Recent from talks

Nothing was collected or created yet.

Complementary metal–oxide–semiconductor (CMOS, pronounced "sea-moss ", /siːmɑːs/, /-ɒs/) is a type of metal–oxide–semiconductor field-effect transistor (MOSFET) fabrication process that uses complementary and symmetrical pairs of p-type and n-type MOSFETs for logic functions.[1] CMOS technology is used for constructing integrated circuit (IC) chips, including microprocessors, microcontrollers, memory chips, and other digital logic circuits. CMOS overtook NMOS logic as the dominant MOSFET fabrication process for very large-scale integration (VLSI) chips in the 1980s, replacing earlier transistor–transistor logic (TTL) technology at the same time. CMOS has since remained the standard fabrication process for MOSFET semiconductor devices. As of 2011[update], 99% of IC chips, including most digital, analog and mixed-signal ICs, were fabricated using CMOS technology.[2]

In 1948, Bardeen and Brattain patented an insulated-gate transistor (IGFET) with an inversion layer. Bardeen's concept forms the basis of CMOS technology today. The CMOS process was presented by Fairchild Semiconductor's Frank Wanlass and Chih-Tang Sah at the International Solid-State Circuits Conference in 1963. Wanlass later filed US patent 3,356,858 for CMOS circuitry and it was granted in 1967. RCA commercialized the technology with the trademark "COS-MOS" in the late 1960s, forcing other manufacturers to find another name, leading to "CMOS" becoming the standard name for the technology by the early 1970s. Two important characteristics of CMOS devices are high noise immunity and low static power consumption.[3] Since one transistor of the MOSFET pair is always off, the series combination draws significant power only momentarily during switching between on and off states. Consequently, CMOS devices do not produce as much waste heat as other forms of logic, like NMOS logic or transistor–transistor logic (TTL), which normally have some standing current even when not changing state. These characteristics allow CMOS to integrate a high density of logic functions on a chip. It was primarily for this reason that CMOS became the most widely used technology to be implemented in VLSI chips.

The phrase "metal–oxide–semiconductor" is a reference to the physical structure of MOS field-effect transistors, having a metal gate electrode placed on top of an oxide insulator, which in turn is on top of a semiconductor material. Aluminium was once used but now the material is polysilicon. Other metal gates have made a comeback with the advent of high-κ dielectric materials in the CMOS process, as announced by IBM and Intel for the 45 nanometer node and smaller sizes.[4]

CMOS technology is also used for analog circuits such as image sensors (CMOS sensors), data converters, RF circuits (RF CMOS), and highly integrated transceivers for many types of communication.

History

[edit]

The principle of complementary symmetry was first introduced by George Sziklai in 1953 who then discussed several complementary bipolar circuits. Paul Weimer, also at RCA, invented in 1962 thin-film transistor (TFT) complementary circuits, a close relative of CMOS. He invented complementary flip-flop and inverter circuits, but did no work in a more complex complementary logic. He was the first person able to put p-channel and n-channel TFTs in a circuit on the same substrate. Three years earlier, John T. Wallmark and Sanford M. Marcus published a variety of complex logic functions implemented as integrated circuits using JFETs, including complementary memory circuits. Frank Wanlass was familiar with work done by Weimer at RCA.[6][7][8][9][10][11]

In 1955, Carl Frosch and Lincoln Derick accidentally grew a layer of silicon dioxide over the silicon wafer, for which they observed surface passivation effects.[12] By 1957 Frosch and Derick, using masking and predeposition, were able to manufacture silicon transistors. They showed that silicon dioxide protected silicon wafers from dopants diffusing into the wafer, and insulated the wafer from damage due to heat during the process.[12][13] J.R. Ligenza and W.G. Spitzer studied the mechanism of thermally grown oxides and fabricated a high quality Si/SiO2 stack in 1960.[14][15][16]

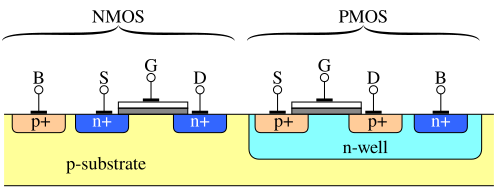

Following this research, Mohamed Atalla and Dawon Kahng proposed a silicon MOS transistor in 1959[17] and successfully demonstrated a working MOS device with their Bell Labs team in 1960.[18][19] Their team included E. E. LaBate and E. I. Povilonis who fabricated the device; M. O. Thurston, L. A. D'Asaro, and J. R. Ligenza who developed the diffusion processes, and H. K. Gummel and R. Lindner who characterized the device.[20][21] There were originally two types of MOSFET logic, PMOS (p-type MOS) and NMOS (n-type MOS).[22]

In 1948, Bardeen and Brattain patented the progenitor of MOSFET, an insulated-gate FET (IGFET) with an inversion layer. Bardeen's patent, and the concept of an inversion layer, forms the basis of CMOS technology today.[23] A new type of MOSFET logic combining both the PMOS and NMOS processes was developed, called complementary MOS (CMOS), by Chih-Tang Sah and Frank Wanlass at Fairchild. In February 1963, they published the invention in a research paper.[24][25] In both the research paper and the patent filed by Wanlass, the fabrication of CMOS devices was outlined, on the basis of thermal oxidation of a silicon substrate to yield a layer of silicon dioxide located between the drain contact and the source contact.[26][25]

CMOS was commercialised by RCA in the late 1960s. RCA adopted CMOS for the design of integrated circuits (ICs), developing CMOS circuits for an Air Force computer in 1965 and then a 288-bit CMOS SRAM memory chip in 1968.[24] RCA also used CMOS for its 4000-series integrated circuits in 1968, starting with a 20 μm semiconductor manufacturing process before gradually scaling to a 10 μm process over the next several years.[27]

CMOS technology was initially overlooked by the American semiconductor industry in favour of NMOS, which was more powerful at the time. However, CMOS was quickly adopted and further advanced by Japanese semiconductor manufacturers due to its low power consumption, leading to the rise of the Japanese semiconductor industry.[28] Toshiba developed C2MOS (clocked CMOS), a circuit technology with lower power consumption and faster operating speed than ordinary CMOS, in 1969. Toshiba used its C2MOS technology to develop a large-scale integration (LSI) chip for Sharp's Elsi Mini LED pocket calculator, developed in 1971 and released in 1972.[29] Suwa Seikosha (now Seiko Epson) began developing a CMOS IC chip for a Seiko quartz watch in 1969, and began mass-production with the launch of the Seiko Analog Quartz 38SQW watch in 1971.[30] The first mass-produced CMOS consumer electronic product was the Hamilton Pulsar "Wrist Computer" digital watch, released in 1970.[31] Due to low power consumption, CMOS logic has been widely used for calculators and watches since the 1970s.[32]

The earliest microprocessors in the early 1970s were PMOS processors, which initially dominated the early microprocessor industry. By the late 1970s, NMOS microprocessors had overtaken PMOS processors.[33] CMOS microprocessors were introduced in 1975, with the Intersil 6100,[33] and RCA CDP 1801.[34] However, CMOS processors did not become dominant until the 1980s.[33]

CMOS was initially slower than NMOS logic, thus NMOS was more widely used for computers in the 1970s.[32] The Intel 5101 (1 kb SRAM) CMOS memory chip (1974) had an access time of 800 ns,[35][36] whereas the fastest NMOS chip at the time, the Intel 2147 (4 kb SRAM) HMOS memory chip (1976), had an access time of 55/70 ns.[32][36] In 1978, a Hitachi research team led by Toshiaki Masuhara introduced the twin-well Hi-CMOS process, with its HM6147 (4 kb SRAM) memory chip, manufactured with a 3 μm process.[32][37][38] The Hitachi HM6147 chip was able to match the performance (55/70 ns access) of the Intel 2147 HMOS chip, while the HM6147 also consumed significantly less power (15 mA) than the 2147 (110 mA). With comparable performance and much less power consumption, the twin-well CMOS process eventually overtook NMOS as the most common semiconductor manufacturing process for computers in the 1980s.[32]

