizontal) tension of the long straight section of wire. To support this lateral load, strain insulators are used. For low voltage lines (less than 11 kV), shackle insulators are used as strain insulators. However, for high voltage transmission lines, strings of cap-and-pin (suspension) insulators are used, attached to the crossarm in a horizontal direction. When the tension load in lines is exceedingly high, such as at long river spans, two or more strings are used in parallel.

- Shackle insulator - In early days, the shackle insulators were used as strain insulators. But nowaday, they are frequently used for low voltage distribution lines. Such insulators can be used either in a horizontal position or in a vertical position. They can be directly fixed to the pole with a bolt or to the cross arm.

- Bushing - enables one or several conductors to pass through a partition such as a wall or a tank, and insulates the conductors from it.[12]

- Line post insulator

- Station post insulator

- Cut-out

Sheath insulator

[edit]

Sheath insulators are insulators that protect a full-length of bottom-contact third rail. Sheath insulators must protect the full length to prevent accidental conduction or contact. Sheath insulators also protect the third rail physically.

Sheath insulators are commonly made out of epoxy, due to its longevity and low conductivity. Ceramic is another choice, and is often used in addition to plastic.

This section needs expansion. You can help by adding to it. (April 2021) |

Suspension insulators

[edit]| Line voltage (kV) |

Discs |

|---|---|

| 34.5 | 3 |

| 69 | 4 |

| 115 | 6 |

| 138 | 8 |

| 161 | 11 |

| 230 | 14 |

| 287 | 15 |

| 345 | 18 |

| 360 | 23 |

| 400 | 24 |

| 500 | 34 |

| 600 | 44 |

| 750 | 59 |

| 765 | 60 |

Pin-type insulators are unsuitable for voltages greater than about 69 kV line-to-line. Higher voltage transmission lines usually use modular suspension insulator designs. The wires are suspended from a 'string' of identical disc-shaped insulators that attach to each other with metal clevis pin or ball-and-socket links. The advantage of this design is that insulator strings with different breakdown voltages, for use with different line voltages, can be constructed by using different numbers of the basic units. String insulators can be made for any practical transmission voltage by adding insulator elements to the string.[14] Also, if one of the insulator units in the string breaks, it can be replaced without discarding the entire string.

Each unit is constructed of a ceramic or glass disc with a metal cap and pin cemented to opposite sides. To make defective units obvious, glass units are designed so that an overvoltage causes a puncture arc through the glass instead of a flashover. The glass is heat-treated so it shatters, making the damaged unit visible. However the mechanical strength of the unit is unchanged, so the insulator string stays together.

Standard suspension disc insulator units are 25 centimetres (9.8 in) in diameter and 15 cm (6 in) long, can support a load of 80–120 kilonewtons (18,000–27,000 lbf), have a dry flashover voltage of about 72 kV, and are rated at an operating voltage of 10–12 kV.[15] However, the flashover voltage of a string is less than the sum of its component discs, because the electric field is not distributed evenly across the string but is strongest at the disc nearest to the conductor, which flashes over first. Metal grading rings are sometimes added around the disc at the high voltage end, to reduce the electric field across that disc and improve flashover voltage.

In very high voltage lines the insulator may be surrounded by corona rings.[16] These typically consist of toruses of aluminium (most commonly) or copper tubing attached to the line. They are designed to reduce the electric field at the point where the insulator is attached to the line, to prevent corona discharge, which results in power losses.

-

Suspension insulator string (the vertical string of discs) on a 275 kV suspension pylon

-

Suspended glass disc insulator unit used in suspension insulator strings for high voltage transmission lines

History

[edit]

The first electrical systems to make use of insulators were telegraph lines; direct attachment of wires to wooden poles was found to give very poor results, especially during damp weather.

The first glass insulators used in large quantities had an unthreaded pinhole. These pieces of glass were positioned on a tapered wooden pin, vertically extending upwards from the pole's crossarm (commonly only two insulators to a pole and maybe one on top of the pole itself). Natural contraction and expansion of the wires tied to these "threadless insulators" resulted in insulators unseating from their pins, requiring manual reseating.

Amongst the first to produce ceramic insulators were companies in the United Kingdom, with Stiff and Doulton using stoneware from the mid-1840s, Joseph Bourne (later renamed Denby) producing them from around 1860 and Bullers from 1868. Utility patent number 48,906 was granted to Louis A. Cauvet on 25 July 1865 for a process to produce insulators with a threaded pinhole: pin-type insulators still have threaded pinholes.

The invention of suspension-type insulators made high-voltage power transmission possible. As transmission line voltages reached and passed 60,000 volts, the insulators required become very large and heavy, with insulators made for a safety margin of 88,000 volts being about the practical limit for manufacturing and installation. Suspension insulators, on the other hand, can be connected into strings as long as required for the line's voltage.

A large variety of telephone, telegraph and power insulators have been made; some people collect them, both for their historic interest and for the aesthetic quality of many insulator designs and finishes. One collectors organisation is the US National Insulator Association, which has over 9,000 members.[17]

Insulation of antennas

[edit]

Often a broadcasting radio antenna is built as a mast radiator, which means that the entire mast structure is energised with high voltage and must be insulated from the ground. Steatite mountings are used. They have to withstand not only the voltage of the mast radiator to ground, which can reach values up to 400 kV at some antennas, but also the weight of the mast construction and dynamic forces. Arcing horns and lightning arresters are necessary because lightning strikes to the mast are common.