In the 1980s, CMOS microprocessors overtook NMOS microprocessors.[33] NASA's Galileo spacecraft, sent to orbit Jupiter in 1989, used the RCA 1802 CMOS microprocessor due to low power consumption.[31]

Intel introduced a 1.5 μm process for CMOS semiconductor device fabrication in 1983.[39] In the mid-1980s, Bijan Davari of IBM developed high-performance, low-voltage, deep sub-micron CMOS technology, which enabled the development of faster computers as well as portable computers and battery-powered handheld electronics.[40] In 1988, Davari led an IBM team that demonstrated a high-performance 250 nanometer CMOS process.[41]

Fujitsu commercialized a 700 nm CMOS process in 1987,[39] and then Hitachi, Mitsubishi Electric, NEC and Toshiba commercialized 500 nm CMOS in 1989.[42] In 1993, Sony commercialized a 350 nm CMOS process, while Hitachi and NEC commercialized 250 nm CMOS. Hitachi introduced a 160 nm CMOS process in 1995, then Mitsubishi introduced 150 nm CMOS in 1996, and then Samsung Electronics introduced 140 nm in 1999.[42]

In 2000, Gurtej Singh Sandhu and Trung T. Doan at Micron Technology invented atomic layer deposition High-κ dielectric films, leading to the development of a cost-effective 90 nm CMOS process.[40][43] Toshiba and Sony developed a 65 nm CMOS process in 2002,[44] and then TSMC initiated the development of 45 nm CMOS logic in 2004.[45] The development of pitch double patterning by Gurtej Singh Sandhu at Micron Technology led to the development of 30 nm class CMOS in the 2000s.[40]

CMOS is used in most modern LSI and VLSI devices.[32] As of 2010, CPUs with the best performance per watt each year have been CMOS static logic since 1976.[citation needed] As of 2019, planar CMOS technology is still the most common form of semiconductor device fabrication, but is gradually being replaced by non-planar FinFET technology, which is capable of manufacturing semiconductor nodes smaller than 20 nm.[46]

Technical details

[edit]"CMOS" refers to both a particular style of digital circuitry design and the family of processes used to implement that circuitry on integrated circuits (chips). CMOS circuitry dissipates less power than logic families with resistive loads. Since this advantage has increased and grown more important, CMOS processes and variants have come to dominate, thus the vast majority of modern integrated circuit manufacturing is on CMOS processes.[47] CMOS logic consumes around one seventh the power of NMOS logic,[32] and about 10 million times less power than bipolar transistor-transistor logic (TTL).[48][49]

CMOS circuits use a combination of p-type and n-type metal–oxide–semiconductor field-effect transistor (MOSFETs) to implement logic gates and other digital circuits. Although CMOS logic can be implemented with discrete devices for demonstrations, commercial CMOS products are integrated circuits composed of up to billions of transistors of both types, on a rectangular piece of silicon of often between 10 and 400 mm2.[citation needed]

CMOS always uses all enhancement-mode MOSFETs (in other words, a zero gate-to-source voltage turns the transistor off).[50]

Inversion

[edit]CMOS circuits are constructed in such a way that all p-type metal–oxide–semiconductor (PMOS) transistors must have either an input from the voltage source or from another PMOS transistor. Similarly, all NMOS transistors must have either an input from ground or from another NMOS transistor. The composition of a PMOS transistor creates low resistance between its source and drain contacts when a low gate voltage is applied and high resistance when a high gate voltage is applied. On the other hand, the composition of an NMOS transistor creates high resistance between source and drain when a low gate voltage is applied and low resistance when a high gate voltage is applied. CMOS accomplishes current reduction by complementing every nMOSFET with a pMOSFET and connecting both gates and both drains together. A high voltage on the gates will cause the nMOSFET to conduct and the pMOSFET not to conduct, while a low voltage on the gates causes the reverse. This arrangement greatly reduces power consumption and heat generation. However, during the switching time, both pMOS and nMOS MOSFETs conduct briefly as the gate voltage transitions from one state to another. This induces a brief spike in power consumption and becomes a serious issue at high frequencies.

The adjacent image shows what happens when an input is connected to both a PMOS transistor (top of diagram) and an NMOS transistor (bottom of diagram). Vdd is some positive voltage connected to a power supply and Vss is ground. A is the input and Q is the output.

When the voltage of A is low (i.e. close to Vss), the NMOS transistor's channel is in a high resistance state, disconnecting Vss from Q. The PMOS transistor's channel is in a low resistance state, connecting Vdd to Q. Q, therefore, registers Vdd.

On the other hand, when the voltage of A is high (i.e. close to Vdd), the PMOS transistor is in a high resistance state, disconnecting Vdd from Q. The NMOS transistor is in a low resistance state, connecting Vss to Q. Now, Q registers Vss.

In short, the outputs of the PMOS and NMOS transistors are complementary such that when the input is low, the output is high, and when the input is high, the output is low. No matter what the input is, the output is never left floating (charge is never stored due to wire capacitance and lack of electrical drain/ground). Because of this behavior of input and output, the CMOS circuit's output is the inverse of the input.

The transistors' resistances are never exactly equal to zero or infinity, so Q will never exactly equal Vss or Vdd, but Q will always be closer to Vss than A was to Vdd (or vice versa if A were close to Vss). Without this amplification, there would be a very low limit to the number of logic gates that could be chained together in series, and CMOS logic with billions of transistors would be impossible.

Power supply pins

[edit]The power supply pins for CMOS are called VDD and VSS, or VCC and ground (GND) depending on the manufacturer. VDD and VSS are carryovers from conventional MOS circuits and stand for the drain and source supplies.[51] These do not apply directly to CMOS, since both supplies are really source supplies. VCC and ground are carryovers from TTL logic and that nomenclature has been retained with the introduction of the 54C/74C line of CMOS.

Duality

[edit]An important characteristic of a CMOS circuit is the duality that exists between its PMOS transistors and NMOS transistors. A CMOS circuit is created to allow a path always to exist from the output to either the power source or ground. To accomplish this, the set of all paths to the voltage source must be the complement of the set of all paths to ground. This can be easily accomplished by defining one in terms of the NOT of the other. Due to the logic based on De Morgan's laws, the PMOS transistors in parallel have corresponding NMOS transistors in series while the PMOS transistors in series have corresponding NMOS transistors in parallel.

Logic

[edit]

More complex logic functions such as those involving AND and OR gates require manipulating the paths between gates to represent the logic. When a path consists of two transistors in series, both transistors must have low resistance to the corresponding supply voltage, modelling an AND. When a path consists of two transistors in parallel, either one or both of the transistors must have low resistance to connect the supply voltage to the output, modelling an OR.

Shown on the right is a circuit diagram of a NAND gate in CMOS logic. If both of the A and B inputs are high, then both the NMOS transistors (bottom half of the diagram) will conduct, neither of the PMOS transistors (top half) will conduct, and a conductive path will be established between the output and Vss (ground), bringing the output low. If both of the A and B inputs are low, then neither of the NMOS transistors will conduct, while both of the PMOS transistors will conduct, establishing a conductive path between the output and Vdd (voltage source), bringing the output high. If either of the A or B inputs is low, one of the NMOS transistors will not conduct, one of the PMOS transistors will, and a conductive path will be established between the output and Vdd (voltage source), bringing the output high. As the only configuration of the two inputs that results in a low output is when both are high, this circuit implements a NAND (NOT AND) logic gate.