Guy wires supporting antenna masts usually have strain insulators inserted in the cable run, to keep the high voltages on the antenna from short circuiting to ground or creating a shock hazard. Often guy cables have several insulators, placed to break up the cable into lengths that prevent unwanted electrical resonances in the guy. These insulators are usually ceramic and cylindrical or egg-shaped (see picture). This construction has the advantage that the ceramic is under compression rather than tension, so it can withstand greater load, and that if the insulator breaks, the cable ends are still linked.

These insulators also have to be equipped with overvoltage protection equipment. For the dimensions of the guy insulation, static charges on guys have to be considered. For high masts, these can be much higher than the voltage caused by the transmitter, requiring guys divided by insulators in multiple sections on the highest masts. In this case, guys which are grounded at the anchor basements via a coil - or if possible, directly - are the better choice.

Feedlines attaching antennas to radio equipment, particularly twin-lead type, often must be kept at a distance from metal structures. The insulated supports used for this purpose are called standoff insulators.

See also

[edit]- Stephen Gray – English physicist

- Dielectric material

- Electrical conductivity

Notes

[edit]- ^ S. L. Kakani (1 January 2005). Electronics Theory and Applications. New Age International. p. 7. ISBN 978-81-224-1536-0.

- ^ Waygood, Adrian (19 June 2013). An Introduction to Electrical Science. Routledge. p. 41. ISBN 978-1-135-07113-4.

- ^ Klein, N.; Gafni, H. (1966). "The maximum dielectric strength of thin silicon oxide films". IEEE Trans. Electron Devices. 13 (2): 281. Bibcode:1966ITED...13..281K. doi:10.1109/T-ED.1966.15681.

- ^ Inuishi, Y.; Powers, D.A. (1957). "Electric breakdown and conduction through Mylar films". J. Appl. Phys. 58 (9): 1017–1022. Bibcode:1957JAP....28.1017I. doi:10.1063/1.1722899.

- ^ Belkin, A.; et., al. (2017). "Recovery of Alumina Nanocapacitors after High Voltage Breakdown". Scientific Reports. 7 (1): 932. Bibcode:2017NatSR...7..932B. doi:10.1038/s41598-017-01007-9. PMC 5430567. PMID 28428625.

- ^ Bernhard, Frank; Bernhard, Frank H. (1921). EMF Electrical Year Book. Electrical Trade Pub. Co. p. 822.

- ^ "Understanding IEC Appliance Insulation Classes: I, II and III". Fidus Power. 6 July 2018. Archived from the original on 17 February 2020. Retrieved 16 October 2018.

- ^ "Electrical Porcelain Insulators" (PDF). Product spec sheet. Universal Clay Products, Ltd. Archived from the original (PDF) on 2009-02-20. Retrieved 2008-10-19.

- ^ Cotton, H. (1958). The Transmission and Distribution of Electrical Energy. London: English Univ. Press. copied on Insulator Usage, A.C. Walker's Insulator Information page

- ^ Hu, Yi; Liu, Kai (2017). "Transmission lines detection technology". Inspection and Monitoring Technologies of Transmission Lines with Remote Sensing: 205–279. doi:10.1016/B978-0-12-812644-8.00004-7. ISBN 978-0-12-812644-8.

Composite insulators can take wind and rain and have good self-cleaning performance under wind and rain, so need checking for pollution only once every 4–5 years, and requiring less time for the repair and power interruption.

- ^ Holtzhausen, J.P. "High Voltage Insulators" (PDF). IDC Technologies. Archived from the original (PDF) on 2014-05-14. Retrieved 2008-10-17.

- ^ IEC 60137:2003. 'Insulated bushings for alternating voltages above 1,000 V.' IEC, 2003.

- ^ Diesendorf, W. (1974). Insulation Coordination in High Voltage Power Systems. UK: Butterworth & Co. ISBN 0-408-70464-0. reprinted on Overvoltage and flashovers, A. C. Walker's Insulator Information website

- ^ Donald G. Fink, H. Wayne Beaty (ed).,Standard Handbook for Electrical Engineers, 11th Edition, McGraw-Hill, 1978, ISBN 0-07-020974-X, pages 14-153, 14-154

- ^ Grigsby, Leonard L. (2001). The Electric Power Engineering Handbook. USA: CRC Press. ISBN 0-8493-8578-4.

- ^ Bakshi, M (2007). Electrical Power Transmission and Distribution. Technical Publications. ISBN 978-81-8431-271-3.

- ^ "Insulators : National Insulator Association Home Page". www.nia.org. Retrieved 2017-12-12.

References

[edit]- Taylor, Sue (May 2003). Bullers of Milton. Churnet Valley Books. ISBN 978-1-897949-96-2.

- Function of Grading rings to Composite Insulator

- Aayush Kejriwal July 12, 2024, Which Is The Best Electrical Insulator- Rubber, Glass, Plastic Or Ceramics?