An advantage of CMOS over NMOS logic is that both low-to-high and high-to-low output transitions are fast since the (PMOS) pull-up transistors have low resistance when switched on, unlike the load resistors in NMOS logic. In addition, the output signal swings the full voltage between the low and high rails. This strong, more nearly symmetric response also makes CMOS more resistant to noise.

See Logical effort for a method of calculating delay in a CMOS circuit.

Example: NAND gate in physical layout

[edit]

This example shows a NAND logic device drawn as a physical representation as it would be manufactured. The physical layout perspective is a "bird's eye view" of a stack of layers. The circuit is constructed on a p-type substrate. The polysilicon, diffusion, and n-well are referred to as "base layers" and are actually inserted into trenches of the p-type substrate. (See steps 1 to 6 in the process diagram below right) The contacts penetrate an insulating layer between the base layers and the first layer of metal (metal1) making a connection.

The inputs to the NAND (illustrated in green color) are in polysilicon. The transistors (devices) are formed by the intersection of the polysilicon and diffusion; N diffusion for the N device & P diffusion for the P device (illustrated in salmon and yellow coloring respectively). The output ("out") is connected together in metal (illustrated in cyan coloring). Connections between metal and polysilicon or diffusion are made through contacts (illustrated as black squares). The physical layout example matches the NAND logic circuit given in the previous example.

The N device is manufactured on a p-type substrate while the P device is manufactured in an n-type well (n-well). A p-type substrate "tap" is connected to VSS and an n-type n-well tap is connected to VDD to prevent latchup.

Power: switching and leakage

[edit]CMOS logic dissipates less power than NMOS logic circuits because CMOS dissipates power only when switching ("dynamic power"). On a typical ASIC in a modern 90 nanometer process, switching the output might take 120 picoseconds, and happens once every ten nanoseconds. NMOS logic dissipates power whenever the transistor is on, because there is a current path from Vdd to Vss through the load resistor and the n-type network.

Static CMOS gates are very power efficient because they dissipate nearly zero power when idle. Earlier, the power consumption of CMOS devices was not the major concern while designing chips. Factors like speed and area dominated the design parameters. As the CMOS technology moved below sub-micron levels the power consumption per unit area of the chip has risen tremendously.

Broadly classifying, power dissipation in CMOS circuits occurs because of two components, static and dynamic:

Static dissipation

[edit]Both NMOS and PMOS transistors have a gate–source threshold voltage (Vth), below which the current (called sub threshold current) through the device will drop exponentially. Historically, CMOS circuits operated at supply voltages much larger than their threshold voltages (Vdd might have been 5 V, and Vth for both NMOS and PMOS might have been 700 mV). A special type of the transistor used in some CMOS circuits is the native transistor, with near zero threshold voltage.

SiO2 is a good insulator, but at very small thickness levels electrons can tunnel across the very thin insulation; the probability drops off exponentially with oxide thickness. Tunnelling current becomes very important for transistors below 130 nm technology with gate oxides of 20 Å or thinner.

Small reverse leakage currents are formed due to formation of reverse bias between diffusion regions and wells (for e.g., p-type diffusion vs. n-well), wells and substrate (for e.g., n-well vs. p-substrate). In modern process diode leakage is very small compared to sub threshold and tunnelling currents, so these may be neglected during power calculations.

If the ratios do not match, then there might be different currents of PMOS and NMOS; this may lead to imbalance and thus improper current causes the CMOS to heat up and dissipate power unnecessarily. Furthermore, recent studies have shown that leakage power reduces due to aging effects as a trade-off for devices to become slower.[52]

To speed up designs, manufacturers have switched to constructions that have lower voltage thresholds but because of this a modern NMOS transistor with a Vth of 200 mV has a significant subthreshold leakage current. Designs (e.g. desktop processors) which include vast numbers of circuits which are not actively switching still consume power because of this leakage current. Leakage power is a significant portion of the total power consumed by such designs. Multi-threshold CMOS (MTCMOS), now available from foundries, is one approach to managing leakage power. With MTCMOS, high Vth transistors are used when switching speed is not critical, while low Vth transistors are used in speed sensitive paths. Further technology advances that use even thinner gate dielectrics have an additional leakage component because of current tunnelling through the extremely thin gate dielectric. Using high-κ dielectrics instead of silicon dioxide that is the conventional gate dielectric allows similar device performance, but with a thicker gate insulator, thus avoiding this current. Leakage power reduction using new material and system designs is critical to sustaining scaling of CMOS.[53]

Dynamic dissipation

[edit]Charging and discharging of load capacitances

[edit]CMOS circuits dissipate power by charging the various load capacitances (mostly gate and wire capacitance, but also drain and some source capacitances) whenever they are switched. In one complete cycle of CMOS logic, current flows from VDD to the load capacitance to charge it and then flows from the charged load capacitance (CL) to ground during discharge. Therefore, in one complete charge/discharge cycle, a total of Q=CLVDD is thus transferred from VDD to ground. Multiply by the switching frequency on the load capacitances to get the current used, and multiply by the average voltage again to get the characteristic switching power dissipated by a CMOS device: .

Since most gates do not operate/switch at every clock cycle, they are often accompanied by a factor , called the activity factor. Now, the dynamic power dissipation may be re-written as .

A clock in a system has an activity factor α=1, since it rises and falls every cycle. Most data has an activity factor of 0.1.[54] If correct load capacitance is estimated on a node together with its activity factor, the dynamic power dissipation at that node can be calculated effectively.

Short-circuit power

[edit]Since there is a finite rise/fall time for both pMOS and nMOS, during transition, for example, from off to on, both the transistors will be on for a small period of time in which current will find a path directly from VDD to ground, hence creating a short-circuit current, sometimes called a crowbar current. Short-circuit power dissipation increases with the rise and fall time of the transistors.

This form of power consumption became significant in the 1990s as wires on chip became narrower and the long wires became more resistive. CMOS gates at the end of those resistive wires see slow input transitions. Careful design which avoids weakly driven long skinny wires reduces this effect, but crowbar power can be a substantial part of dynamic CMOS power.

Input protection

[edit]Parasitic transistors that are inherent in the CMOS structure may be turned on by input signals outside the normal operating range, e.g. electrostatic discharges or line reflections. The resulting latch-up may damage or destroy the CMOS device. Clamp diodes are included in CMOS circuits to deal with these signals. Manufacturers' data sheets specify the maximum permitted current that may flow through the diodes.