- M. Shakiba, F.; M, S. Azizi; M., Zhou (Oct 2022). "A Transfer Learning-Based Method to Detect Insulator Faults of High-Voltage Transmission Lines via Aerial Images: Distinguishing Intact and Broken Insulator Images". IEEE Systems, Man, and Cybernetics Magazine. 8 (4): 15–25. doi:10.1109/MSMC.2022.3198027. ISSN 2333-942X. S2CID 252999399.

Insulator (electricity)

View on GrokipediaBasic Concepts

Definition and Role

An electrical insulator is a material that resists the flow of electric current due to its high electrical resistivity, typically greater than 10^{10} \Omega \cdot \mathrm{m}, and correspondingly low conductivity.[7] This property arises from the material's atomic and molecular structure, which hinders the free movement of charge carriers, such as electrons, under normal operating conditions.[8] Insulators are essential for maintaining the integrity of electrical circuits by preventing unintended conduction paths. In electrical systems, insulators play a critical role in providing electrical isolation between conductive elements, thereby preventing short circuits and enabling the safe handling of voltage differences without dielectric breakdown.[9] They support the transmission and distribution of power by separating live conductors from grounded structures or each other, minimizing energy loss and equipment damage.[10] Additionally, insulators enhance system reliability by blocking current leakage and arcing, which could otherwise lead to failures in devices ranging from household appliances to high-voltage grids.[11] Insulators are distinguished from conductors, which exhibit high conductivity (e.g., metals like copper with resistivity around 10^{-8} \Omega \cdot \mathrm{m}) allowing easy current flow, and semiconductors, which have intermediate conductivity (e.g., silicon with resistivity around 10^3 to 10^{-3} \Omega \cdot \mathrm{m}) that can be modulated.[12] According to band theory, this distinction stems from the energy band structure: in insulators, the valence band (filled with electrons) and the conduction band (empty) are separated by a large band gap exceeding 3 eV, requiring significant thermal or electrical energy to excite electrons across it, unlike the overlapping bands in conductors or the smaller gaps (less than 3 eV) in semiconductors.[13] Common examples of insulators include glass, rubber, porcelain, and air, which are widely used in everyday applications to coat wires or separate components.[14] Their importance is underscored in safety standards, where they form a primary barrier against electrocution by interrupting current paths to human contact, as emphasized in occupational regulations that mandate proper insulation to mitigate shock hazards.[15][16]Physics of Electrical Insulation

In solid-state physics, electrical insulators are characterized by their electronic band structure, where the valence band is fully occupied by electrons at absolute zero temperature, and the conduction band lies separated by a large forbidden energy gap, known as the band gap . This gap prevents electrons from the valence band from easily transitioning to the conduction band, where they could contribute to electrical conduction, as the thermal energy available at room temperature (approximately 0.025 eV) is insufficient to bridge the gap. For materials to behave as insulators, typically exceeds 3 eV, often reaching 5 eV or more, resulting in extremely low electrical conductivity .[17] The resistivity of an insulator, defined as the reciprocal of conductivity , is thus very high, often on the order of to , ensuring minimal current flow under applied electric fields below breakdown thresholds.[7] When an external electric field is applied to an insulator, it induces polarization, where the material's atoms or molecules respond by shifting their charge distributions, creating electric dipoles that partially oppose the field and enhance the material's capacitance. There are three primary mechanisms of polarization: electronic polarization, involving the displacement of electron clouds relative to atomic nuclei; ionic polarization, occurring in materials with ionic bonds where positive and negative ions shift against each other; and orientational polarization, in which permanent molecular dipoles align with the field, predominant in polar dielectrics at lower frequencies. The extent of this polarization is quantified by the relative permittivity (also called the dielectric constant), which measures the material's ability to store electrical energy compared to vacuum, with typical values for insulators ranging from 2 to 10 for non-polar materials and higher for polar ones.[18] Despite their high resistivity, insulators can fail under excessive electric stress through various breakdown mechanisms. Dielectric breakdown represents the irreversible loss of insulating properties, occurring when the applied electric field exceeds the material's dielectric strength , the maximum field sustainable without conduction. For example, mica exhibits a dielectric strength of approximately 100 MV/m. The breakdown voltage for a uniform field across a sample of thickness is given by . Types of breakdown include intrinsic breakdown, driven by electron avalanche in defect-free material; thermal breakdown, where Joule heating causes runaway conductivity; and electromechanical breakdown from mechanical stress. Additionally, partial discharges—localized sparks in voids or at surfaces—can degrade insulation over time, while electrical treeing involves branching conductive paths forming under sustained stress, often initiated by partial discharges. The corona effect, a gaseous partial discharge around high-voltage conductors, further erodes insulation through ionization and chemical reactions.[19][20] The electrical properties of insulators are temperature-sensitive, with most exhibiting a negative temperature coefficient of resistivity, meaning resistivity decreases (and conductivity increases) as temperature rises due to enhanced thermal excitation of electrons across the band gap.[21] This follows an Arrhenius-like behavior, where conductivity , with as Boltzmann's constant and as temperature, leading to potential thermal runaway if heat dissipation is inadequate. At elevated temperatures, this can lower the effective band gap and increase leakage currents, underscoring the importance of thermal management in insulating applications.[22]Materials and Properties

Common Materials

Electrical insulators are primarily categorized into inorganic, organic, and composite materials, each selected for their ability to resist electrical conduction while providing mechanical support in various applications. Inorganic materials have long dominated high-voltage outdoor uses due to their durability, while organic and composite variants offer flexibility and lighter weight for indoor or specialized systems.[23] Inorganic materials form the backbone of traditional electrical insulation, prized for their thermal stability and resistance to environmental degradation. Porcelain, a ceramic composed of kaolin (a plastic clay), feldspar, and quartz, is fired at high temperatures (typically 1200–1400°C) to create a dense, glazed structure that prevents moisture ingress and electrical tracking.[24] Glass insulators, often made from soda-lime formulations (primarily silica, soda ash, and lime) or borosilicate variants for enhanced thermal shock resistance, are produced by melting and shaping the mixture into forms that are subsequently annealed and tempered for strength.[25] Mica, a naturally occurring layered silicate mineral (such as muscovite or phlogopite, with a composition rich in potassium aluminum silicate sheets), is split into thin flexible sheets ideal for high-temperature windings and capacitors due to its inherent dielectric properties.[26] Organic materials provide cost-effective insulation with good processability, commonly used in wiring, cables, and low-to-medium voltage equipment. Rubber, either natural (from latex sap) or synthetic like ethylene propylene rubber (EPR, a copolymer of ethylene and propylene), offers elasticity and weather resistance, often compounded with fillers for enhanced performance.[27] Plastics such as polyvinyl chloride (PVC, a polymer of vinyl chloride), polyethylene (PE, derived from ethylene monomers), and polytetrafluoroethylene (PTFE, known as Teflon, a fluoropolymer), are valued for their low cost, chemical inertness, and varying flexibility—PVC for general cabling, PE for moisture barriers, and PTFE for high-frequency applications.[28] Paper, typically kraft or cellulose-based, is frequently impregnated with insulating oils (like mineral or synthetic variants) to improve dielectric strength and prevent partial discharges, serving as a core material in oil-filled capacitors and transformers.[29] Composite materials combine the strengths of multiple components to achieve superior mechanical and electrical performance, particularly in modern high-stress environments. Epoxy resins, thermosetting polymers formed by reacting epichlorohydrin with bisphenol A, are cast or molded into rigid structures for bushings and switchgear, providing excellent adhesion and arc resistance.[30] Fiberglass-reinforced plastics (FRP), consisting of glass fibers embedded in a polymer matrix like polyester or epoxy, yield lightweight yet robust insulators for composite rods and housings, with the fibers enhancing tensile strength while the resin ensures electrical isolation.[31] Recent advancements (as of 2025) include nanomaterials such as graphene-enhanced composites and self-healing polymers, which improve dielectric strength and longevity while reducing environmental impact.[32][33] The evolution of insulator materials reflects a shift from natural substances to engineered synthetics, driven by the demands of expanding electrical networks. Early insulators relied on natural options like amber (fossilized tree resin, used in rudimentary electrostatic experiments) and gutta-percha (a latex from Malaysian trees, thermoplastic and waterproof for 19th-century telegraph cables), but by the early 1900s, resource limitations and performance needs prompted widespread adoption of synthetics such as rubber derivatives and polymers, enabling reliable mass production post-1925.[34] Manufacturing processes for these materials emphasize precision to maintain insulation integrity. Polymers like rubber and plastics are typically processed via extrusion, where molten material is forced through a die to form continuous profiles such as cables or tubes, followed by cooling and curing.[35] Ceramics such as porcelain and glass undergo molding—either wet or dry pressing for shapes—before high-temperature firing or annealing to achieve vitrification and structural density.[36]Key Properties and Selection Criteria