Analog CMOS

[edit]Besides digital applications, CMOS technology is also used in analog applications. For example, there are CMOS operational amplifier ICs available in the market. Transmission gates may be used as analog multiplexers instead of signal relays. CMOS technology is also widely used for RF circuits all the way to microwave frequencies, in mixed-signal (analog+digital) applications.[citation needed]

RF CMOS

[edit]RF CMOS refers to RF circuits (radio frequency circuits) which are based on mixed-signal CMOS integrated circuit technology. They are widely used in wireless telecommunication technology. RF CMOS was developed by Asad Abidi while working at UCLA in the late 1980s. This changed the way in which RF circuits were designed, leading to the replacement of discrete bipolar transistors with CMOS integrated circuits in radio transceivers.[55] It enabled sophisticated, low-cost and portable end-user terminals, and gave rise to small, low-cost, low-power and portable units for a wide range of wireless communication systems. This enabled "anytime, anywhere" communication and helped bring about the wireless revolution, leading to the rapid growth of the wireless industry.[56]

The baseband processors[57][58] and radio transceivers in all modern wireless networking devices and mobile phones are mass-produced using RF CMOS devices.[55] RF CMOS circuits are widely used to transmit and receive wireless signals, in a variety of applications, such as satellite technology (such as GPS), Bluetooth, Wi-Fi, near-field communication (NFC), mobile networks (such as 3G and 4G), terrestrial broadcast, and automotive radar applications, among other uses.[59]

Examples of commercial RF CMOS chips include Intel's DECT cordless phone, and 802.11 (Wi-Fi) chips created by Atheros and other companies.[60] Commercial RF CMOS products are also used for Bluetooth and wireless LAN (WLAN) networks.[61] RF CMOS is also used in the radio transceivers for wireless standards such as GSM, Wi-Fi, and Bluetooth, transceivers for mobile networks such as 3G, and remote units in wireless sensor networks (WSN).[62]

RF CMOS technology is crucial to modern wireless communications, including wireless networks and mobile communication devices. One of the companies that commercialized RF CMOS technology was Infineon. Its bulk CMOS RF switches sell over 1 billion units annually, reaching a cumulative 5 billion units, as of 2018[update].[63]

Temperature range

[edit]Conventional CMOS devices work over a range of −55 °C to +125 °C.

There were theoretical indications as early as August 2008 that silicon CMOS will work down to −233 °C (40 K).[64] Functioning temperatures near 40 K have since been achieved using overclocked AMD Phenom II processors with a combination of liquid nitrogen and liquid helium cooling.[65]

Silicon carbide CMOS devices have been tested for a year at 500 °C.[66][67]

Single-electron MOS transistors

[edit]Ultra small (L = 20 nm, W = 20 nm) MOSFETs achieve the single-electron limit when operated at cryogenic temperature over a range of −269 °C (4 K) to about −258 °C (15 K). The transistor displays Coulomb blockade due to progressive charging of electrons one by one. The number of electrons confined in the channel is driven by the gate voltage, starting from an occupation of zero electrons, and it can be set to one or many.[68]

See also

[edit]- Beyond CMOS – Possible future digital logic technologies

- Gate equivalent – Measure of circuit complexity

- HCMOS – Specifications for the 74HC00 IC family

- LVCMOS – Class of digital integrated circuits

- sCMOS – Camera technology

Notes

[edit]References

[edit]- ^ "What is CMOS Memory?". Wicked Sago. Archived from the original on 26 September 2014. Retrieved 3 March 2013.

- ^ Voinigescu, Sorin (2013). High-Frequency Integrated Circuits. Cambridge University Press. p. 164. ISBN 978-0-521-87302-4.

- ^ Fairchild. Application Note 77. "CMOS, the Ideal Logic Family"; Archived 2015-01-09 at the Wayback Machine. 1983.

- ^ "Intel Architecture Leads the Microarchitecture Innovation Field". Intel. Archived from the original on 29 June 2011. Retrieved 2 May 2018.

- ^ Frosch, C. J.; Derick, L (1957). "Surface Protection and Selective Masking during Diffusion in Silicon". Journal of the Electrochemical Society. 104 (9): 547. doi:10.1149/1.2428650.

- ^ George Clifford, Sziklai (1953). "Symmetrical Properties of Transistors and Their Applications". Proceedings of the IRE. 41 (6): 717–724. doi:10.1109/JRPROC.1953.274250. S2CID 51639018.

- ^ Lojek, Bo (2007). History of Semiconductor Engineering. Springer. p. 162. ISBN 978-3-540-34258-8.

- ^ Ahrons, Richard (2012). "Industrial Research in Microcircuitry at RCA: The Early Years, 1953–1963". IEEE Annals of the History of Computing. 12 (1): 60–73. Bibcode:2012IAHC...34a..60A. doi:10.1109/MAHC.2011.62. S2CID 18912623.

- ^ "Oral History of Thomas (Tom) Stanley" (PDF).

- ^ "IRE News and Radio Notes". Proceedings of the IRE. 42 (6): 1027–1043. 1954. doi:10.1109/JRPROC.1954.274784.

- ^ Wallmark, J.T.; Marcus, S.M. (1959). "Integrated devices using Direct-Coupled Unipolar Transistor Logic". 1959 IEEE International Solid-State Circuits Conference. Digest of Technical Papers. Vol. EC-8. pp. 58–59. doi:10.1109/ISSCC.1959.1157035.

- ^ a b Huff, Howard; Riordan, Michael (2007-09-01). "Frosch and Derick: Fifty Years Later (Foreword)". The Electrochemical Society Interface. 16 (3): 29. doi:10.1149/2.F02073IF. ISSN 1064-8208.

- ^ Frosch, C. J.; Derick, L (1957). "Surface Protection and Selective Masking during Diffusion in Silicon". Journal of the Electrochemical Society. 104 (9): 547. doi:10.1149/1.2428650.

- ^ Ligenza, J. R.; Spitzer, W. G. (1960-07-01). "The mechanisms for silicon oxidation in steam and oxygen". Journal of Physics and Chemistry of Solids. 14: 131–136. Bibcode:1960JPCS...14..131L. doi:10.1016/0022-3697(60)90219-5. ISSN 0022-3697.

- ^ Deal, Bruce E. (1998). "Highlights Of Silicon Thermal Oxidation Technology". Silicon materials science and technology. The Electrochemical Society. p. 183. ISBN 978-1-56677-193-1.

- ^ Lojek, Bo (2007). History of Semiconductor Engineering. Springer Science & Business Media. p. 322. ISBN 978-3-540-34258-8.

- ^ Bassett, Ross Knox (2007). To the Digital Age: Research Labs, Start-up Companies, and the Rise of MOS Technology. Johns Hopkins University Press. pp. 22–23. ISBN 978-0-8018-8639-3.

- ^ Atalla, M.; Kahng, D. (1960). "Silicon-silicon dioxide field induced surface devices". IRE-AIEE Solid State Device Research Conference.

- ^ "1960 – Metal Oxide Semiconductor (MOS) Transistor Demonstrated". The Silicon Engine. Computer History Museum. Retrieved 2023-01-16.

- ^ KAHNG, D. (1961). "Silicon-Silicon Dioxide Surface Device". Technical Memorandum of Bell Laboratories: 583–596. doi:10.1142/9789814503464_0076. Reprinted in Sze, S. M. (1991). Semiconductor Devices: Pioneering Papers. Singapore: World Scientific. doi:10.1142/1087. ISBN 978-981-02-0209-5.

- ^ Lojek, Bo (2007). History of Semiconductor Engineering. Berlin, Heidelberg: Springer-Verlag Berlin Heidelberg. p. 321. ISBN 978-3-540-34258-8.

- ^ "1960 - Metal Oxide Semiconductor (MOS) Transistor Demonstrated". The Silicon Engine. Computer History Museum.

- ^ Howard R. Duff (2001). "John Bardeen and transistor physics". AIP Conference Proceedings. Vol. 550. pp. 3–32. doi:10.1063/1.1354371.

- ^ a b "1963: Complementary MOS Circuit Configuration is Invented". Computer History Museum. Retrieved 6 July 2019.

- ^ a b Sah, Chih-Tang; Wanlass, Frank (1963). Nanowatt logic using field-effect metal-oxide semiconductor triodes. 1963 IEEE International Solid-State Circuits Conference. Digest of Technical Papers. Vol. VI. pp. 32–33. doi:10.1109/ISSCC.1963.1157450.

- ^ "Low stand-by power complementary field effect circuitry" (PDF).

- ^ Lojek, Bo (2007). History of Semiconductor Engineering. Springer. p. 330. ISBN 978-3-540-34258-8.