Electrical insulators must exhibit specific electrical properties to prevent unintended current flow while withstanding applied voltages. The dielectric constant (ε_r), a measure of a material's ability to store electrical energy in an electric field, typically ranges from 4 to 8 for porcelain, enabling effective capacitance management in high-voltage applications.[37] The dielectric loss factor, or tangent delta (tan δ), indicates energy dissipation as heat; for high-quality insulators like porcelain, it is generally less than 0.01 at power frequencies, ensuring minimal losses during operation. Volume resistivity, which quantifies resistance to current flow through the material, exceeds 10^12 ohm-cm for porcelain, providing robust bulk insulation against leakage.[38] Mechanical properties are crucial for insulators to endure physical stresses from installation, wind, or seismic activity. Porcelain insulators offer high compressive strength, often around 500-1000 MPa, making them suitable for load-bearing roles, though their tensile strength is lower at 40-70 MPa, rendering them brittle under tension.[39] Hardness, measured on the Mohs scale, reaches 6-7 for porcelain, contributing to resistance against surface abrasion.[40] Environmental properties determine suitability for diverse operating conditions. Ceramics like porcelain demonstrate thermal stability up to 1000°C, resisting degradation in high-temperature environments without softening or cracking.[41] In contrast, polymers exhibit vulnerability to ultraviolet (UV) radiation, leading to surface chalking and reduced mechanical integrity over time.[42] Hydrophobicity, the ability to repel water, is a key advantage for polymers, which maintain low surface wettability to minimize leakage currents in wet conditions, unlike hydrophilic ceramics.[42] Selection criteria for insulators prioritize matching material properties to system demands. Voltage rating guides choice, with higher dielectric strength materials like porcelain preferred for ultra-high-voltage lines exceeding 500 kV. Operating environment influences decisions: indoor applications favor stable ceramics, while outdoor settings benefit from polymers' hydrophobicity in polluted or humid areas. Cost considerations balance initial expense—porcelain being more affordable in bulk—with lifecycle factors like maintenance. Compliance with standards such as IEC 60243, which outlines dielectric strength testing under controlled conditions, ensures reliability and safety. Aging and degradation pose long-term challenges, particularly from tracking—carbonized paths formed by dry-band arcing—and erosion, where surface material is ablated by leakage currents. Pollution exacerbates these by depositing conductive layers, reducing insulation effectiveness; in contaminated environments, insulators may experience flashover if not designed for such conditions.[43] Surface resistivity under contamination decreases with pollution severity, often modeled using equivalent salt deposit density (ESDD); the pollution layer volume conductivity is approximately proportional to ESDD divided by layer thickness t, yielding surface resistivity ρ_s = t / (k × ESDD), where k is a constant based on NaCl solution conductivity (typically around 2000–3000 μS·cm³/mg).[44][45]| Property | Porcelain | Polymer (e.g., Silicone Rubber) |

|---|---|---|

| Dielectric Constant (ε_r) | 5-8 | 3-5 |

| Tan δ (at 50/60 Hz) | <0.01 | <0.01 |

| Volume Resistivity (ohm-cm) | >10^12 | >10^14 |

| Compressive Strength (MPa) | 500-1000 | 50-100 (core-dependent) |

| Tensile Strength (MPa) | 40-70 | 10-20 |

| Thermal Stability (°C) | Up to 1000 | Up to 200 (degrades beyond) |

| UV/Weathering Resistance | Excellent (inert) | Moderate (degrades with exposure) |

| Hydrophobicity | Poor (hydrophilic) | Excellent |

Applications in Electrical Systems

Insulation in Electrical Apparatus

Electrical insulation in apparatus serves multiple critical functions, including providing grounding protection to safely divert fault currents to earth, ensuring phase separation to prevent unintended electrical contact between different phases, and facilitating heat dissipation to manage thermal loads generated during operation. Grounding protection involves connecting exposed conductive parts to a protective earth conductor, which limits the potential difference between live parts and earth under fault conditions, thereby reducing the risk of electric shock. Phase separation is achieved through insulating barriers or materials that electrically isolate windings or conductors of different phases, minimizing the risk of short circuits in multi-phase systems like motors and transformers. For heat dissipation, certain insulating materials incorporate thermally conductive fillers to transfer heat away from hot spots while maintaining electrical isolation, preventing overheating that could degrade performance or cause failure. Class I insulation systems provide basic insulation between live parts and accessible conductive parts, supplemented by a protective earth connection, typically in devices with metal enclosures such as industrial motors or transformers. In these systems, safety relies on the grounding mechanism; if the basic insulation fails, the fault current flows through the earth conductor to trip protective devices like circuit breakers, protecting users from shock. For example, metal-cased appliances connect the enclosure to earth via a dedicated conductor in the power cord, ensuring that any insulation breakdown routes current safely to ground rather than through a person. Class II insulation employs double or reinforced insulation, consisting of at least two independent layers of insulation or a single layer providing equivalent protection, without depending on grounding, often seen in plastic-cased household appliances like power tools. This design eliminates the need for an earth connection, as the dual insulation barriers prevent contact with live parts even if one layer fails, enhancing portability and safety in environments where grounding may be unreliable. Reinforced insulation is tested to withstand higher voltages than basic insulation, ensuring no single point of failure compromises the system's integrity. In practical applications, oil-paper insulation is widely used in transformers, where cellulose paper is impregnated with mineral oil to provide high dielectric strength and mechanical support for windings, enabling efficient operation under high voltages while allowing oil to circulate for cooling. Motors commonly feature varnish-coated windings, where insulating varnish is applied to enameled copper wires to seal coils against moisture, vibration, and electrical arcing, improving durability and preventing inter-turn shorts during rotation. For cables within apparatus, cross-linked polyethylene (XLPE) insulation offers excellent thermal stability up to 90°C and resistance to environmental stresses, making it suitable for power distribution in compact devices like switchgear. Standards such as IEC 61140 establish fundamental principles for protection against electric shock, defining requirements for basic, supplementary, and reinforced insulation to ensure safe operation of electrical apparatus by limiting touch voltages and fault currents. Compliance with this standard involves assessing insulation coordination to protect persons and livestock from hazardous potentials under both normal and fault conditions. Testing methods like hipot (high-potential) testing verify insulation integrity by applying elevated voltages to detect weaknesses without causing permanent damage, measuring leakage current to confirm the dielectric withstand capability against overvoltages. Key challenges in insulation for electrical apparatus include partial discharges occurring in voids or cavities within the material, which erode insulation over time through localized ionization and carbonization, potentially leading to complete breakdown. These discharges are particularly problematic in high-voltage environments, where even small voids—arising from manufacturing defects or aging—initiate treeing patterns that compromise long-term reliability. Additionally, thermal runaway poses a risk, where excessive heat from dielectric losses or overloads accelerates insulation degradation, creating a feedback loop that can result in catastrophic failure if not mitigated by proper thermal design and monitoring.Insulators in Power Transmission and Telegraph Lines

Insulators play a critical role in overhead power transmission and telegraph lines by electrically isolating conductors from supporting structures while providing mechanical support against environmental loads such as wind and ice accumulation.[47] They prevent flashover—unintended electrical discharges across the insulator surface—ensuring reliable power delivery over long distances.[48] In addition to electrical insulation, these devices must withstand tensile forces from conductor weight and dynamic stresses, maintaining structural integrity in harsh outdoor conditions.[49] The origins of line insulators trace back to early telegraph systems in the 1840s, where glass pin-type insulators were primarily used to support and insulate wires on wooden poles.[50] Samuel Morse's successful demonstration of the telegraph in 1844 spurred widespread adoption, with these threadless or simple pin designs made from glass to prevent signal leakage and short circuits along lines stretching across continents by the 1850s.[51] Ceramic variants emerged later in the century as alternatives, offering greater durability for expanding networks, though glass remained dominant due to its cost-effectiveness and ease of production.[52] As electrical systems evolved from low-voltage telegraphy to high-voltage power transmission in the late 19th century, insulator designs advanced to handle greater electrical and mechanical demands, transitioning from single pin types to multi-unit configurations for alternating current (AC) and direct current (DC) lines.[53] For voltages exceeding 33 kV, string insulators—comprising series-connected porcelain, glass, or composite discs—became standard, providing scalable insulation strength and flexibility under tension.[54][55] The cap-and-pin design, where each disc features a metal cap and pin for interlocking, allows easy assembly into strings and distributes voltage evenly across units, a configuration widely used in modern overhead lines for both AC and DC transmission up to 765 kV.[56] Transmission line insulators face significant challenges from environmental factors that can compromise performance. Pollution accumulation, such as industrial dust or coastal salt, reduces surface resistivity and triggers flashover during wetting events like fog or rain, particularly in contaminated areas near urban or agricultural sites.[57] Bird contamination, including droppings or nesting materials, creates conductive paths that lead to partial discharges and line outages, accounting for a notable portion of transmission faults globally.[58] Seismic stresses during earthquakes impose additional mechanical loads, requiring insulators with enhanced flexibility to avoid brittle failure in porcelain units.[59] Performance standards ensure insulator reliability, with the American National Standards Institute (ANSI) C29 series specifying requirements for dimensions, electrical strength, and mechanical endurance in overhead applications.[60] For polluted environments, insulators are classified into performance levels (I-IV) based on minimum leakage distance—the creepage path along the surface—which correlates with contamination severity; for instance, class IV demands over 31 mm/kV to mitigate flashover in heavily polluted zones.[61] These guidelines, including ANSI C29.2 for suspension types, guide selection to balance cost and reliability in diverse climatic conditions.[62]Design and Types

Design Principles

The design of electrical insulators prioritizes geometric features that mitigate electric field concentrations and enhance surface insulation to prevent flashover. Sharp edges and corners are avoided by incorporating rounded profiles, which distribute the electric field more uniformly and reduce the risk of corona discharge or partial discharges. For instance, in high-voltage porcelain or composite insulators, sheds are shaped with smooth, curved edges to minimize tangential field stress at the air-insulator interface.[63] Creepage distance, defined as the shortest path along the insulator surface between conductive parts, is engineered to provide adequate surface resistance under contaminated conditions based on pollution severity.[64] Stress management in insulator design focuses on controlling nonuniform electric fields to prevent localized breakdowns. Electric field grading techniques, such as capacitive or resistive grading layers, are employed to homogenize potential distribution along the insulator length, particularly in long-rod or post-type configurations for ultra-high voltages. Finite element analysis (FEA) is a standard computational method used to model and optimize field distributions, simulating complex geometries under applied voltages to identify high-stress regions and refine designs.[65] For basic uniform field approximations in parallel-plate-like structures, the capacitance is given by , where is the permittivity of the insulating material, is the electrode area, and is the insulator thickness; this equation underscores how thinner dielectrics increase stored energy and field intensity, guiding material and dimension selections.[66] Mechanical design principles ensure insulators withstand tensile, compressive, and environmental loads without failure. A factor of safety of approximately 2.5:1 is typically applied to the ultimate tensile strength for suspension insulators, limiting maximum service loads to 40% of the rated mechanical strength to account for dynamic wind, ice, or seismic forces. Puncture strength, the voltage at which the internal dielectric fails, is designed such that the flashover voltage—the external surface arcing threshold—is lower than the puncture strength (with a safety factor greater than 1), to prioritize visible flashover over hidden internal damage, allowing for easier detection and replacement. Testing protocols validate insulator performance under simulated operational stresses. Impulse withstand tests, per IEC 60060-1, apply standard lightning impulses (1.2/50 μs waveform) to assess resistance to transient overvoltages, with the basic insulation level (BIL) specifying the peak voltage the insulator must endure without breakdown. Power frequency withstand tests, conducted at 50/60 Hz per IEC 60060-1, verify steady-state insulation integrity by applying 75% of the rated voltage for one minute, ensuring no partial discharge or leakage current exceeds limits. Pollution simulation tests, outlined in IEC 60507, replicate contaminated environments using salt fog or solid layers to measure flashover voltage under wet conditions, guiding creepage requirements for site-specific deployments. Recent innovations in insulator design emphasize surface treatments to combat pollution-induced failures. Hydrophobic coatings, such as room-temperature vulcanizing (RTV) silicone applied at 0.1-0.5 mm thickness, impart water-repellent properties that promote self-cleaning by causing water to bead and roll off, carrying away contaminants and reducing leakage currents by up to 90% in polluted areas. These coatings maintain hydrophobicity through low-molecular-weight silicone diffusion, extending insulator life in coastal or industrial settings without altering bulk mechanical properties.[67][68]Classification and Specific Types