- ^ Gilder, George (1990). Microcosm: The Quantum Revolution In Economics And Technology. Simon and Schuster. pp. 144–5. ISBN 978-0-671-70592-3.

- ^ "1972 to 1973: CMOS LSI circuits for calculators (Sharp and Toshiba)" (PDF). Semiconductor History Museum of Japan. Archived from the original (PDF) on 2019-07-06. Retrieved 5 July 2019.

- ^ "Early 1970s: Evolution of CMOS LSI circuits for watches" (PDF). Semiconductor History Museum of Japan. Archived from the original (PDF) on 6 July 2019. Retrieved 6 July 2019.

- ^ a b "Tortoise of Transistors Wins the Race - CHM Revolution". Computer History Museum. Retrieved 22 July 2019.

- ^ a b c d e f g "1978: Double-well fast CMOS SRAM (Hitachi)" (PDF). Semiconductor History Museum of Japan. Archived from the original (PDF) on 5 July 2019. Retrieved 5 July 2019.

- ^ a b c d Kuhn, Kelin (2018). "CMOS and Beyond CMOS: Scaling Challenges". High Mobility Materials for CMOS Applications. Woodhead Publishing. p. 1. ISBN 978-0-08-102062-3.

- ^ "CDP 1800 μP Commercially available" (PDF). Microcomputer Digest. 2 (4): 1–3. October 1975. Archived from the original (PDF) on 2019-09-23. Retrieved 2019-07-22.

- ^ "Silicon Gate MOS 2102A". Intel. Retrieved 27 June 2019.

- ^ a b "A chronological list of Intel products. The products are sorted by date" (PDF). Intel museum. Intel Corporation. July 2005. Archived from the original (PDF) on August 9, 2007. Retrieved July 31, 2007.

- ^ Masuhara, Toshiaki; Minato, Osamu; Sasaki, Toshio; Sakai, Yoshio; Kubo, Masaharu; Yasui, Tokumasa (February 1978). A high-speed, low-power Hi-CMOS 4K static RAM. 1978 IEEE International Solid-State Circuits Conference. Digest of Technical Papers. Vol. XXI. pp. 110–111. doi:10.1109/ISSCC.1978.1155749. S2CID 30753823.

- ^ Masuhara, Toshiaki; Minato, Osamu; Sakai, Yoshi; Sasaki, Toshio; Kubo, Masaharu; Yasui, Tokumasa (September 1978). "Short Channel Hi-CMOS Device and Circuits". ESSCIRC 78: 4th European Solid State Circuits Conference - Digest of Technical Papers: 131–2.

- ^ a b Gealow, Jeffrey Carl (10 August 1990). "Impact of Processing Technology on DRAM Sense Amplifier Design" (PDF). Massachusetts Institute of Technology. pp. 149–166. hdl:1721.1/61805/23264695-MIT. Retrieved 25 June 2019 – via CORE.

- ^ a b c "IEEE Andrew S. Grove Award Recipients". IEEE Andrew S. Grove Award. Institute of Electrical and Electronics Engineers. Archived from the original on September 9, 2018. Retrieved 4 July 2019.

- ^ Davari, Bijan; et al. (1988). "A high performance 0.25 mu m CMOS technology". Technical Digest, International Electron Devices Meeting 1988. pp. 56–59. doi:10.1109/IEDM.1988.32749. ISSN 0163-1918. S2CID 114078857. IEEE Cat. No. 88CH2528-8.

- ^ a b "Memory". STOL (Semiconductor Technology Online). Archived from the original on 2 November 2023. Retrieved 25 June 2019.

- ^ Sandhu, Gurtej; Doan, Trung T. (22 August 2001). "Atomic layer doping apparatus and method". Google Patents. Retrieved 5 July 2019.

- ^ "Toshiba and Sony Make Major Advances in Semiconductor Process Technologies". Toshiba. 3 December 2002. Retrieved 26 June 2019.

- ^ "A Banner Year: TSMC Annual Report 2004" (PDF). TSMC. Retrieved 5 July 2019.

- ^ "Global FinFET Technology Market 2024 Growth Analysis by Manufacturers, Regions, Type and Application, Forecast Analysis". Financial Planning. July 3, 2019. Archived from the original on 6 July 2019. Retrieved 6 July 2019.

- ^ Baker, R. Jacob (2008). CMOS: circuit design, layout, and simulation (Second ed.). Wiley-IEEE. p. xxix. ISBN 978-0-470-22941-5.

- ^ Higgins, Richard J. (1983). Electronics with digital and analog integrated circuits. Prentice-Hall. p. 101. ISBN 978-0-13-250704-2.

The dominant difference is power: CMOS gates can consume about 100,000 times less power than their TTL equivalents!

- ^ Stephens, Carlene; Dennis, Maggie (2000). "Engineering Time: Inventing the Electronic Wristwatch" (PDF). The British Journal for the History of Science. 33 (4). Cambridge University Press: 477–497 (485). doi:10.1017/S0007087400004167. ISSN 0007-0874. Archived from the original (PDF) on 2017-12-01. Retrieved 2019-11-10.

- ^ "What is CMOS?". IONOS Digitalguide. 8 December 2021. Retrieved 2022-01-21.

- ^ "CMOS, the Ideal Logic Family" (PDF). Fairchild Semiconductor. January 1983. Archived from the original (PDF) on 2011-12-09. Retrieved 2011-11-25.

- ^ Martínez, A.L.H.; Khursheed, S.; Rossi, D. (2020). "Leveraging CMOS Aging for Efficient Microelectronics Design". 2020 IEEE 26th International Symposium on On-Line Testing and Robust System Design (IOLTS). pp. 1–4. doi:10.1109/IOLTS50870.2020.9159742. ISBN 978-1-7281-8187-5. S2CID 225582202.

- ^ A good overview of leakage and reduction methods are explained in the book Leakage in Nanometer CMOS Technologies Archived 2011-12-02 at the Wayback Machine ISBN 0-387-25737-3.

- ^ Moiseev, Konstantin; Kolodny, Avinoam; Wimer, Shmuel (September 2008). "Timing-aware power-optimal ordering of signals". ACM Trans. Des. Autom. Electron. Syst. 13 (4). Article 65. CiteSeerX 10.1.1.222.9211. doi:10.1145/1391962.1391973. S2CID 18895687.

- ^ a b O'Neill, A. (2008). "Asad Abidi Recognized for Work in RF-CMOS". IEEE Solid-State Circuits Society Newsletter. 13 (1): 57–58. doi:10.1109/N-SSC.2008.4785694. ISSN 1098-4232.

- ^ Daneshrad, Babal; Eltawil, Ahmed M. (2002). "Integrated Circuit Technologies for Wireless Communications". Wireless Multimedia Network Technologies. The International Series in Engineering and Computer Science. 524. Springer US: 227–244. doi:10.1007/0-306-47330-5_13. ISBN 0-7923-8633-7.

- ^ Chen, Wai-Kai (2018). The VLSI Handbook. CRC Press. pp. 60–2. ISBN 978-1-4200-0596-7.

- ^ Morgado, Alonso; Río, Rocío del; Rosa, José M. de la (2011). Nanometer CMOS Sigma-Delta Modulators for Software Defined Radio. Springer. p. 1. ISBN 978-1-4614-0037-0.

- ^ Veendrick, Harry J. M. (2017). Nanometer CMOS ICs: From Basics to ASICs. Springer. p. 243. ISBN 978-3-319-47597-4.

- ^ Nathawad, L.; Zargari, M.; Samavati, H.; Mehta, S.; Kheirkhaki, A.; Chen, P.; Gong, K.; Vakili-Amini, B.; Hwang, J.; Chen, M.; Terrovitis, M.; Kaczynski, B.; Limotyrakis, S.; Mack, M.; Gan, H.; Lee, M.; Abdollahi-Alibeik, B.; Baytekin, B.; Onodera, K.; Mendis, S.; Chang, A.; Jen, S.; Su, D.; Wooley, B. "20.2: A Dual-band CMOS MIMO Radio SoC for IEEE 802.11n Wireless LAN" (PDF). IEEE Entity Web Hosting. IEEE. Archived from the original (PDF) on 23 October 2016. Retrieved 22 October 2016.

- ^ Olstein, Katherine (Spring 2008). "Abidi Receives IEEE Pederson Award at ISSCC 2008". IEEE Solid-State Circuits Society Newsletter. 13 (2): 12. doi:10.1109/N-SSC.2008.4785734. S2CID 30558989.

- ^ Oliveira, Joao; Goes, João (2012). Parametric Analog Signal Amplification Applied to Nanoscale CMOS Technologies. Springer. p. 7. ISBN 978-1-4614-1670-8.

- ^ "Infineon Hits Bulk-CMOS RF Switch Milestone". EE Times. 20 November 2018. Retrieved 26 October 2019.

- ^ Edwards C., "Temperature control", Engineering & Technology 26 July – 8 August 2008, IET.

- ^ Moorhead, Patrick (January 15, 2009). "Breaking Records with Dragons and Helium in the Las Vegas Desert". blogs.amd.com/patmoorhead. Archived from the original on September 15, 2010. Retrieved 2009-09-18.

- ^ Clark, D.T.; Ramsay, E.P.; Murphy, A.E.; Smith, D.A.; Thompson, Robin.F.; Young, R.A.R.; Cormack, J.D.; Zhu, C.; Finney, S.; Fletcher, J. (2011). "High Temperature Silicon Carbide CMOS Integrated Circuits". Materials Science Forum. 679–680: 726–729. doi:10.4028/www.scientific.net/msf.679-680.726. S2CID 110071501.

- ^ Mantooth, Alan; Zetterling, Carl-Mikael; Rusu, Ana (28 April 2021). "The Radio We Could Send to Hell: Silicon carbide radio circuits can take the volcanic heat of Venus". IEEE Spectrum.

- ^ Prati, E.; De Michielis, M.; Belli, M.; Cocco, S.; Fanciulli, M.; Kotekar-Patil, D.; Ruoff, M.; Kern, D. P.; Wharam, D. A.; Verduijn, J.; Tettamanzi, G. C.; Rogge, S.; Roche, B.; Wacquez, R.; Jehl, X.; Vinet, M.; Sanquer, M. (2012). "Few electron limit of n-type metal oxide semiconductor single electron transistors". Nanotechnology. 23 (21) 215204. arXiv:1203.4811. Bibcode:2012Nanot..23u5204P. doi:10.1088/0957-4484/23/21/215204. PMID 22552118. S2CID 206063658.

Further reading

[edit]- Bader, S.J.; Lee, H.; Chaudhuri, R.; Huang, S.; Hickman, A.; Molnar, A.; Xing, H.G.; Jena, D.; W. Then, H.; Chowdhury, N.; Palacios, T. (October 2020). "Prospects for Wide Bandgap and Ultrawide Bandgap CMOS Devices" (PDF). IEEE Transactions on Electron Devices. 67 (10): 4010–20. Bibcode:2020ITED...67.4010B. doi:10.1109/TED.2020.3010471. S2CID 221913316.

- Baker, R. Jacob (2010). CMOS: Circuit Design, Layout, and Simulation (3rd ed.). Wiley-IEEE. ISBN 978-0-470-88132-3.

- Mead, Carver A.; Conway, Lynn (1980). Introduction to VLSI systems. Addison-Wesley. ISBN 0-201-04358-0.

- Veendrick, H.J.M. (2025). Nanometer CMOS ICs: From Basics to ASICs. Springer. doi:10.1007/978-3-031-64249-4. ISBN 978-3-031-64248-7.

- Weste, Neil H. E.; Harris, David M. (2010). CMOS VLSI Design: A Circuits and Systems Perspective (4th ed.). Pearson/Addison-Wesley. ISBN 978-0-321-54774-3.

External links

[edit]Fundamentals

Definition and Principles

Complementary Metal–Oxide–Semiconductor (CMOS) is a semiconductor fabrication technology that integrates both n-type and p-type metal–oxide–semiconductor field-effect transistors (MOSFETs) on the same substrate to create complementary pairs for logic functions.[7] This approach enables the construction of integrated circuits with enhanced efficiency by leveraging the complementary conduction properties of the transistors.[8] The fundamental structure of CMOS logic is exemplified by the inverter, which consists of a p-type MOSFET (PMOS) forming the pull-up network connected to the positive supply voltage and an n-type MOSFET (NMOS) forming the pull-down network connected to ground, with their gates serving as the common input and drains as the output.[9] In this configuration, when the input is low, the PMOS conducts to pull the output high, and when the input is high, the NMOS conducts to pull the output low, ensuring complementary operation.[8] The core principle of CMOS is complementary conduction, wherein for any valid logic input, one transistor type is in the on-state while the other is off, thereby minimizing steady-state current flow through the circuit and achieving near-zero static power dissipation during non-switching periods.[10] The MOSFET serves as the basic building block for these complementary pairs.[8] The voltage transfer characteristic (VTC) of a CMOS inverter illustrates its operation by plotting output voltage against input voltage, revealing a high-gain transition region where the input equals the output at the switching threshold V_M, typically near half the supply voltage for symmetric designs.[11] This steep slope in the VTC ensures robust noise margins, quantified as the low noise margin (V_IL - V_OL) and high noise margin (V_OH - V_IH), where V_IL and V_IH are the input thresholds defining the maximum low and minimum high input levels, respectively, and V_OL and V_OH are the corresponding output levels.[12] CMOS technology provides key advantages including low static power consumption due to its complementary switching, high noise immunity from full rail-to-rail output voltage swing, and scalability that supports dense integration in modern integrated circuits.[8]MOS Transistor Operation