Electrical insulators are classified primarily by their mounting configuration, physical shape, structural form in relation to material types, and specialized functions to suit diverse applications in power systems. Insulators categorized by mounting include pin types and suspension types. Pin insulators are employed for low- to medium-voltage overhead distribution lines, typically up to 33 kV, where the conductor is secured in a groove atop a threaded porcelain or glass body that mounts directly onto a pin fixed to the cross-arm of a utility pole.[55] This design provides rigid vertical support while minimizing material use for economical installation.[69] Suspension or disc insulators, in contrast, serve high-voltage transmission lines exceeding 33 kV and consist of multiple porcelain, glass, or composite discs assembled in a flexible chain that suspends vertically from the tower cross-arm, distributing the voltage stress across units to enhance reliability under heavy mechanical loads.[55][69] Classifications by shape encompass sheath and spool or egg variants. Sheath insulators adopt a cylindrical form to encase and protect busbars in substations and switchgear enclosures, ensuring insulation along the length of horizontal rigid conductors while allowing compact assembly.[70] Spool or egg-type insulators feature an oval, compact profile and are specifically used for insulating guy or stay wires in low-voltage distribution setups, where they attach to tensioned support wires to isolate them from grounded poles or the earth, typically installed at heights over 3 meters to avoid contact hazards.[69][71] In terms of structural forms, ceramic and composite insulators represent key variants with distinct geometries. Ceramic insulators, often porcelain-based, include traditional pin and suspension designs but are being supplemented by composite alternatives for improved durability. Composite long-rod suspension insulators feature a single elongated fiberglass core with polymer sheds, suitable for high-voltage overhead lines up to 500 kV, offering reduced weight and easier handling compared to multi-disc ceramics.[72][73] Hollow core composite insulators, with a tubular internal structure, are designed for bushings in high-voltage apparatus like transformers and circuit breakers, providing internal insulation for conductors passing through enclosures while maintaining structural integrity under pressure.[74][73] Specialized functional types address unique operational demands, such as strain and interphase spacers. Strain insulators, akin to suspension units but oriented horizontally, are deployed at dead-ends, line terminals, or angular deviations to withstand longitudinal tension forces from conductor pull, often in assemblies rated for tensions up to several tons.[55][69] Interphase spacers function as motion-control devices clamped between adjacent phase conductors on transmission lines, maintaining lateral separation to mitigate flashovers from conductor galloping or swinging induced by wind or ice accumulation.[75][76] A critical performance metric influencing insulator selection is the specific creepage distance, defined as the minimum surface path length per kilovolt of phase-to-ground voltage to avert dry-band arcing in contaminated environments; per IEC 60815, standards recommend 16 mm/kV for light pollution, 20 mm/kV for medium pollution, 25 mm/kV for heavy pollution, and 31 mm/kV for very heavy pollution.[77]Historical Development