The metal-oxide-semiconductor field-effect transistor (MOSFET) consists of four primary terminals: the gate, source, drain, and substrate (or body). The gate is separated from the semiconductor substrate by a thin insulating oxide layer, typically silicon dioxide (SiO₂), which acts as a dielectric. The source and drain are heavily doped regions of opposite type to the substrate (n+ for n-channel MOSFETs on p-type substrate, or p+ for p-channel MOSFETs on n-type substrate), forming p-n junctions with the substrate. When biased appropriately, a conductive channel forms in the substrate beneath the gate oxide, enabling current flow between source and drain.[13] The operation of a MOSFET is characterized by three primary regions: cutoff, triode (also called linear), and saturation, determined by the gate-to-source voltage (V_{GS}) and drain-to-source voltage (V_{DS}). In the cutoff region, V_{GS} is below the threshold voltage (V_{th}), resulting in negligible drain current (I_D ≈ 0) as no conductive channel exists. The triode region occurs when V_{GS} > V_{th} and V_{DS} < V_{GS} - V_{th}, where the channel is fully formed and acts as a voltage-controlled resistor, with I_D given by I_D = μ C_{ox} (W/L) [(V_{GS} - V_{th}) V_{DS} - (V_{DS}^2)/2], exhibiting a linear I_D-V_{DS} relationship at low V_{DS}. In saturation, V_{DS} ≥ V_{GS} - V_{th}, the channel pinches off near the drain, and I_D saturates at I_D = (1/2) μ C_{ox} (W/L) (V_{GS} - V_{th})^2, independent of V_{DS} (ideally). These characteristics apply to both n-channel (NMOS) and p-channel (PMOS) devices, though PMOS equations use absolute values for voltages and currents due to opposite carrier polarity, with holes as majority carriers in the channel.[14][13] The threshold voltage V_{th} defines the onset of strong inversion and is expressed as V_{th} = V_{FB} + 2\phi_F + \frac{\sqrt{4\epsilon_{si} q N_A \phi_F}}{C_{ox}}, where V_{FB} is the flat-band voltage accounting for work function differences and oxide charges, \phi_F is the Fermi potential, \epsilon_{si} is the permittivity of silicon, q is the elementary charge, N_A is the substrate doping concentration, and C_{ox} is the gate oxide capacitance per unit area. Factors such as substrate bias introduce the body effect, modifying V_{th} to V_{th} = V_{th0} + \gamma (\sqrt{2\phi_F + V_{SB}} - \sqrt{2\phi_F}), where V_{th0} is the zero-bias threshold, \gamma is the body effect coefficient, and V_{SB} is the source-to-body voltage; this increases |V_{th}| for reverse-biased body, enhancing isolation but requiring higher gate drive. For PMOS, the equation is analogous but uses acceptor doping N_D and negative voltages.[15][16] Channel formation in a MOSFET involves surface potential changes under gate bias, progressing through accumulation, depletion, and strong inversion. For an NMOS on p-type substrate, negative or low positive V_{GS} induces accumulation of holes at the silicon-oxide interface. As V_{GS} increases beyond flat-band, a depletion region forms by repelling holes, creating a positive space charge balanced by gate voltage. Strong inversion occurs when V_{GS} reaches V_{th}, attracting electrons to form a thin n-type inversion layer (channel) at the interface, overriding the p-type substrate doping and enabling conduction. In PMOS on n-type substrate, the process inverts: positive V_{GS} depletes electrons, and strong negative V_{GS} forms a p-type inversion channel with holes. This inversion layer thickness is typically 5-10 nm, with carrier density exceeding substrate doping by orders of magnitude.[16] Carrier transport in the MOSFET channel relies on drift and diffusion, governed by mobility μ, which quantifies charge velocity per unit electric field. In silicon, electron mobility (μ_n ≈ 1400 cm²/V·s at 300 K) significantly exceeds hole mobility (μ_p ≈ 450 cm²/V·s), leading to higher drive currents and performance in NMOS compared to PMOS for equivalent dimensions. Surface scattering and interface traps reduce effective mobility to ~200-500 cm²/V·s in inversion layers, with n-channel electrons benefiting more from tensile strain enhancements while p-channel holes gain from compressive strain. These differences necessitate wider PMOS transistors in CMOS designs to balance currents.[17] MOSFET performance is influenced by parasitic capacitances, including the gate oxide capacitance C_{ox} = \epsilon_{ox}/t_{ox} (where \epsilon_{ox} is the oxide permittivity and t_{ox} the thickness, typically 1-10 nm yielding C_{ox} ≈ 1-10 fF/μm²), which stores charge in the channel. Overlap capacitances arise from gate extension over source/drain regions, C_{ov} = W L_{ov} C_{ox} (L_{ov} ≈ 0.1-0.5 μm), contributing to gate-to-source (C_{gs}) and gate-to-drain (C_{gd}) totals. Junction capacitances form at source/drain-to-substrate p-n junctions, modeled as C_j = C_{j0} / \sqrt{1 + V_R / \phi}, where C_{j0} is the zero-bias value (≈ 0.5-1 fF/μm²) and V_R the reverse bias, varying with area and doping. These capacitances affect switching speed, with total gate capacitance scaling as C_g = C_{ox} W L + 2 C_{ov} W in strong inversion.[18][19]Complementary Pairing

In complementary metal-oxide-semiconductor (CMOS) technology, the pairing of n-channel (NMOS) and p-channel (PMOS) transistors leverages their inherent duality in conduction behavior. The PMOS transistor turns on when the gate input is low (near ground potential), forming a pull-up network that connects the output to the positive supply voltage (VDD), while the NMOS transistor activates when the gate input is high (near VDD), creating a pull-down network that connects the output to ground. This complementary operation ensures that the output voltage swings fully from rail-to-rail (0 to VDD), minimizing signal degradation and enabling efficient logic inversion without intermediate voltage levels.[20][21] The body effect, which increases the threshold voltage of a MOSFET when its source-body voltage differs from zero, poses challenges in complementary pairing due to the opposite doping types of NMOS (p-substrate or n-well) and PMOS (n-substrate or p-well) devices. To mitigate this, twin-tub (or twin-well) processes create separate n- and p-wells in a substrate, allowing independent control of well potentials and reducing body bias impacts on threshold voltages. Triple-well processes further isolate the substrate, providing an additional deep n-well beneath the p-well to suppress latch-up and body effect coupling between devices. These structures enable better isolation of p- and n-substrates, optimizing transistor performance in dense integrated circuits.[22][23][24] Threshold voltage matching between complementary NMOS and PMOS pairs is essential for symmetric operation, particularly in inverters where equal rise and fall times are desired to balance propagation delays. The magnitude of the NMOS threshold voltage (|Vtn|) is typically designed to match that of the PMOS (|Vtp|), often around 0.4–0.7 V in modern processes, to ensure the switching point occurs near VDD/2. Mismatches, arising from process variations or body effect, can degrade noise margins and increase dynamic power by prolonging transition times; thus, precise doping profiles and well engineering are used to achieve this matching, impacting overall circuit speed and power efficiency.[13][25] A key application of complementary pairing is the CMOS transmission gate, formed by connecting an NMOS and PMOS transistor in parallel with complementary control signals applied to their gates. This configuration yields a low on-resistance (typically 100–500 Ω) bidirectional switch that conducts full-strength signals in both directions, passing both logic high and low levels without the voltage degradation seen in single-transistor pass gates. The NMOS handles strong low-level transmission due to high electron mobility, while the PMOS excels at high-level transmission via hole conduction, resulting in a nearly constant resistance over the voltage range and enabling applications like analog switches and multiplexers.[26][27] Latch-up represents a critical reliability issue in complementary CMOS structures, triggered by the formation of parasitic p-n-p-n thyristors (silicon-controlled rectifiers, or SCRs) from vertically and laterally adjacent bipolar junctions between n-wells, p-substrates, and diffused regions. When activated by transients, radiation, or overvoltages, these parasitics create a regenerative feedback loop, shunting high current from VDD to ground and potentially destroying the device through thermal runaway. Prevention strategies include layout rules such as placing guard rings—diffused regions that collect minority carriers—and increasing well/substrate resistances to interrupt the thyristor path; epitaxial substrates with buried layers further enhance immunity by reducing gain in the parasitic bipolars.[28][29][30] In terms of performance, NMOS-only logic, which relies on resistive or depletion-mode loads, exhibits higher static power dissipation (often 10–100 μW per gate) due to continuous current flow through the load during steady states, limiting its use in low-power applications. In contrast, CMOS logic achieves near-zero static power by avoiding DC paths between power rails, with power dominated by dynamic switching (proportional to CLVDD2f, where CL is load capacitance, VDD is supply voltage, and f is frequency). However, CMOS speed is typically 20–50% slower than equivalent NMOS due to the lower hole mobility in PMOS (about half that of electrons in NMOS), requiring wider PMOS transistors to compensate and equalize drive strengths, though this enables superior energy efficiency in battery-powered and high-density systems.[31][32]Historical Development

Origins and Invention

The invention of complementary metal-oxide-semiconductor (CMOS) technology is credited to Frank Wanlass, who, while working at Fairchild Semiconductor, developed the concept in 1963 as a means to achieve low standby power in integrated circuits using complementary pairs of p-channel and n-channel MOSFETs.[33] Wanlass and Chih-Tang Sah presented the CMOS concept at the 1963 International Solid-State Circuits Conference (ISSCC), highlighting its low-power potential.[2] Wanlass filed for a patent on June 18, 1963, which was granted as U.S. Patent No. 3,356,858 on December 5, 1967, describing circuitry for inverters, NOR gates, and NAND gates based on this complementary symmetry approach.[4] Collaborating with Chih-Tang Sah at Fairchild, Wanlass demonstrated the first discrete CMOS inverter that year, achieving a propagation delay of about 100 nanoseconds while consuming only nanowatts in standby mode.[33] This innovation was motivated by the need to reduce power consumption in electronics during the Cold War era, particularly for space and battery-powered applications where high power draw from existing technologies posed significant limitations.[2] Earlier bipolar transistor-transistor logic (TTL) circuits, dominant in the early 1960s, consumed milliwatts even in standby due to constant current flow, making them unsuitable for low-power scenarios, while single-channel PMOS and NMOS technologies suffered from higher static power and lower circuit density compared to bipolar but still fell short of CMOS's efficiency.[33] CMOS addressed these issues by enabling near-zero static power dissipation—up to six orders of magnitude lower than bipolar or PMOS—through the complementary action of transistors, where one type is off while the other is on.[33] The foundational MOSFET device itself had been co-invented in 1959 by Dawon Kahng and Mohamed Atalla at Bell Labs, providing the building block for MOS-based logics, with Bell Labs' contributions emphasizing insulated-gate field-effect transistors for improved stability and scalability.[34] The first integrated demonstration of CMOS came from RCA Laboratories, which produced early CMOS circuits for a 1965 U.S. Air Force computer project and introduced the CD4000 series logic family in 1968, marking the technology's initial commercialization with devices fabricated on a 20 μm process.[2] Despite its promise, early adoption faced significant hurdles in the 1960s, including high defect densities from immature fabrication yields, unstable threshold voltages (often 10-20 V) in MOSFETs, and process complexities like sodium contamination during aluminum gate evaporation, which caused device drift and required innovations such as electron-beam evaporation techniques to resolve.[33] These challenges initially limited CMOS to niche low-power uses, as its switching speeds were about half those of bipolar TTL and only roughly ten times faster than PMOS, though its power advantages foreshadowed broader dominance.[33]Evolution and Key Milestones

The adoption of CMOS technology accelerated in the 1970s, particularly in low-power consumer electronics like digital watches and calculators, where its energy efficiency provided a significant advantage over earlier NMOS designs. A key early milestone was the introduction of the Intel 5101, a 1 Kb static RAM chip released in 1974, which demonstrated CMOS's viability for memory applications with access times around 800 ns and notably lower power dissipation compared to contemporary NMOS alternatives like the Intel 2147. Concurrently, the RCA 4000-series CMOS logic family, first commercialized in the late 1960s but widely adopted in the 1970s, enabled battery-powered devices such as handheld calculators, offering operation from 3V to 18V supplies and static power consumption under 10 µW per gate, which facilitated the proliferation of portable electronics.[35] By the 1980s, CMOS had established dominance in microprocessors, driven by scaling improvements and the shift toward higher-performance computing. Intel's 80386 microprocessor, launched in 1985, marked a pivotal transition to full CMOS fabrication at the 1.5 µm process node, delivering 32-bit architecture with clock speeds up to 40 MHz and integrating over 275,000 transistors while reducing power to about 2W, far below NMOS predecessors. This era also saw advancements in scaling through CMOS-on-sapphire (SOS) technology, which enabled sub-micron features by isolating transistors on insulating substrates, improving speed and radiation hardness for military and aerospace applications, with early demonstrations achieving 0.5 µm gate lengths by the mid-1980s.[36] The 1990s and 2000s witnessed CMOS's adherence to Moore's Law through aggressive dimensional scaling, culminating in the widespread introduction of the 90 nm process node in 2004 by leading foundries like Intel and TSMC, which incorporated strained silicon channels to boost carrier mobility by up to 30% and supported hundreds of millions of transistors per chip in high-volume production, such as Intel's Prescott processor with 125 million transistors.[37] A transformative innovation was the adoption of high-k dielectric materials, such as hafnium-based oxides, first integrated by Intel in 2007 at the 45 nm node to replace traditional SiO2 gates, reducing leakage currents by orders of magnitude while maintaining equivalent oxide thickness below 1 nm, thereby enabling continued voltage scaling without excessive power loss. These developments sustained transistor density doublings every two years, underpinning the explosion of personal computing and mobile devices.[37] In the 2010s, CMOS scaling entered the multi-gate era with Intel's adoption of FinFET transistors at the 22 nm node in 2011, which used a 3D fin structure to enhance gate control, improving drive current by 20-30% and reducing leakage, as seen in products like the Ivy Bridge processors with approximately 1.4 billion transistors. Further milestones included the rollout of 3D integration techniques, such as through-silicon vias (TSVs) for stacking dies, enabling heterogeneous systems like IBM's 2015 cognitive computing chips, and the introduction of extreme ultraviolet (EUV) lithography at the 7 nm node around 2018 by Samsung, with TSMC adopting it later at the 5 nm node in 2020, which allowed patterning of features below 20 nm with single-exposure precision, slashing manufacturing costs for complex layouts.[38] As of 2025, the 2020s have brought CMOS to the 2 nm process regime, with TSMC initiating high-volume manufacturing of its N2 node in 2025, featuring gate-all-around (GAA) nanosheet transistors for 15-20% performance gains over 3 nm, while Samsung commenced 2 nm production in the second half of 2025 using similar GAA structures to target AI and mobile applications.[39][40] Chiplet-based designs have emerged as a complementary strategy to monolithic scaling, allowing modular integration of specialized dies via advanced packaging like 2.5D/3D interconnects, as exemplified by AMD's EPYC processors since 2017 and expanding to Apple's M-series chips, where the M4 (2024) and anticipated M5 (2025) leverage 3 nm and below processes with unified memory architectures to integrate AI accelerators, delivering up to 38 TOPS in neural processing while optimizing power for edge computing. These advancements have profoundly shaped the global economy, enabling ubiquitous computing ecosystems from smartphones—approximately 1.17 billion units shipped in 2023—to data centers supporting AI workloads valued at trillions in market impact, by driving down costs per transistor to below $0.01 and fostering innovations in IoT, cloud services, and high-performance computing.[41][42][43]Digital CMOS Design

Basic Logic Gates

The basic logic gates in complementary metal-oxide-semiconductor (CMOS) technology form the foundation of digital integrated circuits, leveraging complementary pairs of n-type and p-type metal-oxide-semiconductor field-effect transistors (MOSFETs) to implement Boolean functions with low static power dissipation. These gates operate by selectively connecting the output to the supply voltage (VDD) or ground (VSS) through pull-up (PMOS) and pull-down (NMOS) networks, ensuring full rail-to-rail output swings and inherent logic level restoration that prevents signal degradation across cascaded stages.[44][45] The inverter serves as the simplest gate, while NAND and NOR gates provide universal logic capabilities, enabling the realization of any Boolean function. The CMOS inverter, or NOT gate, inverts the input signal using a single PMOS transistor in parallel with an NMOS transistor in series from VDD to VSS. Its truth table is as follows:| Input (VIN) | Output (VOUT) |

|---|---|

| 0 | 1 |

| 1 | 0 |