Early Innovations

The earliest recognition of insulating materials in the context of electricity dates back to ancient times, when natural substances like amber—known in Greek as "elektron"—were observed to produce static electricity when rubbed with fur or cloth. The ancient Greeks, around the 6th century BCE, noted that amber could attract lightweight objects such as dust or threads after friction, laying the groundwork for understanding electrostatic phenomena, though practical applications as insulators emerged much later.[78][79] The advent of the electrical telegraph in the 19th century marked the first widespread use of purpose-built insulators. In 1837, Samuel F.B. Morse developed his electromagnetic telegraph system, which by 1844 utilized glass insulators to support and isolate wires along poles, enabling the first public demonstration from Washington, D.C., to Baltimore on May 24 of that year.[80] Production of these early glass insulators ramped up through companies like the Brookfield Glass Works, established in the 1840s and becoming a major supplier of threadless, pin-type glass pieces for telegraph lines by the 1850s and 1860s, supporting the rapid expansion of communication networks across the United States.[81] Key innovations in the mid-19th century included the adoption of gutta-percha, a natural latex from Southeast Asian trees, as an effective insulator for submarine telegraph cables. First successfully applied in the 1850 Dover-Calais cable across the English Channel, gutta-percha provided waterproof insulation for copper conductors, facilitating reliable underwater transmission and paving the way for transoceanic links.[82] As electrical systems evolved toward higher voltages in the 1880s, porcelain insulators—fired clay bodies offering superior mechanical strength and dielectric properties—were incorporated into early power distribution setups, transitioning from glass for more demanding applications. However, early glass insulators faced significant challenges, including cracking from thermal expansion, manufacturing defects, or environmental stress, which allowed moisture ingress via capillary action and caused leakage currents; this prompted the development of standardized shapes, such as the threaded pin-type, to enhance durability and uniformity by the late 19th century.[83] Into the early 20th century, the introduction of suspension string insulators, pioneered by companies like Ohio Brass around 1907, allowed for higher voltage transmission lines by chaining multiple porcelain or glass units, enabling reliable operation up to 110 kV and supporting the expansion of electrical grids.[53] A pivotal milestone came at the 1893 World's Columbian Exposition in Chicago, where Westinghouse Electric demonstrated high-voltage alternating-current transmission using polyphase systems, supported by advanced glass and porcelain insulators on overhead lines and in underground conduits to power the fairgrounds' extensive lighting—over 100,000 incandescent bulbs—proving the viability of long-distance power distribution.Modern Advancements

In the late 20th century, polymer composites emerged as a significant advancement in electrical insulation, particularly silicone rubber insulators introduced in the 1970s for high-voltage applications. These materials were developed to address limitations of traditional porcelain in polluted environments, offering superior hydrophobicity that repels water and contaminants, thereby reducing flashover risks.[84][73] Compared to porcelain, silicone rubber insulators are substantially lighter, reducing structural loads on transmission towers, and shatterproof, minimizing breakage during installation or extreme weather.[85][86] Their adoption has grown steadily, with composite designs now comprising a notable portion of new installations due to enhanced pollution performance and cost efficiencies over time.[87] Post-2000 developments integrated cryogenic insulators with high-temperature superconductors (HTS), enabling compact and efficient power devices like transformers cooled to around 77 K using liquid nitrogen. These insulators, often based on epoxy or polymer matrices adapted for low-temperature operation, maintain dielectric integrity under thermal cycling and high voltages, supporting HTS applications in grid infrastructure.[88] Research has focused on their aging characteristics, confirming reliability for long-term use in superconducting systems where conventional materials might degrade.[89] By 2000, prototypes demonstrated viable high-voltage insulation for HTS conductors in cryogenic environments, paving the way for lighter, higher-efficiency alternatives to copper-based systems.[90] The 2010s introduced smart insulators equipped with embedded sensors for real-time condition monitoring, particularly tracking leakage currents to predict failures in high-voltage lines. Optoelectronic and IoT-enabled sensors, integrated into insulator housings, transmit data wirelessly to detect pollution buildup or partial discharges, allowing proactive maintenance.[91][92] For instance, systems using narrowband IoT have achieved low-power, continuous monitoring on 500 kV lines, improving grid reliability by alerting operators to anomalies before outages occur.[93] Sustainability efforts gained momentum with the EU's RoHS Directive in 2006, which restricted lead in electrical equipment, prompting reforms in ceramic insulator production to eliminate hazardous substances while maintaining performance.[94] Concurrently, recyclable polymer composites have been developed, featuring thermoplastic matrices that allow end-of-life recovery without environmental impact, contrasting with non-recyclable traditional ceramics.[95] Porcelain variants, derived from abundant minerals, achieve full recyclability at 100% efficiency, supporting circular economy principles in power infrastructure.[96] Recent research in the 2020s has advanced nano-enhanced dielectrics, incorporating silica nanoparticles into epoxy resins to boost breakdown strength by up to 20-30% through improved filler-matrix interfaces that suppress charge accumulation. Core-shell silica structures, such as SiO2-coated particles at 7 wt%, have demonstrated enhanced DC and AC withstand voltages, making them suitable for next-generation compact insulators in renewable energy systems.[98] These nanocomposites also exhibit better mechanical toughness, addressing vulnerabilities in high-stress applications.[99] Complementary to material innovations, unmanned aerial vehicle (UAV) technology has revolutionized insulator inspection since the 2010s, enabling non-contact assessment of transmission lines using thermal imaging and LiDAR to identify cracks, contamination, or overheating without human risk.[100] Drones equipped with high-resolution cameras can inspect thousands of insulators per flight, reducing downtime and costs by 50-70% compared to manual methods.[101] By 2025, AI-integrated UAVs provide automated defect detection, enhancing predictive maintenance for aging grids.[102] Global standards have evolved to accommodate these advancements, with IEC/TS 60815 (2008) emphasizing site-specific pollution severity measurements for insulator selection in contaminated areas, updated in the 2010s including part 4 (2016) for composite insulators to incorporate unified criteria for creepage distances and profiles, polymeric options, and laboratory validation of pollution performance, with ongoing revisions since 2017.[77][103][104][105]References

- https://www.[researchgate](/page/ResearchGate).net/publication/363025952_Enhanced_switching_electric_field_and_breakdown_strength_of_epoxy_composites_with_core-shell_silicon_carbide_nanoparticles